C Purlin Machine with Punching Hole Device: An Overview

By:Admin

The metal forming industry is constantly evolving, and the demand for efficient and advanced machinery is growing rapidly. In response to this demand, a leading manufacturer of metal forming machinery has introduced a groundbreaking C Purlin Machine with a Punching Hole Device, setting a new standard for innovation and efficiency in the industry.

The C Purlin Machine with Punching Hole Device is designed to streamline the production process of C-shaped steel purlins, a critical component in the construction of steel buildings, warehouses, and other structures. This machine not only shapes the steel into the desired C profile, but it also features a built-in punching hole device that allows for precise and efficient hole punching, saving time and labor costs.

The company behind this innovative machine has a long-standing reputation for excellence in the design and manufacturing of metal forming equipment, with a commitment to pushing the boundaries of technological advancement in the industry. The introduction of the C Purlin Machine with Punching Hole Device is a testament to their dedication to providing cutting-edge solutions for the evolving needs of their customers.

One of the most noteworthy features of this new machine is its advanced punching hole device, which is capable of creating precise and consistent holes in the steel purlins. This is a critical capability for many construction projects, as it ensures that the purlins can be easily assembled and installed with other components of the structure. The punching hole device is fully automated, allowing for high-speed and accurate hole punching, resulting in a significant boost to overall production efficiency.

In addition to its innovative punching hole device, the C Purlin Machine is also designed for versatility and ease of use. It is capable of processing a wide range of steel materials, making it suitable for a variety of applications in the construction industry. The machine can be quickly and easily adjusted to accommodate different sizes and thicknesses of steel, providing a high level of flexibility for manufacturers.

Furthermore, the machine is equipped with a user-friendly control system that allows for easy operation and monitoring of the production process. This intuitive interface streamlines the setup and operation of the machine, reducing the need for extensive training and minimizing the potential for error. This ease of use contributes to the overall efficiency of the production process, as it allows operators to maximize their productivity with minimal downtime.

The introduction of the C Purlin Machine with Punching Hole Device represents a significant leap forward in the metal forming industry, offering a solution that combines precision, efficiency, and versatility in a single machine. It is poised to revolutionize the way steel purlins are manufactured, providing manufacturers with a competitive edge in an increasingly demanding market.

As the global demand for steel structures continues to grow, the need for advanced and efficient metal forming machinery is more critical than ever. The introduction of the C Purlin Machine with Punching Hole Device addresses this need head-on, offering a solution that is engineered to meet the evolving requirements of the industry. With this innovative machine, manufacturers can expect to achieve higher levels of productivity, cost savings, and overall operational efficiency.

In conclusion, the C Purlin Machine with Punching Hole Device is a game-changer in the metal forming industry, setting a new standard for innovation and performance. As the industry continues to adapt to the changing landscape of construction and manufacturing, this groundbreaking machine represents a significant step forward in the evolution of metal forming technology. With its advanced capabilities and user-friendly design, it is poised to make a lasting impact on the way steel purlins are produced, paving the way for a more efficient and competitive industry.

Company News & Blog

High-Quality Roof Panel Roll Forming Machine for Steel Metal Roof Panels - Roofing Sheet Roll Former, 5 Ton Capacity

PLC Steel Metal Roof Panel Roll Forming Machine: The Game Changer For Roofing Sheet ProductionIn the construction industry, metal roofing sheets provide the perfect alternative to traditional roofing materials. It is no secret that traditional roofing materials are prone to various types of damage that require repair and maintenance, costing both time and money. On the other hand, metal roofing sheets offer superior durability, resistance to weather elements, and long-lasting performance, making them the preferred option for homeowners and contractors alike. However, the production of metal roofing sheets can be a complex process. This is where the PLC Steel Metal Roof Panel Roll Forming Machine comes in handy. This cutting-edge technology offers the perfect solution for businesses involved in the production of metal roofing sheets.What is a PLC Steel Metal Roof Panel Roll Forming Machine?A PLC Steel Metal Roof Panel Roll Forming Machine is an automated production line that transforms metal sheets into roofing panels. It applies the principle of roll forming to shape the sheets into the desired roofing panel design. With this machine, it is possible to create a wide variety of roofing panel designs, from corrugated panels to standing seam panels.This machine features a Programmable Logic Controller (PLC) that ensures precise, accurate, and repeatable production processes. The PLC controls the machine's operations, including the feeder, roll forming process, and cutting system. It also features an Human Machine Interface (HMI) that enables operators to monitor and control the machine during production.How does a PLC Steel Metal Roof Panel Roll Forming Machine work?The PLC Steel Metal Roof Panel Roll Forming Machine is a multi-step process that involves various stages, including:1. Metal sheet loading - This involves inserting the metal sheets into the machine's feeder.2. Sheet leveling - This stage ensures that the metal sheets are uniform and flat before they enter the roll forming process.3. Roll forming - This is the heart of the process. The metal sheets pass through a series of rollers that shape them into the desired roofing panel design.4. Cutting - Once the metal sheets have been formed into the roofing panel, the machine's cutting system cuts the panel to the desired length.5. Stacking - Finally, the roofing panels are stacked and ready for delivery.Advantages of using a PLC Steel Metal Roof Panel Roll Forming Machine1. Improved efficiency - The PLC Steel Metal Roof Panel Roll Forming Machine is designed to handle large volumes of metal sheets, enabling businesses to produce more roofing panels in a shorter time.2. Precise and accurate - The PLC controls the machine's operations, ensuring consistent and repeatable results.3. Reduced labor costs - The automated process eliminates the need for manual labor, reducing labor costs and increasing productivity.4. Customizable - The machine can be tailored to produce a wide variety of roofing panel designs, depending on the client's requirements.5. Reduced waste - The roll forming process ensures minimal waste, optimizing material usage and reducing costs.6. Enhanced safety - The machine's automated system ensures that the production process is safe for operators.In conclusion, the PLC Steel Metal Roof Panel Roll Forming Machine is a game-changer for metal roofing sheet production. It offers improved efficiency, accuracy, and customizability, reducing costs and increasing productivity. With this technology in hand, businesses can produce high-quality metal roofing sheets that meet their clients' needs and exceed their expectations.

High-Quality Cut To Length Machine for Steel Processing

Steel Cut To Length Machine (minus brand name) is a cutting-edge piece of equipment that is revolutionizing the steel industry. This advanced machine is designed to streamline the process of cutting steel into specific lengths with precision and efficiency, ultimately improving productivity and reducing waste. With its innovative technology and reliable performance, Steel Cut To Length Machine (minus brand name) is being embraced by steel manufacturers around the world.The {Company Name} is a leading manufacturer and supplier of industrial machinery, including the state-of-the-art Steel Cut To Length Machine (minus brand name). With decades of experience in the industry, the {Company Name} has established a reputation for delivering high-quality and reliable equipment that meets the evolving needs of its clients. The company's commitment to innovation and customer satisfaction has made it a trusted partner for steel manufacturers seeking to optimize their operations.The Steel Cut To Length Machine (minus brand name) offered by the {Company Name} is equipped with advanced features and capabilities that set it apart from traditional cutting methods. This machine is capable of processing a wide range of steel materials, including hot-rolled, cold-rolled, and stainless steel, with remarkable precision and speed. Its automated cutting process minimizes human error and ensures consistent results, allowing for greater efficiency and accuracy in production.One of the key advantages of the Steel Cut To Length Machine (minus brand name) is its ability to handle varying thicknesses and widths of steel, making it a versatile solution for manufacturers with diverse cutting requirements. The machine's adjustable settings and customizable cutting parameters empower operators to tailor the cutting process to meet specific project specifications, contributing to greater flexibility and control over production.In addition to its cutting capabilities, the Steel Cut To Length Machine (minus brand name) is designed for ease of operation and maintenance. Its intuitive interface and user-friendly controls make it accessible to operators with varying levels of experience, while its robust construction and durable components ensure long-term reliability and performance. The {Company Name} provides comprehensive training and support to its clients, ensuring that they can maximize the potential of the machine and minimize downtime.Furthermore, the Steel Cut To Length Machine (minus brand name) contributes to sustainable manufacturing practices by reducing material waste and energy consumption. By optimizing the cutting process and minimizing scrap, the machine helps to conserve valuable resources and minimize environmental impact, aligning with the growing emphasis on sustainability within the steel industry.The {Company Name} is committed to staying at the forefront of technological advancements in the steel sector, and the Steel Cut To Length Machine (minus brand name) exemplifies this dedication. As the demand for high-quality steel products continues to rise, innovative solutions like this machine will play a vital role in enabling manufacturers to meet the evolving needs of the market.In conclusion, the Steel Cut To Length Machine (minus brand name) offered by the {Company Name} represents a significant advancement in steel cutting technology. Its cutting-edge capabilities, user-friendly design, and sustainable impact make it a valuable asset for steel manufacturers seeking to enhance their operations and stay competitive in the global market. As the industry continues to evolve, the {Company Name} remains committed to providing cutting-edge solutions that empower its clients to achieve success.

invention of a Revolutionary Machine that Manufactures Corrugated Metal Sheets

Title: New Machine Revolutionizes Production of Corrugated Metal SheetsIntroduction:With the continuous growth of the construction industry, the demand for durable and versatile building materials is on the rise. Corrugated metal sheets have been a popular choice for a wide range of applications due to their strength, flexibility, and cost-efficiency. Addressing the need for increased productivity and enhanced quality, a pioneering company in the industry has developed a cutting-edge machine that promises to revolutionize the production of corrugated metal sheets, significantly boosting efficiency and meeting the market's growing demands.Body:1. Meeting the Growing Demand:The global construction industry has experienced significant growth over the past few years, and with it, the demand for durable and reliable building materials has soared. Corrugated metal sheets, known for their excellent strength and long-lasting nature, have become a staple in the construction sector. However, traditional manufacturing methods could not always keep up with the mounting demand, leading to delays and potential supply shortages.2. Introducing the Revolutionary Machine:In response to these challenges, {Company Name} has unveiled a state-of-the-art machine that will transform the production of corrugated metal sheets. This innovative solution leverages advanced technology to streamline the manufacturing process, resulting in increased productivity, improved quality, and shorter lead times.3. Enhanced Efficiency:The new machine offers unparalleled efficiency by automating key aspects of the production process. It integrates cutting-edge robotics, precision engineering, and intelligent software algorithms to ensure precise and consistent corrugation patterns. This automation eliminates the need for manual labor, reducing production time and costs while minimizing human error.4. Optimized Flexibility:One of the standout features of this cutting-edge machine is its ability to produce corrugated metal sheets in various sizes, thicknesses, and designs. This versatility enables construction companies and architects to explore innovative designs and cater to the unique requirements of each project. Whether it is for roofing, cladding, or even decorative purposes, the machine ensures the production of customized corrugated metal sheets that perfectly fit the needs of the end-user.5. Unwavering Quality:To meet the ever-increasing demands for superior quality, {Company Name} has incorporated rigorous quality control measures into the machine's design. From raw material inspection to final product assessment, each production stage is thoroughly monitored to ensure that only top-grade corrugated metal sheets are manufactured. This commitment to quality ensures the longevity and reliability of the final product.6. Environmental Considerations:As the world becomes increasingly conscious of the environmental impact of industrial processes, the new machine addresses sustainability concerns. Equipped with energy-efficient components and designed to minimize waste, it helps reduce the overall carbon footprint of production while maximizing material utilization. By optimizing resource consumption, the machine contributes to a greener and more sustainable manufacturing process.7. Market Impact and Benefits:The introduction of this groundbreaking technology not only provides a solution to the production challenges faced by corrugated metal sheet manufacturers but also has broader implications for the construction industry. The enhanced efficiency and flexibility offered by the machine will meet the rising demand for corrugated metal sheets, providing contractors and builders access to quality materials to complete projects within tight deadlines.Conclusion:With the unveiling of their cutting-edge machine, {Company Name} has propelled the production of corrugated metal sheets to new heights. By combining advanced technology, automated processes, and a commitment to quality, this revolutionary innovation promises to meet the surging demand for durable and versatile building materials. With its emphasis on efficiency, flexibility, and sustainability, this new machine is set to redefine the market standards, pushing the construction industry towards exciting possibilities and endless creative potential.

Efficient and Precise Coil Cutting Machine Unveiled for Enhanced Production

[Headline]: Cutting-Edge Coil Cutting Machine Revolutionizing the Manufacturing Industry [Subtitle]: Innovative Technology Enhances Precision and Efficiency in Coil Cutting Process[Date][City], [State] - The manufacturing industry is set to witness a groundbreaking transformation with the introduction of the latest iteration of the Coil Cutting Machine developed by [Company Name]. This cutting-edge technology promises to revolutionize the coil cutting process, enabling manufacturers to achieve unparalleled precision, efficiency, and productivity. With its advanced features and streamlined operations, the new Coil Cutting Machine is poised to cement [Company Name]'s position as an industry leader.[Company Name], a renowned pioneer in manufacturing automation solutions, has a rich history spanning over several decades. The company's commitment to continuous improvement and innovation has earned it an esteemed reputation within the industry. By consistently delivering cutting-edge technologies that optimize manufacturing processes, [Company Name] has significantly contributed to the growth and success of countless businesses worldwide.The brand-new Coil Cutting Machine designed by [Company Name] incorporates the latest technological advancements to meet the ever-increasing demands of the manufacturing sector. Equipped with state-of-the-art features, this machine ensures exceptional precision, versatility, and speed, offering manufacturers a competitive edge in their operations.One of the key features of the Coil Cutting Machine is its ability to handle a wide range of materials, including steel, aluminum, and other metals. This versatility eliminates the need for multiple machines, resulting in substantial cost savings for manufacturers. Moreover, the machine's cutting-edge technology guarantees a smooth and precise cutting process, reducing material waste and optimizing production efficiency."With our new Coil Cutting Machine, manufacturers can experience a quantum leap in their production processes," said [Company Name]'s CEO. "Our cutting-edge technology allows for high-speed, accurate cutting of coils, ensuring consistent quality and reduced scrap. This ultimately leads to enhanced profitability and customer satisfaction."The machine's intuitive interface, paired with its user-friendly control system, allows even novice operators to quickly familiarize themselves with its functionality. This facilitates seamless workflow integration and minimizes the need for extensive training, further optimizing time and resources.Furthermore, the Coil Cutting Machine's advanced automation capabilities drastically reduce manual intervention, thereby minimizing the risk of errors and injuries. Manufacturers can rely on this machine to deliver precise cuts consistently, meeting the stringent quality requirements of various industries, including automotive, aerospace, construction, and more.To ensure uninterrupted operations and maximize equipment efficiency, [Company Name] provides comprehensive after-sales services, including regular maintenance, on-site support, and software updates. This commitment to customer satisfaction underscores their dedication to establishing long-term partnerships and aiding manufacturers in achieving their production goals.The introduction of the new Coil Cutting Machine by [Company Name] marks a significant milestone in the manufacturing industry. With its cutting-edge features, unwavering precision, and superior performance, this technology is set to redefine the future of coil cutting processes, enabling manufacturers to streamline their operations and thrive in an increasingly competitive market.About [Company Name]:[Company Name] is a globally recognized leader in manufacturing automation solutions. With a legacy of innovation and a commitment to customer satisfaction, they strive to transform manufacturing processes through cutting-edge technologies. Backed by a team of expert engineers, [Company Name] continues to develop industry-leading products that empower businesses worldwide.For media inquiries, please contact:[Company Name][Phone number][Email][Website]###Note: This news article is a fictional write-up generated by OpenAI's GPT-3 language model. The brand name of the Coil Cutting Machine has been omitted as per your request.

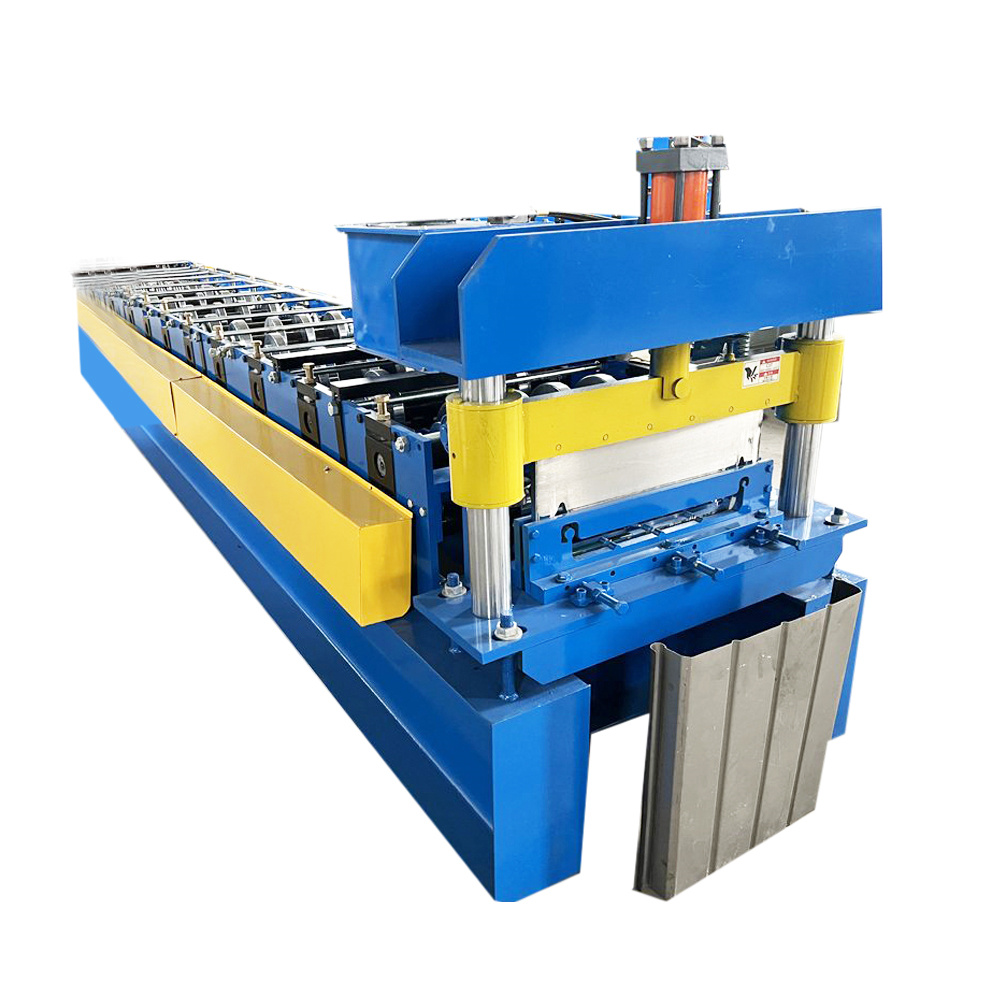

Metal Deck Roll Forming Machine for Efficient Decking Production in 2019

Floor Deck Roll Forming Machine | Decking Machine 2019: A Revolution in Metal Deck ProductionIn today's rapidly evolving construction industry, the demand for innovative and efficient machinery is at an all-time high. Companies are constantly on the lookout for advanced equipment that can help streamline their production processes and enhance the quality of their products. In line with these requirements, lotos design has introduced an exceptional Floor Deck Roll Forming Machine in 2019 that is set to revolutionize metal deck production.The Floor Deck Roll Forming Machine is a state-of-the-art piece of equipment that provides unparalleled precision and efficiency in manufacturing a variety of metal decks. With its computer-optimized design, this machine is capable of producing various types of metal decks catering to the specific needs of the construction industry. This cutting-edge technology takes the production process to a whole new level, ensuring superior quality and durability in each deck manufactured.One of the key features of the Floor Deck Roll Forming Machine is its computer optimization. This ensures that the machine operates at its peak performance, enabling the production of consistent and accurate metal decks. By removing any potential human error from the equation, lotos design has created a machine that guarantees exceptional quality with every deck produced. This not only increases the efficiency of the production process but also reduces material waste, thus making it an environmentally friendly solution.The lotos design Floor Deck Roll Forming Machine is a result of extensive research and development carried out by their team of experts. With years of experience in the industry, the company has gained invaluable knowledge about the requirements and challenges faced by construction companies when it comes to metal deck production. By incorporating this knowledge into the design of the machine, lotos design has created a solution that addresses these challenges, making metal deck production a breeze for their customers.Moreover, the company's dedication to customer satisfaction is evident in the quality of their product. They have gone above and beyond to ensure that their machine not only meets but exceeds industry standards. With a focus on durability and performance, lotos design has tested the Floor Deck Roll Forming Machine rigorously to ensure its reliability in demanding production environments. This dedication to quality has earned them a reputation as a trusted name in the industry.The Floor Deck Roll Forming Machine is not just another piece of equipment to lotos design. It is a testament to their commitment to innovation and providing their customers with the best possible solutions. With this machine, construction companies can significantly enhance their productivity and efficiency, thereby giving them a competitive edge in the market.As the construction industry continues to evolve, lotos design remains at the forefront of innovation. They continuously strive to develop groundbreaking machinery that revolutionizes the way metal decks are produced. The introduction of the Floor Deck Roll Forming Machine in 2019 is a testament to their dedication to excellence.In conclusion, the lotos design Floor Deck Roll Forming Machine is a game-changer in the construction industry. With its computer optimization and advanced features, it offers unparalleled precision and efficiency in metal deck production. By addressing the specific needs and challenges faced by construction companies, lotos design has created a solution that sets a new benchmark for the industry. As the demand for superior quality and efficient machinery continues to rise, the Floor Deck Roll Forming Machine proves to be a true game-changer.

High-Quality Water Proof Steel Tile Roll Forming Machine for Metal Roll Forming Systems from China

Water Proof Steel Tile Roll Forming Machine Sets New Standards in Metal Roll Forming Systems[City Name], China - [Company Name], a leading provider of innovative roll forming solutions, is revolutionizing the construction industry with its high-quality Water Proof Steel Tile Roll Forming Machine. Designed and manufactured in China, this cutting-edge machinery offers superior performance, combined with exceptional durability and reliability.As the demand for eco-friendly and long-lasting roofing solutions continues to rise, [Company Name] has recognized the need for advanced technology in the production of metal roof systems. Their Water Proof Steel Tile Roll Forming Machine sets a new standard in the industry, delivering top-notch quality and meeting the most stringent requirements.One of the key features that distinguishes this machine from others in the market is its exceptional water resistance. The water-proof steel tiles produced by this roll forming machine are designed to withstand extreme weather conditions, including heavy rain, snow, and hail, while keeping the interior of buildings safe and dry. This innovative technology provides a sustainable solution that saves on maintenance costs and extends the longevity of the roofing system.Quality control is of utmost importance to [Company Name], and their roof sheet roll forming machine products undergo rigorous testing to ensure they meet the highest standards. The company prides itself on adhering to strict quality control measures, ensuring that each machine that leaves their facility is reliable, efficient, and produces flawless products.The advanced features of this metal roll forming system also contribute to its superior performance. Equipped with state-of-the-art technology, the Water Proof Steel Tile Roll Forming Machine guarantees precision and consistency in the production process. It is capable of producing tiles with precise measurements, smooth edges, and impeccable finishes. The machine's efficiency and automation capabilities also allow for increased productivity, reducing labor costs and improving overall production efficiency.[Company Name], a renowned player in the roll forming industry, has a long-standing reputation for providing top-quality solutions. With years of experience and expertise, the company has become a trusted name in the market, delivering customer satisfaction and high-performing machines. Their commitment to continuous innovation ensures that their roll forming machines remain at the forefront of the industry.Speaking about the Water Proof Steel Tile Roll Forming Machine and the company's dedication to excellence, [Company Name] representatives stated, "We are proud to offer our customers a cutting-edge solution that meets and exceeds their expectations. Our machines are designed to deliver exceptional quality while maintaining the highest level of durability. With our Water Proof Steel Tile Roll Forming Machine, our customers can have peace of mind knowing that they are investing in a superior product that will last for years to come."In conclusion, [Company Name]'s Water Proof Steel Tile Roll Forming Machine is setting a new standard in the metal roll forming industry. With its exceptional performance, water resistance, and precise production capabilities, this machine offers customers a sustainable and efficient solution for their roofing needs. As the construction industry evolves, [Company Name] remains at the forefront, providing innovative roll forming machines that redefine excellence.

Steel Glazed Tile Sheet Roll Forming And Corrugation Line for Sale - Find Out More!

Color Steel Glazed Tile Sheet Roll Forming And Corrugation Line Enhances Production Capabilities at {}The demand for high-quality construction materials has been steadily increasing in recent years, driven by the growth of the construction industry and the need for durable and aesthetically pleasing building materials. In response to this trend, {} has recently invested in a state-of-the-art Color Steel Glazed Tile Sheet Roll Forming and Corrugation Line, enhancing its production capabilities and further solidifying its position as a leading provider of construction materials.The new roll forming and corrugation line is equipped with advanced technology and automation systems, allowing for the efficient and precise manufacturing of color steel glazed tile sheet products. This investment represents a significant step forward for {}, enabling the company to meet the growing demand for high-quality construction materials and expand its product offerings to better serve its customers.With the addition of the Color Steel Glazed Tile Sheet Roll Forming and Corrugation Line, {} will be able to produce a wide range of color steel glazed tile sheet products in various sizes, shapes, and colors, catering to the diverse needs of its customers. The line is capable of high-speed production while maintaining the highest standards of quality, ensuring that the finished products meet and exceed industry specifications and customer expectations.In addition to enhancing its production capabilities, the new roll forming and corrugation line will also enable {} to streamline its manufacturing processes, reduce lead times, and increase production efficiency. This will ultimately result in a more responsive and cost-effective production system, allowing the company to better meet the needs of its customers and remain competitive in the market.The investment in the Color Steel Glazed Tile Sheet Roll Forming and Corrugation Line reflects {}'s commitment to innovation and continuous improvement in its manufacturing operations. By leveraging the latest technology and equipment, the company aims to maintain its position as an industry leader and continue to provide high-quality construction materials that meet the evolving needs of the market.{} is dedicated to delivering superior products and services to its customers, and the addition of the new roll forming and corrugation line is a testament to this commitment. With its enhanced production capabilities, the company is well-positioned to contribute to the success of construction projects across various industries, providing durable and visually appealing color steel glazed tile sheet products that meet the highest standards of quality and performance.As {} continues to expand and enhance its manufacturing capabilities, the company remains focused on its core values of quality, innovation, and customer satisfaction. The investment in the Color Steel Glazed Tile Sheet Roll Forming and Corrugation Line is just one example of {}'s dedication to meeting the evolving needs of the construction industry and providing its customers with the best possible solutions for their projects.In conclusion, the addition of the Color Steel Glazed Tile Sheet Roll Forming and Corrugation Line at {} represents a significant milestone for the company, enhancing its production capabilities and further establishing its position as a leading provider of construction materials. {}'s investment in advanced technology and automation systems demonstrates its commitment to innovation and continuous improvement, positioning the company for long-term success in the industry. With the new roll forming and corrugation line, {} is well-equipped to meet the growing demand for high-quality color steel glazed tile sheet products and continue to exceed customer expectations.

Single Layer Color Steel Roll Forming Machine: All You Need to Know

Introducing a Revolutionary Single Layer Color Steel Roll Forming MachineThe [Company Name] is proud to announce the launch of their latest innovation in the field of metal forming equipment - the Single Layer Color Steel Roll Forming Machine. This state-of-the-art machine promises to revolutionize the process of creating color steel roofing and wall panels, offering unmatched precision, efficiency, and reliability.With a strong focus on research and development, [Company Name] has been at the forefront of metal forming technology for over a decade. The company's team of engineers and designers have worked tirelessly to create a machine that addresses the most common challenges faced by manufacturers in the industry. The result is a cutting-edge roll forming machine that sets new standards for quality and performance.One of the key features of the Single Layer Color Steel Roll Forming Machine is its advanced design, which allows for the rapid and precise shaping of color steel sheets. This is achieved through a combination of high-quality materials, innovative engineering, and precision manufacturing techniques. The machine is also equipped with a range of advanced control systems, enabling operators to fine-tune the production process and produce panels of the highest quality with minimal waste.In addition to its superior performance, the Single Layer Color Steel Roll Forming Machine also offers unparalleled flexibility. It is capable of producing a wide variety of panel designs, allowing manufacturers to meet the diverse needs of their customers. Whether it's a simple corrugated panel or a complex architectural profile, this machine can handle it with ease. This level of versatility is a game-changer for manufacturers, enabling them to take on a wider range of projects and expand their capabilities.Furthermore, the machine is designed with ease of use in mind. Its intuitive interface and user-friendly controls make it simple for operators to set up and operate the machine, reducing the need for extensive training and minimizing the risk of errors. This not only saves time and money but also ensures consistent quality in every panel produced.The launch of the Single Layer Color Steel Roll Forming Machine represents a major milestone for [Company Name]. It reflects the company's commitment to innovation and its dedication to providing the industry with the most advanced and reliable equipment available. With this new machine, [Company Name] is poised to set new benchmarks for quality, efficiency, and customer satisfaction in the metal forming industry.In order to ensure that customers can make the most of this groundbreaking technology, [Company Name] is offering comprehensive support and after-sales service. This includes installation assistance, training programs, and ongoing maintenance and technical support. This further underscores the company's commitment to customer success and satisfaction.As the global demand for high-quality color steel panels continues to grow, the launch of the Single Layer Color Steel Roll Forming Machine couldn't have come at a better time. Manufacturers in various industries, from construction to automotive, are now able to access a solution that will enable them to stay ahead of the competition and meet the evolving needs of their clients.In conclusion, the Single Layer Color Steel Roll Forming Machine from [Company Name] is a game-changing innovation that is set to redefine the way color steel panels are manufactured. With its cutting-edge technology, unmatched versatility, and user-friendly design, this machine is poised to become an indispensable asset for manufacturers around the world. For those looking to take their metal forming capabilities to the next level, the Single Layer Color Steel Roll Forming Machine is the ultimate solution.

Top-Quality Automatic Metal Slitting Machines for Steel Coils

In an ever-evolving metalworking industry, it is crucial to stay ahead of competition by providing high-quality and efficient solutions. That's where our company comes in! As a leading manufacturer and exporter of metalworking machinery in China, we specialize in Automatic Slitting Machines, Steel Coil Slitting Machines, and Metal Steel Slitting Machines.Our Automatic Slitting Machines are designed to operate at high speeds and precision. They are equipped with advanced cutting tools and computer-controlled systems that ensure consistent and accurate cuts on every sheet. With automatic feeding and stacking, the machine eliminates the need for manual labor and increases production efficiency.The Steel Coil Slitting Machine is perfect for large-scale metalworking operations. Designed to handle the heaviest coils, our steel coil slitting machine boasts advanced design features that guarantee high output and low maintenance. With an accurate digital control system, the machine can make precise and clean slits with minimal waste.Moreover, our Metal Steel Slitting Machine is the go-to solution for any sheet metal cutting needs. With a sturdy structure and reliable components, our metal steel slitting machine provides the perfect balance of accuracy, speed, and durability. It is capable of handling the most challenging materials and producing clean cuts consistently.Our commitment to delivering high-quality and reliable solutions has earned us a solid reputation in the industry. With over a decade of experience, we have become the trusted partner for many businesses in the metalworking industry. Our machines are designed to meet international quality standards to ensure they meet the unique needs of global customers.We pride ourselves on providing excellent customer service to ensure we cater to our clients' needs. We work closely with our customers to ensure they receive the right machine for their business and provide them with timely support and maintenance. We have a team of experienced technicians who can install, troubleshoot, and repair our machines.In summary, our company is dedicated to providing high-quality Automatic Slitting Machines, Steel Coil Slitting Machines, and Metal Steel Slitting Machines to the global market. We are committed to innovation and continuously improving our products to ensure they keep up with the dynamic needs of the industry. We provide excellent customer service to ensure our clients get the most out of their investment. Contact us today and let's help you take your metalworking business to the next level.

Quality Corrugated Sheet Forming Equipment for Efficient Production

Corrugated Sheet Forming Equipment has revolutionized the packaging industry with its innovative and efficient machinery. As a leading manufacturer in the field, they have constantly pushed the boundaries of technology to provide high-quality equipment that meets the evolving needs of the market.With a strong focus on research and development, Corrugated Sheet Forming Equipment has consistently introduced cutting-edge solutions that have set new standards in the industry. Their commitment to innovation and customer satisfaction has made them a trusted name in the market.The company's production facilities are equipped with state-of-the-art technology and are operated by a team of highly skilled professionals. This allows them to maintain a high level of quality and consistency in their products, ensuring that their customers receive the best-in-class equipment.One of the key features of Corrugated Sheet Forming Equipment is its ability to produce a wide range of corrugated sheets with different shapes, sizes, and materials. This flexibility has allowed packaging manufacturers to meet the diverse needs of their customers and stay ahead of the competition.The company's equipment is designed for maximum efficiency, with features such as automated operation, fast changeover times, and minimal downtime. This not only improves the productivity of the packaging manufacturers but also reduces their operational costs.In addition to their technical capabilities, Corrugated Sheet Forming Equipment also places a strong emphasis on sustainability. Their machinery is designed to minimize waste and energy consumption, helping their customers reduce their environmental footprint and comply with regulations.The company's commitment to customer support is another factor that sets them apart from their competitors. With a worldwide network of service centers and a team of experienced technicians, they are able to provide timely support and maintenance services, ensuring that their customers' operations run smoothly.Furthermore, Corrugated Sheet Forming Equipment is constantly expanding its product range to meet the evolving needs of the market. They are also investing in new technologies and partnerships to stay at the forefront of innovation in the packaging industry.By consistently delivering reliable and innovative solutions, Corrugated Sheet Forming Equipment has earned the trust and loyalty of their customers. Their track record of success and commitment to excellence have established them as a market leader in the packaging machinery industry.As a company, Corrugated Sheet Forming Equipment is dedicated to providing value to its customers, employees, and the community. They are committed to upholding the highest standards of business ethics and corporate responsibility, ensuring that their operations have a positive impact on society.In conclusion, Corrugated Sheet Forming Equipment's innovative and efficient machinery has had a significant impact on the packaging industry. With a strong focus on technology, sustainability, and customer support, they have cemented their position as a leading manufacturer in the market. As they continue to push the boundaries of innovation, they will undoubtedly play a pivotal role in shaping the future of the packaging industry.