Corrugated Roof Tile Barrel Sheet Profiling Machine: Everything You Need to Know

By:Admin

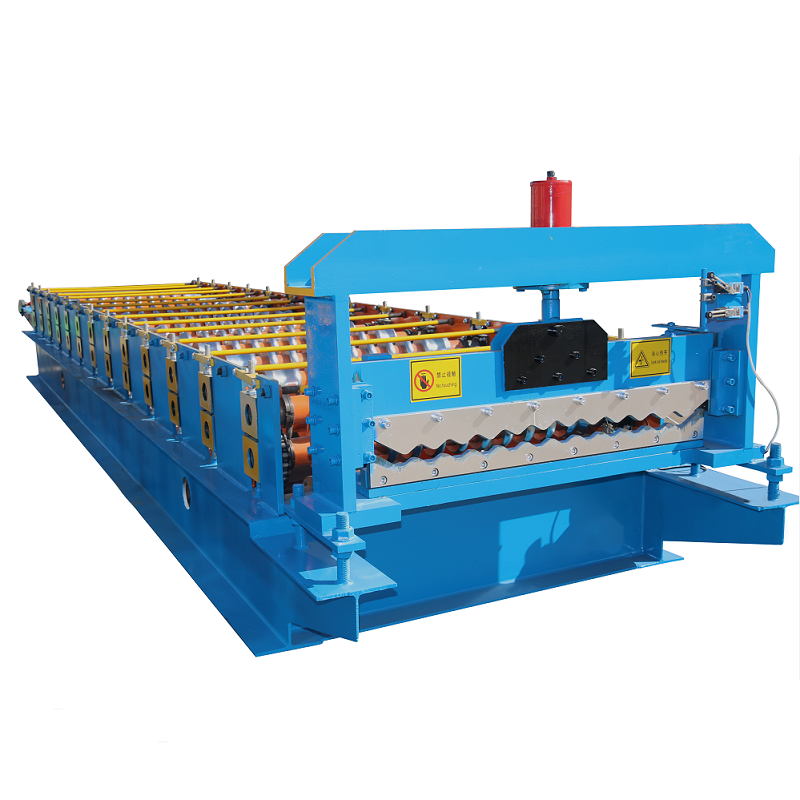

The manufacturing industry is constantly evolving, with new technological advancements revolutionizing the way products are made. One such innovation is the Corrugated Roof Tile Barrel Sheet Profiling Machine, which has been developed by a leading company in the industry.

This groundbreaking machine is designed to streamline the production of corrugated roof tiles, barrel sheets, and other similar roofing products. It utilizes advanced profiling technology to accurately shape and cut metal sheets, resulting in a precise and high-quality finished product. The use of this machine has dramatically reduced production time and labor costs, making it a game-changer for manufacturers in the roofing industry.

The Corrugated Roof Tile Barrel Sheet Profiling Machine is equipped with a state-of-the-art control system, allowing for easy and precise operation. This ensures that each product is consistently manufactured to the highest standards, meeting the strict requirements of the industry. The machine is also highly versatile, capable of producing a wide range of designs and sizes to meet the diverse needs of customers.

In addition to its advanced technological features, the machine is also designed with safety and efficiency in mind. It is equipped with safety guards and emergency stop mechanisms to protect operators and prevent accidents. Furthermore, the machine’s energy-efficient design helps reduce energy consumption, making it a sustainable choice for manufacturers.

The company behind this innovative machine has a long history of excellence in the manufacturing industry. With a strong focus on research and development, they have consistently delivered cutting-edge solutions to meet the evolving needs of their customers. Their commitment to quality and innovation has earned them a reputation as a trusted leader in the industry.

In addition to the Corrugated Roof Tile Barrel Sheet Profiling Machine, the company offers a wide range of other manufacturing equipment and solutions. From roll forming machines to metal cutting systems, they are dedicated to providing comprehensive and custom-tailored solutions to their clients. Their team of skilled engineers and technicians work closely with customers to develop the perfect manufacturing solution for their specific needs.

Through their dedication to excellence and innovation, the company has established a strong global presence, serving clients in various industries around the world. Their commitment to quality and customer satisfaction has earned them numerous accolades and recognition within the industry.

The introduction of the Corrugated Roof Tile Barrel Sheet Profiling Machine is yet another example of the company’s commitment to innovation and progress. By offering a groundbreaking solution to streamline the manufacturing process, they are helping their clients stay ahead of the competition and meet the growing demands of the market.

In conclusion, the Corrugated Roof Tile Barrel Sheet Profiling Machine represents a significant advancement in the manufacturing industry. Its cutting-edge technology, precision engineering, and commitment to safety and efficiency make it a valuable asset for manufacturers in the roofing industry. As the company continues to push the boundaries of innovation, we can expect to see more groundbreaking solutions that will shape the future of manufacturing.

Company News & Blog

Highly Efficient and Durable Rain Pipe Roll Forming Machine Impresses with Innovative Color Steel Technology

Title: State-of-the-Art Color Steel Rain Pipe Roll Forming Machine Revolutionizes the IndustryIntroduction:In an ever-evolving world of technology and innovation, the manufacturing industry is no exception. Introducing a cutting-edge Color Steel Rain Pipe Roll Forming Machine, the industry is set to witness a remarkable transformation in production processes. This state-of-the-art machine is designed to streamline the manufacturing of rain pipes, ensuring high precision, durability, and efficiency. In this article, we will delve into the features and benefits of this remarkable equipment and explore how it is set to revolutionize the industry.Paragraph 1:The Color Steel Rain Pipe Roll Forming Machine, developed by leading experts in the field, offers a remarkable solution for the manufacturing of rain pipes. Equipped with advanced technology and precise engineering, this machine has the potential to usher in a new era in the production process. By optimizing the use of raw materials and maximizing output, manufacturers can improve efficiency and reduce costs.Paragraph 2:One of the key features of this Color Steel Rain Pipe Roll Forming Machine is its flexibility. Designed to accommodate various pipe sizes and shapes, manufacturers can easily adapt the machine to meet specific project requirements. This adaptability not only saves time but also reduces the need for additional equipment, ultimately reducing production costs.Paragraph 3:The machine's high precision capabilities ensure that each rain pipe is manufactured to exact specifications. This eliminates any inconsistencies that can occur with traditional manufacturing methods, guaranteeing a superior product that meets industry standards. The precision of the machine ensures that rain pipes are uniform in shape, size, and thickness, enhancing their durability and longevity.Paragraph 4:Furthermore, the Color Steel Rain Pipe Roll Forming Machine is equipped with automatic controls and feedback systems. This allows manufacturers to monitor and maintain optimal production conditions, minimizing errors and ensuring a seamless manufacturing process. With adjustable settings and real-time data monitoring, production efficiency is significantly increased, resulting in higher output and reduced downtime.Paragraph 5:In addition to the technical advantages, the machine's user-friendly interface and intuitive design make it accessible to operators of all skill levels. This eliminates the need for extensive training and allows manufacturers to quickly integrate the machine into their production line. The simplified operation also reduces the likelihood of human errors, further improving product quality and minimizing waste.Paragraph 6:The environmental impact of manufacturing is a growing concern in today's world. The Color Steel Rain Pipe Roll Forming Machine addresses this concern by optimizing the use of raw materials and minimizing waste. Through precise control and measurement during the manufacturing process, the machine ensures the efficient use of resources, making it an environmentally sustainable solution.Conclusion:The introduction of the Color Steel Rain Pipe Roll Forming Machine marks a significant milestone in the manufacturing industry. With its advanced technology, precision engineering, and user-friendly interface, this machine promises to revolutionize the production of rain pipes. From its versatility and high precision capabilities to its efficiency and environmental sustainability, the machine offers a comprehensive solution for manufacturers in this sector. As the industry embraces this cutting-edge technology, we can expect to witness enhanced productivity, improved product quality, and reduced costs.

Corrugated Roof Tile Barrel Sheet Profiling Machine: Everything You Need to Know

Innovative Corrugated Roof Tile Barrel Sheet Profiling Machine Revolutionizes Manufacturing ProcessThe manufacturing industry is constantly evolving, with new technological advancements revolutionizing the way products are made. One such innovation is the Corrugated Roof Tile Barrel Sheet Profiling Machine, which has been developed by a leading company in the industry.This groundbreaking machine is designed to streamline the production of corrugated roof tiles, barrel sheets, and other similar roofing products. It utilizes advanced profiling technology to accurately shape and cut metal sheets, resulting in a precise and high-quality finished product. The use of this machine has dramatically reduced production time and labor costs, making it a game-changer for manufacturers in the roofing industry.The Corrugated Roof Tile Barrel Sheet Profiling Machine is equipped with a state-of-the-art control system, allowing for easy and precise operation. This ensures that each product is consistently manufactured to the highest standards, meeting the strict requirements of the industry. The machine is also highly versatile, capable of producing a wide range of designs and sizes to meet the diverse needs of customers.In addition to its advanced technological features, the machine is also designed with safety and efficiency in mind. It is equipped with safety guards and emergency stop mechanisms to protect operators and prevent accidents. Furthermore, the machine’s energy-efficient design helps reduce energy consumption, making it a sustainable choice for manufacturers.The company behind this innovative machine has a long history of excellence in the manufacturing industry. With a strong focus on research and development, they have consistently delivered cutting-edge solutions to meet the evolving needs of their customers. Their commitment to quality and innovation has earned them a reputation as a trusted leader in the industry.In addition to the Corrugated Roof Tile Barrel Sheet Profiling Machine, the company offers a wide range of other manufacturing equipment and solutions. From roll forming machines to metal cutting systems, they are dedicated to providing comprehensive and custom-tailored solutions to their clients. Their team of skilled engineers and technicians work closely with customers to develop the perfect manufacturing solution for their specific needs.Through their dedication to excellence and innovation, the company has established a strong global presence, serving clients in various industries around the world. Their commitment to quality and customer satisfaction has earned them numerous accolades and recognition within the industry.The introduction of the Corrugated Roof Tile Barrel Sheet Profiling Machine is yet another example of the company’s commitment to innovation and progress. By offering a groundbreaking solution to streamline the manufacturing process, they are helping their clients stay ahead of the competition and meet the growing demands of the market.In conclusion, the Corrugated Roof Tile Barrel Sheet Profiling Machine represents a significant advancement in the manufacturing industry. Its cutting-edge technology, precision engineering, and commitment to safety and efficiency make it a valuable asset for manufacturers in the roofing industry. As the company continues to push the boundaries of innovation, we can expect to see more groundbreaking solutions that will shape the future of manufacturing.

High quality PVC Corrugated and Composite Roof Tile Production Line for durable and attractive roofing. This line is used to produce PVC corrugated tiles with customizable width and thickness using PVC, ASA, PMMA compounds. It includes a conical twin screw extruder, forming machine, haul-off, cutter and stacker. The product is treated with hot-stamping or water transferring for a smooth and shining marble-like surface. Formula guide is provided for easy production.

, PVC Roofing Sheet Making Machine, Anti-Aging PVC Plastic Tile Extruder, PVC Corrugated Tile Production Line, Composite Roof Tile Production LineAre you tired of constantly replacing your old, worn-out roof tiles? Look no further than our High Performance Corrugated Anti-Aging PVC Plastic Glazed Color Roof Tile PVC Roofing Sheet Making Machine.Our PVC Corrugated and Composite Roof Tile Extruder is manufactured with the highest quality materials, ensuring durability and longevity. The surface is treated with hot-stamping machine directly in line or water transferring after extrusion, which creates a mirror-like surface with a strong feeling of smooth and shining marble.This machine is perfect for anyone who needs to produce PVC corrugated tile, with a width of 1130mm and a thickness between 1.5-3mm. Additionally, our PVC, ASA, PMMA compound roof tile production line consists of conical twin screw extruder SJZ80/156, co-extruder, extruding tools, forming machine for the main tile and ridge tiles, haul-off, cutter, and stacker. We even provide a supply formula guide (brand name removed) to ensure the best results for your production needs. So whether you're tackling a small DIY project or a larger commercial job, our PVC Corrugated and Composite Roof Tile Production Line can meet your needs. Contact us today for more information on our Glazed Roof Tile Making Machinery, PVC Roofing Sheet Making Machine, Anti-Aging PVC Plastic Tile Extruder, PVC Corrugated Tile Production Line, and Composite Roof Tile Production Line.

Steel Coil Slitter: The Ultimate Guide

Steel Coil Slitter: Enhancing Efficiency and Precision in Metal ProcessingIn the world of metal processing, precision and efficiency are essential components to ensuring high-quality products and optimal production capabilities. One company that has been at the forefront of innovation in this field is {}. With a strong commitment to excellence and a dedication to meeting the evolving needs of the industry, {} has recently introduced its latest innovation – the Steel Coil Slitter.The Steel Coil Slitter is a cutting-edge machine that has been designed to enhance efficiency and precision in the process of slitting steel coils. This state-of-the-art equipment is capable of processing large steel coils into narrower coils of various widths with exceptional accuracy and speed. By utilizing advanced technology and innovative engineering, the Steel Coil Slitter has set a new standard for performance and productivity in the metal processing industry.One of the key features of the Steel Coil Slitter is its ability to accommodate a wide range of coil widths and thicknesses, making it highly versatile and suitable for a variety of applications. This flexibility allows metal processing companies to streamline their operations and achieve greater levels of efficiency in their production processes. Additionally, the Steel Coil Slitter is equipped with precision cutting blades and advanced control systems that ensure consistent and accurate results, minimizing material waste and maximizing the yield of high-quality slit coils.Furthermore, the Steel Coil Slitter is designed with user-friendly interfaces and intuitive controls, facilitating ease of operation and reducing the need for extensive training. This user-centric approach reflects {}'s commitment to delivering innovative solutions that not only optimize performance but also simplify workflow and improve overall productivity.In addition to its impressive performance capabilities, the Steel Coil Slitter is also built with a strong emphasis on durability and reliability. {} has integrated robust construction and high-quality components into the design of the machine, ensuring that it can withstand the demands of heavy-duty industrial applications and deliver consistent results over an extended lifespan. This emphasis on long-term value and reliability underscores {}'s dedication to providing equipment that not only meets current needs but also anticipates future requirements.As a leader in the metal processing equipment industry, {} has a long-standing reputation for delivering cutting-edge solutions that empower metal fabricators, service centers, and other related businesses to achieve their production goals with precision and efficiency. The introduction of the Steel Coil Slitter further solidifies {}'s position as an innovative force in the industry, offering a solution that addresses the complexities and demands of modern metal processing operations.With a focus on continuous improvement and a deep understanding of the evolving needs of the industry, {} has remained dedicated to staying ahead of the curve through research, development, and the integration of the latest technological advancements. The Steel Coil Slitter is a testament to this ongoing commitment, providing metal processing companies with a powerful tool to enhance their capabilities and drive their success in an increasingly competitive market.In conclusion, the Steel Coil Slitter represents a significant advancement in the field of metal processing equipment, offering a compelling combination of precision, efficiency, and versatility. As {} continues to push the boundaries of innovation, it is poised to redefine the standards of excellence in the industry and empower its customers to achieve new levels of productivity and success. With the introduction of the Steel Coil Slitter, {} has once again demonstrated its dedication to delivering state-of-the-art solutions that meet the complex needs of modern metal processing operations.

Competitive Intelligence by Key Players in the Automatic Roll Forming Machine Market: Global Market Analysis and Size

Automatic Roll Forming Machine Market: Increasing Industrialization Driving Demand for C/Z Purlin Roll Forming MachinesThe global Automatic Roll Forming Machine market is expected to witness robust growth in the coming years, driven by increasing industrialization across the globe. The Automatic Roll Forming Machine is a highly versatile equipment that is used in industries such as construction, automotive, electronics, and aerospace, among others. It is used for forming metal sheets and strips into different shapes and sizes. Among the various types of Roll Forming Machines, C/Z Purlin Roll Forming Machine is a popular choice for manufacturing structures that require strong supports for roofing, cladding, and walls.C/Z Purlin Roll Forming Machine is a type of Roll Forming Machine that is designed specifically for producing C-shaped and Z-shaped purlins. These purlins are used for making pre-engineered steel buildings, industrial sheds, warehouses, and other structures. The machine works by feeding a strip of metal through a series of rollers that shape the metal into the desired profile. The final product is a strong, lightweight, and durable purlin that can withstand heavy loads and adverse weather conditions.Key Market Players in Automatic Roll Forming Machine MarketThe key market players in the Automatic Roll Forming Machine market include Bradbury Group, Framing Tech, Formtek Group, Gasparini Industries, HILALMAK, Howick, Isolaminas, JET USA, Knauer Engineering, L.B. Bohle Maschinen + Verfahren, M.Torres, Onward Machinery, PEP brainin, Taicang Keboer, TOX Pressotechnik, TRL Krosaki Refractories Limited, Xiamen Zheng Liming Metallurgical Machinery, and Yoder.Market SegmentationThe global Automatic Roll Forming Machine market can be segmented based on product type, application, and region.Based on Product Type, the market can be segmented into:• C/Z Purlin Roll Forming Machine• Corrugated Sheet Roll Forming Machine• Tile Roll Forming Machine• OthersBased on Application, the market can be segmented into:• Construction• Automotive• Electronics• Aerospace• OthersBased on Region, the market can be segmented into:• North America• Europe• Asia-Pacific• Middle East and Africa• South AmericaRegional AnalysisThe Asia-Pacific region is expected to dominate the Automatic Roll Forming Machine market in the forecast period, owing to the increasing demand for industrialization in countries such as China, India, and Japan. The region also has a large base of manufacturers and a significant consumer base for Roll Forming Machines. The North American and European markets are also expected to witness steady growth due to the increasing demand for lightweight and durable materials in the construction and automotive industries.ConclusionThe Automatic Roll Forming Machine market is expected to witness robust growth in the coming years, owing to the increasing demand for lightweight and durable materials in the construction, automotive, electronics, and aerospace industries. C/Z Purlin Roll Forming Machines are expected to witness significant demand, owing to the increasing demand for pre-engineered steel buildings, industrial sheds, and warehouses. The Asia-Pacific region is expected to dominate the market, owing to the increasing demand for industrialization in the region. The key market players in the market are Bradbury Group, Framing Tech, Formtek Group, Gasparini Industries, HILALMAK, among others.

Top-quality Manufacturers of Roofing Sheet Roll Forming and Glazed Tile Roll Forming Machines in China

Glazed Roofing Sheet Roll Forming Machine: The Perfect Solution for High-Quality RoofingWhen it comes to building structures, the importance of a sturdy and reliable roof cannot be overstated. A properly constructed roof not only protects the building from external elements but also adds to its aesthetic appeal. One crucial component in roofing construction is the roofing sheet. With the advancements in technology, the process of manufacturing roofing sheets has become much more efficient and precise, thanks to the introduction of roll forming machines.Among the various roll forming machines available in the market, the glazed roofing sheet roll forming machine stands out as a reliable and efficient solution. This machine offers several advantages, including high-quality production, durability, and exceptional performance. If you're in search of a top-quality glazed roofing sheet roll forming machine, look no further than trusted manufacturers like ZhongHeng Machine Manufacture Co.,Ltd., who specialize in providing the best roll forming machines in the industry.High-Quality Roofing Sheet Roll Forming MachineThe quality of roofing sheets significantly impacts the overall performance and lifespan of a roof. A durable and weather-resistant roofing sheet ensures long-lasting protection for any structure. The glazed roofing sheet roll forming machine from ZhongHeng Machine Manufacture Co.,Ltd. guarantees top-notch quality production, meeting and exceeding industry standards.By utilizing advanced technology and state-of-the-art manufacturing processes, the glazed roofing sheet roll forming machine produces roofing sheets of exceptional strength and durability. These machines are designed with precision and accuracy to transform raw materials into flawless roofing sheets with ease. Additionally, the machine's robust build ensures continuous productivity, reducing downtime and optimizing efficiency.Durability and LongevityWhen investing in a roofing sheet roll forming machine, durability is a critical factor to consider. The machine should be constructed with high-quality materials to withstand harsh working conditions and regular usage. ZhongHeng Machine Manufacture Co.,Ltd. excels in this area by providing robust and long-lasting glazed roofing sheet roll forming machines.These machines are built to endure rigorous manufacturing processes without compromising their performance. Built with heavy-duty frames and components, they can withstand prolonged use without experiencing significant wear and tear. This durability ensures maximum return on investment (ROI) and minimizes maintenance costs, making ZhongHeng Machine Manufacture Co.,Ltd. the preferred choice for businesses in need of reliable machines.Exceptional PerformanceThe performance of a glazed roofing sheet roll forming machine directly affects production efficiency and output. ZhongHeng Machine Manufacture Co.,Ltd.'s glazed roofing sheet roll forming machines are engineered to deliver unmatched performance, guaranteeing quick and precise sheet formation with every cycle.Equipped with cutting-edge technology, these machines feature automated processes that reduce dependencies on manual labor, making them highly efficient in terms of time and cost. Furthermore, the machines are equipped with advanced control systems, allowing operators to monitor and adjust the speed and parameters, resulting in consistent and high-quality sheet production.ConclusionWhen it comes to sourcing the best roofing sheet roll forming machines, ZhongHeng Machine Manufacture Co.,Ltd. is a reputable and trusted manufacturer known for their high-quality production and exceptional customer service. Their glazed roofing sheet roll forming machines offer top-notch quality, durability, and exceptional performance.Investing in a glazed roofing sheet roll forming machine from ZhongHeng Machine Manufacture Co.,Ltd. ensures that you receive a reliable, durable, and high-performing machine that will contribute to the success of your roofing business. Don't compromise on the quality of your roofing sheets; choose a dependable and renowned manufacturer for a seamless roofing experience.

Top Roller for Corrugated Roofing: Must-Have Tool for Easy Installation

Roller for Corrugated Roof: A Game-Changer in the Roofing IndustryCorrugated roofing has long been a popular choice for residential and commercial buildings due to its durability and cost-effectiveness. However, the process of installing and maintaining corrugated roofs has always been a time-consuming and labor-intensive task. That is, until now.Introducing the new Roller for Corrugated Roof, a revolutionary tool that has the potential to change the way corrugated roofs are installed and maintained. This innovative product, developed by a leading manufacturer in the roofing industry, is set to make waves in the construction and roofing sectors.The Roller for Corrugated Roof is designed to streamline the installation process, making it faster and more efficient than ever before. Its ergonomic and user-friendly design allows for easy handling, reducing the physical strain on workers during the installation process. This not only improves productivity but also enhances worker safety, a critical factor in any construction project.What sets the Roller for Corrugated Roof apart from other tools in the market is its ability to ensure a smooth and even finish on corrugated roofs. Its advanced technology allows for precise and consistent rolling, resulting in a professional-looking finish that adds to the aesthetic appeal of the building.In addition to its installation benefits, the Roller for Corrugated Roof also offers significant advantages in terms of maintenance. By using the roller to apply protective coatings and sealants, maintenance teams can extend the lifespan of corrugated roofs, preventing leaks and other damage that can result from exposure to harsh weather conditions.The company behind the Roller for Corrugated Roof, with a proven track record of delivering high-quality roofing products and tools, has invested considerable resources in research and development to bring this innovative tool to the market. With a commitment to excellence and a dedication to meeting the evolving needs of the construction industry, they have positioned themselves as a leader in the market.The company's mission is not only to provide innovative solutions but also to contribute to the sustainability of the industry. The Roller for Corrugated Roof is an environmentally friendly tool that minimizes waste and reduces the need for additional resources during the installation and maintenance processes. This eco-conscious approach aligns with the company's commitment to responsible and sustainable business practices.In line with its dedication to customer satisfaction, the company offers comprehensive support and training programs for the Roller for Corrugated Roof. This ensures that contractors and maintenance teams are equipped with the knowledge and skills to make the most of this game-changing tool, ultimately delivering superior results for their clients.The release of the Roller for Corrugated Roof has generated significant excitement within the roofing industry, with early adopters praising its performance and efficiency. Contractors and building owners alike are recognizing the potential of this tool to revolutionize the way corrugated roofs are installed and maintained, ultimately saving time and costs while delivering exceptional results.As the demand for innovative and sustainable construction solutions continues to grow, the Roller for Corrugated Roof stands out as a prime example of how cutting-edge technology can drive positive change in the industry. With its combination of efficiency, quality, and sustainability, this tool is set to become a staple in the toolkit of roofing professionals around the world.

High-Quality Metal Roofing Sheet Roll Forming Machines

Roofing Sheet Roll Forming Machine Revolutionizing the Roofing IndustryRoofing is an essential part of any building, providing protection from the elements and adding structural integrity. The process of manufacturing roofing sheets has evolved over the years, and modern technology has played a significant role in revolutionizing the industry. One such technological advancement is the Roofing Sheet Roll Forming Machine, which has made the production of roofing sheets more efficient, cost-effective, and of higher quality.The Roofing Sheet Roll Forming Machine, offered by a leading manufacturing company in the industry, is a cutting-edge piece of equipment that has transformed the way roofing sheets are produced. This machine is designed to take flat metal coils and transform them into finished roofing sheets through a series of rolling, bending, and cutting processes. The result is a highly precise and uniform roofing sheet that meets the highest industry standards.The company behind this innovative machine, has been at the forefront of the roofing industry for over two decades. With a focus on quality, innovation, and customer satisfaction, they have established themselves as a trusted name in the market. Their commitment to excellence is evident in the Roofing Sheet Roll Forming Machine, which has set a new standard for efficiency and reliability in the production of roofing sheets.One of the key advantages of the Roofing Sheet Roll Forming Machine is its ability to produce roofing sheets in a variety of materials, including steel, aluminum, and copper. This versatility allows manufacturers to meet the diverse needs of their customers, whether it's for residential, commercial, or industrial applications. The machine is also highly customizable, with adjustable settings for sheet thickness, length, and profile, ensuring that each roofing sheet meets the specific requirements of the project.In addition to its flexibility, the Roofing Sheet Roll Forming Machine is also incredibly efficient. Its automated process minimizes manual labor, reduces waste, and improves production speed, resulting in cost savings for manufacturers. The machine's precision and repeatability also lead to a higher quality end product, with consistent dimensions and smooth finishes on every roofing sheet.Furthermore, the company's dedication to customer support and service ensures that their clients receive the assistance they need to maximize the potential of the Roofing Sheet Roll Forming Machine. From installation and training to ongoing maintenance and technical support, they are committed to helping their customers achieve success with this revolutionary piece of equipment.As a result of these innovations, the Roofing Sheet Roll Forming Machine has been widely adopted by manufacturers around the world. Its impact on the roofing industry has been significant, driving improvements in productivity, product quality, and overall competitiveness. Whether it's for a small-scale roofing business or a large manufacturing facility, this machine has proven to be a game-changer, propelling the industry into a new era of efficiency and innovation.In conclusion, the Roofing Sheet Roll Forming Machine offered by the company has redefined the production of roofing sheets, setting new standards for quality, efficiency, and versatility. By harnessing the latest in technology and engineering, they have delivered a machine that empowers manufacturers to meet the evolving demands of the market. With their ongoing commitment to excellence and customer satisfaction, they continue to lead the way in the roofing industry, driving forward a new era of progress and innovation.

Glazed Tile Roll Forming Machine for Metal Roofing Sheet Production

If you are in search for a reliable and efficient Glazed Tile Roll Forming Machine, then Dahezb Metal has got you covered. Dahezb Metal specializes in designing and manufacturing high quality auto glazed tile forming machines that produce metal roof tiles of 0.3-0.6mm thickness. They specialize in Aluminum roofing step tile machines, glazed roll forming machines, and glazed tile roll forming machines that are specifically designed for making glazed tiles for roofing sheets.One of the unique features of the Glazed Tile Roll Forming Machine from Dahezb Metal is its ability to effectively remove brand names from the roofing sheet during production. This feature is particularly important for customers who need to produce roofing sheets for their own brand without having to purchase expensive equipment or worry about legal issues.The Glazed Tile Roll Forming Machine is a versatile production machine that can be used to produce a wide range of roofing sheets including Aluminum, Color Steel, and Glazed Steel tiles. It is a durable and high-performance machine that is designed and built with high-quality materials and advanced technology to ensure accuracy, precision, and speed.With a production capacity of up to 15 meters per minute, the Glazed Tile Roll Forming Machine from Dahezb Metal is one of the most efficient and profitable investments for anyone looking to venture into the roofing sheet production business. The machine is easy to operate, maintain, and requires minimal technical skills to effectively run and produce high-quality roofing sheets.The Glazed Tile Roll Forming Machine is designed with safety in mind. It features an emergency stop button and other safety features to ensure that operators are always protected from potential hazards. The machine also comes with a user-friendly interface that allows operators to easily adjust the production settings and monitor the production process.In conclusion, if you are looking for an efficient and reliable Glazed Tile Roll Forming Machine, then Dahezb Metal Glazed Tile Roll Forming Machine is the perfect choice. It is a high-performance machine that is designed to produce high-quality roofing sheets in an efficient, cost-effective, and safe manner. It is a valuable investment that guarantees a high return on investment and long-term profitability. So, if you want to get ahead in the roofing sheet production business, the Glazed Tile Roll Forming Machine from Dahezb Metal is your best bet.

Glazed Tile Roll Forming Machine - Industrial Steel Rolling Machines for Metal Roofing Sheet Production

Title: ZhongTuoCN Revolutionizes Roofing Industry with Advanced Glazed Tile Roll Forming MachineIntroduction:ZhongTuoCN, a renowned leader in the steel rolling machine industry, has unveiled its latest product, the Color Steel Glazed Roof Tile Roll Forming Machine. This advanced machinery has revolutionized the roofing industry by enabling the efficient production of high-quality metal glazed tiles. With its cutting-edge technology and precision engineering, ZhongTuoCN is empowering manufacturers to meet growing demands for durable and aesthetically pleasing roofing solutions.1. Meeting the Rising Demand for Glazed Roofing Tiles:The demand for glazed roofing tiles has been steadily increasing due to their exceptional durability, weather resistance, and stunning visual appeal. Recognizing this trend, ZhongTuoCN's engineers have developed a state-of-the-art roll forming machine specifically designed to cater to this niche segment. Manufacturers can now produce glazed tiles efficiently, ensuring timely delivery and meeting customer expectations.2. Cutting-Edge Technology Enhances Efficiency:The Color Steel Glazed Roof Tile Roll Forming Machine stands out for its advanced features, guaranteeing optimal efficiency. Equipped with state-of-the-art automation technology, this innovative machine minimizes human intervention, reducing labor costs and increasing productivity. With high-speed forming capabilities, it guarantees a smooth and streamlined production process, allowing manufacturers to meet large-scale orders efficiently.3. Unparalleled Precision and Durability:ZhongTuoCN's Glazed Tile Roll Forming Machine is meticulously engineered to deliver unmatched precision and durability. Its robust frame, constructed from high-quality steel, ensures long-term stability and reliability. The rollers are made from top-grade materials, facilitating seamless tile formation without any deformities. This ensures that every finished tile exhibits consistent dimensions and exceptional surface quality.4. Flexibility in Tile Design and Customization:In addition to its standard features, the Color Steel Glazed Roof Tile Roll Forming Machine provides manufacturers with unparalleled flexibility in tile design and customization. By incorporating adjustable features in the machine, manufacturers can easily tailor the dimensions, profile, and curvature of the glazed tiles to meet various customer requirements. This adaptability sets ZhongTuoCN's machinery apart from its competitors and allows clients to offer unique and personalized roofing solutions.5. Strict Quality Control and After-Sales Support:ZhongTuoCN prioritizes quality control throughout the manufacturing process. Each component of the Glazed Tile Roll Forming Machine undergoes stringent testing to ensure optimal performance and durability. Additionally, ZhongTuoCN provides comprehensive after-sales support, including installation guidance, training programs, and 24/7 technical assistance. This commitment to customer satisfaction has earned the company an excellent reputation in the industry.Conclusion:With the introduction of the Color Steel Glazed Roof Tile Roll Forming Machine, ZhongTuoCN has reaffirmed its position as a pioneer in the steel rolling machine industry. This cutting-edge technology guarantees exceptional efficiency, precision, and customization options for manufacturers in the roofing sector. By empowering clients to meet the rising demand for glazed tiles, ZhongTuoCN is revolutionizing the roofing industry and offering an unparalleled solution for businesses worldwide.