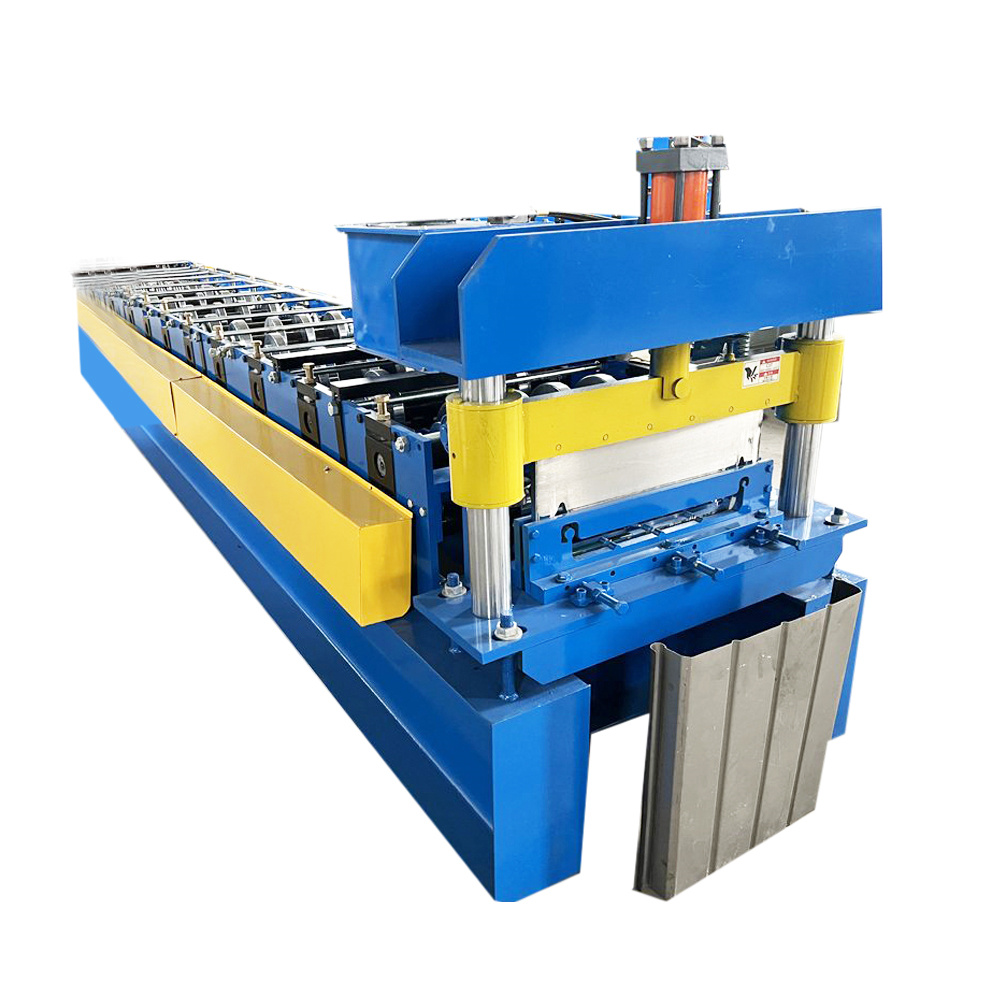

Durable Highway Guardrail Machine for Efficient Road Safety Installation

By:Admin

In a bid to improve road safety and streamline the installation of guardrails on highways, {Company Name} has introduced a cutting-edge Highway Guardrail Machine. This innovative piece of equipment is set to revolutionize the way guardrails are installed, ultimately leading to safer roads for both drivers and pedestrians.

The {Company Name} is a leader in the manufacturing and distribution of industrial equipment designed for infrastructure development and construction projects. With a strong focus on innovation and efficiency, the company has continuously provided solutions that address the challenges faced in the construction industry.

The newly introduced Highway Guardrail Machine is the latest addition to {Company Name}’s lineup of construction equipment. This machine is specifically designed to streamline the process of installing guardrails along highways, ensuring that they are securely and accurately placed to enhance road safety.

The Highway Guardrail Machine is equipped with advanced features that set it apart from traditional methods of guardrail installation. Its automated system enables precise measurement and cutting of guardrails, reducing the margin of error and ensuring that the guardrails are installed with utmost accuracy. This level of precision is vital in ensuring that the guardrails provide optimal protection in the event of a roadside accident.

Additionally, the Highway Guardrail Machine is designed for efficiency, allowing for faster installation of guardrails without compromising on quality. This means that construction projects can be completed in a shorter timeframe, minimizing disruption to traffic and reducing overall project costs.

Furthermore, the machine is equipped with safety features that prioritize the well-being of the workers involved in the installation process. By minimizing the need for manual labor and repetitive tasks, the Highway Guardrail Machine helps to reduce the risk of work-related injuries, creating a safer working environment for construction crews.

The introduction of the Highway Guardrail Machine underscores {Company Name}’s commitment to innovation and its dedication to improving construction practices. By providing a solution that enhances road safety and construction efficiency, the company is contributing to the overall improvement of infrastructure development.

In addition to the Highway Guardrail Machine, {Company Name} offers a range of construction equipment and machinery that cater to various aspects of infrastructure development. From road paving machines to concrete mixers, the company’s products are designed to meet the diverse needs of construction projects, regardless of scale or complexity.

With a strong emphasis on customer satisfaction, {Company Name} also provides comprehensive support and maintenance services for its equipment. This ensures that clients can maximize the performance and longevity of their machinery, ultimately leading to greater efficiency and cost-effectiveness in their construction endeavors.

The introduction of the Highway Guardrail Machine has been met with enthusiasm from construction companies and infrastructure development authorities. Its potential to significantly improve road safety and construction practices has positioned it as a game-changer in the industry.

As road networks continue to expand and evolve, the importance of ensuring the safety and integrity of highways cannot be overstated. With the introduction of innovative equipment like the Highway Guardrail Machine, the construction industry is taking significant steps towards achieving this goal.

In summary, the introduction of the Highway Guardrail Machine by {Company Name} represents a significant advancement in the construction industry. Its potential to enhance road safety, streamline construction practices, and improve overall efficiency underscores the company’s commitment to innovation and excellence. As construction projects continue to play a crucial role in shaping our infrastructure, the adoption of such innovative solutions is essential in ensuring the continued development of safe and reliable road networks.

Company News & Blog

High-quality Roof and Tile Roll Forming Machines for Efficient Roofing Solutions

Roof Tile Roll Forming Machine: Revolutionizing the Roofing IndustryIn today's rapidly evolving construction industry, innovative technology is constantly paving the way for more efficient and effective processes. One such groundbreaking technology is the Roof Tile Roll Forming Machine, a game-changer in the field of roofing. This advanced machinery has revolutionized the way roofs are installed, providing a faster and more cost-effective solution for both residential and commercial projects.Before the advent of the Roof Tile Roll Forming Machine, traditional roofing methods required skilled laborers to manually cut, shape, and assemble individual tiles. This process was not only time-consuming but also prone to errors, resulting in unnecessary wastage of materials and increased costs. However, with the introduction of the Roof Tile Roll Forming Machine, all these drawbacks have become a thing of the past.The Roof Tile Roll Forming Machine utilizes state-of-the-art technology that allows for the precise and automated production of roof tiles. The machine consists of a series of rollers and tooling stations that gradually shape the metal coils into perfectly formed tiles. This process eliminates the need for manual cutting and shaping, significantly reducing labor costs and improving overall efficiency.One of the key advantages of the Roof Tile Roll Forming Machine is its versatility. The machine can produce a wide range of tile profiles, catering to the diverse needs and preferences of customers. From classic clay tiles to modern metal alternatives, the Roof Tile Roll Forming Machine can effortlessly produce high-quality tiles in various shapes, sizes, and textures. This flexibility not only enhances design possibilities but also ensures that customers can find the perfect fit for their specific roofing requirements.Additionally, the Roof Tile Roll Forming Machine offers excellent precision and consistency in tile production. The automated process guarantees consistent tile dimensions, ensuring a seamless end result. The machine's robust build and advanced control systems allow for high-speed production without compromising on quality. This not only enhances the overall efficiency of the roofing process but also leads to long-lasting and aesthetically pleasing roofs.Furthermore, the Roof Tile Roll Forming Machine prioritizes safety and user-friendliness. With built-in safety features and easy-to-use controls, the machine minimizes the risk of accidents and errors, making it suitable for operators of all skill levels. This accessibility ensures that both experienced roofers and new entrants into the industry can quickly adapt to this transformative technology.The advantages offered by the Roof Tile Roll Forming Machine are not limited to its performance alone. This innovative machinery also contributes to environmental sustainability. By optimizing material usage and minimizing waste, the machine significantly reduces the carbon footprint associated with traditional roofing methods. Moreover, the longevity of the tiles produced by the machine ensures reduced maintenance and replacement requirements, leading to long-term sustainability benefits.As the demand for efficient and cost-effective roofing solutions continues to grow, the Roof Tile Roll Forming Machine has emerged as a standout solution. Its ability to streamline the roofing process, enhance design possibilities, and prioritize safety makes it an indispensable tool for roofing contractors and manufacturers.In conclusion, the Roof Tile Roll Forming Machine has revolutionized the roofing industry by providing an efficient and precise solution for producing high-quality roof tiles. Its versatility, precision, user-friendliness, and sustainability make it an indispensable tool for modern construction. As this technology continues to grow and evolve, it is undoubtedly set to become an industry standard, shaping the future of roofing worldwide.

High Precision CNC Machine for Aluminum Extrusions

The demand for precision-engineered aluminum extrusions has been on the rise in various industries such as construction, automotive, and aerospace. In response to this increasing demand, a leading manufacturing company has recently invested in state-of-the-art CNC machinery to enhance their capabilities in producing high-quality aluminum extrusions.With a legacy of over 50 years in the industry, {} has built a strong reputation for delivering innovative and customized solutions to their clients. Specializing in aluminum extrusion, the company has been at the forefront of technological advancements and has consistently invested in cutting-edge equipment to meet the evolving needs of their customers.The latest addition to their manufacturing arsenal is the advanced CNC machine specially designed for aluminum extrusions. This new equipment is equipped with high precision cutting and milling capabilities, allowing {} to achieve tight tolerances and intricate designs with utmost accuracy. The CNC machine also offers greater flexibility in producing complex shapes and profiles, enabling the company to cater to a wide range of applications across different industries.One of the key advantages of the new CNC machine is its efficiency in handling large-scale production while maintaining superior quality. This increased production capacity will enable {} to meet the growing demand for aluminum extrusions within shorter lead times, giving them a competitive edge in the market. Moreover, the CNC machine is integrated with advanced software that enables seamless programming and automation, thereby streamlining the manufacturing process and reducing the time required for setup and tool changes.In addition to enhancing their production capabilities, the investment in the CNC machine reflects {}'s commitment to upholding the highest standards of quality and precision. The company adheres to stringent quality control measures at every stage of the manufacturing process, ensuring that the aluminum extrusions meet the exact specifications and performance requirements of their customers. The new CNC machine further reinforces this commitment by enabling precise and consistent machining of extruded aluminum profiles, resulting in products that exhibit exceptional dimensional accuracy and surface finish.Furthermore, the implementation of the CNC machine underscores {}'s dedication to innovation and continuous improvement. By leveraging the latest technology, the company aims to push the boundaries of what is achievable in aluminum extrusion manufacturing. This proactive approach not only showcases their willingness to invest in the future of their business but also positions them as a reliable and forward-thinking partner for their clients.The investment in the CNC machine is also aligned with {}'s sustainability initiatives. Aluminum is widely recognized for its recyclability and environmental benefits, and {} is committed to minimizing their environmental footprint by optimizing material usage and reducing waste in their manufacturing processes. The precision and efficiency offered by the new CNC machine will contribute to the sustainable production of aluminum extrusions, further reinforcing {}'s position as an eco-conscious industry leader.In conclusion, the introduction of the CNC machine for aluminum extrusions marks a significant milestone for {}. This strategic investment not only enhances their manufacturing capabilities but also underscores their dedication to delivering top-quality, precision-engineered solutions to their clients. By embracing the latest technology and upholding their commitment to excellence, {} is poised to meet the evolving needs of the industry and continue setting new benchmarks in the field of aluminum extrusion manufacturing.

Efficient Horizontal Barrel Vault Panel Cutting Machine for Improved Productivity

Horizontal Barrel Vault Panel Cutting Machine Revolutionizes the IndustryThe manufacturing industry is constantly evolving and adapting to new technologies. In recent years, the demand for precision and efficiency in panel cutting has grown significantly, prompting companies to invest in advanced machinery to meet these requirements. One such innovative solution is the Horizontal Barrel Vault Panel Cutting Machine, a cutting-edge tool that is revolutionizing the industry.This groundbreaking machine, produced by a leading global manufacturing company, is designed to meet the specific needs of panel cutting for a wide range of industries, including construction, automotive, aerospace, and more. With its advanced technology and versatile capabilities, the Horizontal Barrel Vault Panel Cutting Machine has quickly become the go-to solution for businesses looking to enhance their cutting operations.One of the key features of the Horizontal Barrel Vault Panel Cutting Machine is its precision cutting capabilities. The machine is equipped with state-of-the-art technology that allows for extremely accurate and consistent cuts, ensuring high-quality results every time. This level of precision is crucial for industries that require intricate and complex panel designs, such as the aerospace and automotive sectors.In addition to its precision cutting abilities, the Horizontal Barrel Vault Panel Cutting Machine also offers exceptional speed and efficiency. Its advanced automation and cutting processes enable rapid production without compromising on quality. This not only saves businesses valuable time and resources but also allows for increased output and productivity.Furthermore, the versatility of the Horizontal Barrel Vault Panel Cutting Machine makes it an invaluable asset for a wide range of applications. Whether it's cutting materials such as metal, plastic, or composite panels, this machine can easily accommodate various materials and thicknesses, making it a versatile and adaptable solution for different manufacturing needs.The company behind this cutting-edge technology has a long-standing reputation for delivering high-quality manufacturing machinery. With a strong focus on innovation and continuous improvement, the company is committed to providing reliable and efficient solutions that meet the evolving needs of the industry.The Horizontal Barrel Vault Panel Cutting Machine is just one example of the company's dedication to developing cutting-edge technology that pushes the boundaries of what is possible in manufacturing. By combining advanced engineering with practical solutions, the company has established itself as a leader in the industry, with a track record of delivering innovative and reliable products.In addition to its cutting-edge machinery, the company also offers comprehensive support and services to ensure that its customers can maximize the potential of their equipment. From installation and training to maintenance and technical support, the company is dedicated to providing ongoing value to its customers, helping them achieve their production goals and maintain a competitive edge in the market.The impact of the Horizontal Barrel Vault Panel Cutting Machine on the manufacturing industry cannot be understated. Its precision, speed, and versatility have set a new standard for panel cutting, raising the bar for efficiency and quality in manufacturing operations. As businesses continue to embrace advanced technology and automation, the demand for innovative solutions like this machine is only expected to grow.In conclusion, the Horizontal Barrel Vault Panel Cutting Machine represents a significant advancement in the manufacturing industry, offering game-changing capabilities that are redefining the way panels are cut. With its precision, speed, and versatility, this cutting-edge machine is empowering businesses to elevate their manufacturing processes and achieve new levels of efficiency and quality. As the industry continues to evolve, the impact of this revolutionary technology is sure to be felt for years to come.

Roll Forming Machines for Metal Roof and Drywall Studs and Track

If you are involved in the construction industry, you probably know how important it is to have the right equipment to get the job done quickly and efficiently. One of the most essential pieces of equipment that you need is a metal stud making machine.There are many different types of metal stud making machines on the market, but the most popular ones are those that are designed to produce high-quality metal studs and tracks used in drywall installation and house making. These machines are known for their precision, accuracy, and speed, making them the perfect tools for any construction project.One of the best things about metal stud making machines is that they are incredibly versatile. They can be used to produce a wide range of metal studs and tracks, including those made from steel, aluminum, and other metals. This means that you can use them for a variety of different projects, from small-scale jobs like installing a new drywall partition to large commercial construction projects.Metal stud making machines come in a range of sizes and configurations to meet the needs of different construction businesses. Some machines are designed to be portable, while others are more stationary. Some machines are designed to produce only metal studs, while others can produce both studs and tracks.To ensure that you are getting the best metal stud making machine for your needs, it is important to do your research and compare different models and brands. Look for a machine that is easy to use, has a high level of automation, and can produce high-quality metal studs quickly and efficiently.One popular brand of metal stud making machines is Alibaba. Their drywall stud roll forming machine is designed to produce high-quality studs and tracks for drywall installation and house framing. This machine is easy to operate and can produce metal studs and tracks in a range of different sizes and configurations.Another popular brand of metal stud making machine is Jobsite Roll Forming Equipment. Their machines are designed to produce metal studs and tracks for a range of different applications, including both residential and commercial construction projects. These machines are known for their precision and speed, making them the perfect choice for any construction business.In conclusion, if you are in the construction industry and looking to invest in a metal stud making machine, there are plenty of options to choose from. Whether you are looking for a portable machine or a more stationary model, there is sure to be a machine that fits your needs. Just be sure to do your research and compare different brands and models to find the best machine for your construction business.

Roll Forming Machines for Drywall and House Making: Metal Studs, Tracks and Dumplings

and Roll Forming Equipment.Metal Roof Roll Machine For Drywall – Top Quality House Making MachineIf you are looking for a top-quality house making machine, look no further than the metal roof roll machine for drywall. This versatile machine is capable of producing all the components needed for constructing a sturdy, reliable house, including metal studs, tracks, roofing, and more.One of the primary advantages of the metal roof roll machine for drywall is its ability to generate metal studs and tracks using a specialized technique known as roll forming. In this technique, sheets of metal are fed through a series of rollers that gradually bend the metal into the desired shape. This produces a durable, strong, and uniform product that is perfectly suited for use in residential and commercial construction.The metal stud and track roll forming machine from Alibaba is an excellent example of this type of equipment. It is capable of producing high-quality metal studs and tracks in a variety of sizes and configurations, making it suitable for a wide range of construction applications. Whether you are building a small residential property or a large commercial complex, this machine can help you create the perfect metal framing to get the job done.Other Benefits of Steel FramingIn addition to being strong, durable, and reliable, steel framing also offers a number of other advantages for construction projects. For example, steel is much lighter than traditional building materials like bricks and concrete, which can help reduce the overall weight of a building and make it easier to erect. It is also non-combustible, which can help reduce the risk of fires in buildings.Steel framing is also extremely flexible, allowing contractors to create customized designs and incorporate a wide range of materials and finishes into their projects. And because it is produced using sophisticated manufacturing processes like roll forming, it is possible to create extremely precise, uniform components that are easy to install and require very little maintenance.Finding the Right Metal Stud Making MachineIf you are interested in using roll forming equipment to produce metal studs and tracks for your construction projects, it is important to choose the right machine for your needs. Look for equipment that offers a high level of precision and flexibility, and that is capable of producing a wide range of different shapes and sizes.Also, be sure to choose a machine that is backed by a reputable manufacturer with a track record of producing high-quality equipment. This will ensure that you receive reliable, long-lasting equipment that meets your needs and exceeds your expectations.ConclusionOverall, the metal roof roll machine for drywall is a top-quality house making machine that is capable of producing a wide range of components for any construction project. Whether you are constructing a single-family home or a large commercial complex, this equipment is the perfect tool for ensuring that your building is strong, durable, and reliable. So if you are in the market for a metal stud making machine or roll forming equipment, look no further than the metal roof roll machine for drywall – the best choice for your construction needs!

Efficient Slitting And Cutting Machine Simplifies Industrial Operations

Title: Innovative Slitting and Cutting Machine Revolutionizes Industrial ProcessesIntroduction:In today's manufacturing landscape, technological advancements continue to shape industries and transform production processes. Companies are constantly seeking innovative solutions to enhance efficiency and improve overall productivity. The Slitting and Cutting Machine, developed by an industry-leading company, has emerged as a groundbreaking solution that revolutionizes cutting-edge industrial processes. This groundbreaking machine addresses the challenges of precision, speed, and versatility, positioning the manufacturing industry on a path to unprecedented growth and success.Precision and Accuracy:The Slitting and Cutting Machine is designed with precision and accuracy as its primary goals. Incorporating cutting-edge technology and state-of-the-art components, it has the ability to achieve highly precise cuts on various materials, including metal sheets, plastic films, and textiles. Equipped with advanced sensors and intelligent software, this machine ensures that each cut made is consistent and error-free, eliminating the inconsistencies that conventional machines often encounter. This level of precision minimizes material waste and enhances production quality, ultimately boosting enterprises' bottom line.Speed and Efficiency:One of the key advantages of the Slitting and Cutting Machine is its ability to operate at high speeds, significantly increasing production efficiency. With an integrated servo motor system and advanced control algorithms, this machine can rapidly process large quantities of material within a short timeframe. By minimizing downtime and maximizing output, it empowers businesses to stay ahead in an increasingly competitive market. Furthermore, its user-friendly interface and customizable settings allow operators to easily adjust cutting parameters and optimize performance, ensuring seamless integration into existing production workflows.Versatility and Adaptability:The Slitting and Cutting Machine offers remarkable flexibility and adaptability across a wide range of industrial applications. It can efficiently handle materials of varying thicknesses and dimensions, accommodating diverse production requirements. Furthermore, its modular design enables quick tool changeovers, allowing for a seamless transition between different materials and cutting patterns. As a result, the machine empowers enterprises to diversify their product offerings, explore new markets, and meet the ever-changing demands of customers, enhancing their overall competitiveness and growth potential.Safety and Reliability:The Slitting and Cutting Machine prioritizes safety and reliability, boasting numerous built-in features to ensure a secure operational environment. It is equipped with comprehensive safety measures, including emergency stop buttons, intelligent sensors, and protective barriers to prevent accidents and injuries. Additionally, the machine's robust construction and high-quality components guarantee long-term reliability and durability, reducing maintenance costs and enhancing overall operational efficiency.Conclusion:The Slitting and Cutting Machine, developed by an industry-leading company, represents a significant milestone in the realm of manufacturing. Its precision, speed, versatility, safety features, and reliability make it the go-to solution for businesses seeking to optimize their production processes and gain a competitive edge. With this innovative machine at their disposal, enterprises can streamline operations, reduce waste, enhance overall product quality, and explore new opportunities for growth. The Slitting and Cutting Machine paves the way for a more efficient and prosperous industrial landscape, while solidifying the position of its manufacturer as a pioneer in cutting-edge technology.

The Ultimate Guide to Coil Slitting Process in Manufacturing

Today, we are excited to share with you the innovative coil slitting process that our company has developed to meet the growing demands of our customers. As a leading manufacturer in the metal industry, we are constantly striving to improve our processes and provide the best quality products to our clients. Our dedication to innovation and customer satisfaction has led us to develop a state-of-the-art coil slitting process that sets us apart from our competitors.The coil slitting process is a crucial step in the production of metal sheets and coils. It involves cutting large coils of metal into smaller, more manageable coils that are ready for further processing or shipping. The precision and efficiency of this process are vital to ensuring the quality and integrity of the final product. With our new and improved coil slitting process, we are able to deliver products of the highest quality while maintaining a high level of productivity.Our coil slitting process begins with the arrival of large coils of metal at our facility. These coils are thoroughly inspected for any defects or imperfections before being loaded onto our state-of-the-art slitting line. Our advanced machinery and equipment ensure that the coils are slit with precision and accuracy, resulting in uniform and consistent product quality. Additionally, our process is highly efficient, allowing us to meet the demanding production schedules of our clients without compromising on quality.One of the key features of our coil slitting process is the use of advanced technology to monitor and control the slitting parameters in real time. This ensures that each coil is slit to the exact specifications required by our customers. Our highly skilled technicians are trained to operate and maintain the equipment, and they are dedicated to upholding the highest standards of quality and safety throughout the process.In addition to the technical aspects of our coil slitting process, we also place a strong emphasis on environmental sustainability. We have implemented measures to minimize waste and reduce energy consumption in our production process. This commitment to sustainability not only benefits the environment but also allows us to offer our customers products that are produced in a responsible and ethical manner.Our dedication to innovation and continuous improvement has positioned us as a leader in the metal industry. With our advanced coil slitting process, we are able to offer our customers a level of quality and precision that is unmatched by our competitors. We are proud to be able to meet the diverse needs of our clients and provide them with products that meet the highest standards of excellence.As we look to the future, we are committed to further advancing our coil slitting process and other manufacturing technologies. We will continue to invest in research and development to stay ahead of industry trends and deliver innovative solutions to our customers. With our unwavering commitment to quality, efficiency, and sustainability, we are confident that we will remain a trusted partner for all metal processing needs.In conclusion, our company's new coil slitting process represents a significant advancement in the metal industry. With our state-of-the-art technology, unwavering commitment to quality, and dedication to sustainability, we are setting new standards for excellence in metal processing. We are excited to continue serving our customers with the best products and solutions, and we look forward to the opportunities that lie ahead as we continue to innovate and grow.

High-Speed Steel Tile Forming Machine: A Game-Changer in Roofing Industry

Title: Revolutionary Steel Tile Forming Machine Transforms Construction IndustryIntroduction:In a significant breakthrough for the construction industry, a leading company has unveiled its groundbreaking Steel Tile Forming Machine. Designed to revolutionize the way steel tiles are manufactured, this advanced machinery promises to enhance efficiency, quality, and sustainability in the construction sector. By automating the tile forming process, this innovative solution aims to simplify production, reduce costs, and ensure durable and aesthetically pleasing steel tile roofs.Innovative Features:The Steel Tile Forming Machine boasts a range of innovative features that set it apart from traditional manufacturing methods. Equipped with cutting-edge technology, this machinery can efficiently shape and mold steel into precise and intricate tile profiles. Additionally, it offers flexibility in terms of tile dimensions, enabling manufacturers to produce custom designs to meet specific architectural styles and project requirements.The incorporation of a highly intelligent control system ensures seamless operation and precise measurements. The machine's user-friendly interface allows operators to modify settings, monitor production progress, and address any potential issues, thereby increasing productivity and reducing human error. Moreover, the machine's advanced sensors and safety features guarantee safe and reliable operation, prioritizing worker welfare while minimizing production interruptions.Enhanced Efficiency and Cost Savings:The Steel Tile Forming Machine's ability to automate the tile forming process has significant implications for efficiency and cost savings within the construction industry. By eliminating labor-intensive manual labor, the machine accelerates production, resulting in quicker turnaround times for projects. This increased efficiency translates into reduced costs and improved competitiveness for manufacturers and construction firms.Furthermore, the use of this machine enables manufacturers to optimize raw material usage, minimizing waste and enhancing resource efficiency. This sustainable manufacturing approach not only supports eco-conscious initiatives but also contributes to cost savings by reducing material expenses. Additionally, the reduced labor requirements allow manufacturers to allocate their workforce to more critical tasks, such as quality control and innovation.Superior Quality and Aesthetics:Traditional manufacturing methods often produce steel tiles with slight variations in dimensions and quality. However, the Steel Tile Forming Machine ensures consistent output, resulting in superior-quality tiles that meet stringent industry standards. The precise molding and shaping capabilities of the machine, combined with its intelligent control system, eliminate variations and imperfections, guaranteeing a flawless end product.Moreover, the ability to produce custom designs offers architects and homeowners an extensive range of options, facilitating the creation of aesthetically pleasing and architecturally harmonious steel tile roofs. The machine's capacity to replicate intricate designs with immaculate precision allows for stunning and eye-catching roof finishes, enhancing the overall appeal of residential and commercial buildings.Future Outlook:The introduction of the Steel Tile Forming Machine is set to disrupt the construction industry, transforming the way steel tile roofs are manufactured. With its impressive blend of advanced technology, enhanced efficiency, cost savings, and superior quality, this machine showcases the potential for innovation in the sector. As manufacturers embrace this groundbreaking solution, it is anticipated that more sustainable and visually striking steel tile roofs will become readily available, shaping the future of construction aesthetics.Conclusion:The Steel Tile Forming Machine represents a paradigm shift in steel tile manufacturing. By combining cutting-edge technology, enhanced efficiency, cost savings, and superior quality, this machinery paves the way for innovative and sustainable construction practices. As the industry embraces this game-changing solution, it is clear that construction aesthetics, durability, and production processes will be forever transformed.

Glazed Tile Roll Forming Machine for Metal Roofing Sheet Production

If you are in search for a reliable and efficient Glazed Tile Roll Forming Machine, then Dahezb Metal has got you covered. Dahezb Metal specializes in designing and manufacturing high quality auto glazed tile forming machines that produce metal roof tiles of 0.3-0.6mm thickness. They specialize in Aluminum roofing step tile machines, glazed roll forming machines, and glazed tile roll forming machines that are specifically designed for making glazed tiles for roofing sheets.One of the unique features of the Glazed Tile Roll Forming Machine from Dahezb Metal is its ability to effectively remove brand names from the roofing sheet during production. This feature is particularly important for customers who need to produce roofing sheets for their own brand without having to purchase expensive equipment or worry about legal issues.The Glazed Tile Roll Forming Machine is a versatile production machine that can be used to produce a wide range of roofing sheets including Aluminum, Color Steel, and Glazed Steel tiles. It is a durable and high-performance machine that is designed and built with high-quality materials and advanced technology to ensure accuracy, precision, and speed.With a production capacity of up to 15 meters per minute, the Glazed Tile Roll Forming Machine from Dahezb Metal is one of the most efficient and profitable investments for anyone looking to venture into the roofing sheet production business. The machine is easy to operate, maintain, and requires minimal technical skills to effectively run and produce high-quality roofing sheets.The Glazed Tile Roll Forming Machine is designed with safety in mind. It features an emergency stop button and other safety features to ensure that operators are always protected from potential hazards. The machine also comes with a user-friendly interface that allows operators to easily adjust the production settings and monitor the production process.In conclusion, if you are looking for an efficient and reliable Glazed Tile Roll Forming Machine, then Dahezb Metal Glazed Tile Roll Forming Machine is the perfect choice. It is a high-performance machine that is designed to produce high-quality roofing sheets in an efficient, cost-effective, and safe manner. It is a valuable investment that guarantees a high return on investment and long-term profitability. So, if you want to get ahead in the roofing sheet production business, the Glazed Tile Roll Forming Machine from Dahezb Metal is your best bet.