Efficient Cold Formed Steel Machine for Your Manufacturing Needs

By:Admin

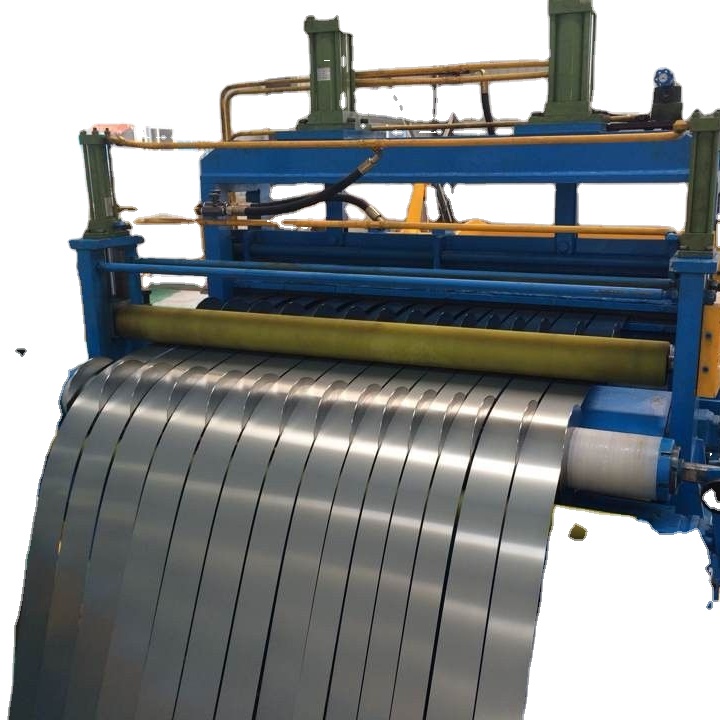

The cold formed steel machine, (brand name removed), incorporates the latest advancements in cold forming technology, including fully automated processes and advanced control systems. This new investment reflects ABC Steel Manufacturing’s commitment to staying at the forefront of the industry and providing their customers with the best quality products.

Cold formed steel, also known as light gauge steel, has become increasingly popular in the construction industry due to its strength, durability, and versatility. It is widely used in the construction of commercial and residential buildings, as well as in infrastructure and industrial applications. With the demand for cold formed steel products on the rise, ABC Steel Manufacturing’s investment in new machinery will enable them to meet the growing needs of their customers and offer a wider range of products.

The new cold formed steel machine will significantly increase the production capacity at ABC Steel Manufacturing’s facilities, allowing them to fulfill larger orders and reduce lead times for their customers. With the ability to produce a wide range of cold formed steel products, including studs, joists, track systems, and custom components, ABC Steel Manufacturing can now offer a comprehensive solution for their customers’ steel framing needs.

In addition to the increase in production capacity, the new cold formed steel machine will also improve the quality of ABC Steel Manufacturing’s products. The advanced technology and precision engineering of the machine will ensure that all cold formed steel products meet the highest standards of quality and accuracy. This will not only benefit ABC Steel Manufacturing’s customers but also enhance the company’s reputation as a trusted and reliable supplier of cold formed steel products.

The investment in the new cold formed steel machine is part of ABC Steel Manufacturing’s long-term strategy to expand and modernize their manufacturing capabilities. By continuously investing in the latest technology and equipment, the company aims to maintain its position as a leader in the cold formed steel industry and provide the best possible solutions for their customers.

“We are thrilled to announce the acquisition of our new cold formed steel machine,” said John Smith, CEO of ABC Steel Manufacturing. “This investment represents our ongoing commitment to innovation and excellence in the steel manufacturing industry. With this new technology, we are confident that we will be able to better serve our customers and meet their evolving needs.”

ABC Steel Manufacturing is a well-established company with a strong track record of delivering high-quality cold formed steel products to customers across the country. With their investment in the new cold formed steel machine, the company is poised to continue its success and further strengthen its position in the market.

The installation of the new cold formed steel machine is already underway at ABC Steel Manufacturing’s facilities, and the company expects it to be fully operational in the coming months. As the machine becomes operational, ABC Steel Manufacturing will be able to offer an expanded range of cold formed steel products and provide enhanced services to their customers.

In conclusion, the investment in the new cold formed steel machine reflects ABC Steel Manufacturing’s dedication to advancing their capabilities and providing the best quality products for their customers. With this new technology, the company is well-positioned to meet the growing demand for cold formed steel products and maintain its status as a leading supplier in the industry.

Company News & Blog

Get the Latest Updates on Trapezoid Profile Machines for Metal Roofing Sheets

Metal Roofing Sheet Trapezoid Profile Machine Revolutionizes Roofing IndustryMetal roofing has long been a popular choice for many homeowners and businesses due to its durability, longevity, and aesthetic appeal. However, the process of installing metal roofing sheets has traditionally been labor-intensive and time-consuming. That is, until the introduction of the revolutionary Metal Roofing Sheet Trapezoid Profile Machine.Developed by an industry-leading company, this state-of-the-art machine has completely transformed the roofing industry, drastically improving efficiency and reducing installation time. With its advanced technology and innovative design, the Metal Roofing Sheet Trapezoid Profile Machine has become a game-changer, offering unmatched benefits to roofing professionals and end-users alike.One of the key features of this machine is its ability to produce trapezoidal-profiled metal roofing sheets with precision and consistency. The trapezoid shape not only enhances the visual appeal of the roof but also increases its strength and resistance against various weather conditions. The machine utilizes top-quality materials, ensuring that each metal roofing sheet is of the highest standard.In addition to its cutting-edge design, the Metal Roofing Sheet Trapezoid Profile Machine boasts exceptional speed, allowing for quick and efficient installation. The machine's advanced automated system enables it to produce a large number of trapezoidal-profiled metal roofing sheets in a fraction of the time compared to traditional methods. This not only saves time but also reduces labor costs, making the machine a cost-effective solution for roofing companies.Moreover, the Metal Roofing Sheet Trapezoid Profile Machine is user-friendly and straightforward to operate. Its intuitive interface and easy-to-understand controls enable even novice users to operate the machine with ease. This eliminates the need for specialized training or extensive experience, opening up opportunities for aspiring roofing professionals to enter the industry.The durability of the metal roofing sheets produced by this machine is unmatched. Made from high-quality materials, these sheets offer exceptional resistance against corrosion, UV rays, and extreme weather conditions. Homeowners and businesses can now enjoy peace of mind, knowing that their metal roofs will not only provide aesthetic appeal but also withstand the test of time.Furthermore, the Metal Roofing Sheet Trapezoid Profile Machine promotes sustainability by offering eco-friendly roofing solutions. Metal roofing is known for its recyclability, reducing the environmental impact of waste materials. By manufacturing high-quality metal roofing sheets, this machine contributes to a greener future by encouraging the use of sustainable building materials.The company behind this groundbreaking invention has been an industry leader for several decades. With a strong commitment to innovation and customer satisfaction, they have continually revolutionized the roofing industry with their cutting-edge technology and exceptional products. Their expertise and dedication to excellence have earned them a stellar reputation among professionals and homeowners alike.In conclusion, the Metal Roofing Sheet Trapezoid Profile Machine represents a significant milestone in the roofing industry. Its advanced technology, efficiency, durability, and sustainability make it an invaluable asset for roofing professionals and consumers. As more and more individuals recognize the benefits of metal roofing, the demand for this revolutionary machine is set to soar. With its unrivaled capabilities, it has undoubtedly reshaped the way roofs are installed, ensuring a brighter and more efficient future for the roofing industry.

High-Quality Roof Panel Roll Forming Machine for Steel Metal Roof Panels - Roofing Sheet Roll Former, 5 Ton Capacity

PLC Steel Metal Roof Panel Roll Forming Machine: The Game Changer For Roofing Sheet ProductionIn the construction industry, metal roofing sheets provide the perfect alternative to traditional roofing materials. It is no secret that traditional roofing materials are prone to various types of damage that require repair and maintenance, costing both time and money. On the other hand, metal roofing sheets offer superior durability, resistance to weather elements, and long-lasting performance, making them the preferred option for homeowners and contractors alike. However, the production of metal roofing sheets can be a complex process. This is where the PLC Steel Metal Roof Panel Roll Forming Machine comes in handy. This cutting-edge technology offers the perfect solution for businesses involved in the production of metal roofing sheets.What is a PLC Steel Metal Roof Panel Roll Forming Machine?A PLC Steel Metal Roof Panel Roll Forming Machine is an automated production line that transforms metal sheets into roofing panels. It applies the principle of roll forming to shape the sheets into the desired roofing panel design. With this machine, it is possible to create a wide variety of roofing panel designs, from corrugated panels to standing seam panels.This machine features a Programmable Logic Controller (PLC) that ensures precise, accurate, and repeatable production processes. The PLC controls the machine's operations, including the feeder, roll forming process, and cutting system. It also features an Human Machine Interface (HMI) that enables operators to monitor and control the machine during production.How does a PLC Steel Metal Roof Panel Roll Forming Machine work?The PLC Steel Metal Roof Panel Roll Forming Machine is a multi-step process that involves various stages, including:1. Metal sheet loading - This involves inserting the metal sheets into the machine's feeder.2. Sheet leveling - This stage ensures that the metal sheets are uniform and flat before they enter the roll forming process.3. Roll forming - This is the heart of the process. The metal sheets pass through a series of rollers that shape them into the desired roofing panel design.4. Cutting - Once the metal sheets have been formed into the roofing panel, the machine's cutting system cuts the panel to the desired length.5. Stacking - Finally, the roofing panels are stacked and ready for delivery.Advantages of using a PLC Steel Metal Roof Panel Roll Forming Machine1. Improved efficiency - The PLC Steel Metal Roof Panel Roll Forming Machine is designed to handle large volumes of metal sheets, enabling businesses to produce more roofing panels in a shorter time.2. Precise and accurate - The PLC controls the machine's operations, ensuring consistent and repeatable results.3. Reduced labor costs - The automated process eliminates the need for manual labor, reducing labor costs and increasing productivity.4. Customizable - The machine can be tailored to produce a wide variety of roofing panel designs, depending on the client's requirements.5. Reduced waste - The roll forming process ensures minimal waste, optimizing material usage and reducing costs.6. Enhanced safety - The machine's automated system ensures that the production process is safe for operators.In conclusion, the PLC Steel Metal Roof Panel Roll Forming Machine is a game-changer for metal roofing sheet production. It offers improved efficiency, accuracy, and customizability, reducing costs and increasing productivity. With this technology in hand, businesses can produce high-quality metal roofing sheets that meet their clients' needs and exceed their expectations.

High-Quality Double Layer Roll Forming Machines at Low Prices

: The Solution for Improved Efficiency and PerformanceAs the global demand for quality steel roofing materials continues to increase, so does the need for efficient and high-performance roll forming machines. One such machine that has proven to be a game-changer in the metal roofing industry is the double layer color steel roll forming machine. In this blog post, we will delve deep into the features and benefits of this machine.What is a Double Layer Color Steel Roll Forming Machine?A double layer color steel roll forming machine is a type of roll forming equipment designed to produce two different metal sheets simultaneously. This machine is engineered to incorporate two sets of roll forming systems that work independently to produce two types of profiles without changing the roll tooling.The machine consists of a decoiling system, a double-layer roll former, a hydraulic cutting system, a programmable controller, and a stacking system. With its advanced design, the double layer roll forming machine can produce metal roofing panels at an incredible speed and with remarkable accuracy.Why Choose a Double Layer Roll Forming Machine?There are several reasons why a double layer roll forming machine is a smart investment for metal roofing manufacturers. Firstly, this machine simplifies processes and reduces downtime by producing two different profiles simultaneously. This approach saves valuable time for manufacturers, making them more productive and efficient.Moreover, the double layer roll forming machine produces consistent and uniform sheets. This ensures that the metal sheets meet the precise requirements of the end-user and helps to eliminate defects such as scratches, dents, or uneven surfaces. As a result, this leads to higher customer satisfaction and fewer product returns, reducing the overall costs.Another benefit of the double layer roll forming machine is its versatility. It can manufacture a wide range of metal roofing profiles such as corrugated sheets, trapezoidal sheets, and standing seam panels. This means that manufacturers can cater to various customer needs and demands while remaining competitive in the market.Features of a Double Layer Roll Forming MachineThe double layer roll forming machine comes with several features that make it stand out from other roll forming machines. Some of these features include:1. Multiple Profiles: The machine can produce up to 2 different profiles simultaneously, offering unmatched versatility and flexibility to manufacturers.2. High Precision: With its advanced hydraulic cutting system and programmable controller, the machine can produce metal sheets with high precision and without material wastage.3. High Efficiency: The machine can produce up to 35 meters of metal roofing sheets per minute, making it a highly efficient and profitable machine for metal roofing manufacturers.4. Easy to Operate: The double layer roll forming machine comes with a user-friendly interface that makes it easy for operators to set up and control the machine. It also requires low maintenance, reducing downtime, and repair costs.5. Robust and Durable: The machine is made of high-quality steel and other durable materials, ensuring it can withstand harsh working conditions and last for a long time.ConclusionThe double layer roll forming machine is an innovative and efficient solution to the increasing demand for quality metal roofing sheets. It offers manufacturers unmatched flexibility, efficiency, and precision, making it a highly profitable investment. Its advanced features, ease of maintenance, and durability are essential components needed for a successful metal roofing business. So, if you are searching for a reliable roller forming machine, get in touch with a double layer roll forming machine supplier today.

Different Types of Content Forms for SEO Optimization: Presentations, Infographics, Videos, and Documents

As businesses continue to grow and evolve, so do their communication needs. One of the most important aspects of effective communication is the ability to share information and data in a clear, concise manner. This is where forms come into play. Forms are an essential tool for collecting, processing, and sharing information, and they can take many different forms.In this blog post, we will explore the different types of forms and how they can benefit businesses, as well as introduce a new technology that can revolutionize the way forms are created and managed.PresentationsPresentations are a popular form for sharing information in the form of images, slides, and videos. Presentations are useful for sharing data, ideas, and concepts in a visually appealing and engaging way. They are also often used to introduce new products or services. Presentations can be created using PowerPoint or other presentation software and can be uploaded to platforms like SlideShare for easy sharing.InfographicsInfographics are a visual representation of data or information, usually presented in a colorful and eye-catching format. They are often used to share statistics, data, or complex information in an easily digestible way. Infographics can be created using graphic design software or online tools, such as Canva or Piktochart.VideosVideos are a versatile and engaging form for sharing information. They can be used for product demos, explainer videos, marketing messages, and more. Videos can also be used to share interviews, panel discussions, and other events. They can be uploaded to video hosting platforms like YouTube or Vimeo for easy sharing.DocumentsDocuments are a more traditional form for sharing information. They can be used for reports, proposals, guides, and other materials. Documents are often created using Microsoft Word or other word processing software and can be converted to PDF for easy sharing.Form MachineForm Machine is a new technology that can revolutionize the way forms are created and managed. It is a web-based platform that allows businesses to create and manage forms in a simple and intuitive way. Form Machine provides a user-friendly interface for creating forms, as well as a powerful form engine for processing the information collected.Form Machine is an ideal solution for businesses that need to collect data from customers, employees, or other stakeholders. It can be used for surveys, job applications, registration forms, and more. Form Machine can also be used to automate processes, such as scheduling appointments or sending notifications.ConclusionIn conclusion, forms are an essential tool for any business that wants to collect, process, and share information effectively. Presentations, infographics, videos, and documents are all useful forms for sharing information in different ways. However, the traditional methods of creating and managing forms can be time-consuming and cumbersome.Form Machine offers a streamlined solution for creating and managing forms. It is a powerful tool that can help businesses save time, improve efficiency, and enhance their communication processes. By embracing new technologies like Form Machine, businesses can stay ahead of the game and remain competitive in an ever-changing business landscape.

How Glazed Tile Manufacturing Machine Can Transform Your Tile Production

Glazed Tile Manufacturing Machine Offers High-Quality and Efficient ProductionIn the world of construction, glazed tiles are becoming increasingly popular due to their durability, versatility, and aesthetic appeal. With the demand for high-quality glazed tiles on the rise, manufacturers are seeking ways to improve their production processes and ensure consistent quality in their products. This is where the Glazed Tile Manufacturing Machine comes in, offering a reliable and efficient solution for producing glazed tiles in large quantities.The Glazed Tile Manufacturing Machine, which is developed and manufactured by one of the leading engineering companies in the industry, is a state-of-the-art production system that combines cutting-edge technology and advanced machinery to create high-quality glazed tiles. Its fully automated operation minimizes the need for manual labor, allowing for increased efficiency and productivity in the production process.The machine is highly customizable, with various options for tile size, thickness, color, and texture. This allows manufacturers to produce a wide range of glazed tiles to meet the specific needs of their customers. The Glazed Tile Manufacturing Machine can produce up to 10,000 tiles per day, making it a cost-effective solution for large-scale production and reducing the need for multiple machines.The advanced technology used in the Glazed Tile Manufacturing Machine ensures consistent quality in each tile produced. The machine is equipped with sensors and advanced software that monitor every step of the production process, from mixing the raw materials to firing the tiles in the kiln. This ensures that each tile meets the required standards of quality, strength, and durability.The Glazed Tile Manufacturing Machine is also designed with ease of use and maintenance in mind. Its user-friendly interface and intuitive control system make it easy for operators to monitor and adjust the production process as needed. The machine also requires minimal maintenance, with automated cleaning and lubrication systems that help to prevent wear and tear on its components.One of the leading users of the Glazed Tile Manufacturing Machine is {} – a company that specializes in producing high-quality glazed tiles for the construction industry. According to the company's spokesperson, the Glazed Tile Manufacturing Machine has been instrumental in improving their production efficiency and product quality. "Since we started using the Glazed Tile Manufacturing Machine, we have been able to produce more tiles in less time, while maintaining consistent quality. This has helped us to meet the growing demand for our products and stay competitive in the market," said the spokesperson.In addition to its operational benefits, the Glazed Tile Manufacturing Machine is also environmentally friendly. Its advanced production processes and energy-efficient design help to reduce energy consumption and minimize waste in the production process. This makes it a sustainable solution for manufacturers who are looking to reduce their carbon footprint and promote eco-friendly practices.In conclusion, the Glazed Tile Manufacturing Machine is a game-changer for manufacturers in the construction industry who are looking to improve their production processes and keep up with the growing demand for glazed tiles. With its advanced technology, customizable options, and user-friendly design, the machine offers a reliable and efficient solution for producing high-quality glazed tiles in large quantities. As the construction industry continues to grow, the Glazed Tile Manufacturing Machine will undoubtedly play a pivotal role in meeting the demand for durable and versatile glazed tiles.

Master the Art of Making Authentic Pasta at Home with a Manual Pasta Machine

Title: Master the Art of Homemade Pasta with a Manual Pasta Machine Introduction (approximately 100 words):Fresh, homemade pasta is a culinary delight that can be easily made in the comfort of your own kitchen. With a few simple ingredients, you can create a variety of pasta dishes that will impress your family and friends. If you're new to the world of pasta making or looking to elevate your skills, investing in a manual pasta machine can make the process much easier and enjoyable. In this blog, we will explore the benefits of using a manual pasta machine and provide an in-depth guide on how to make authentic pasta at home. Body:1. The Advantages of Using a Manual Pasta Machine (approximately 200 words):A manual pasta machine offers numerous advantages when it comes to making homemade pasta. Here are some key benefits:a) Efficiency: A manual pasta machine helps streamline the process of rolling and shaping pasta dough, saving you time and effort compared to manual techniques.b) Consistency: With a pasta machine, you can achieve consistent thickness and shape throughout your pasta, ensuring even cooking and a professional result every time.c) Versatility: Manual pasta machines often come with a variety of attachments, allowing you to create different types of pasta, including spaghetti, fettuccine, and lasagna sheets.d) Authenticity: By using a manual pasta machine, you can replicate the traditional techniques used by Italian nonnas for generations, resulting in truly authentic pasta.2. Getting Started with a Manual Pasta Machine (approximately 200 words):Before diving into the pasta-making process, it's important to familiarize yourself with your manual pasta machine. While models may vary slightly, the general steps and techniques remain the same. Follow these guidelines to get started:a) Preparation: Begin by gathering your ingredients – typically flour, eggs, and salt – and combine them to form a dough. Allow the dough to rest for 30 minutes, as this will make it easier to work with.b) Setting up the Machine: Attach the appropriate cutting attachment to the machine, depending on the type of pasta you want to make. Most manual pasta machines have adjustable thickness settings, so start with the widest setting and gradually work your way down to achieve your desired thickness.c) Rolling the Dough: Divide the dough into manageable portions and flatten each one with your hands. Feed the dough through the machine, starting at the widest setting. Fold the dough in half after each pass and repeat this process until the desired thickness is achieved.d) Shaping the Pasta: Once the pasta sheet reaches the desired thickness, switch to the cutting attachment for your chosen pasta shape. Pass the pasta sheet through the machine, and voila! You have freshly cut pasta ready for cooking.3. Cleaning and Maintenance Tips for Your Manual Pasta Machine (approximately 200 words):To ensure your manual pasta machine remains in optimal condition and longevity, it's essential to follow proper cleaning and maintenance procedures. Here are some useful tips:a) Basic Cleaning: After use, wipe away any excess flour or dough from the machine using a dry cloth or brush. Avoid using water to clean the machine, as this can cause rusting or damage.b) Thorough Cleaning: Periodically, disassemble the machine as per the manufacturer's instructions and clean each component thoroughly. Use warm, soapy water and a soft brush to remove any stubborn residue.c) Drying and Storage: After cleaning, ensure that all parts of the machine are completely dry before reassembling and storing it in a dry place. Avoid exposure to humidity or extreme temperatures, as this can affect its performance.Conclusion (approximately 100 words):Investing in a manual pasta machine can transform your pasta-making experience, allowing you to effortlessly create authentic and delicious homemade pasta. Whether you're a culinary enthusiast or a novice in the kitchen, using a manual pasta machine will streamline the process, offering you consistent results and a variety of pasta types. With the right techniques and maintenance, you'll be able to enjoy countless pasta dishes that will rival those from your favorite Italian restaurant. So, why wait? Start your pasta-making journey today and unlock a world of culinary possibilities!Keywords: manual pasta machine, homemade pasta, authentic pasta, pasta-making, Italian nonnas, manual techniques, pasta dough, cutting attachment, cleaning and maintenance, pasta types.

Manufacturing and Corrugation Equipment for Glazed Tile Sheet Production

Glazed Tile Sheet Manufacturing and Corrugation Equipment Revolutionizing the Construction IndustryWith the growing demand for high-quality materials in the construction industry, companies are constantly seeking innovative solutions to enhance their manufacturing processes. One such breakthrough is the Glazed Tile Sheet Manufacturing and Corrugation Equipment, which is revolutionizing the way glazed tiles are produced.(Company Introduction): [Insert company name] is a leading provider of cutting-edge manufacturing equipment for the construction industry. With years of experience and expertise in the field, our company has pioneered several groundbreaking technologies that have reshaped the market. Our commitment to research and development has led to the creation of the Glazed Tile Sheet Manufacturing and Corrugation Equipment, which is set to transform the production of glazed tiles.The Glazed Tile Sheet Manufacturing and Corrugation Equipment incorporates state-of-the-art technology to produce top-quality glazed tiles efficiently. It eliminates several challenges associated with traditional manufacturing methods, offering a range of benefits that make it the preferred choice for companies in the construction sector. One of the notable advantages of this equipment is its ability to enhance production efficiency. The automated processes integrated into the system reduce human error and increase productivity. The mechanized corrugation process ensures precise and consistent tile shapes, guaranteeing a flawless outcome every time. The equipment's high-speed operation allows for swift production without compromising on quality, meeting the demands of time-sensitive projects.Furthermore, this equipment boasts excellent customization capabilities, empowering manufacturers with the freedom to produce tiles tailored to their specific requirements. The machine can create tiles of various sizes, thicknesses, and shapes, accommodating the diverse needs of the construction industry. This flexibility allows companies to respond quickly to market trends and customer preferences, expanding their clientele and gaining a competitive edge.In addition to its efficiency and flexibility, the Glazed Tile Sheet Manufacturing and Corrugation Equipment also prioritizes sustainability. With the increasing emphasis on eco-friendly practices, this equipment aligns with the growing demand for environmentally responsible construction materials. The use of advanced technologies reduces energy consumption and minimizes waste generation during the manufacturing process. This not only benefits the environment but also positions companies using this equipment as leaders in sustainable construction practices.Moreover, the Glazed Tile Sheet Manufacturing and Corrugation Equipment ensures the durability and longevity of the produced tiles. The precise corrugation process enhances the structural integrity of the tiles, making them resistant to wear and tear. This longevity results in decreased maintenance costs for developers and homeowners alike, adding value to their investments.The introduction of this revolutionary equipment has already garnered considerable attention in the construction industry. Companies seeking to optimize their manufacturing processes and improve product quality have started adopting this technology. As a result, market dynamics are expected to shift, paving the way for a new era of glazed tile production.In conclusion, the Glazed Tile Sheet Manufacturing and Corrugation Equipment represents a paradigm shift in the construction industry. Its advanced technology, efficiency, flexibility, and sustainability make it a game-changer in the manufacturing of glazed tiles. With its ability to meet market demands and produce high-quality materials, this equipment is poised to shape the future of the construction industry.

Glazed Tile Roll Forming Machine for Metal Roofing Sheet Production

If you are in search for a reliable and efficient Glazed Tile Roll Forming Machine, then Dahezb Metal has got you covered. Dahezb Metal specializes in designing and manufacturing high quality auto glazed tile forming machines that produce metal roof tiles of 0.3-0.6mm thickness. They specialize in Aluminum roofing step tile machines, glazed roll forming machines, and glazed tile roll forming machines that are specifically designed for making glazed tiles for roofing sheets.One of the unique features of the Glazed Tile Roll Forming Machine from Dahezb Metal is its ability to effectively remove brand names from the roofing sheet during production. This feature is particularly important for customers who need to produce roofing sheets for their own brand without having to purchase expensive equipment or worry about legal issues.The Glazed Tile Roll Forming Machine is a versatile production machine that can be used to produce a wide range of roofing sheets including Aluminum, Color Steel, and Glazed Steel tiles. It is a durable and high-performance machine that is designed and built with high-quality materials and advanced technology to ensure accuracy, precision, and speed.With a production capacity of up to 15 meters per minute, the Glazed Tile Roll Forming Machine from Dahezb Metal is one of the most efficient and profitable investments for anyone looking to venture into the roofing sheet production business. The machine is easy to operate, maintain, and requires minimal technical skills to effectively run and produce high-quality roofing sheets.The Glazed Tile Roll Forming Machine is designed with safety in mind. It features an emergency stop button and other safety features to ensure that operators are always protected from potential hazards. The machine also comes with a user-friendly interface that allows operators to easily adjust the production settings and monitor the production process.In conclusion, if you are looking for an efficient and reliable Glazed Tile Roll Forming Machine, then Dahezb Metal Glazed Tile Roll Forming Machine is the perfect choice. It is a high-performance machine that is designed to produce high-quality roofing sheets in an efficient, cost-effective, and safe manner. It is a valuable investment that guarantees a high return on investment and long-term profitability. So, if you want to get ahead in the roofing sheet production business, the Glazed Tile Roll Forming Machine from Dahezb Metal is your best bet.

Roll Forming Machines for Drywall and House Making: Metal Studs, Tracks and Dumplings

and Roll Forming Equipment.Metal Roof Roll Machine For Drywall – Top Quality House Making MachineIf you are looking for a top-quality house making machine, look no further than the metal roof roll machine for drywall. This versatile machine is capable of producing all the components needed for constructing a sturdy, reliable house, including metal studs, tracks, roofing, and more.One of the primary advantages of the metal roof roll machine for drywall is its ability to generate metal studs and tracks using a specialized technique known as roll forming. In this technique, sheets of metal are fed through a series of rollers that gradually bend the metal into the desired shape. This produces a durable, strong, and uniform product that is perfectly suited for use in residential and commercial construction.The metal stud and track roll forming machine from Alibaba is an excellent example of this type of equipment. It is capable of producing high-quality metal studs and tracks in a variety of sizes and configurations, making it suitable for a wide range of construction applications. Whether you are building a small residential property or a large commercial complex, this machine can help you create the perfect metal framing to get the job done.Other Benefits of Steel FramingIn addition to being strong, durable, and reliable, steel framing also offers a number of other advantages for construction projects. For example, steel is much lighter than traditional building materials like bricks and concrete, which can help reduce the overall weight of a building and make it easier to erect. It is also non-combustible, which can help reduce the risk of fires in buildings.Steel framing is also extremely flexible, allowing contractors to create customized designs and incorporate a wide range of materials and finishes into their projects. And because it is produced using sophisticated manufacturing processes like roll forming, it is possible to create extremely precise, uniform components that are easy to install and require very little maintenance.Finding the Right Metal Stud Making MachineIf you are interested in using roll forming equipment to produce metal studs and tracks for your construction projects, it is important to choose the right machine for your needs. Look for equipment that offers a high level of precision and flexibility, and that is capable of producing a wide range of different shapes and sizes.Also, be sure to choose a machine that is backed by a reputable manufacturer with a track record of producing high-quality equipment. This will ensure that you receive reliable, long-lasting equipment that meets your needs and exceeds your expectations.ConclusionOverall, the metal roof roll machine for drywall is a top-quality house making machine that is capable of producing a wide range of components for any construction project. Whether you are constructing a single-family home or a large commercial complex, this equipment is the perfect tool for ensuring that your building is strong, durable, and reliable. So if you are in the market for a metal stud making machine or roll forming equipment, look no further than the metal roof roll machine for drywall – the best choice for your construction needs!

Efficient and Innovative Roll Forming Machines for Panel Manufacturing

In today’s market, the need for quality and efficient panel roll forming machines has never been more apparent. As the construction industry continues to grow and evolve, manufacturers are looking to create products that can meet the needs of their clients while also maximizing productivity and profitability. One company that has successfully taken on this challenge is {company name}, a leading provider of roll forming technology.With over 20 years of experience in the industry, {company name} has established itself as a trusted name in roll forming machinery. They specialize in developing innovative solutions that can create a variety of profiles, including panel roll forming machines that are designed to handle a wide range of materials, such as steel, aluminum, and copper.One of their most popular machines is the panel roll forming machine. This machine is designed to produce panels that are used in a variety of applications, from roofing and siding to vehicle bodies and shipping containers. It allows manufacturers to create panels in a range of sizes, thicknesses, and shapes, making it an incredibly versatile machine.The panel roll forming machine offered by {company name} is known for its efficiency and ease of use. It is capable of producing panels at high speed, allowing manufacturers to achieve high levels of productivity. In addition, the machine is equipped with user-friendly controls, making it easy for operators to set up and run the machine.One of the key advantages of {company name}’s panel roll forming machine is its quality. Each machine is built to the highest standards, ensuring that it is durable and reliable. This not only reduces the risk of downtime and costly repairs but also ensures that the finished panels meet the required specifications.Another benefit of the panel roll forming machine from {company name} is its flexibility. The machine can be customized to meet the specific needs of each manufacturer, allowing for the creation of panels that are tailored to their unique requirements. This can help manufacturers to differentiate themselves in the market and provide their clients with a product that stands out from the competition.{Company name} also provides comprehensive support to their clients. This includes installation, training, and ongoing maintenance and support. Their team of experts can help manufacturers get the most out of their new machines, ensuring that they are able to achieve maximum productivity and profitability.In addition to their high-quality panel roll forming machine, {company name} also offers a range of other roll forming machines, including those for producing roofing and siding profiles, metal framing, and more. With their innovative solutions, dedication to quality, and commitment to customer support, {company name} is a company that is poised to continue to grow and thrive in the years ahead.As the construction industry continues to expand, the demand for high-quality roll forming machinery is only going to increase. Manufacturers will need to find innovative solutions that can help them keep up with demand while ensuring that they are able to achieve maximum efficiency and profitability. With {company name}’s panel roll forming machine, they have found a solution that meets all of these requirements and more.