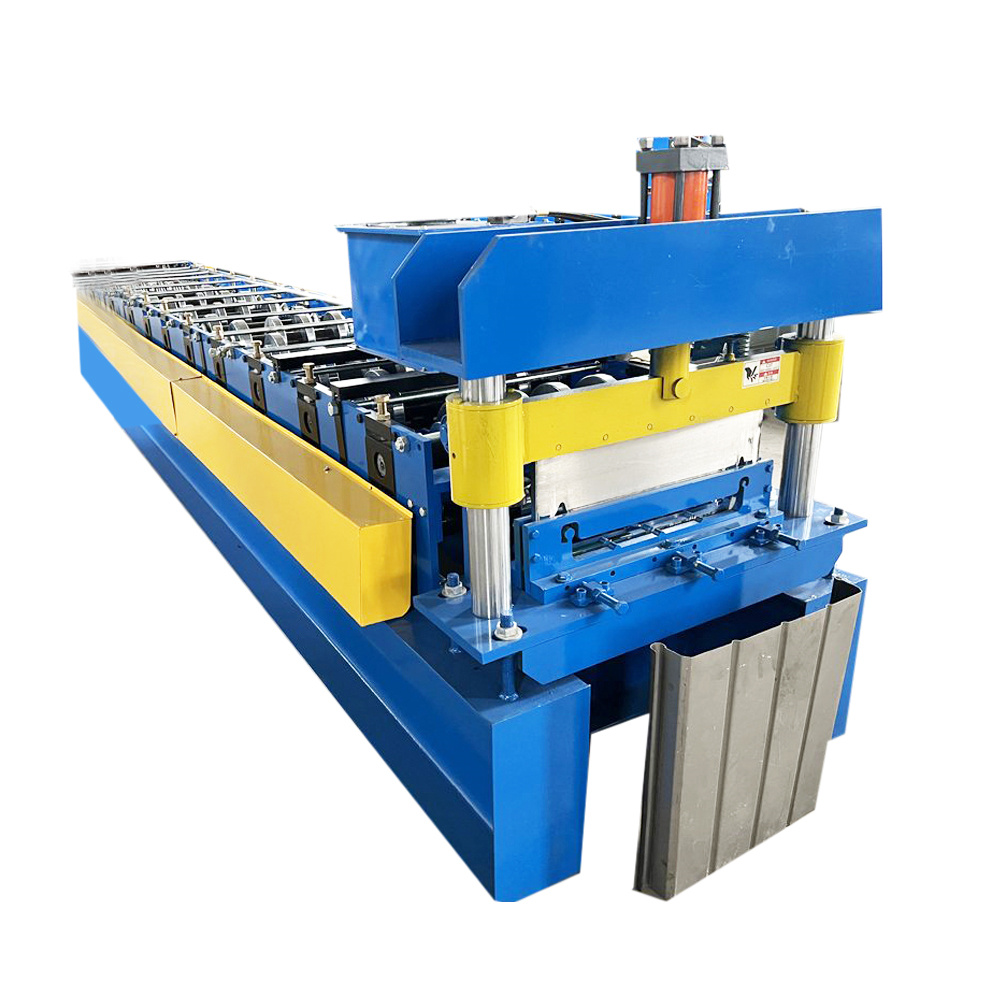

High-quality Corrugated Roof Sheet Manufacturing Machine for Sale: Find Out More Today!

By:Admin

With a focus on technological innovation and customer satisfaction, the company has developed a range of advanced manufacturing machines that are capable of producing corrugated roof sheets with precision and speed. These machines are designed to cater to the varying needs of construction companies and builders, offering flexibility in terms of sheet size, material type, and production capacity.

The company's state-of-the-art manufacturing machines incorporate the latest advancements in engineering and automation, ensuring that the production process is efficient, reliable, and cost-effective. This enables their customers to meet the growing demand for corrugated roof sheets without compromising on quality or turnaround time.

Furthermore, the company provides comprehensive support and service to their clients, including installation, training, and maintenance of the manufacturing machines. This commitment to customer care has earned them a reputation for being a reliable and trusted partner in the industry.

In addition to their focus on product quality and customer service, the company also places a strong emphasis on sustainability and environmental responsibility in their manufacturing processes. They have implemented eco-friendly practices in their operations, ensuring that their machines are energy-efficient and produce minimal waste during the production of corrugated roof sheets. This aligns with the growing trend in the construction industry towards green building materials and sustainable manufacturing practices.

With a proven track record of delivering cutting-edge manufacturing solutions, the company has established itself as a leader in the corrugated roof sheet manufacturing industry. Their commitment to innovation, quality, and customer satisfaction has set them apart from their competitors, earning them the trust and loyalty of a growing customer base.

As the demand for corrugated roof sheets continues to rise, the company remains dedicated to meeting the needs of their clients with advanced manufacturing machines and unparalleled service. They are poised to play a crucial role in shaping the future of the construction industry by providing essential equipment that facilitates the production of high-quality building materials.

In conclusion, the company's expertise in corrugated roof sheet manufacturing machines, combined with their dedication to innovation and customer satisfaction, has positioned them as a leading provider of solutions for the construction industry. With a focus on technological advancement, sustainability, and reliable customer support, they are well-equipped to meet the increasing demand for corrugated roof sheets and contribute to the growth and development of the industry.

Company News & Blog

Half Omega Steel Furring Channel Roll Forming Machine for Resilient Furring Channel Keel

In the world of construction and building, innovation and new technology are constantly shaping the way we create structures. One such advancement comes in the form of the Light Steel Half Omega Steel Furring Channel Roll Former Resilient Furring Channel Keel Roll Forming Machine which is set to revolutionize the industry.This new technology has been developed by a leading company in the field of construction machinery and equipment. With a focus on innovation and efficiency, the company has been at the forefront of developing advanced solutions for the construction industry. Their latest product, the Light Steel Half Omega Steel Furring Channel Roll Former Resilient Furring Channel Keel Roll Forming Machine, is set to make a significant impact on how buildings are constructed.The Light Steel Half Omega Steel Furring Channel Roll Former Resilient Furring Channel Keel Roll Forming Machine is a state-of-the-art piece of equipment designed to streamline the process of creating steel furring channels. These channels are crucial in the construction of walls and ceilings, providing a sturdy and reliable framework for drywall and other materials. The new machine is capable of producing these furring channels with incredible precision and efficiency, saving time and resources for construction companies.One of the key features of the Light Steel Half Omega Steel Furring Channel Roll Former Resilient Furring Channel Keel Roll Forming Machine is its ability to produce furring channels with a half omega shape. This unique design increases the strength and durability of the channels, ensuring that the resulting structures will be able to withstand the test of time. Additionally, the machine is equipped with resilient furring channel keel roll forming technology, further enhancing the quality and reliability of the channels it produces.The company behind this innovative technology has a long history of providing top-of-the-line machinery and equipment to the construction industry. With a team of experienced engineers and designers, they have continuously pushed the boundaries of what is possible in the field of construction technology. The development of the Light Steel Half Omega Steel Furring Channel Roll Former Resilient Furring Channel Keel Roll Forming Machine is just the latest example of their commitment to driving the industry forward.In addition to its impressive capabilities, the new machine is also designed with ease of use in mind. The company has incorporated user-friendly features to ensure that construction workers of all skill levels can operate the machine with confidence. This focus on accessibility and user experience sets the Light Steel Half Omega Steel Furring Channel Roll Former Resilient Furring Channel Keel Roll Forming Machine apart from other similar products on the market.The introduction of this new technology is expected to have a significant impact on the construction industry. By streamlining the process of creating steel furring channels, the machine has the potential to reduce construction timelines and improve the overall quality of finished structures. This will not only benefit construction companies, but also the end users who will be able to enjoy buildings that are built to last.As the construction industry continues to evolve, innovative technologies like the Light Steel Half Omega Steel Furring Channel Roll Former Resilient Furring Channel Keel Roll Forming Machine will play a crucial role in shaping its future. With its advanced capabilities and user-friendly design, this new machine is set to make a lasting impact on how buildings are constructed. It is a testament to the company's dedication to pushing the boundaries of what is possible in construction technology, and a sign of exciting things to come in the industry.

Top Roller for Corrugated Roofing: Must-Have Tool for Easy Installation

Roller for Corrugated Roof: A Game-Changer in the Roofing IndustryCorrugated roofing has long been a popular choice for residential and commercial buildings due to its durability and cost-effectiveness. However, the process of installing and maintaining corrugated roofs has always been a time-consuming and labor-intensive task. That is, until now.Introducing the new Roller for Corrugated Roof, a revolutionary tool that has the potential to change the way corrugated roofs are installed and maintained. This innovative product, developed by a leading manufacturer in the roofing industry, is set to make waves in the construction and roofing sectors.The Roller for Corrugated Roof is designed to streamline the installation process, making it faster and more efficient than ever before. Its ergonomic and user-friendly design allows for easy handling, reducing the physical strain on workers during the installation process. This not only improves productivity but also enhances worker safety, a critical factor in any construction project.What sets the Roller for Corrugated Roof apart from other tools in the market is its ability to ensure a smooth and even finish on corrugated roofs. Its advanced technology allows for precise and consistent rolling, resulting in a professional-looking finish that adds to the aesthetic appeal of the building.In addition to its installation benefits, the Roller for Corrugated Roof also offers significant advantages in terms of maintenance. By using the roller to apply protective coatings and sealants, maintenance teams can extend the lifespan of corrugated roofs, preventing leaks and other damage that can result from exposure to harsh weather conditions.The company behind the Roller for Corrugated Roof, with a proven track record of delivering high-quality roofing products and tools, has invested considerable resources in research and development to bring this innovative tool to the market. With a commitment to excellence and a dedication to meeting the evolving needs of the construction industry, they have positioned themselves as a leader in the market.The company's mission is not only to provide innovative solutions but also to contribute to the sustainability of the industry. The Roller for Corrugated Roof is an environmentally friendly tool that minimizes waste and reduces the need for additional resources during the installation and maintenance processes. This eco-conscious approach aligns with the company's commitment to responsible and sustainable business practices.In line with its dedication to customer satisfaction, the company offers comprehensive support and training programs for the Roller for Corrugated Roof. This ensures that contractors and maintenance teams are equipped with the knowledge and skills to make the most of this game-changing tool, ultimately delivering superior results for their clients.The release of the Roller for Corrugated Roof has generated significant excitement within the roofing industry, with early adopters praising its performance and efficiency. Contractors and building owners alike are recognizing the potential of this tool to revolutionize the way corrugated roofs are installed and maintained, ultimately saving time and costs while delivering exceptional results.As the demand for innovative and sustainable construction solutions continues to grow, the Roller for Corrugated Roof stands out as a prime example of how cutting-edge technology can drive positive change in the industry. With its combination of efficiency, quality, and sustainability, this tool is set to become a staple in the toolkit of roofing professionals around the world.

The Ultimate Guide to Coil Slitting Process in Manufacturing

Today, we are excited to share with you the innovative coil slitting process that our company has developed to meet the growing demands of our customers. As a leading manufacturer in the metal industry, we are constantly striving to improve our processes and provide the best quality products to our clients. Our dedication to innovation and customer satisfaction has led us to develop a state-of-the-art coil slitting process that sets us apart from our competitors.The coil slitting process is a crucial step in the production of metal sheets and coils. It involves cutting large coils of metal into smaller, more manageable coils that are ready for further processing or shipping. The precision and efficiency of this process are vital to ensuring the quality and integrity of the final product. With our new and improved coil slitting process, we are able to deliver products of the highest quality while maintaining a high level of productivity.Our coil slitting process begins with the arrival of large coils of metal at our facility. These coils are thoroughly inspected for any defects or imperfections before being loaded onto our state-of-the-art slitting line. Our advanced machinery and equipment ensure that the coils are slit with precision and accuracy, resulting in uniform and consistent product quality. Additionally, our process is highly efficient, allowing us to meet the demanding production schedules of our clients without compromising on quality.One of the key features of our coil slitting process is the use of advanced technology to monitor and control the slitting parameters in real time. This ensures that each coil is slit to the exact specifications required by our customers. Our highly skilled technicians are trained to operate and maintain the equipment, and they are dedicated to upholding the highest standards of quality and safety throughout the process.In addition to the technical aspects of our coil slitting process, we also place a strong emphasis on environmental sustainability. We have implemented measures to minimize waste and reduce energy consumption in our production process. This commitment to sustainability not only benefits the environment but also allows us to offer our customers products that are produced in a responsible and ethical manner.Our dedication to innovation and continuous improvement has positioned us as a leader in the metal industry. With our advanced coil slitting process, we are able to offer our customers a level of quality and precision that is unmatched by our competitors. We are proud to be able to meet the diverse needs of our clients and provide them with products that meet the highest standards of excellence.As we look to the future, we are committed to further advancing our coil slitting process and other manufacturing technologies. We will continue to invest in research and development to stay ahead of industry trends and deliver innovative solutions to our customers. With our unwavering commitment to quality, efficiency, and sustainability, we are confident that we will remain a trusted partner for all metal processing needs.In conclusion, our company's new coil slitting process represents a significant advancement in the metal industry. With our state-of-the-art technology, unwavering commitment to quality, and dedication to sustainability, we are setting new standards for excellence in metal processing. We are excited to continue serving our customers with the best products and solutions, and we look forward to the opportunities that lie ahead as we continue to innovate and grow.

PM Modi to participate in UN's Yoga Day, announces big preparations in India

Prime Minister Narendra Modi has announced that he will be participating in the upcoming United Nations' Yoga Day celebrations. According to the Prime Minister, plans for Yoga Day are well underway in the country, with preparations being made for a successful event.The upcoming Yoga Day celebration is not to be taken lightly. The United Nations first declared June 21st as International Yoga Day on December 11, 2014. The declaration was a result of a proposal made by Prime Minister Modi during his address to the United Nations General Assembly. Since then, every year on June 21st, people around the world come together to celebrate Yoga, which has become an integral part of Indian culture.According to the Prime Minister, the benefits of Yoga are well-known and he encourages all people to practice it regularly. With the ongoing pandemic, he also highlighted the importance of Yoga in boosting one's immunity and overall health. He thanked the nation for its enthusiastic participation in past Yoga Day celebrations and urged people to continue taking part in commemorating the day.In light of the pandemic, this year's Yoga Day celebrations may look different than previous years. The government has mandated strict guidelines to ensure the safety of individuals who will be participating in-person. However, participants are welcome to participate in the Yoga Day celebrations from their homes, which is a viable option given that technology has made it possible to partake in activities remotely.Furthermore, the Prime Minister emphasized that Yoga was not just an exercise practice but a way of life. He said that by practicing Yoga, people are not only taking care of their physical health but also enriching their spiritual and mental well-being. He also mentioned that Yoga is an excellent tool for managing stress and anxiety, which have become increasingly prevalent during the pandemic.The Prime Minister's participation in the Yoga Day celebration is likely to boost the morale of individuals who will be taking part in the event. His leadership has been instrumental in raising the profile of Yoga on the global stage. The government has also taken several measures to promote Yoga, such as initiating programs like the International Yoga Festival in Rishikesh, India, and creating the Ministry of AYUSH (Ayurveda, Yoga, and Naturopathy, Unani, Siddha, and Homeopathy) to promote traditional Indian medicine.In addition to the Prime Minister's announcement, the company {Profile Sheet Banane Ki Machine} has expressed their support for the event. They believe that Yoga is a universally beneficial practice that promotes a healthy lifestyle and mental well-being. They encourage individuals to take part in the Yoga Day celebration, whether in-person or remotely.In conclusion, the Prime Minister's announcement of his participation in the United Nations' Yoga Day celebrations is a significant development. It serves as an inspiration and encouragement for individuals to participate in commemorating an event that promotes physical, mental, and spiritual well-being. With preparations in full swing, the government and companies like {Profile Sheet Banane Ki Machine} are leading the way in making the event a success.

Top Quality Machinery for Forming Processes

Forming Machinery Celebrates Milestone AchievementForming Machinery, a global leader in the manufacturing of forming equipment, has recently achieved a significant milestone in its journey of providing top-quality machinery solutions to its customers. With an unwavering commitment to innovation, precision engineering, and customer satisfaction, the company has established itself as a trusted partner for businesses across various industries.With over [X] years of experience in the industry, Forming Machinery has continually pushed the boundaries of technology to deliver cutting-edge solutions that meet the evolving needs of its clientele. The company's dedication to research and development has enabled it to stay ahead of the curve and anticipate market trends, resulting in the creation of advanced, efficient, and reliable forming equipment.One of Forming Machinery's key strengths lies in its comprehensive product range, which includes [list of products]. From standard machines to custom-built solutions, the company has the capabilities to cater to a wide array of requirements, ensuring that its customers have access to the best machinery for their specific applications.The company's commitment to quality is evident in its state-of-the-art manufacturing facilities and stringent quality control measures. Every machine that bears the Forming Machinery name is a testament to the company's dedication to excellence, durability, and performance. Furthermore, the company also offers comprehensive after-sales support, spare parts availability, and technical assistance, ensuring that customers can maximize the value of their investments.In addition to its impressive product lineup, Forming Machinery takes pride in its team of highly skilled and experienced professionals. The company's engineers, technicians, and support staff are deeply passionate about their work and are driven by a shared vision of delivering unparalleled service to customers around the world. This team's expertise and dedication have been instrumental in establishing Forming Machinery as a benchmark for quality and reliability in the industry.As part of its ongoing commitment to innovation, Forming Machinery has consistently invested in research and development to drive the creation of next-generation forming equipment. The company's focus on technological advancement and continuous improvement has resulted in cutting-edge solutions that offer higher productivity, energy efficiency, and cost savings for its customers.Furthermore, Forming Machinery's dedication to sustainability is reflected in its efforts to develop eco-friendly manufacturing processes and energy-efficient machinery. By prioritizing environmental responsibility, the company aims to minimize its carbon footprint and promote sustainable practices within the industry.Looking to the future, Forming Machinery remains dedicated to upholding its reputation as a leader in the forming equipment sector. The company is steadfast in its commitment to delivering innovative solutions that exceed customer expectations, while also fostering long-term partnerships based on trust, reliability, and mutual success.As Forming Machinery celebrates this milestone achievement, it reaffirms its mission to continue setting new standards for excellence and serving as a driving force for positive change within the industry. With its unwavering dedication to quality, innovation, and customer satisfaction, the company is well-positioned to shape the future of forming machinery and make a lasting impact on businesses worldwide.

Roll Forming Machine for Manufacturing Wall Panels

In recent years, there has been an increasing need for high-quality wall panels for use in a variety of applications, from commercial structures to residential homes. To meet this demand, a new system has been developed that has revolutionized the way that wall panels are manufactured. This system, known as the Wall Panel Roll Forming Machine, has quickly become one of the most popular and widely used technologies in the industry.The Wall Panel Roll Forming Machine is essentially a specialized piece of equipment that is designed to take a flat piece of raw material and transform it into a custom-fabricated wall panel. The machine operates on a continuous basis, allowing for a virtually uninterrupted flow of material and seamless production of large quantities of panels. This level of efficiency and consistency is critical for meeting the high demands of modern construction projects.Perhaps the most important aspect of the Wall Panel Roll Forming Machine is its versatility. It is capable of producing wall panels of virtually any size or shape, from standard rectangular panels to more complex designs with intricate curves and details. This opens up possibilities for architects and designers to create truly unique and impressive structures that were previously impossible to construct using traditional methods.One of the key advantages of the Wall Panel Roll Forming Machine is its automation. The technology used in the machine allows for precise control and accuracy in the manufacturing process. This reduces the need for human intervention, which not only increases efficiency but also reduces the chances of errors and defects in the final product. The end result is a high-quality wall panel that meets or exceeds all industry standards and is sure to provide years of reliable service.At the heart of the Wall Panel Roll Forming Machine is the roll forming process. In this process, a sheet of material is passed through a series of rollers that gradually bend and shape it into the desired form. The Wall Panel Roll Forming Machine uses a custom-designed set of rollers that are specifically tailored to the requirements of each individual project. This ensures maximum precision and accuracy in the finished product.Another key advantage of the Wall Panel Roll Forming Machine is its speed of production. Because the machine operates on a continuous basis, it is capable of producing large quantities of high-quality wall panels in a relatively short amount of time. This makes it an ideal solution for construction companies and contractors who need to meet tight deadlines and strict schedules.The Wall Panel Roll Forming Machine is also highly customizable. It can be tailored to fit the specific requirements of each individual project, allowing for a wide range of options in terms of materials, sizes, and shapes. This versatility makes it an ideal choice for architects and designers who need to create unique and innovative structures that require custom-made panels.In conclusion, the Wall Panel Roll Forming Machine is a cutting-edge technology that has changed the way that wall panels are manufactured. Its precision, speed, and versatility have made it an essential tool for construction companies and contractors who need to meet the demands of modern construction projects. With its automation and customization options, it is sure to continue to be a popular choice in the industry for years to come.

Portable Standing Seam Metal Roof Roll Forming Machine: Small Size Standing Seam Roof Panel Roll Forming Machine

: A Game-Changer for the Metal Roofing IndustryMetal roofing has been gaining popularity over the years due to its durability, longevity, and aesthetic appeal. However, installing a metal roof comes with a fair amount of challenges, including finding a reliable and efficient roll forming machine that can produce the necessary roofing panels onsite. Enter the Portable Standing Seam Roll Forming Machine.The Portable Standing Seam Roll Forming Machine, also known as KLS25-220-530, is a small size metal standing seam roof panel roll forming machine that is designed to produce high-quality roof panels quickly and efficiently. It features a compact design, making it easy to transport and set up on-site, making it the perfect solution for contractors who need to produce standing seam metal roof panels on the job site.The machine is designed to roll-form metal roofing panels with a standing seam profile, which provides superior weather resistance and no visible fasteners. The standing seam design also makes it easier to install the panels, reducing the installation time and minimizing the risk of leaks.One of the standout features of the Portable Standing Seam Roll Forming Machine is its ease of use. It comes with an intuitive control system that allows operators to adjust the roll-forming settings quickly and easily. The machine also has a hydraulic cutting system, which cuts the panels to the desired length accurately.The KLS25-220-530 is capable of producing roofing panels with a width of 220mm and a thickness of 0.4-0.6mm. The machine also has a roll-forming speed of up to 15 meters per minute, ensuring that you can produce high-quality panels quickly and efficiently.Moreover, the machine comes with a durable construction, ensuring that it can withstand harsh job site conditions. It is also designed with safety features such as protective covers and emergency stop buttons, ensuring that operators are protected while using the machine.In conclusion, the Portable Standing Seam Roll Forming Machine is a game-changer for the metal roofing industry. Its portability, ease of use, and ability to produce high-quality standing seam metal roof panels quickly and efficiently make it an excellent investment for contractors looking to save time and money on their metal roofing projects. Don't wait any longer; invest in the KLS25-220-530 today.

High-Quality Roll Forming Machine for Efficient Production

Roll Forming Machine Revolutionizing the Manufacturing IndustryIn the ever-evolving world of manufacturing, the demand for efficient and high-quality production processes is constantly on the rise. Companies are constantly seeking innovative solutions to streamline their manufacturing operations and stay ahead of the competition. One of the most crucial machines in this aspect is the roll forming machine, which has been gaining traction in the manufacturing industry for its high precision and flexibility.With the growing interest in roll forming machines, companies like [company name] have been at the forefront of providing cutting-edge solutions for the manufacturing industry. [Company name] has been a leading player in the roll forming machine market, providing a wide range of advanced machines that are tailored to meet the unique needs of different industries.The roll forming machine offered by [company name] boasts a number of impressive features that set it apart from traditional manufacturing methods. The machine is designed to efficiently and accurately produce metal sheets of various shapes and sizes, making it an ideal solution for a wide range of industries, from automotive to construction. With its high precision and flexibility, the roll forming machine from [company name] allows for greater customization and faster production, helping companies to meet the demands of their customers with ease.In addition to its impressive technical capabilities, the roll forming machine from [company name] also comes with a user-friendly interface that makes it easy to operate and maintain. This means that companies can maximize their production capabilities without having to invest heavily in training and maintenance costs.One of the key advantages of the roll forming machine from [company name] is its ability to produce high-quality products consistently. By using state-of-the-art technology and materials, the machine can ensure that every product meets the strictest quality standards, which is essential in industries where precision and durability are paramount.Furthermore, [company name] offers comprehensive after-sales support, guaranteeing that their customers can always count on the reliability and performance of their roll forming machine. The company's team of experts are always on hand to provide assistance and guidance, ensuring that the machine operates at its optimal level at all times.The demand for roll forming machines like the one offered by [company name] is only expected to grow as manufacturers continue to seek innovative solutions to enhance their production processes. With its cutting-edge technology and commitment to customer satisfaction, [company name] is well-positioned to meet this growing demand and further solidify its position as a leading provider of roll forming machines.In conclusion, the roll forming machine from [company name] is revolutionizing the manufacturing industry by offering a highly efficient and flexible solution for companies looking to streamline their production processes. With its advanced technology, high precision, and user-friendly design, the machine is helping manufacturers to stay ahead of the competition and meet the demands of their customers with ease. As the demand for such advanced manufacturing solutions continues to rise, [company name] is poised to play a key role in shaping the future of the manufacturing industry.

Roll Former Machine for Efficient Panel Manufacturing

Innovation is the key to success, and companies that prioritize the use of innovative technologies and practices are the ones that can stay ahead of the competition. One of the latest technological advancements in the manufacturing industry is the R Panel Roll Former. This machine is an advanced tool that helps manufacturers to produce high-quality steel panels quickly and efficiently.R Panel Roll Former is a revolutionary machine that has been designed to create panels used in roofing, walls, siding, and decking. The machine uses a series of rollers to bend and shape the steel into the desired shape and size. The R Panel Roll Former is an exceptional machine that has a number of advanced features that make it stand out from other types of roll formers.One of the most notable features of the R Panel Roll Former is its flexible design. The machine has been designed to produce a wide range of panel sizes, which makes it suitable for use in a variety of industries. The machine can create panels that range from as low 1ft to as high as 50ft. This feature makes the R Panel Roll Former an invaluable tool for manufacturers who need to produce panels with varying sizes.Another notable feature of the R Panel Roll Former is its speed. The machine has been designed to operate at a high-speed rate, which means that manufacturers can produce large quantities of panels within a short period of time. This feature is particularly useful for manufacturers who have large orders to fulfill within a tight timeframe.The R Panel Roll Former is also exceptionally user-friendly. The machine has been designed with both novice and experienced operators in mind. The machine comes with a simple control panel that makes it easy for operators to program the machine to produce the desired panel sizes. The machine also has an automatic lubrication system that ensures it operates smoothly without any hitches.The R Panel Roll Former is an exceptional machine that has changed the face of the manufacturing industry. Companies that use this machine can produce high-quality panels quickly and efficiently. This feature gives them a competitive edge in the market, as they can fulfill large orders within a short period of time.One of the companies that have embraced the use of the R Panel Roll Former is the XXX company. The company has been in the manufacturing industry for over 20 years and has built a reputation for producing high-quality products.The XXX company has invested in the R Panel Roll Former to enhance its production capabilities. Since the company started using the machine, it has been able to produce panels of varying sizes and designs, which has enabled the company to attract more customers.The XXX company is a firm believer in the use of innovative technologies and practices. The company understands that investing in new technologies and practices is the key to staying ahead of the competition. The investment in the R Panel Roll Former is part of XXX's continuous effort to innovate and improve its production capabilities.In conclusion, the R Panel Roll Former is an exceptional machine that has revolutionized the manufacturing industry. Companies that invest in this machine can produce high-quality panels quickly and efficiently, giving them a competitive edge in the market. The XXX company is a firm believer in the use of innovative technologies and practices. The investment in the R Panel Roll Former is a testament to the company's commitment to enhancing its production capabilities and staying ahead of the competition.

Metal Deck Roll Forming Machine for Efficient Decking Production in 2019

Floor Deck Roll Forming Machine | Decking Machine 2019: A Revolution in Metal Deck ProductionIn today's rapidly evolving construction industry, the demand for innovative and efficient machinery is at an all-time high. Companies are constantly on the lookout for advanced equipment that can help streamline their production processes and enhance the quality of their products. In line with these requirements, lotos design has introduced an exceptional Floor Deck Roll Forming Machine in 2019 that is set to revolutionize metal deck production.The Floor Deck Roll Forming Machine is a state-of-the-art piece of equipment that provides unparalleled precision and efficiency in manufacturing a variety of metal decks. With its computer-optimized design, this machine is capable of producing various types of metal decks catering to the specific needs of the construction industry. This cutting-edge technology takes the production process to a whole new level, ensuring superior quality and durability in each deck manufactured.One of the key features of the Floor Deck Roll Forming Machine is its computer optimization. This ensures that the machine operates at its peak performance, enabling the production of consistent and accurate metal decks. By removing any potential human error from the equation, lotos design has created a machine that guarantees exceptional quality with every deck produced. This not only increases the efficiency of the production process but also reduces material waste, thus making it an environmentally friendly solution.The lotos design Floor Deck Roll Forming Machine is a result of extensive research and development carried out by their team of experts. With years of experience in the industry, the company has gained invaluable knowledge about the requirements and challenges faced by construction companies when it comes to metal deck production. By incorporating this knowledge into the design of the machine, lotos design has created a solution that addresses these challenges, making metal deck production a breeze for their customers.Moreover, the company's dedication to customer satisfaction is evident in the quality of their product. They have gone above and beyond to ensure that their machine not only meets but exceeds industry standards. With a focus on durability and performance, lotos design has tested the Floor Deck Roll Forming Machine rigorously to ensure its reliability in demanding production environments. This dedication to quality has earned them a reputation as a trusted name in the industry.The Floor Deck Roll Forming Machine is not just another piece of equipment to lotos design. It is a testament to their commitment to innovation and providing their customers with the best possible solutions. With this machine, construction companies can significantly enhance their productivity and efficiency, thereby giving them a competitive edge in the market.As the construction industry continues to evolve, lotos design remains at the forefront of innovation. They continuously strive to develop groundbreaking machinery that revolutionizes the way metal decks are produced. The introduction of the Floor Deck Roll Forming Machine in 2019 is a testament to their dedication to excellence.In conclusion, the lotos design Floor Deck Roll Forming Machine is a game-changer in the construction industry. With its computer optimization and advanced features, it offers unparalleled precision and efficiency in metal deck production. By addressing the specific needs and challenges faced by construction companies, lotos design has created a solution that sets a new benchmark for the industry. As the demand for superior quality and efficient machinery continues to rise, the Floor Deck Roll Forming Machine proves to be a true game-changer.