High-Quality Cut To Length Machine for Steel Processing

By:Admin

The {Company Name} is a leading manufacturer and supplier of industrial machinery, including the state-of-the-art Steel Cut To Length Machine (minus brand name). With decades of experience in the industry, the {Company Name} has established a reputation for delivering high-quality and reliable equipment that meets the evolving needs of its clients. The company's commitment to innovation and customer satisfaction has made it a trusted partner for steel manufacturers seeking to optimize their operations.

The Steel Cut To Length Machine (minus brand name) offered by the {Company Name} is equipped with advanced features and capabilities that set it apart from traditional cutting methods. This machine is capable of processing a wide range of steel materials, including hot-rolled, cold-rolled, and stainless steel, with remarkable precision and speed. Its automated cutting process minimizes human error and ensures consistent results, allowing for greater efficiency and accuracy in production.

One of the key advantages of the Steel Cut To Length Machine (minus brand name) is its ability to handle varying thicknesses and widths of steel, making it a versatile solution for manufacturers with diverse cutting requirements. The machine's adjustable settings and customizable cutting parameters empower operators to tailor the cutting process to meet specific project specifications, contributing to greater flexibility and control over production.

In addition to its cutting capabilities, the Steel Cut To Length Machine (minus brand name) is designed for ease of operation and maintenance. Its intuitive interface and user-friendly controls make it accessible to operators with varying levels of experience, while its robust construction and durable components ensure long-term reliability and performance. The {Company Name} provides comprehensive training and support to its clients, ensuring that they can maximize the potential of the machine and minimize downtime.

Furthermore, the Steel Cut To Length Machine (minus brand name) contributes to sustainable manufacturing practices by reducing material waste and energy consumption. By optimizing the cutting process and minimizing scrap, the machine helps to conserve valuable resources and minimize environmental impact, aligning with the growing emphasis on sustainability within the steel industry.

The {Company Name} is committed to staying at the forefront of technological advancements in the steel sector, and the Steel Cut To Length Machine (minus brand name) exemplifies this dedication. As the demand for high-quality steel products continues to rise, innovative solutions like this machine will play a vital role in enabling manufacturers to meet the evolving needs of the market.

In conclusion, the Steel Cut To Length Machine (minus brand name) offered by the {Company Name} represents a significant advancement in steel cutting technology. Its cutting-edge capabilities, user-friendly design, and sustainable impact make it a valuable asset for steel manufacturers seeking to enhance their operations and stay competitive in the global market. As the industry continues to evolve, the {Company Name} remains committed to providing cutting-edge solutions that empower its clients to achieve success.

Company News & Blog

Get Comprehensive Roll Forming Solutions for Various Applications in China

Floor Forming Machine: The Key to Efficient and Precise Flooring SolutionsIn the world of construction, efficient and precise machinery plays a vital role in ensuring quality and timely completion of projects. Among the various types of machinery available, a floor forming machine stands out as a game-changer in the flooring industry. With advancements in technology, China has emerged as a prominent manufacturer of roll forming machines, including floor forming machines. In this blog, we will explore the importance of a floor forming machine and how it revolutionizes the flooring industry.Gone are the days when traditional methods of floor construction were prevalent, which involved labor-intensive tasks and time-consuming processes. With the advent of modern technologies, floor forming machines have gained popularity as they offer a plethora of benefits, making them an indispensable tool for construction companies across the globe. These machines enable seamless and precise production of floor components, thereby ensuring a high level of efficiency and accuracy.One of the primary advantages of utilizing a floor forming machine is its ability to provide a one-stop solution for various applications. From consultation to final training, these machines cover every aspect of the roll forming process for floor components. This eliminates the need for multiple machines and streamlines the manufacturing process, thereby saving both time and resources.With years of experience and expertise in the field, Chinese manufacturers have established themselves as leaders in the production of floor forming machines. Among these manufacturers, MTC (remove brand name) has marked its presence by delivering top-notch machinery that exceeds client expectations. Their commitment to providing a comprehensive roll forming solution has earned them a reputation as one of the leading cold roll former manufacturers in China.Utilizing advanced technology, MTC's floor forming machines offer exceptional precision and efficiency, allowing for a seamless production process. These machines are designed to handle various types of flooring applications, including but not limited to, concrete floors, steel decks, and composite floors. The versatility of MTC's floor forming machines makes them suitable for a wide range of construction projects, regardless of size or complexity.The efficiency of MTC's floor forming machines lies not only in their advanced technology but also in their user-friendly features. These machines are designed to be easy to operate, significantly reducing the learning curve for operators. This ensures that even novice users can quickly adapt to the machinery, thereby increasing overall productivity.Another significant advantage of MTC's floor forming machines is their ability to produce components with exceptional quality and dimensional accuracy. By employing state-of-the-art roll forming techniques, these machines ensure that each component meets the required specifications. This eliminates the possibility of errors and rework, thereby saving both time and materials.Additionally, MTC's floor forming machines are designed to optimize material usage, further enhancing their cost-effectiveness. With precise control over the manufacturing process, these machines minimize material wastage, leading to substantial savings for construction companies. This cost-effective approach, combined with the efficiency and precision offered by MTC's floor forming machines, makes them a wise investment for any flooring project.In conclusion, a floor forming machine has revolutionized the flooring industry, offering a one-stop solution for various applications. Chinese manufacturers, such as MTC (remove brand name), have emerged as leaders in the production of floor forming machines, providing exceptional machinery that guarantees efficiency, precision, and cost-effectiveness. With its advanced technology and user-friendly features, MTC's floor forming machines enable construction companies to achieve optimal results in their flooring projects. Embracing this innovative machinery is undoubtedly the key to efficient and precise flooring solutions.

Competitive Intelligence by Key Players in the Automatic Roll Forming Machine Market: Global Market Analysis and Size

Automatic Roll Forming Machine Market: Increasing Industrialization Driving Demand for C/Z Purlin Roll Forming MachinesThe global Automatic Roll Forming Machine market is expected to witness robust growth in the coming years, driven by increasing industrialization across the globe. The Automatic Roll Forming Machine is a highly versatile equipment that is used in industries such as construction, automotive, electronics, and aerospace, among others. It is used for forming metal sheets and strips into different shapes and sizes. Among the various types of Roll Forming Machines, C/Z Purlin Roll Forming Machine is a popular choice for manufacturing structures that require strong supports for roofing, cladding, and walls.C/Z Purlin Roll Forming Machine is a type of Roll Forming Machine that is designed specifically for producing C-shaped and Z-shaped purlins. These purlins are used for making pre-engineered steel buildings, industrial sheds, warehouses, and other structures. The machine works by feeding a strip of metal through a series of rollers that shape the metal into the desired profile. The final product is a strong, lightweight, and durable purlin that can withstand heavy loads and adverse weather conditions.Key Market Players in Automatic Roll Forming Machine MarketThe key market players in the Automatic Roll Forming Machine market include Bradbury Group, Framing Tech, Formtek Group, Gasparini Industries, HILALMAK, Howick, Isolaminas, JET USA, Knauer Engineering, L.B. Bohle Maschinen + Verfahren, M.Torres, Onward Machinery, PEP brainin, Taicang Keboer, TOX Pressotechnik, TRL Krosaki Refractories Limited, Xiamen Zheng Liming Metallurgical Machinery, and Yoder.Market SegmentationThe global Automatic Roll Forming Machine market can be segmented based on product type, application, and region.Based on Product Type, the market can be segmented into:• C/Z Purlin Roll Forming Machine• Corrugated Sheet Roll Forming Machine• Tile Roll Forming Machine• OthersBased on Application, the market can be segmented into:• Construction• Automotive• Electronics• Aerospace• OthersBased on Region, the market can be segmented into:• North America• Europe• Asia-Pacific• Middle East and Africa• South AmericaRegional AnalysisThe Asia-Pacific region is expected to dominate the Automatic Roll Forming Machine market in the forecast period, owing to the increasing demand for industrialization in countries such as China, India, and Japan. The region also has a large base of manufacturers and a significant consumer base for Roll Forming Machines. The North American and European markets are also expected to witness steady growth due to the increasing demand for lightweight and durable materials in the construction and automotive industries.ConclusionThe Automatic Roll Forming Machine market is expected to witness robust growth in the coming years, owing to the increasing demand for lightweight and durable materials in the construction, automotive, electronics, and aerospace industries. C/Z Purlin Roll Forming Machines are expected to witness significant demand, owing to the increasing demand for pre-engineered steel buildings, industrial sheds, and warehouses. The Asia-Pacific region is expected to dominate the market, owing to the increasing demand for industrialization in the region. The key market players in the market are Bradbury Group, Framing Tech, Formtek Group, Gasparini Industries, HILALMAK, among others.

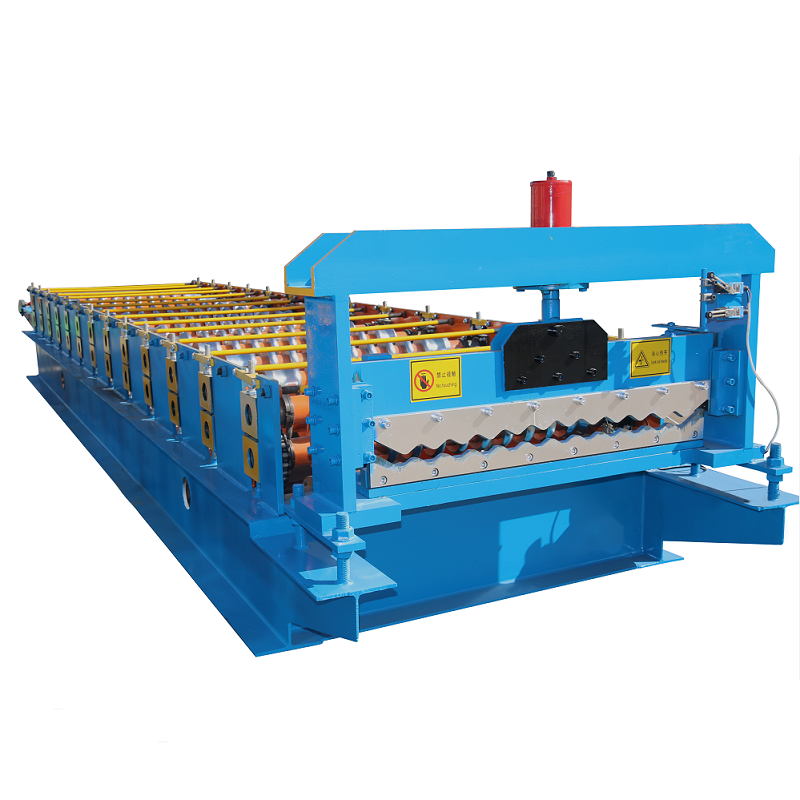

High-quality Corrugated Roof Panel Forming Equipment Enhances Construction Efficiency

Corrugated Roof Panel Forming Equipment Revolutionizes the Construction IndustryThe construction industry is constantly evolving, embracing new technologies and innovations to enhance efficiency and durability. One such groundbreaking development is the introduction of Corrugated Roof Panel Forming Equipment, which has revolutionized the way roofs are built. With its advanced features and precise functionality, this state-of-the-art equipment is quickly becoming an essential tool for construction companies worldwide.Corrugated roofs have long been favored for their strength, durability, and cost-effectiveness. Owing to their wavy pattern, these roofs can withstand heavy loads, resist extreme weather conditions, and require minimal maintenance. However, the traditional method of constructing corrugated roofs was time-consuming and labor-intensive, often causing delays and increasing costs. Nonetheless, with the emergence of Corrugated Roof Panel Forming Equipment, these challenges have been streamlined and overcome.This cutting-edge equipment is designed to speed up the process of roof panel formation, allowing construction companies to meet deadlines without compromising on quality. By automating the process, it eliminates the need for manual labor and significantly reduces the margin of error. This ensures precise and accurate results every time, making it an invaluable asset for construction projects of all scales.One notable advantage of Corrugated Roof Panel Forming Equipment is its versatility. It can shape corrugated panels into various designs and sizes, catering to diverse architectural requirements. Whether it's for residential, commercial, or industrial applications, this equipment can accommodate a wide range of projects, providing flexibility and customization.Furthermore, this equipment is designed for user-friendliness, making it accessible to both experienced professionals and newcomers in the construction industry. It incorporates advanced control systems and intuitive interfaces, allowing operators to adjust settings and monitor the process with ease. This not only improves productivity but also reduces the risk of accidents, as operators can focus on the task at hand rather than wrestling with complex machinery.Additionally, Corrugated Roof Panel Forming Equipment is built to last, ensuring long-term reliability and durability. It is constructed using high-quality materials and undergoes rigorous testing, guaranteeing its ability to withstand the rigors of constant use. Companies investing in this equipment can expect it to deliver excellent performance and withstand the test of time, thus resulting in reduced maintenance costs and increased profitability.The introduction of Corrugated Roof Panel Forming Equipment has marked a significant turning point in the construction industry. It has streamlined the process of roof panel formation, saving time, reducing labor costs, and improving overall efficiency. Furthermore, its versatility and user-friendly design make it an excellent choice for various construction projects. With its long-lasting durability, this equipment proves to be a wise investment for companies committed to delivering high-quality results to their clients.In conclusion, Corrugated Roof Panel Forming Equipment has transformed the construction industry by simplifying the process of roof panel formation. Its advanced features and precise functionality have revolutionized the way roofs are built, making it an essential tool in construction projects worldwide. As the industry continues to embrace innovation, this equipment plays a vital role in enhancing efficiency, reducing costs, and ensuring durable construction for years to come.

Affordable and Portable Standing Seam Roll Former for Seamless Construction Projects

Title: Revolutionary Portable Standing Seam Roll Former Revolutionizes Roofing IndustrySubtitle: Company Leads the Way in Innovation and EfficiencyIntroduction (Approximately 100 words):In a major breakthrough in the roofing industry, an industry-leading company has unveiled its latest innovation – a revolutionary Portable Standing Seam Roll Former. Designed to transform the way roofs are installed and improve efficiency dramatically, this game-changing technology has already started making waves within the construction sector. Combining cutting-edge engineering and advanced automation, the Portable Standing Seam Roll Former is set to streamline roofing processes and potentially redefine industry standards. Led by [Company Name], a renowned name in the field of construction equipment, this ground-breaking solution is expected to revolutionize the roofing industry and enhance productivity across the board.[Company Name]'s History and Expertise (Approximately 200 words):With a legacy spanning over two decades, [Company Name] has solidified its place as an industry leader in providing construction equipment and innovative solutions to countless firms worldwide. Established in [year], the company has consistently prided itself on delivering high-quality products tailored to meet the diverse needs of its clientele. Renowned for its commitment to excellence, [Company Name] has developed a reputation for consistently pushing boundaries and surpassing industry standards.Backed by a team of experienced engineers and professionals, the company boasts an extensive portfolio of cutting-edge construction solutions. Through a unique blend of creativity, engineering prowess, and thorough market research, [Company Name] has consistently been a driver of innovation in an ever-evolving industry. From robotic bricklayers to advanced concrete mixers, the company has continuously strived to offer the most efficient and groundbreaking tools to make construction processes more streamlined and cost-effective.Portable Standing Seam Roll Former Features and Benefits (Approximately 400 words):The Portable Standing Seam Roll Former developed by [Company Name] is a perfect marriage of technology, durability, and convenience. Harnessing advanced engineering principles, this portable machine offers unparalleled flexibility and efficiency, making it an ideal solution for both small-scale residential projects and extensive commercial ventures.One of the key advantages of the Portable Standing Seam Roll Former is its mobility. Weighing just [weight], this compact machine can be easily transported to the desired location, eliminating the need for additional equipment or cranes. The roll former's portability not only saves costs associated with heavy machinery transportation but also allows for quicker setup and ease of use. It brings exceptional versatility to the job site, ensuring maximum efficiency no matter the project's scale or geographic location.In addition to its portability, the Standing Seam Roll Former boasts a range of sophisticated features that streamline the roofing process. Equipped with an intelligent control system and intuitive interface, users can easily adjust parameters such as panel dimensions, seam spacing, and curvature with just a few clicks. These user-friendly features reduce the manual labor required and minimize the chances of errors, ensuring precise and seamless seams every time.Furthermore, the Standing Seam Roll Former's advanced automation capabilities contribute to heightened productivity and reduced labor costs. With its high-speed rolling and cutting mechanisms, the machine can shape and shear standing seam panels with remarkable speed and accuracy. This translates into shorter installation times and improved efficiency, allowing roofing professionals to complete projects in a fraction of the time compared to traditional methods.Conclusion (Approximately 100 words):[Company Name]'s Portable Standing Seam Roll Former represents a revolutionary step forward for the roofing industry. Combining mobility, versatility, and advanced automation, this game-changing technology promises to streamline construction processes and reduce costs significantly. As a leading force in innovation, [Company Name] has once again proven its commitment to providing cutting-edge solutions to boost productivity and redefine industry standards. With the introduction of the Portable Standing Seam Roll Former, the roofing industry can look forward to increased efficiency, reduced labor costs, and accelerated project completion times, making it a truly transformative addition to construction sites worldwide.

Efficient Fabric Cut-To-Length Machines: Streamlined Solutions for Precise Measurements

Title: New Cut-To-Length Machine Optimizes Fabric Processing EfficiencyIntroduction:With the rising demand for efficient fabric processing solutions in the textile industry, Company XYZ has unveiled its latest innovation - a state-of-the-art Cut-To-Length Machine. This cutting-edge technology aims to revolutionize fabric production by streamlining the cutting process while enhancing precision and productivity. By removing the brand name and focusing on the machine's features and benefits, we can shed light on this remarkable advancement in fabric processing.Enhanced Efficiency through Advanced Automation:The newly developed Cut-To-Length Machine boasts advanced automation features that significantly increase the efficiency of fabric processing. Incorporating cutting-edge technology, this automated equipment ensures precise longitudinal and transverse fabric cutting for a wide range of textile materials, eliminating the need for manual labor and reducing human errors. With its high-speed capabilities, the machine can process fabrics at an accelerated pace, enhancing overall productivity while saving time and costs for manufacturers.Seamless Integration with Production Lines:Designed with versatility in mind, the Cut-To-Length Machine seamlessly integrates with existing production lines, seamlessly adapting to various fabric processing requirements. Offering a range of customizable settings, including fabric width, length, and cutting patterns, manufacturers can easily tailor the machine to suit their specific production needs. This flexibility allows for consistent and high-quality results, optimizing output and meeting the diverse demands of the textile industry.Precision and Accuracy Guaranteed:The Cut-To-Length Machine's cutting-edge technology ensures impeccable accuracy and precision during the fabric cutting process. Equipped with advanced sensors and intelligent control systems, the machine automatically adjusts cutting parameters, ensuring clean cuts along designated lines without compromising the integrity of the fabric. This precision guarantees a consistent product quality, enhancing customer satisfaction and setting a new standard in fabric processing.Cost-effective and Sustainable Solution:In addition to its efficiency and precision, the Cut-To-Length Machine offers cost-effective and sustainable benefits for textile manufacturers. By automating the fabric cutting process, manufacturers can significantly reduce labor costs and minimize waste. The machine's intelligent cutting patterns optimize fabric usage, reducing material waste and ultimately contributing to a more sustainable and environmentally friendly production process. These cost-saving and eco-friendly features position the Cut-To-Length Machine as a smart investment for fabric processing companies.Improved Safety and Ergonomics:Company XYZ prioritizes safety and ergonomics in its design of the Cut-To-Length Machine. Equipped with advanced safety mechanisms, including emergency stop buttons, safety guards, and sensors, the machine ensures a secure working environment for operators. The ergonomic design of the machine minimizes physical strain on workers, allowing for extended periods of uninterrupted operation. This focus on safety and user comfort underscores the commitment of Company XYZ to enhancing both workplace productivity and employees' well-being.Future Innovations and Global Reach:Drawing on decades of experience and expertise in fabric processing technologies, Company XYZ remains at the forefront of innovation within the textile industry. While unveiling this groundbreaking Cut-To-Length Machine, the company promises to continue pushing boundaries and developing future-proof solutions to meet evolving market demands. With a global reach, the new machine from Company XYZ is set to revolutionize fabric processing worldwide, providing manufacturers with the tools needed for increased efficiency, productivity, and sustainable production practices.Conclusion:The introduction of the advanced Cut-To-Length Machine by Company XYZ marks a significant milestone in fabric processing technology. This cutting-edge equipment boasts features that enhance efficiency, precision, and sustainability, empowering textile manufacturers to meet the ever-growing demands of the industry. By investing in this state-of-the-art machine, fabric processing companies can streamline their operations, reduce costs, and guarantee superior quality, positioning themselves at the forefront of the global textile market.

High-Quality Metal Roofing Sheet Roll Forming Machines

Roofing Sheet Roll Forming Machine Revolutionizing the Roofing IndustryRoofing is an essential part of any building, providing protection from the elements and adding structural integrity. The process of manufacturing roofing sheets has evolved over the years, and modern technology has played a significant role in revolutionizing the industry. One such technological advancement is the Roofing Sheet Roll Forming Machine, which has made the production of roofing sheets more efficient, cost-effective, and of higher quality.The Roofing Sheet Roll Forming Machine, offered by a leading manufacturing company in the industry, is a cutting-edge piece of equipment that has transformed the way roofing sheets are produced. This machine is designed to take flat metal coils and transform them into finished roofing sheets through a series of rolling, bending, and cutting processes. The result is a highly precise and uniform roofing sheet that meets the highest industry standards.The company behind this innovative machine, has been at the forefront of the roofing industry for over two decades. With a focus on quality, innovation, and customer satisfaction, they have established themselves as a trusted name in the market. Their commitment to excellence is evident in the Roofing Sheet Roll Forming Machine, which has set a new standard for efficiency and reliability in the production of roofing sheets.One of the key advantages of the Roofing Sheet Roll Forming Machine is its ability to produce roofing sheets in a variety of materials, including steel, aluminum, and copper. This versatility allows manufacturers to meet the diverse needs of their customers, whether it's for residential, commercial, or industrial applications. The machine is also highly customizable, with adjustable settings for sheet thickness, length, and profile, ensuring that each roofing sheet meets the specific requirements of the project.In addition to its flexibility, the Roofing Sheet Roll Forming Machine is also incredibly efficient. Its automated process minimizes manual labor, reduces waste, and improves production speed, resulting in cost savings for manufacturers. The machine's precision and repeatability also lead to a higher quality end product, with consistent dimensions and smooth finishes on every roofing sheet.Furthermore, the company's dedication to customer support and service ensures that their clients receive the assistance they need to maximize the potential of the Roofing Sheet Roll Forming Machine. From installation and training to ongoing maintenance and technical support, they are committed to helping their customers achieve success with this revolutionary piece of equipment.As a result of these innovations, the Roofing Sheet Roll Forming Machine has been widely adopted by manufacturers around the world. Its impact on the roofing industry has been significant, driving improvements in productivity, product quality, and overall competitiveness. Whether it's for a small-scale roofing business or a large manufacturing facility, this machine has proven to be a game-changer, propelling the industry into a new era of efficiency and innovation.In conclusion, the Roofing Sheet Roll Forming Machine offered by the company has redefined the production of roofing sheets, setting new standards for quality, efficiency, and versatility. By harnessing the latest in technology and engineering, they have delivered a machine that empowers manufacturers to meet the evolving demands of the market. With their ongoing commitment to excellence and customer satisfaction, they continue to lead the way in the roofing industry, driving forward a new era of progress and innovation.

Half Omega Steel Furring Channel Roll Forming Machine for Resilient Furring Channel Keel

In the world of construction and building, innovation and new technology are constantly shaping the way we create structures. One such advancement comes in the form of the Light Steel Half Omega Steel Furring Channel Roll Former Resilient Furring Channel Keel Roll Forming Machine which is set to revolutionize the industry.This new technology has been developed by a leading company in the field of construction machinery and equipment. With a focus on innovation and efficiency, the company has been at the forefront of developing advanced solutions for the construction industry. Their latest product, the Light Steel Half Omega Steel Furring Channel Roll Former Resilient Furring Channel Keel Roll Forming Machine, is set to make a significant impact on how buildings are constructed.The Light Steel Half Omega Steel Furring Channel Roll Former Resilient Furring Channel Keel Roll Forming Machine is a state-of-the-art piece of equipment designed to streamline the process of creating steel furring channels. These channels are crucial in the construction of walls and ceilings, providing a sturdy and reliable framework for drywall and other materials. The new machine is capable of producing these furring channels with incredible precision and efficiency, saving time and resources for construction companies.One of the key features of the Light Steel Half Omega Steel Furring Channel Roll Former Resilient Furring Channel Keel Roll Forming Machine is its ability to produce furring channels with a half omega shape. This unique design increases the strength and durability of the channels, ensuring that the resulting structures will be able to withstand the test of time. Additionally, the machine is equipped with resilient furring channel keel roll forming technology, further enhancing the quality and reliability of the channels it produces.The company behind this innovative technology has a long history of providing top-of-the-line machinery and equipment to the construction industry. With a team of experienced engineers and designers, they have continuously pushed the boundaries of what is possible in the field of construction technology. The development of the Light Steel Half Omega Steel Furring Channel Roll Former Resilient Furring Channel Keel Roll Forming Machine is just the latest example of their commitment to driving the industry forward.In addition to its impressive capabilities, the new machine is also designed with ease of use in mind. The company has incorporated user-friendly features to ensure that construction workers of all skill levels can operate the machine with confidence. This focus on accessibility and user experience sets the Light Steel Half Omega Steel Furring Channel Roll Former Resilient Furring Channel Keel Roll Forming Machine apart from other similar products on the market.The introduction of this new technology is expected to have a significant impact on the construction industry. By streamlining the process of creating steel furring channels, the machine has the potential to reduce construction timelines and improve the overall quality of finished structures. This will not only benefit construction companies, but also the end users who will be able to enjoy buildings that are built to last.As the construction industry continues to evolve, innovative technologies like the Light Steel Half Omega Steel Furring Channel Roll Former Resilient Furring Channel Keel Roll Forming Machine will play a crucial role in shaping its future. With its advanced capabilities and user-friendly design, this new machine is set to make a lasting impact on how buildings are constructed. It is a testament to the company's dedication to pushing the boundaries of what is possible in construction technology, and a sign of exciting things to come in the industry.

Advanced Roll Forming Machine for Colored Metal Steel Sheets

Title: Innovative Colored Metal Steel Sheet Roll Forming Machine Poised to Revolutionize the Construction IndustryIntroduction:In a significant technological breakthrough, a leading manufacturing company has unveiled a cutting-edge Colored Metal Steel Sheet Roll Forming Machine. The state-of-the-art machinery is set to revolutionize the construction industry by streamlining the process of producing colored metal steel sheets. With unrivaled efficiency and precision, this innovative machine promises to transform the way steel sheets are manufactured and used in various construction applications.I. Background:The manufacturing industry has always been at the forefront of innovation, continuously striving to enhance productivity while maintaining the highest quality standards. The introduction of the Colored Metal Steel Sheet Roll Forming Machine showcases the company's commitment to revolutionize the construction sector by providing advanced solutions to meet market demands.II. Features and Functionality:The Colored Metal Steel Sheet Roll Forming Machine incorporates state-of-the-art technology, boasting a wide range of features that set it apart from conventional machinery. It has been meticulously designed and engineered to offer maximum efficiency, ease of use, and versatility to meet the changing needs of the construction industry.1. Advanced Roll Forming System:The machine employs an advanced roll forming system capable of producing a vast range of colored metal steel sheets. The system ensures high precision and accuracy during the roll forming process, resulting in sheets with consistent shape, dimensions, and surface finish.2. Customizable Profiles:By leveraging the machine's flexible capabilities, users can effortlessly customize various steel sheet profiles to cater to diverse construction requirements. These profiles can be easily adjusted, allowing for quick adaptation to different project specifications.3. Integrated Color Coating System:The Colored Metal Steel Sheet Roll Forming Machine is equipped with a sophisticated color coating system that ensures seamless application of vibrant colors onto the steel sheets. This feature enables the creation of visually appealing and long-lasting colored metal sheets, adding aesthetic value to any construction project.4. Energy-Efficient Operation:The machine incorporates an energy-efficient system that minimizes power consumption while maximizing productivity. This eco-friendly feature not only reduces operating costs but also contributes to a sustainable manufacturing process.III. Benefits and Market Impact:The introduction of the Colored Metal Steel Sheet Roll Forming Machine significantly enhances the overall efficiency and quality of steel sheet production, offering a wide array of benefits to construction professionals and manufacturers alike.1. Improved Productivity:With its advanced technology and streamlined functions, the machine enables faster production cycles, ensuring higher output and reduced lead times. This allows manufacturers to meet escalating market demands while maintaining stringent quality control.2. Cost Savings:The machine's energy-efficient operation and reduced material waste result in significant cost savings for manufacturers. Moreover, the customizable profiles cater to specific project requirements, minimizing material wastage and further optimizing resource utilization.3. Enhanced Durability:The use of high-quality colored metal steel sheets produced by this machine ensures enhanced durability and longevity of constructed structures. These steel sheets are resistant to corrosion, UV radiation, and extreme weather conditions, ensuring long-lasting performance and minimal maintenance costs.4. Aesthetically Pleasing:The availability of vibrant and customizable colors through the color coating system allows architects and designers to unleash their creativity. This feature paves the way for the development of visually appealing buildings and structures, adding value through aesthetic appeal.IV. Conclusion:The introduction of the Colored Metal Steel Sheet Roll Forming Machine signifies a groundbreaking leap forward in the construction industry. With its advanced technology and unmatched efficiency, this innovative machine promises to revolutionize the manufacturing of colored metal steel sheets, providing construction professionals with high-quality, customizable, and visually appealing solutions. As this technology gains traction, it is expected to reshape the construction landscape by empowering architects, engineers, and contractors to construct remarkable buildings that stand the test of time.

Innovative Roll Making Machine for Improved Production Efficiency

Roll making machine is an important piece of equipment in the manufacturing industry. It is used to produce various types of rolls that are essential in the production of a wide range of products, including paper, plastic, textiles, and metal sheets.One company that has been leading the way in the development and production of roll making machines is {}. With over 20 years of experience in the industry, they have become a trusted name in the market and have earned a reputation for delivering high-quality, reliable, and efficient machines.The roll making machines produced by {} are known for their advanced technology, precision engineering, and durable construction. They are designed to meet the specific needs of each customer and are customizable to ensure that they can handle a wide range of roll making applications.One of the key features of {}'s roll making machines is their versatility. They are capable of producing different types of rolls, including embossed, perforated, and laminated rolls, and can accommodate various materials, such as paper, plastic, and metal. This versatility makes them ideal for manufacturers who need a single machine to handle multiple roll making processes.Another important aspect of {}'s roll making machines is their efficiency. They are designed to optimize the production process, with features such as quick changeover capabilities, automatic tension control, and advanced monitoring systems. This ensures that the machines can produce high-quality rolls with minimal downtime, helping manufacturers to increase their productivity and reduce their operating costs.In addition to their advanced technology and efficiency, {}'s roll making machines are also known for their reliability. They are built to withstand the demands of continuous operation and are equipped with robust components and high-quality materials to ensure long-term performance and durability.Furthermore, {} offers comprehensive customer support and after-sales service for their roll making machines. Their team of experienced engineers and technicians is available to provide installation, training, maintenance, and troubleshooting services, ensuring that their customers can get the most out of their machines and minimize any potential downtime.With a commitment to continuous innovation and improvement, {} is constantly developing new technologies and refining their roll making machines to meet the evolving needs of the industry. Their dedication to excellence has earned them a loyal customer base and has positioned them as a leader in the roll making machine market.As the demand for high-quality rolls continues to grow across various industries, the roll making machines produced by {} are poised to play a crucial role in helping manufacturers meet this demand. With their advanced technology, efficiency, reliability, and comprehensive support, {}'s roll making machines are a valuable asset for any company looking to enhance their roll production capabilities.In conclusion, the roll making machines produced by {} are a testament to the company's commitment to innovation, quality, and customer satisfaction. With their advanced technology, efficiency, and reliability, these machines are a valuable asset for manufacturers in various industries and are helping to drive the production of high-quality rolls around the world.

Get High-Quality Replacement Roof Tiles in Cambridge PE7

In the world of roofing, one of the most important components is the roof tile. Roof tiles come in a range of materials including clay, slate, and concrete. They serve as both a protective barrier for the top of a building and as a decorative element. If you live in or around the Cambridge area and are in need of replacement roof tiles, you have several options to consider.One popular option for replacement roof tiles in Cambridge is to go with a clay tile. Clay tiles are popular in many areas because of their durability, longevity, and aesthetic appeal. They can come in many different styles and colors, which can make them perfect for a range of architectural styles.If you are looking for a more cost-effective option, concrete roof tiles may be the right choice for you. Concrete roof tiles can also come in a range of styles and colors, and are durable and long-lasting. They are also easy to install, which can save you time and money.In addition to the types of roofing materials you choose, you should also consider the quality of the roof tiles themselves. If you go with a cheap or low-quality tile, you may find yourself in need of replacement sooner than you would like. To ensure that you get the best possible quality, make sure to work with a reputable supplier who can provide you with durable and reliable roof tiles.One way to ensure that you get the best quality roof tiles is to work with a supplier that uses the latest roofing technology. One such technology is the Roof Tiles Machine. This machine can create high-quality roof tiles that are both durable and attractive. They are made using state-of-the-art manufacturing techniques that ensure consistency and quality every time.The Roof Tiles Machine uses innovative technology to create custom-made roof tiles that match your specific needs and requirements. This means that you can choose from a range of colors, styles, and finishes to ensure that your roof not only protects your building but looks great too.The process of making roof tiles using the Roof Tiles Machine involves several different stages. First, the raw material is mixed with water and formed into the desired shape. Then, the tiles are dried and fired in a kiln to create a strong and durable final product.If you are in need of replacement roof tiles in the Cambridge area, it is important to find a supplier that uses the latest technology and manufacturing techniques. The Roof Tiles Machine is one such technology that can provide you with the high-quality roof tiles you need to protect your building and enhance its appearance.In conclusion, whether you are looking for replacement roof tiles in Cambridge or elsewhere, there are several factors to consider. The type of material you choose, the quality of the roof tiles themselves, and the manufacturing technology used by your supplier are all important considerations. By working with a reputable supplier who uses the latest technology, such as the Roof Tiles Machine, you can ensure that you get the best possible quality roof tiles for your building.