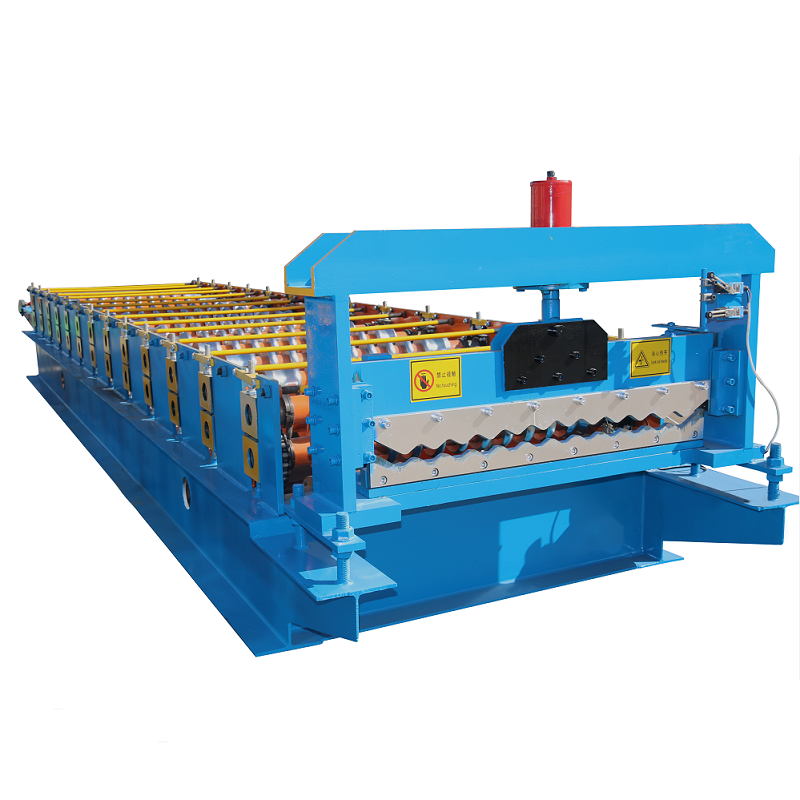

High-Quality Glazed Tile Corrugation Equipment for Color Steel Manufacturing

By:Admin

The Color Steel Glazed Tile Corrugation Equipment is equipped with advanced technology that enables it to produce tiles with intricate designs and smooth glazed finishes. The equipment is designed for durability and long-term performance, making it an ideal choice for manufacturers and contractors looking to produce high-quality roofing materials.

The company behind this advanced equipment is a leading manufacturer of construction machinery, with a strong focus on research and development. With years of experience in the industry, the company has established itself as a trusted provider of innovative solutions for the construction sector. The Color Steel Glazed Tile Corrugation Equipment is a testament to the company's commitment to excellence and customer satisfaction.

In addition to its advanced technology, the Color Steel Glazed Tile Corrugation Equipment is also known for its user-friendly design and ease of operation. The equipment is engineered to streamline the production process, allowing for increased productivity and cost savings for manufacturers. Its automated features and customizable options make it a versatile solution for a wide range of roofing and construction projects.

Furthermore, the Color Steel Glazed Tile Corrugation Equipment is designed with environmental sustainability in mind. The equipment utilizes energy-efficient processes and materials, reducing its carbon footprint and making it a responsible choice for environmentally conscious manufacturers.

The company's dedication to quality and innovation is reflected in the performance of the Color Steel Glazed Tile Corrugation Equipment. The equipment consistently delivers precise and high-quality results, meeting the stringent requirements of the construction industry. Its reliability and durability make it a valuable asset for manufacturers and contractors seeking to enhance their production capabilities.

The Color Steel Glazed Tile Corrugation Equipment has already garnered positive feedback from industry professionals who have praised its performance and capabilities. The equipment has been used in a variety of construction projects, ranging from residential buildings to commercial complexes, demonstrating its versatility and effectiveness in diverse applications.

In conclusion, the Color Steel Glazed Tile Corrugation Equipment represents a leap forward in the production of high-quality roofing materials. Its advanced technology, user-friendly design, and environmental sustainability make it a top choice for manufacturers and contractors in the construction industry. With the backing of a reputable and experienced company, this equipment is set to make a significant impact on the way steel roofing materials are produced and utilized. As the construction industry continues to evolve, the Color Steel Glazed Tile Corrugation Equipment stands out as a reliable and innovative solution for meeting the growing demand for top-notch construction materials.

Company News & Blog

High-Quality Metal Roof Sheet Making Machine for Sale

Metal Roof Sheet Making Machine Revolutionizes Roofing IndustryThe roofing industry has seen a significant advancement with the introduction of the Metal Roof Sheet Making Machine, a game-changing innovation that has revolutionized the way metal roofing sheets are manufactured. This cutting-edge machine, developed and manufactured by a leading machinery company, has set new standards for efficiency, productivity, and quality in the production of metal roof sheets.The Metal Roof Sheet Making Machine is a fully automated system that is capable of producing high-quality metal roof sheets with exceptional precision and speed. Equipped with state-of-the-art technology, this machine can handle various types of metal materials, including galvanized steel, aluminum, and stainless steel, making it extremely versatile and adaptable to different roofing requirements.One of the key features of the Metal Roof Sheet Making Machine is its ability to produce custom-designed roof sheets according to the specific needs and preferences of customers. This allows for a high level of flexibility and customization, enabling roofing companies to offer a wider range of products to their clients.In addition to its advanced technological capabilities, this machine is also designed with efficiency and cost-effectiveness in mind. By streamlining the manufacturing process and minimizing material waste, it helps companies reduce production costs and maximize their profitability. This is especially important in the current economic climate, where businesses are constantly looking for ways to improve their bottom line.Furthermore, the Metal Roof Sheet Making Machine is engineered for durability and reliability, ensuring long-term performance and minimal maintenance requirements. Its robust construction and high-quality components make it a sound investment for roofing companies looking to enhance their production capabilities.The company behind the Metal Roof Sheet Making Machine is a renowned manufacturer of industrial machinery with a strong track record of delivering innovative and reliable solutions to the market. With a commitment to excellence and customer satisfaction, the company has earned a solid reputation for its engineering expertise and dedication to quality.As a leader in the machinery industry, the company is continuously investing in research and development to stay at the forefront of technological advancements. The Metal Roof Sheet Making Machine is a testament to its commitment to innovation and its ability to meet the evolving needs of the market.In response to the growing demand for sustainable and energy-efficient building materials, the Metal Roof Sheet Making Machine is also designed to support green initiatives. By using metal roofing sheets produced by this machine, buildings can benefit from improved insulation, reduced energy consumption, and lower carbon emissions, contributing to a greener and more sustainable environment.The introduction of the Metal Roof Sheet Making Machine has already made a significant impact on the roofing industry, empowering companies to deliver superior products and services to their customers. With its advanced capabilities, efficiency, and flexibility, this machine is driving the industry towards a new era of excellence and innovation.In conclusion, the Metal Roof Sheet Making Machine represents a major leap forward for the roofing industry, offering a powerful solution for companies seeking to elevate their production capabilities and address the evolving needs of the market. With its cutting-edge technology, efficiency, and versatility, this machine is poised to shape the future of metal roofing and set new standards for quality and performance. As the industry continues to embrace innovation, the Metal Roof Sheet Making Machine stands out as a game-changing asset that is redefining the way metal roof sheets are manufactured.

Efficient and Innovative Roll Forming Machines for Panel Manufacturing

In today’s market, the need for quality and efficient panel roll forming machines has never been more apparent. As the construction industry continues to grow and evolve, manufacturers are looking to create products that can meet the needs of their clients while also maximizing productivity and profitability. One company that has successfully taken on this challenge is {company name}, a leading provider of roll forming technology.With over 20 years of experience in the industry, {company name} has established itself as a trusted name in roll forming machinery. They specialize in developing innovative solutions that can create a variety of profiles, including panel roll forming machines that are designed to handle a wide range of materials, such as steel, aluminum, and copper.One of their most popular machines is the panel roll forming machine. This machine is designed to produce panels that are used in a variety of applications, from roofing and siding to vehicle bodies and shipping containers. It allows manufacturers to create panels in a range of sizes, thicknesses, and shapes, making it an incredibly versatile machine.The panel roll forming machine offered by {company name} is known for its efficiency and ease of use. It is capable of producing panels at high speed, allowing manufacturers to achieve high levels of productivity. In addition, the machine is equipped with user-friendly controls, making it easy for operators to set up and run the machine.One of the key advantages of {company name}’s panel roll forming machine is its quality. Each machine is built to the highest standards, ensuring that it is durable and reliable. This not only reduces the risk of downtime and costly repairs but also ensures that the finished panels meet the required specifications.Another benefit of the panel roll forming machine from {company name} is its flexibility. The machine can be customized to meet the specific needs of each manufacturer, allowing for the creation of panels that are tailored to their unique requirements. This can help manufacturers to differentiate themselves in the market and provide their clients with a product that stands out from the competition.{Company name} also provides comprehensive support to their clients. This includes installation, training, and ongoing maintenance and support. Their team of experts can help manufacturers get the most out of their new machines, ensuring that they are able to achieve maximum productivity and profitability.In addition to their high-quality panel roll forming machine, {company name} also offers a range of other roll forming machines, including those for producing roofing and siding profiles, metal framing, and more. With their innovative solutions, dedication to quality, and commitment to customer support, {company name} is a company that is poised to continue to grow and thrive in the years ahead.As the construction industry continues to expand, the demand for high-quality roll forming machinery is only going to increase. Manufacturers will need to find innovative solutions that can help them keep up with demand while ensuring that they are able to achieve maximum efficiency and profitability. With {company name}’s panel roll forming machine, they have found a solution that meets all of these requirements and more.

Why Choose IBR Roofing Systems for Your Roof Sheeting Needs

When it comes to choosing a roofing system, there are numerous options available on the market. However, IBR roof systems have been gaining popularity due to their durability, strength, and versatility. This type of roofing is designed to withstand harsh weather conditions such as extreme temperatures, strong winds, and heavy rainfall.One of the main reasons IBR roof systems are a great choice is because of the Roof Sheeting Machine used to manufacture them. This machine is designed to evenly roll and cut metal sheets at high speeds, ensuring precision and accuracy in each piece. The result is a perfectly formed sheet that can be easily installed on any roofing structure.Another advantage of IBR roof systems is that they come in various thicknesses, ranging from 0.4mm to 0.8mm. This allows for customization depending on the needs of your specific roofing project. The thicker the sheet, the more durable it is, which means it will last longer and require less maintenance. Furthermore, IBR roof sheets are highly resistant to corrosion, making them ideal for coastal areas and regions with high levels of humidity.IBR roof systems are also highly versatile and can be used in a wide range of roofing applications. They can be easily installed on a variety of roofing structures, including residential homes, commercial buildings, and industrial facilities. Additionally, they can be molded and shaped to create unique roofing designs, adding to the aesthetic appeal of any building.In terms of cost-effectiveness, IBR roof systems are a great investment. They are relatively affordable compared to other roofing systems, and their durability and longevity mean that they require minimal maintenance and replacement over time. IBR roofs are also energy-efficient as they reflect the sun's rays, reducing the amount of heat absorbed by the building.Overall, IBR roof systems provide a range of benefits that make them a great choice for any roofing project. The precision and accuracy of the Roof Sheeting Machine used in their manufacturing ensure that each sheet is of the highest quality, while their strength, durability, and versatility make them a practical and cost-effective investment. Whether you are looking to install a new roof or replace an existing one, IBR roof systems are certainly worth considering.

Advanced Roll Forming Machine for Color Steel Tile Production: Discover the Latest News!

Color Steel Tile Roll Forming Machine Industry Analysis and Top PlayersThe Global Color Steel Tile Roll Forming Machine Market research report is a comprehensive analysis of the industry, focusing on key trends, market share, and growth opportunities. The report covers a detailed analysis of the market size, segmentation, and competitive landscape in various regions across the globe.Introduction:Color Steel Tile Roll Forming Machine (need to remove brand name) is a leading player in the roll forming machine industry. With its advanced technology and superior quality, the company has been providing efficient roll forming solutions to various industries. Their color steel tile roll forming machines are widely used in the construction industry for making high-quality roof and wall tiles.Color Steel Tile Roll Forming Machine Industry Analysis:The global color steel tile roll forming machine market is projected to grow at a significant rate in the coming years. The increasing demand for color steel tiles in the construction industry, coupled with the growing need for automated roll forming machines, is driving the market growth. The rise in urbanization and industrialization in developing countries is also contributing to the market expansion.The report highlights the key factors influencing the market, including the technological advancements in roll forming machines, the availability of raw materials, and the regulatory landscape. The increasing focus on sustainable construction practices and the use of eco-friendly materials is also expected to boost the demand for color steel tile roll forming machines.Segmentation Analysis:Based on product type, the color steel tile roll forming machine market can be segmented into single layer, double layer, and multiple layer machines. The single-layer machines are the most commonly used in the industry due to their simplicity and cost-effectiveness. However, the demand for double layer and multiple layer machines is expected to grow at a higher rate in the coming years, as they provide increased flexibility and efficiency in tile production.In terms of application, the market can be categorized into residential, commercial, and industrial sectors. The residential sector holds the largest market share, owing to the increasing construction of residential buildings. However, the commercial and industrial sectors are witnessing significant growth, driven by the construction of commercial complexes, warehouses, and manufacturing units.Competitive Landscape:Color Steel Tile Roll Forming Machine (need to remove brand name) is one of the key players in the market, with a wide range of innovative roll forming machines. The company focuses on research and development to introduce advanced technologies and enhance its product offerings. It also emphasizes strategic collaborations and partnerships to expand its distribution network and reach a wider customer base.Some of the other prominent players in the market include XYZ Company, ABC Corporation, and PQR Industries. These companies are also investing in research and development activities to improve their product portfolios and gain a competitive edge in the market.Conclusion:The global color steel tile roll forming machine market is witnessing significant growth, driven by the increasing demand for color steel tiles in the construction industry. The market is highly competitive, with key players focusing on technological advancements and partnerships to stay ahead. With the rise in urbanization and industrialization, the demand for efficient roll forming machines is expected to continue growing in the coming years.

Sheet Metal Roll Forming Machine for Horizontal Barrel Corrugated Sheets News Update

Title: Revolutionary Horizontal Barrel Corrugated Sheet Roll Forming Machine Set to Transform the Metal Manufacturing IndustryIntroduction:In a bid to revolutionize the metal manufacturing industry, an innovative company has introduced the groundbreaking Horizontal Barrel Corrugated Sheet Roll Forming Machine. This cutting-edge technology promises to offer unprecedented efficiency and accuracy, thus reducing production time and costs. With its seamless design and state-of-the-art features, this ingenious machine is poised to redefine the future of metal forming processes.Developed by a renowned company specializing in advanced machinery, the Horizontal Barrel Corrugated Sheet Roll Forming Machine aims to address the limitations of traditional roll forming methodologies. By incorporating advanced technological advancements, this revolutionary equipment exhibits remarkable capabilities, translating into enhanced productivity for metal manufacturers.Features and Technical Advancements:The Horizontal Barrel Corrugated Sheet Roll Forming Machine boasts a myriad of impressive features that make it stand out in the industry. A few of these notable features include:1. Innovative Design: The machine incorporates a horizontal barrel configuration, allowing for easier feeding and achieving a more precise corrugated sheet formation. This unique design ensures flawless output with minimal material wastage.2. High-Speed Production: Equipped with cutting-edge control systems, this machine offers faster production speeds compared to conventional roll forming equipment. This increased efficiency translates into higher output volumes and reduced production timelines.3. Customization: The machine offers flexible settings, enabling manufacturers to easily adjust the dimensions, thickness, and corrugation patterns of the sheets according to their specific requirements. This adaptability ensures the production of tailor-made metal sheets for various applications.4. Enhanced Accuracy: The precision engineering of the machine ensures consistently accurate dimensions, resulting in high-quality corrugated sheets that meet industry standards. This accuracy minimizes the need for additional processing or rectification, further streamlining the manufacturing process.Implications for the Metal Manufacturing Industry:The introduction of the Horizontal Barrel Corrugated Sheet Roll Forming Machine is set to have far-reaching implications for the metal manufacturing industry. Its numerous advantages and technical advancements hold significant potential to transform the way metal sheets are produced, offering benefits such as:1. Increased Efficiency and Cost Savings: The machine's faster production speeds and reduced material wastage significantly improve overall manufacturing efficiency. This, in turn, leads to substantial cost savings for metal manufacturers, making them more competitive in the market.2. Streamlined Supply Chain: The machine's customization capabilities enable manufacturers to swiftly adjust production parameters, resulting in shorter lead times and quicker response to customer demands. This streamlined supply chain ensures better customer satisfaction and increased market competitiveness.3. Improved Product Quality: With its heightened accuracy and precision, the Horizontal Barrel Corrugated Sheet Roll Forming Machine eliminates variations and defects often encountered in traditional manufacturing processes. The production of consistently high-quality metal sheets enhances product reliability and durability.4. Sustainability and Resource Optimization: The reduced material wastage, achieved through the machine's seamless design and precision engineering, significantly contributes to environmental sustainability. By optimizing resource utilization, metal manufacturing companies can significantly reduce their carbon footprint.Conclusion:The introduction of the Horizontal Barrel Corrugated Sheet Roll Forming Machine marks a significant milestone in the evolution of the metal manufacturing industry. With its innovative design, advanced features, and multiple benefits such as increased efficiency, reduced costs, and improved product quality, this revolutionary machine is set to redefine the future of metal forming processes. As more companies adopt this cutting-edge technology, the industry can expect to witness enhanced productivity, sustainability, and competitiveness.

PM Modi to participate in UN's Yoga Day, announces big preparations in India

Prime Minister Narendra Modi has announced that he will be participating in the upcoming United Nations' Yoga Day celebrations. According to the Prime Minister, plans for Yoga Day are well underway in the country, with preparations being made for a successful event.The upcoming Yoga Day celebration is not to be taken lightly. The United Nations first declared June 21st as International Yoga Day on December 11, 2014. The declaration was a result of a proposal made by Prime Minister Modi during his address to the United Nations General Assembly. Since then, every year on June 21st, people around the world come together to celebrate Yoga, which has become an integral part of Indian culture.According to the Prime Minister, the benefits of Yoga are well-known and he encourages all people to practice it regularly. With the ongoing pandemic, he also highlighted the importance of Yoga in boosting one's immunity and overall health. He thanked the nation for its enthusiastic participation in past Yoga Day celebrations and urged people to continue taking part in commemorating the day.In light of the pandemic, this year's Yoga Day celebrations may look different than previous years. The government has mandated strict guidelines to ensure the safety of individuals who will be participating in-person. However, participants are welcome to participate in the Yoga Day celebrations from their homes, which is a viable option given that technology has made it possible to partake in activities remotely.Furthermore, the Prime Minister emphasized that Yoga was not just an exercise practice but a way of life. He said that by practicing Yoga, people are not only taking care of their physical health but also enriching their spiritual and mental well-being. He also mentioned that Yoga is an excellent tool for managing stress and anxiety, which have become increasingly prevalent during the pandemic.The Prime Minister's participation in the Yoga Day celebration is likely to boost the morale of individuals who will be taking part in the event. His leadership has been instrumental in raising the profile of Yoga on the global stage. The government has also taken several measures to promote Yoga, such as initiating programs like the International Yoga Festival in Rishikesh, India, and creating the Ministry of AYUSH (Ayurveda, Yoga, and Naturopathy, Unani, Siddha, and Homeopathy) to promote traditional Indian medicine.In addition to the Prime Minister's announcement, the company {Profile Sheet Banane Ki Machine} has expressed their support for the event. They believe that Yoga is a universally beneficial practice that promotes a healthy lifestyle and mental well-being. They encourage individuals to take part in the Yoga Day celebration, whether in-person or remotely.In conclusion, the Prime Minister's announcement of his participation in the United Nations' Yoga Day celebrations is a significant development. It serves as an inspiration and encouragement for individuals to participate in commemorating an event that promotes physical, mental, and spiritual well-being. With preparations in full swing, the government and companies like {Profile Sheet Banane Ki Machine} are leading the way in making the event a success.

Maximizing Efficiency and Durability: A Comprehensive Guide to Roll Forming Techniques

article discussing the benefits and applications of roll forming in manufacturing.Roll Forming: A Highly Efficient Tool in Modern ManufacturingAs the manufacturing industry continues to evolve, new technologies and innovations are constantly emerging to meet the needs of the market and keep companies competitive. One of the tools that has gained popularity in recent years is roll forming, a process of shaping metal sheets or coils into specific shapes using specialized machinery.At its core, roll forming involves passing a continuous strip of metal through a series of rolls, each of which gradually bends the metal into the desired shape. The end result is a precisely formed product that can be used in a wide range of applications, from construction and automotive to aerospace and electronics.According to industry experts and manufacturers, roll forming offers several benefits over traditional metal forming processes. For one, it is highly efficient and can produce large volumes of parts quickly. Because the process is continuous, manufacturers can create long runs of parts without having to stop and start the machinery between each piece, which can help reduce downtime and increase productivity.Additionally, roll forming allows for greater flexibility in design and customization. With a wide range of roll forming tools and dies available, manufacturers can create complex shapes and profiles that would be difficult or impossible to achieve with other methods. This flexibility can be especially useful in industries with unique or specialized requirements, such as aerospace or medical device manufacturing.Another advantage of roll forming is its high level of precision and consistency. Because the machinery is designed to produce identical parts each time, manufacturers can ensure a high level of quality control and reduce the risk of defects or errors. This can help improve the overall reliability and durability of the final product, making it more appealing to customers and end-users.Roll forming is also a highly cost-effective process in many cases. The tooling required for roll forming can be expensive upfront, but the cost per part is typically much lower than with other metal forming methods due to the efficiencies of the process. Additionally, the ability to create long runs of parts without interruptions can help reduce labor costs and minimize scrap and waste.One company that has embraced roll forming as a core part of its manufacturing capabilities is (Total Roll Forming). The company specializes in creating custom roll formed parts for a wide range of industries, from construction and transportation to petrochemicals and telecommunications.According to (Total Roll Forming)’s website, the company utilizes a combination of state-of-the-art roll forming machinery and experienced technicians to create high-quality, precision parts. Their capabilities include forming a wide range of metals, including steel, aluminum, and copper, and creating parts in a variety of shapes and thicknesses.Some of the products that (Total Roll Forming) produces include metal roofing and siding panels, framing components for construction, and components for HVAC and electrical systems. They also offer custom roll forming services for clients who require specialized parts or unique shapes.Ultimately, roll forming is a powerful tool for modern manufacturers who seek to maximize efficiency, precision, and cost-effectiveness in their operations. Whether it is to create simple parts or complex profiles, this process offers a range of benefits that can help companies stay ahead of the competition and meet the demands of their customers.

Affordable and Top-Quality Floor Deck Roll Forming Machine in China: Unveiling the Best Supplier & Manufacturer

In the world of modern architecture, building structures that are both aesthetically pleasing and structurally sound is the ultimate goal. And no building can be truly complete without the right flooring system. The floor deck is an essential component of any building project, and it serves as the foundational layer for all other flooring materials. The floor deck not only provides structural support but also plays a significant role in the building's overall design and appearance. And this is where the Floor Metal Deck Roll Forming Machine comes in.The Floor Metal Deck Roll Forming Machine, also known as the Metal Floor Decking Tile Roll Forming Machine, is a specialized piece of equipment used to produce metal floor decking sheets. These sheets are commonly used in commercial and industrial constructions as they enhance the structural integrity of the building. The metal deck sheets produced by the machine are usually made of cold-rolled galvanized steel or aluminum, which can withstand the weight and stress of heavy loads.With a wide range of applications, the Floor Metal Decking Tile Roll Forming Machine is ideal for manufacturing metal decking sheets that can be used in roofing, flooring, and cladding systems. The machine's primary function is to produce metal floor decking sheets that have a uniform shape, thickness, and quality. This eliminates the need for on-site cutting, simplifying the installation process and saving time.Moreover, the roll forming process guarantees the uniformity of the metal decking sheets, which translates to improved structural stability and overall building safety. The metal decking sheets produced by the machine are highly durable, fire-resistant, and moisture-resistant, making them perfect for use in harsh environments.In terms of the machine's features, it is designed with automated controls, making it easy to operate, monitor and adjust. Its robust frame and stable base help to minimize vibrations during the production process, which ensures a more precise output. Additionally, the machine can be customized to produce decks of different sizes, shapes, and profiles to meet specific project requirements.With China Floor Deck Roll Forming Machine supplier & manufacturer, it's possible to purchase a high-quality Floor Metal Deck Roll Forming Machine at an affordable price. These machines are designed using advanced technology, and they undergo rigorous quality checks before being released to the market. Also, their low maintenance requirements and long lifespan ensure a lower cost of ownership.In conclusion, the Floor Metal Deck Roll Forming Machine is an essential tool for anyone involved in the construction industry. It enables the production of highly durable, fire-resistant, and moisture-resistant metal decking sheets that can withstand the demands of heavy industrial and commercial applications. By investing in a Floor Metal Deck Roll Forming Machine, businesses can improve their productivity, reduce their overhead costs, and enhance the quality of their output. As a result, they can stay ahead of the competition and grow their business.

China's Top Supplier and Manufacturer of High-Quality Light Keel Roll Forming Machine - Unveiling Impressive Products

Title: Light Keel Roll Forming Machine: Revolutionizing the Construction IndustryIntroductionIn recent years, the construction industry has witnessed a significant shift towards efficient and cost-effective building techniques. One innovation that has gained immense popularity is the Light Keel Roll Forming Machine. This advanced machinery has transformed the way light keel components are produced, offering numerous benefits over traditional manufacturing methods. In this blog post, we will explore the remarkable advantages of the Light Keel Roll Forming Machine and delve into its exceptional capabilities.1. Understanding Light Keel Roll Forming MachineThe Light Keel Roll Forming Machine represents the pinnacle of precision manufacturing in the construction industry. Designed by leading manufacturers in China, this machine utilizes cutting-edge technology to create light keel components with remarkable accuracy and efficiency. Unlike manual or semi-automatic forming processes, the Light Keel Roll Forming Machine automates the entire production procedure, eliminating the risk of human error and dramatically reducing time and labor costs.2. Enhanced Efficiency for Increased ProductivityBy implementing the Light Keel Roll Forming Machine, manufacturers can significantly boost their productivity. This machinery can seamlessly produce light keel components by swiftly transforming raw materials, such as steel coils, into precisely shaped profiles. With its high-speed production capability and uninterrupted workflow, the Light Keel Roll Forming Machine ensures a consistent output, meeting project deadlines and increasing overall efficiency.3. Customizable Design CapabilitiesWith the Light Keel Roll Forming Machine, customization options are limitless. Manufacturers can effortlessly adapt the machine's settings to create light keel components of varying lengths, widths, and thicknesses. This adaptability gives construction professionals the freedom to design and construct projects according to their exact specifications. Whether it's for residential, commercial, or industrial purposes, the Light Keel Roll Forming Machine enables the creation of tailor-made light keel structures.4. Unmatched Precision and ConsistencyOne of the key advantages of the Light Keel Roll Forming Machine is its unparalleled precision. The machine operates with meticulous accuracy, ensuring that each light keel component is shaped and cut to perfection. This consistency eliminates the need for additional manual adjustments or reworks, reducing material wastage and enhancing the overall product quality. The Light Keel Roll Forming Machine guarantees the production of uniform components that fit seamlessly within the construction process.5. Cost Savings and Increased ROIBy investing in the Light Keel Roll Forming Machine, manufacturers can experience substantial cost savings throughout the project lifecycle. The efficiency of this machinery drastically reduces labor costs and diminishes the need for additional manual labor. Moreover, the machine's precision minimizes material wastage, optimizing resource utilization and reducing overall expenses. The return on investment for the Light Keel Roll Forming Machine is undoubtedly impressive, making it an attractive option for construction companies of all sizes.ConclusionIn conclusion, the Light Keel Roll Forming Machine presents a revolutionary solution for the construction industry. Its advanced technology, efficiency, precision, and cost-saving benefits make it an invaluable asset for manufacturers worldwide. By harnessing the capabilities of the Light Keel Roll Forming Machine, construction professionals can streamline their production processes, deliver superior quality products, and ultimately remain at the forefront of innovation in the ever-evolving construction sector.Keywords: Light Keel Roll Forming Machine, light keel components, precision manufacturing, increased productivity, customization options, unmatched precision, cost savings, return on investment, construction industry.

Premium Steel Sheets: Cut-to-Length, Shear and Slitter Cut Services at Unbeatable Prices!

Title: Enhance Your Project's Efficiency and Quality with Hot Rolled Slitter Steel SheetsIntroductionIn today's fast-paced construction and manufacturing industries, the demand for high-quality steel sheets that can be customized to specific requirements is at an all-time high. Hot rolled steel sheets have become an exceptionally popular choice due to their durability and versatility.This blog aims to shed light on the benefits and applications of hot rolled steel sheets and the key role played by slitter cutting services in meeting the varied needs of different projects. So, let's delve deeper into the world of hot rolled slitter steel sheets!Understanding Hot Rolled Steel SheetsHot rolled steel sheets are produced through a process involving heating steel slabs above their recrystallization temperature, followed by cooling them to room temperature. This technique results in a flexible, strong, and malleable steel product that can be further processed to various specifications. The hot rolling process eliminates impurities, while the controlled cooling ensures uniformity and consistency in the sheet's strength.Applications and Advantages1. Versatility: One of the primary benefits of hot rolled steel sheets lies in their versatility. From automotive manufacturing and construction to machinery fabrication and shipbuilding, these sheets find application across a wide range of industries. Their strength and malleability allow for seamless forming and shaping, making them suitable for diverse projects.2. Durability: Hot rolled steel sheets are known for their exceptional durability. They can withstand heavy loads, extreme temperatures, and harsh environments, ensuring a longer lifespan for your projects. Whether it's a structural application or a component in heavy machinery, hot rolled steel sheets provide the necessary strength and resilience.3. Cost-effectiveness: With their cost-effective production process, hot rolled steel sheets offer excellent value for money. Affordable and readily available, they are a preferred choice for projects that demand a high-volume supply of steel sheets without compromising on quality.The Role of Slitter Cutting ServicesTo maximize the benefits of hot rolled steel sheets, slitter cutting services come into play. Slitter cut refers to the process of cutting wide coils of steel into narrower strips, catering to specific project requirements. This technique ensures precision and accuracy, ensuring that the sheets are tailored to the desired dimensions.Importance of Slitter Cutting1. Customization: Slitter cutting enables customization by accommodating different project needs. Sheets can be cut into a variety of widths, lengths, and thicknesses, ensuring an exact fit for your project requirements. This flexibility eliminates the need for additional processing and minimizes waste, thereby optimizing overall efficiency and cost-effectiveness.2. Simplicity and Time Efficiency: Slitter cutting services streamline the manufacturing process by providing ready-to-use steel strips. This eliminates the need for additional cutting and reduces the time and effort spent in modifying the sheets on-site. Better time management and enhanced simplicity contribute to meeting project deadlines and improving overall work efficiency.3. Precision and Quality: Slitter cutting techniques ensure precise and accurate cuts, resulting in high-quality steel strips. The accurate dimensions obtained through slitter cutting services reduce the risk of errors and ensure a perfect fit for your project's requirements. This level of precision translates into improved structural integrity and better overall performance.ConclusionHot rolled slitter steel sheets offer a range of benefits that meet the demands of various industries. Their versatility, durability, and cost-effectiveness make them an ideal choice for your projects. By employing slitter cutting services, you can further enhance the efficiency and quality of your projects. Customization, time efficiency, and precision are some of the significant advantages that slitter cutting brings to the table.When sourcing steel sheets, consider partnering with a reliable supplier offering hot rolled slitter steel sheets. By doing so, you can rest assured that you will receive quality products that are tailored to your exact requirements. Remember, investing in high-quality materials and services ensures the success and longevity of your projects in the long run.So, why wait? Embrace the versatility and reliability of hot rolled slitter steel sheets for your next construction or manufacturing project, and witness the remarkable difference it can make!