High-Quality Half Omega Steel Furring Channel Roll Former for Efficient Construction

By:Admin

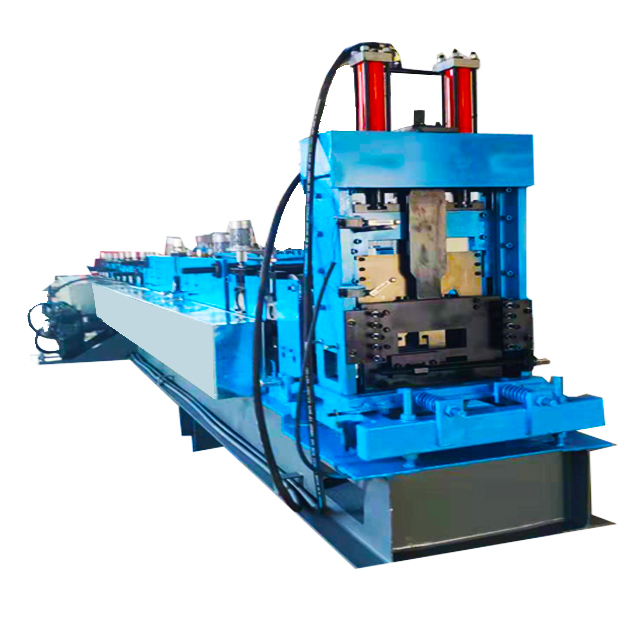

In response to this market demand, [Company Name] has introduced its latest innovation: the Light Steel Half Omega Steel Furring Channel Roll Former Resilient Furring Channel Keel Roll Forming Machine. This state-of-the-art machine has been designed and manufactured with precision engineering to meet the needs of modern construction projects.

The [Company Name] Light Steel Half Omega Steel Furring Channel Roll Former Resilient Furring Channel Keel Roll Forming Machine is equipped with advanced technology and features that ensure high-speed production, superior quality, and long-term reliability. Its ability to produce resilient furring channel keels with precision and efficiency makes it an indispensable asset for construction companies and steel frame manufacturers.

With a focus on durability and performance, the roll forming machine is constructed using high-quality materials and components. Its robust design and engineering ensure minimal maintenance requirements, reducing downtime and increasing productivity. Additionally, the machine is user-friendly, with intuitive controls and easy setup procedures, making it suitable for operators of all skill levels.

One of the key highlights of the [Company Name] Light Steel Half Omega Steel Furring Channel Roll Former Resilient Furring Channel Keel Roll Forming Machine is its versatility. It can produce a wide range of furring channel keel profiles, catering to the diverse needs of construction projects. Whether it's for residential, commercial, or industrial applications, this roll forming machine delivers exceptional results across the board.

Furthermore, the machine's production capacity and speed are impressive, ensuring that large volumes of furring channel keels can be manufactured within tight project timelines. This is particularly beneficial for construction companies working on time-sensitive projects where efficient production is crucial.

[Company Name] has a strong reputation for delivering reliable and innovative roll forming solutions to the market. With a commitment to continuous research and development, the company has consistently raised the bar in terms of quality, performance, and customer satisfaction. The introduction of the Light Steel Half Omega Steel Furring Channel Roll Former Resilient Furring Channel Keel Roll Forming Machine is a testament to [Company Name]'s dedication to meeting the evolving needs of the construction industry.

As a company, [Company Name] is not only focused on providing cutting-edge machinery but also on building long-term partnerships with its clients. The company offers comprehensive support services, including installation, training, and aftersales assistance, ensuring that customers can maximize the benefits of their investment in the roll forming machine.

In conclusion, the introduction of the Light Steel Half Omega Steel Furring Channel Roll Former Resilient Furring Channel Keel Roll Forming Machine by [Company Name] is set to make a significant impact in the construction industry. Its advanced capabilities, reliability, and versatility position it as a game-changer in the production of resilient furring channel keels. With [Company Name]'s track record of excellence and commitment to customer satisfaction, the roll forming machine is bound to set new standards for efficiency and quality in construction projects.

Company News & Blog

Master the Art of Making Authentic Pasta at Home with a Manual Pasta Machine

Title: Master the Art of Homemade Pasta with a Manual Pasta Machine Introduction (approximately 100 words):Fresh, homemade pasta is a culinary delight that can be easily made in the comfort of your own kitchen. With a few simple ingredients, you can create a variety of pasta dishes that will impress your family and friends. If you're new to the world of pasta making or looking to elevate your skills, investing in a manual pasta machine can make the process much easier and enjoyable. In this blog, we will explore the benefits of using a manual pasta machine and provide an in-depth guide on how to make authentic pasta at home. Body:1. The Advantages of Using a Manual Pasta Machine (approximately 200 words):A manual pasta machine offers numerous advantages when it comes to making homemade pasta. Here are some key benefits:a) Efficiency: A manual pasta machine helps streamline the process of rolling and shaping pasta dough, saving you time and effort compared to manual techniques.b) Consistency: With a pasta machine, you can achieve consistent thickness and shape throughout your pasta, ensuring even cooking and a professional result every time.c) Versatility: Manual pasta machines often come with a variety of attachments, allowing you to create different types of pasta, including spaghetti, fettuccine, and lasagna sheets.d) Authenticity: By using a manual pasta machine, you can replicate the traditional techniques used by Italian nonnas for generations, resulting in truly authentic pasta.2. Getting Started with a Manual Pasta Machine (approximately 200 words):Before diving into the pasta-making process, it's important to familiarize yourself with your manual pasta machine. While models may vary slightly, the general steps and techniques remain the same. Follow these guidelines to get started:a) Preparation: Begin by gathering your ingredients – typically flour, eggs, and salt – and combine them to form a dough. Allow the dough to rest for 30 minutes, as this will make it easier to work with.b) Setting up the Machine: Attach the appropriate cutting attachment to the machine, depending on the type of pasta you want to make. Most manual pasta machines have adjustable thickness settings, so start with the widest setting and gradually work your way down to achieve your desired thickness.c) Rolling the Dough: Divide the dough into manageable portions and flatten each one with your hands. Feed the dough through the machine, starting at the widest setting. Fold the dough in half after each pass and repeat this process until the desired thickness is achieved.d) Shaping the Pasta: Once the pasta sheet reaches the desired thickness, switch to the cutting attachment for your chosen pasta shape. Pass the pasta sheet through the machine, and voila! You have freshly cut pasta ready for cooking.3. Cleaning and Maintenance Tips for Your Manual Pasta Machine (approximately 200 words):To ensure your manual pasta machine remains in optimal condition and longevity, it's essential to follow proper cleaning and maintenance procedures. Here are some useful tips:a) Basic Cleaning: After use, wipe away any excess flour or dough from the machine using a dry cloth or brush. Avoid using water to clean the machine, as this can cause rusting or damage.b) Thorough Cleaning: Periodically, disassemble the machine as per the manufacturer's instructions and clean each component thoroughly. Use warm, soapy water and a soft brush to remove any stubborn residue.c) Drying and Storage: After cleaning, ensure that all parts of the machine are completely dry before reassembling and storing it in a dry place. Avoid exposure to humidity or extreme temperatures, as this can affect its performance.Conclusion (approximately 100 words):Investing in a manual pasta machine can transform your pasta-making experience, allowing you to effortlessly create authentic and delicious homemade pasta. Whether you're a culinary enthusiast or a novice in the kitchen, using a manual pasta machine will streamline the process, offering you consistent results and a variety of pasta types. With the right techniques and maintenance, you'll be able to enjoy countless pasta dishes that will rival those from your favorite Italian restaurant. So, why wait? Start your pasta-making journey today and unlock a world of culinary possibilities!Keywords: manual pasta machine, homemade pasta, authentic pasta, pasta-making, Italian nonnas, manual techniques, pasta dough, cutting attachment, cleaning and maintenance, pasta types.

New Steel Stud Forming Machine Revolutionizes Construction Industry

Steel Stud Forming Machine Revolutionizes the Construction IndustryThe construction industry has always been at the forefront of innovation and technology. From the development of new materials to the use of advanced machinery, there is a continual drive to improve efficiency, reduce costs, and increase quality. One such innovation that is making waves in the industry is the Steel Stud Forming Machine, which is revolutionizing the way steel studs are manufactured for use in construction projects.The Steel Stud Forming Machine is a state-of-the-art piece of equipment that is designed to quickly and efficiently produce steel studs of various shapes and sizes. This machine has the capability to form both standard and custom studs, allowing for greater flexibility in construction and design. Additionally, the machine is capable of producing studs at a much faster rate than traditional methods, leading to significant time and cost savings for construction companies.One company that is leading the way in the development and implementation of the Steel Stud Forming Machine is [Company Name]. With a strong focus on innovation and quality, [Company Name] has become a trusted partner for construction companies looking to improve their processes and reduce their environmental impact. The Steel Stud Forming Machine is just one example of how [Company Name] is bringing cutting-edge technology to the construction industry.The Steel Stud Forming Machine works by feeding a roll of steel into the machine, where it is then cut, punched, and formed into the desired shape and size. The entire process is automated, with minimal human intervention required, leading to greater efficiency and accuracy. The machine is also equipped with advanced safety features to ensure the protection of the operators and the production of high-quality studs.One of the key benefits of the Steel Stud Forming Machine is its ability to produce custom studs to meet specific project requirements. This level of flexibility allows for greater design freedom and the ability to tailor studs to fit the unique needs of each construction project. Additionally, the machine's high-speed production capabilities mean that construction projects can be completed much faster, leading to reduced overall costs and faster completion times.[Company Name] is proud to offer the Steel Stud Forming Machine as part of its commitment to providing innovative solutions for the construction industry. With a focus on sustainability and efficiency, [Company Name] is dedicated to helping construction companies reduce their environmental impact and improve their bottom line. The Steel Stud Forming Machine is just one example of how [Company Name] is working to bring cutting-edge technology to the construction industry.In addition to the Steel Stud Forming Machine, [Company Name] offers a wide range of other advanced equipment and technologies for the construction industry. From automated concrete mixers to energy-efficient lighting solutions, [Company Name] is always at the forefront of innovation and sustainability. By partnering with [Company Name], construction companies can access the latest technologies and equipment to improve their processes and reduce their environmental footprint.In conclusion, the Steel Stud Forming Machine is revolutionizing the construction industry by providing a faster, more efficient, and more flexible method for producing steel studs. With its ability to produce custom studs and its high-speed production capabilities, this machine is leading the way in modern construction practices. With companies like [Company Name] leading the charge, the construction industry is poised to continue its tradition of innovation and technology adoption for years to come.

Single Layer Color Steel Roll Forming Machine: All You Need to Know

Introducing a Revolutionary Single Layer Color Steel Roll Forming MachineThe [Company Name] is proud to announce the launch of their latest innovation in the field of metal forming equipment - the Single Layer Color Steel Roll Forming Machine. This state-of-the-art machine promises to revolutionize the process of creating color steel roofing and wall panels, offering unmatched precision, efficiency, and reliability.With a strong focus on research and development, [Company Name] has been at the forefront of metal forming technology for over a decade. The company's team of engineers and designers have worked tirelessly to create a machine that addresses the most common challenges faced by manufacturers in the industry. The result is a cutting-edge roll forming machine that sets new standards for quality and performance.One of the key features of the Single Layer Color Steel Roll Forming Machine is its advanced design, which allows for the rapid and precise shaping of color steel sheets. This is achieved through a combination of high-quality materials, innovative engineering, and precision manufacturing techniques. The machine is also equipped with a range of advanced control systems, enabling operators to fine-tune the production process and produce panels of the highest quality with minimal waste.In addition to its superior performance, the Single Layer Color Steel Roll Forming Machine also offers unparalleled flexibility. It is capable of producing a wide variety of panel designs, allowing manufacturers to meet the diverse needs of their customers. Whether it's a simple corrugated panel or a complex architectural profile, this machine can handle it with ease. This level of versatility is a game-changer for manufacturers, enabling them to take on a wider range of projects and expand their capabilities.Furthermore, the machine is designed with ease of use in mind. Its intuitive interface and user-friendly controls make it simple for operators to set up and operate the machine, reducing the need for extensive training and minimizing the risk of errors. This not only saves time and money but also ensures consistent quality in every panel produced.The launch of the Single Layer Color Steel Roll Forming Machine represents a major milestone for [Company Name]. It reflects the company's commitment to innovation and its dedication to providing the industry with the most advanced and reliable equipment available. With this new machine, [Company Name] is poised to set new benchmarks for quality, efficiency, and customer satisfaction in the metal forming industry.In order to ensure that customers can make the most of this groundbreaking technology, [Company Name] is offering comprehensive support and after-sales service. This includes installation assistance, training programs, and ongoing maintenance and technical support. This further underscores the company's commitment to customer success and satisfaction.As the global demand for high-quality color steel panels continues to grow, the launch of the Single Layer Color Steel Roll Forming Machine couldn't have come at a better time. Manufacturers in various industries, from construction to automotive, are now able to access a solution that will enable them to stay ahead of the competition and meet the evolving needs of their clients.In conclusion, the Single Layer Color Steel Roll Forming Machine from [Company Name] is a game-changing innovation that is set to redefine the way color steel panels are manufactured. With its cutting-edge technology, unmatched versatility, and user-friendly design, this machine is poised to become an indispensable asset for manufacturers around the world. For those looking to take their metal forming capabilities to the next level, the Single Layer Color Steel Roll Forming Machine is the ultimate solution.

Roll Forming Machine for Manufacturing Wall Panels

In recent years, there has been an increasing need for high-quality wall panels for use in a variety of applications, from commercial structures to residential homes. To meet this demand, a new system has been developed that has revolutionized the way that wall panels are manufactured. This system, known as the Wall Panel Roll Forming Machine, has quickly become one of the most popular and widely used technologies in the industry.The Wall Panel Roll Forming Machine is essentially a specialized piece of equipment that is designed to take a flat piece of raw material and transform it into a custom-fabricated wall panel. The machine operates on a continuous basis, allowing for a virtually uninterrupted flow of material and seamless production of large quantities of panels. This level of efficiency and consistency is critical for meeting the high demands of modern construction projects.Perhaps the most important aspect of the Wall Panel Roll Forming Machine is its versatility. It is capable of producing wall panels of virtually any size or shape, from standard rectangular panels to more complex designs with intricate curves and details. This opens up possibilities for architects and designers to create truly unique and impressive structures that were previously impossible to construct using traditional methods.One of the key advantages of the Wall Panel Roll Forming Machine is its automation. The technology used in the machine allows for precise control and accuracy in the manufacturing process. This reduces the need for human intervention, which not only increases efficiency but also reduces the chances of errors and defects in the final product. The end result is a high-quality wall panel that meets or exceeds all industry standards and is sure to provide years of reliable service.At the heart of the Wall Panel Roll Forming Machine is the roll forming process. In this process, a sheet of material is passed through a series of rollers that gradually bend and shape it into the desired form. The Wall Panel Roll Forming Machine uses a custom-designed set of rollers that are specifically tailored to the requirements of each individual project. This ensures maximum precision and accuracy in the finished product.Another key advantage of the Wall Panel Roll Forming Machine is its speed of production. Because the machine operates on a continuous basis, it is capable of producing large quantities of high-quality wall panels in a relatively short amount of time. This makes it an ideal solution for construction companies and contractors who need to meet tight deadlines and strict schedules.The Wall Panel Roll Forming Machine is also highly customizable. It can be tailored to fit the specific requirements of each individual project, allowing for a wide range of options in terms of materials, sizes, and shapes. This versatility makes it an ideal choice for architects and designers who need to create unique and innovative structures that require custom-made panels.In conclusion, the Wall Panel Roll Forming Machine is a cutting-edge technology that has changed the way that wall panels are manufactured. Its precision, speed, and versatility have made it an essential tool for construction companies and contractors who need to meet the demands of modern construction projects. With its automation and customization options, it is sure to continue to be a popular choice in the industry for years to come.

Advanced Roll Forming Machine for Colored Metal Steel Sheets

Title: Innovative Colored Metal Steel Sheet Roll Forming Machine Poised to Revolutionize the Construction IndustryIntroduction:In a significant technological breakthrough, a leading manufacturing company has unveiled a cutting-edge Colored Metal Steel Sheet Roll Forming Machine. The state-of-the-art machinery is set to revolutionize the construction industry by streamlining the process of producing colored metal steel sheets. With unrivaled efficiency and precision, this innovative machine promises to transform the way steel sheets are manufactured and used in various construction applications.I. Background:The manufacturing industry has always been at the forefront of innovation, continuously striving to enhance productivity while maintaining the highest quality standards. The introduction of the Colored Metal Steel Sheet Roll Forming Machine showcases the company's commitment to revolutionize the construction sector by providing advanced solutions to meet market demands.II. Features and Functionality:The Colored Metal Steel Sheet Roll Forming Machine incorporates state-of-the-art technology, boasting a wide range of features that set it apart from conventional machinery. It has been meticulously designed and engineered to offer maximum efficiency, ease of use, and versatility to meet the changing needs of the construction industry.1. Advanced Roll Forming System:The machine employs an advanced roll forming system capable of producing a vast range of colored metal steel sheets. The system ensures high precision and accuracy during the roll forming process, resulting in sheets with consistent shape, dimensions, and surface finish.2. Customizable Profiles:By leveraging the machine's flexible capabilities, users can effortlessly customize various steel sheet profiles to cater to diverse construction requirements. These profiles can be easily adjusted, allowing for quick adaptation to different project specifications.3. Integrated Color Coating System:The Colored Metal Steel Sheet Roll Forming Machine is equipped with a sophisticated color coating system that ensures seamless application of vibrant colors onto the steel sheets. This feature enables the creation of visually appealing and long-lasting colored metal sheets, adding aesthetic value to any construction project.4. Energy-Efficient Operation:The machine incorporates an energy-efficient system that minimizes power consumption while maximizing productivity. This eco-friendly feature not only reduces operating costs but also contributes to a sustainable manufacturing process.III. Benefits and Market Impact:The introduction of the Colored Metal Steel Sheet Roll Forming Machine significantly enhances the overall efficiency and quality of steel sheet production, offering a wide array of benefits to construction professionals and manufacturers alike.1. Improved Productivity:With its advanced technology and streamlined functions, the machine enables faster production cycles, ensuring higher output and reduced lead times. This allows manufacturers to meet escalating market demands while maintaining stringent quality control.2. Cost Savings:The machine's energy-efficient operation and reduced material waste result in significant cost savings for manufacturers. Moreover, the customizable profiles cater to specific project requirements, minimizing material wastage and further optimizing resource utilization.3. Enhanced Durability:The use of high-quality colored metal steel sheets produced by this machine ensures enhanced durability and longevity of constructed structures. These steel sheets are resistant to corrosion, UV radiation, and extreme weather conditions, ensuring long-lasting performance and minimal maintenance costs.4. Aesthetically Pleasing:The availability of vibrant and customizable colors through the color coating system allows architects and designers to unleash their creativity. This feature paves the way for the development of visually appealing buildings and structures, adding value through aesthetic appeal.IV. Conclusion:The introduction of the Colored Metal Steel Sheet Roll Forming Machine signifies a groundbreaking leap forward in the construction industry. With its advanced technology and unmatched efficiency, this innovative machine promises to revolutionize the manufacturing of colored metal steel sheets, providing construction professionals with high-quality, customizable, and visually appealing solutions. As this technology gains traction, it is expected to reshape the construction landscape by empowering architects, engineers, and contractors to construct remarkable buildings that stand the test of time.

Glazed Tile Roll Forming Machine - Industrial Steel Rolling Machines for Metal Roofing Sheet Production

Title: ZhongTuoCN Revolutionizes Roofing Industry with Advanced Glazed Tile Roll Forming MachineIntroduction:ZhongTuoCN, a renowned leader in the steel rolling machine industry, has unveiled its latest product, the Color Steel Glazed Roof Tile Roll Forming Machine. This advanced machinery has revolutionized the roofing industry by enabling the efficient production of high-quality metal glazed tiles. With its cutting-edge technology and precision engineering, ZhongTuoCN is empowering manufacturers to meet growing demands for durable and aesthetically pleasing roofing solutions.1. Meeting the Rising Demand for Glazed Roofing Tiles:The demand for glazed roofing tiles has been steadily increasing due to their exceptional durability, weather resistance, and stunning visual appeal. Recognizing this trend, ZhongTuoCN's engineers have developed a state-of-the-art roll forming machine specifically designed to cater to this niche segment. Manufacturers can now produce glazed tiles efficiently, ensuring timely delivery and meeting customer expectations.2. Cutting-Edge Technology Enhances Efficiency:The Color Steel Glazed Roof Tile Roll Forming Machine stands out for its advanced features, guaranteeing optimal efficiency. Equipped with state-of-the-art automation technology, this innovative machine minimizes human intervention, reducing labor costs and increasing productivity. With high-speed forming capabilities, it guarantees a smooth and streamlined production process, allowing manufacturers to meet large-scale orders efficiently.3. Unparalleled Precision and Durability:ZhongTuoCN's Glazed Tile Roll Forming Machine is meticulously engineered to deliver unmatched precision and durability. Its robust frame, constructed from high-quality steel, ensures long-term stability and reliability. The rollers are made from top-grade materials, facilitating seamless tile formation without any deformities. This ensures that every finished tile exhibits consistent dimensions and exceptional surface quality.4. Flexibility in Tile Design and Customization:In addition to its standard features, the Color Steel Glazed Roof Tile Roll Forming Machine provides manufacturers with unparalleled flexibility in tile design and customization. By incorporating adjustable features in the machine, manufacturers can easily tailor the dimensions, profile, and curvature of the glazed tiles to meet various customer requirements. This adaptability sets ZhongTuoCN's machinery apart from its competitors and allows clients to offer unique and personalized roofing solutions.5. Strict Quality Control and After-Sales Support:ZhongTuoCN prioritizes quality control throughout the manufacturing process. Each component of the Glazed Tile Roll Forming Machine undergoes stringent testing to ensure optimal performance and durability. Additionally, ZhongTuoCN provides comprehensive after-sales support, including installation guidance, training programs, and 24/7 technical assistance. This commitment to customer satisfaction has earned the company an excellent reputation in the industry.Conclusion:With the introduction of the Color Steel Glazed Roof Tile Roll Forming Machine, ZhongTuoCN has reaffirmed its position as a pioneer in the steel rolling machine industry. This cutting-edge technology guarantees exceptional efficiency, precision, and customization options for manufacturers in the roofing sector. By empowering clients to meet the rising demand for glazed tiles, ZhongTuoCN is revolutionizing the roofing industry and offering an unparalleled solution for businesses worldwide.

High-quality Corrugated Roof Panel Forming Equipment Enhances Construction Efficiency

Corrugated Roof Panel Forming Equipment Revolutionizes the Construction IndustryThe construction industry is constantly evolving, embracing new technologies and innovations to enhance efficiency and durability. One such groundbreaking development is the introduction of Corrugated Roof Panel Forming Equipment, which has revolutionized the way roofs are built. With its advanced features and precise functionality, this state-of-the-art equipment is quickly becoming an essential tool for construction companies worldwide.Corrugated roofs have long been favored for their strength, durability, and cost-effectiveness. Owing to their wavy pattern, these roofs can withstand heavy loads, resist extreme weather conditions, and require minimal maintenance. However, the traditional method of constructing corrugated roofs was time-consuming and labor-intensive, often causing delays and increasing costs. Nonetheless, with the emergence of Corrugated Roof Panel Forming Equipment, these challenges have been streamlined and overcome.This cutting-edge equipment is designed to speed up the process of roof panel formation, allowing construction companies to meet deadlines without compromising on quality. By automating the process, it eliminates the need for manual labor and significantly reduces the margin of error. This ensures precise and accurate results every time, making it an invaluable asset for construction projects of all scales.One notable advantage of Corrugated Roof Panel Forming Equipment is its versatility. It can shape corrugated panels into various designs and sizes, catering to diverse architectural requirements. Whether it's for residential, commercial, or industrial applications, this equipment can accommodate a wide range of projects, providing flexibility and customization.Furthermore, this equipment is designed for user-friendliness, making it accessible to both experienced professionals and newcomers in the construction industry. It incorporates advanced control systems and intuitive interfaces, allowing operators to adjust settings and monitor the process with ease. This not only improves productivity but also reduces the risk of accidents, as operators can focus on the task at hand rather than wrestling with complex machinery.Additionally, Corrugated Roof Panel Forming Equipment is built to last, ensuring long-term reliability and durability. It is constructed using high-quality materials and undergoes rigorous testing, guaranteeing its ability to withstand the rigors of constant use. Companies investing in this equipment can expect it to deliver excellent performance and withstand the test of time, thus resulting in reduced maintenance costs and increased profitability.The introduction of Corrugated Roof Panel Forming Equipment has marked a significant turning point in the construction industry. It has streamlined the process of roof panel formation, saving time, reducing labor costs, and improving overall efficiency. Furthermore, its versatility and user-friendly design make it an excellent choice for various construction projects. With its long-lasting durability, this equipment proves to be a wise investment for companies committed to delivering high-quality results to their clients.In conclusion, Corrugated Roof Panel Forming Equipment has transformed the construction industry by simplifying the process of roof panel formation. Its advanced features and precise functionality have revolutionized the way roofs are built, making it an essential tool in construction projects worldwide. As the industry continues to embrace innovation, this equipment plays a vital role in enhancing efficiency, reducing costs, and ensuring durable construction for years to come.

Get High-Quality Replacement Roof Tiles in Cambridge PE7

In the world of roofing, one of the most important components is the roof tile. Roof tiles come in a range of materials including clay, slate, and concrete. They serve as both a protective barrier for the top of a building and as a decorative element. If you live in or around the Cambridge area and are in need of replacement roof tiles, you have several options to consider.One popular option for replacement roof tiles in Cambridge is to go with a clay tile. Clay tiles are popular in many areas because of their durability, longevity, and aesthetic appeal. They can come in many different styles and colors, which can make them perfect for a range of architectural styles.If you are looking for a more cost-effective option, concrete roof tiles may be the right choice for you. Concrete roof tiles can also come in a range of styles and colors, and are durable and long-lasting. They are also easy to install, which can save you time and money.In addition to the types of roofing materials you choose, you should also consider the quality of the roof tiles themselves. If you go with a cheap or low-quality tile, you may find yourself in need of replacement sooner than you would like. To ensure that you get the best possible quality, make sure to work with a reputable supplier who can provide you with durable and reliable roof tiles.One way to ensure that you get the best quality roof tiles is to work with a supplier that uses the latest roofing technology. One such technology is the Roof Tiles Machine. This machine can create high-quality roof tiles that are both durable and attractive. They are made using state-of-the-art manufacturing techniques that ensure consistency and quality every time.The Roof Tiles Machine uses innovative technology to create custom-made roof tiles that match your specific needs and requirements. This means that you can choose from a range of colors, styles, and finishes to ensure that your roof not only protects your building but looks great too.The process of making roof tiles using the Roof Tiles Machine involves several different stages. First, the raw material is mixed with water and formed into the desired shape. Then, the tiles are dried and fired in a kiln to create a strong and durable final product.If you are in need of replacement roof tiles in the Cambridge area, it is important to find a supplier that uses the latest technology and manufacturing techniques. The Roof Tiles Machine is one such technology that can provide you with the high-quality roof tiles you need to protect your building and enhance its appearance.In conclusion, whether you are looking for replacement roof tiles in Cambridge or elsewhere, there are several factors to consider. The type of material you choose, the quality of the roof tiles themselves, and the manufacturing technology used by your supplier are all important considerations. By working with a reputable supplier who uses the latest technology, such as the Roof Tiles Machine, you can ensure that you get the best possible quality roof tiles for your building.

PM Modi to participate in UN's Yoga Day; massive preparations underway in India

Prime Minister Narendra Modi announced his participation in the United Nations' Yoga Day during his recent "Mann Ki Baat" address. He also stated that preparations for the event were extensively underway throughout the country.With an emphasis on holistic health and wellbeing, yoga has long been an essential part of the Indian lifestyle. Over the years, PM Modi has been a vocal proponent of yoga and has helped spread its benefits across India and the world. With the establishment of UN's International Yoga Day, India has further solidified its position as a global leader in this field.The International Yoga Day is celebrated annually on the 21st of June. It was first proposed by PM Modi during his address to the United Nations General Assembly in 2014, and it received unanimous support from the member nations. Since then, the day has been celebrated with great enthusiasm across the world, with people of different backgrounds and nationalities coming together to celebrate yoga and its benefits.This year, the event will be held with much fervor despite the ongoing COVID-19 pandemic. In keeping with the social distancing norms, events and celebrations will be conducted online. Through this, yoga enthusiasts and practitioners from different parts of the globe will participate in the event from the safety of their homes.In his address, PM Modi further highlighted the benefits of practicing yoga, particularly in light of the current circumstances. The pandemic has caused immense stress and anxiety, leading to a surge in mental health issues. Yoga, with its calming and relaxing effects, can play a significant role in alleviating these issues.The PM also called for the adoption of yoga as a way of life, instead of just viewing it as a form of physical exercise. He urged people to incorporate yogic practices into their daily routines and lifestyles to maintain physical and mental wellbeing.The preparations for Yoga Day are in full swing across the country, with organizations and individuals gearing up for the celebrations. Many yoga schools and institutions are conducting virtual classes and workshops to spread awareness about the importance and benefits of yoga.The enthusiasm around Yoga Day reflects the growing popularity of yoga worldwide. From Hollywood celebrities to sports stars, people from different walks of life have embraced yoga as a way of life. This has not only helped spread awareness about the practice but has also led to increased interest in Indian culture and traditions.In conclusion, PM Modi's announcement of his participation in UN's Yoga Day is a testament to his commitment to promoting yoga and its benefits. As the world continues to navigate through these challenging times, yoga offers a path towards physical, mental, and spiritual wellbeing. Its widespread adoption and acceptance can, therefore, help build a healthier and happier world.