How a Roofing Roll Former Can Benefit Your Next Project

By:Admin

With over 20 years of experience in the field, Roofing Roll Former has established itself as a trusted name in the industry. The company is known for its commitment to innovation, quality, and customer satisfaction. By continually investing in research and development, Roofing Roll Former has consistently delivered cutting-edge solutions to meet the evolving needs of the market.

The TRF-550 Roll Former is the latest addition to the company's extensive product line. This machine is capable of producing a wide range of roofing materials, including standing seam panels, corrugated panels, and other custom profiles. Its high precision and efficiency make it an ideal choice for both small-scale and large-scale roofing projects.

One of the key features of the TRF-550 Roll Former is its versatility. It is designed to accommodate various materials, including steel, aluminum, and copper, making it suitable for a diverse range of roofing applications. Additionally, the machine is equipped with advanced controls that allow for easy customization of panel profiles, ensuring that customers can achieve their desired aesthetic and functional requirements.

The TRF-550 Roll Former is also designed with the operator in mind. Its user-friendly interface and automated processes streamline production, reducing the need for manual intervention and minimizing the risk of errors. This not only enhances productivity but also ensures consistent quality in every finished product.

Furthermore, Roofing Roll Former's commitment to customer support sets it apart in the industry. The company provides comprehensive training and technical assistance to ensure that customers can maximize the potential of their investment in the TRF-550 Roll Former. This includes on-site support, remote troubleshooting, and access to a dedicated team of experts who are readily available to address any queries or concerns.

In addition to its focus on innovation and customer support, Roofing Roll Former remains dedicated to sustainability and environmental responsibility. The TRF-550 Roll Former is designed to minimize material wastage and energy consumption, aligning with the company's commitment to promoting eco-friendly practices within the industry.

As the construction industry continues to evolve, Roofing Roll Former stands at the forefront of innovation, delivering solutions that meet the demands of modern roofing projects. The introduction of the TRF-550 Roll Former further solidifies the company's position as a trusted partner for contractors, architects, and builders seeking reliable and efficient roofing solutions.

With its proven track record of excellence, Roofing Roll Former is poised to make a significant impact with the launch of the TRF-550 Roll Former. The company's unwavering dedication to quality, innovation, and customer satisfaction ensures that it will continue to be a leading force in the roofing industry for years to come.

Company News & Blog

Affordable and Efficient Steel Making Machine for Light Gauge Construction

Title: Revolutionizing the Construction Industry: Innovations in Light Gauge Steel Making MachinesIntroduction:In recent years, the construction industry has seen significant advancements that have revolutionized the way buildings are designed and constructed. One such groundbreaking innovation is the Light Gauge Steel Making Machine, developed by a pioneering company. This cutting-edge technology in steel construction offers remarkable advantages over traditional methods, providing strength, durability, and cost-effectiveness to modern infrastructure projects.Section 1: The Rise of Light Gauge Steel ConstructionIn the ever-evolving construction sector, light gauge steel construction has witnessed a surge in popularity due to its numerous benefits. Unlike conventional building materials such as wood or concrete, light gauge steel (LGS) exhibits exceptional strength-to-weight ratio, making it an ideal choice for both residential and commercial structures. It offers superior resistance to fire, termites, and environmental forces like earthquakes. This growing preference for LGS construction has led to the development of innovative machinery that streamlines the production process, such as the Light Gauge Steel Making Machine.Section 2: The Light Gauge Steel Making Machine: An OverviewDeveloped by the leading company {}, the Light Gauge Steel Making Machine is at the forefront of revolutionizing LGS construction. This machine automates the entire production process, from roll forming to cutting, bending, and punching, significantly reducing labor and time requirements. The state-of-the-art technology employed by this machine ensures precision, consistency, and high-quality end products, meeting the stringent standards of modern construction.Section 3: Advantages of Light Gauge Steel Making Machine3.1 Efficiency and Cost-effectiveness:By automating the production process, the Light Gauge Steel Making Machine enables faster and more efficient construction. The reduced labor requirements translate into cost-saving benefits, making LGS construction an economically viable option for a wide range of projects. Additionally, the machine ensures minimal material wastage, contributing to a more sustainable construction approach.3.2 Design Versatility:The Light Gauge Steel Making Machine offers unparalleled design versatility. It can create various profiles, shapes, and sizes, allowing architects and engineers to unleash their creativity. This flexibility in design empowers construction firms to cater to diverse client needs, thereby expanding the scope of their projects.3.3 Structural Integrity:One of the key advantages of LGS construction facilitated by the Light Gauge Steel Making Machine is its inherent structural integrity. Steel boasts exceptional tensile strength, ensuring that buildings remain sturdy and resilient. Moreover, the accurate fabrication process enabled by the machine guarantees consistency and precision in the construction, minimizing any structural defects.Section 4: Environmental SustainabilityThe Light Gauge Steel Making Machine promotes sustainable construction practices due to the inherent environmental benefits of LGS. Steel is a fully recyclable material, and its use significantly reduces deforestation and wastage of natural resources. Furthermore, by automating the fabrication process, the machine curtails energy consumption and carbon emissions, contributing to a greener construction industry.Section 5: Future Implications and ConclusionThe Light Gauge Steel Making Machine marks a significant turning point in the construction industry. Its efficiency, cost-effectiveness, design versatility, and environmental sustainability make it an ideal choice for architects, contractors, and developers. As this technology continues to advance, we can expect to witness a widespread adoption of LGS construction, transforming skylines and revolutionizing the way we build.In conclusion, the introduction of the Light Gauge Steel Making Machine by {} is a game-changer in the construction industry. With its numerous advantages, this innovative technology sets new benchmarks for efficiency, cost-effectiveness, design flexibility, and environmental sustainability. As the demand for modern infrastructure grows, it is clear that LGS construction, propelled by state-of-the-art machinery like this, is the way forward for the industry.

Metal Steel Roof Sheet Roll Forming Machine for Step Tile Production

In an effort to meet the growing demand for high-quality roofing materials, {Company Name} has recently announced the launch of their new Step Tile Metal Steel Roof Sheet Roll Forming Machine. The machine, which was developed by a team of experienced engineers and designers, is set to revolutionize the production of metal roofing sheets by offering improved efficiency and precision.The Step Tile Metal Steel Roof Sheet Roll Forming Machine is designed to produce step tile roof sheets, which are known for their durability and aesthetic appeal. With the ability to form metal sheets into precise, uniform shapes, this machine is expected to significantly reduce the time and labor required for manufacturing high-quality roofing materials.One of the key features of this new machine is its advanced automation capabilities. Equipped with state-of-the-art controls and sensors, the machine is able to continuously monitor and adjust the forming process to ensure consistently accurate results. This not only improves the overall quality of the roofing sheets but also minimizes material waste and production costs.In addition to its advanced automation, the Step Tile Metal Steel Roof Sheet Roll Forming Machine is also designed for user-friendly operation. Its intuitive interface and easy-to-use controls make it accessible to operators of varying skill levels, reducing the need for extensive training and supervision."We are thrilled to introduce our new Step Tile Metal Steel Roof Sheet Roll Forming Machine to the market," said {Company CEO}. "With its innovative design and advanced features, we believe that this machine will set a new standard for the production of metal roofing materials. We are confident that it will help our customers streamline their operations and deliver exceptional products to their clients."As a leading manufacturer and supplier of metal roofing materials, {Company Name} is committed to providing innovative solutions that meet the evolving needs of the construction industry. With the introduction of the Step Tile Metal Steel Roof Sheet Roll Forming Machine, the company is reaffirming its dedication to quality, efficiency, and customer satisfaction.The launch of this new machine comes at a time of increased demand for metal roofing materials, driven by the growing focus on sustainable and long-lasting construction solutions. By investing in advanced manufacturing technology, {Company Name} is positioning itself as a reliable partner for contractors, builders, and distributors seeking to source high-quality metal roofing products.In addition to the new Step Tile Metal Steel Roof Sheet Roll Forming Machine, {Company Name} offers a comprehensive range of metal roofing solutions, including various profiles, coatings, and colors to suit diverse architectural styles and project requirements. With a strong commitment to product innovation and customer service, the company has established itself as a trusted provider in the metal roofing industry.Looking ahead, {Company Name} plans to continue investing in research and development to further enhance its product offerings and manufacturing capabilities. By staying at the forefront of technological advancements, the company aims to anticipate market trends and deliver solutions that empower its customers to achieve their project goals efficiently and economically.The introduction of the Step Tile Metal Steel Roof Sheet Roll Forming Machine marks a significant milestone for {Company Name}, signaling its ongoing commitment to excellence and innovation in the metal roofing industry. With its cutting-edge design and performance, this machine is set to elevate the standard for metal roofing production and contribute to the advancement of sustainable and resilient construction practices.

Half Omega Steel Furring Channel Roll Forming Machine for Resilient Furring Channel Keel

In the world of construction and building, innovation and new technology are constantly shaping the way we create structures. One such advancement comes in the form of the Light Steel Half Omega Steel Furring Channel Roll Former Resilient Furring Channel Keel Roll Forming Machine which is set to revolutionize the industry.This new technology has been developed by a leading company in the field of construction machinery and equipment. With a focus on innovation and efficiency, the company has been at the forefront of developing advanced solutions for the construction industry. Their latest product, the Light Steel Half Omega Steel Furring Channel Roll Former Resilient Furring Channel Keel Roll Forming Machine, is set to make a significant impact on how buildings are constructed.The Light Steel Half Omega Steel Furring Channel Roll Former Resilient Furring Channel Keel Roll Forming Machine is a state-of-the-art piece of equipment designed to streamline the process of creating steel furring channels. These channels are crucial in the construction of walls and ceilings, providing a sturdy and reliable framework for drywall and other materials. The new machine is capable of producing these furring channels with incredible precision and efficiency, saving time and resources for construction companies.One of the key features of the Light Steel Half Omega Steel Furring Channel Roll Former Resilient Furring Channel Keel Roll Forming Machine is its ability to produce furring channels with a half omega shape. This unique design increases the strength and durability of the channels, ensuring that the resulting structures will be able to withstand the test of time. Additionally, the machine is equipped with resilient furring channel keel roll forming technology, further enhancing the quality and reliability of the channels it produces.The company behind this innovative technology has a long history of providing top-of-the-line machinery and equipment to the construction industry. With a team of experienced engineers and designers, they have continuously pushed the boundaries of what is possible in the field of construction technology. The development of the Light Steel Half Omega Steel Furring Channel Roll Former Resilient Furring Channel Keel Roll Forming Machine is just the latest example of their commitment to driving the industry forward.In addition to its impressive capabilities, the new machine is also designed with ease of use in mind. The company has incorporated user-friendly features to ensure that construction workers of all skill levels can operate the machine with confidence. This focus on accessibility and user experience sets the Light Steel Half Omega Steel Furring Channel Roll Former Resilient Furring Channel Keel Roll Forming Machine apart from other similar products on the market.The introduction of this new technology is expected to have a significant impact on the construction industry. By streamlining the process of creating steel furring channels, the machine has the potential to reduce construction timelines and improve the overall quality of finished structures. This will not only benefit construction companies, but also the end users who will be able to enjoy buildings that are built to last.As the construction industry continues to evolve, innovative technologies like the Light Steel Half Omega Steel Furring Channel Roll Former Resilient Furring Channel Keel Roll Forming Machine will play a crucial role in shaping its future. With its advanced capabilities and user-friendly design, this new machine is set to make a lasting impact on how buildings are constructed. It is a testament to the company's dedication to pushing the boundaries of what is possible in construction technology, and a sign of exciting things to come in the industry.

Advanced Manufacturing Equipment for Horizontal Profiled Panels

[Company Introduction]Company A is a leading manufacturer and supplier of advanced manufacturing equipment, with a focus on providing innovative solutions for the construction industry. With over 20 years of experience, the company has earned a reputation for delivering high-quality, reliable equipment to its customers. Company A is committed to continuously improving its products and services, and has a strong track record of meeting the evolving needs of the market.[News Content]Company A is proud to announce the launch of its latest innovation – the Horizontal Profiled Panel Manufacturing Equipment. This state-of-the-art machinery is set to revolutionize the production of horizontal profiled panels, offering an unmatched level of precision, efficiency, and versatility.The Horizontal Profiled Panel Manufacturing Equipment has been designed to meet the growing demand for advanced paneling solutions in the construction industry. With the ability to produce a wide range of panel profiles, including wall and roof panels, the new machinery is set to provide manufacturers with a competitive edge in the market.One of the key features of the Horizontal Profiled Panel Manufacturing Equipment is its advanced automation capabilities. The equipment is equipped with cutting-edge technology that allows for seamless operation and precise control over the manufacturing process. This not only ensures consistent quality output but also significantly reduces production times, leading to improved efficiency and cost savings for manufacturers.In addition to its automation capabilities, the Horizontal Profiled Panel Manufacturing Equipment also boasts a high degree of customization options. Manufacturers can easily adjust the settings to accommodate different panel dimensions, profiles, and material specifications, making it a versatile solution for a wide range of production requirements.Furthermore, the equipment is built with durability and reliability in mind, minimizing downtime and maintenance requirements. This will allow manufacturers to maximize their productivity and throughput, ultimately leading to increased profitability.The launch of the Horizontal Profiled Panel Manufacturing Equipment underscores Company A's commitment to innovation and customer-centric solutions. The company has leveraged its extensive industry knowledge and expertise to develop a product that not only meets but exceeds the expectations of its customers.With the introduction of the Horizontal Profiled Panel Manufacturing Equipment, Company A aims to address the evolving needs of the construction industry and provide manufacturers with a competitive advantage. By offering a cutting-edge solution that delivers superior performance and efficiency, the company is well-positioned to drive positive change within the industry.The new equipment also aligns with Company A's broader mission to deliver sustainable and environmentally-friendly solutions. By optimizing the manufacturing process and minimizing material waste, the Horizontal Profiled Panel Manufacturing Equipment contributes to a more resource-efficient and eco-friendly production approach.In conclusion, the unveiling of the Horizontal Profiled Panel Manufacturing Equipment represents a significant milestone for Company A and the construction industry as a whole. With its advanced capabilities and customer-focused design, the equipment is set to reshape the landscape of panel manufacturing, empowering manufacturers to achieve new levels of productivity and quality in their operations. Company A continues to be at the forefront of innovation, driving progress and success for its customers and the industry at large.

Advanced Roll Forming Machine for Colored Metal Steel Sheets

Title: Innovative Colored Metal Steel Sheet Roll Forming Machine Poised to Revolutionize the Construction IndustryIntroduction:In a significant technological breakthrough, a leading manufacturing company has unveiled a cutting-edge Colored Metal Steel Sheet Roll Forming Machine. The state-of-the-art machinery is set to revolutionize the construction industry by streamlining the process of producing colored metal steel sheets. With unrivaled efficiency and precision, this innovative machine promises to transform the way steel sheets are manufactured and used in various construction applications.I. Background:The manufacturing industry has always been at the forefront of innovation, continuously striving to enhance productivity while maintaining the highest quality standards. The introduction of the Colored Metal Steel Sheet Roll Forming Machine showcases the company's commitment to revolutionize the construction sector by providing advanced solutions to meet market demands.II. Features and Functionality:The Colored Metal Steel Sheet Roll Forming Machine incorporates state-of-the-art technology, boasting a wide range of features that set it apart from conventional machinery. It has been meticulously designed and engineered to offer maximum efficiency, ease of use, and versatility to meet the changing needs of the construction industry.1. Advanced Roll Forming System:The machine employs an advanced roll forming system capable of producing a vast range of colored metal steel sheets. The system ensures high precision and accuracy during the roll forming process, resulting in sheets with consistent shape, dimensions, and surface finish.2. Customizable Profiles:By leveraging the machine's flexible capabilities, users can effortlessly customize various steel sheet profiles to cater to diverse construction requirements. These profiles can be easily adjusted, allowing for quick adaptation to different project specifications.3. Integrated Color Coating System:The Colored Metal Steel Sheet Roll Forming Machine is equipped with a sophisticated color coating system that ensures seamless application of vibrant colors onto the steel sheets. This feature enables the creation of visually appealing and long-lasting colored metal sheets, adding aesthetic value to any construction project.4. Energy-Efficient Operation:The machine incorporates an energy-efficient system that minimizes power consumption while maximizing productivity. This eco-friendly feature not only reduces operating costs but also contributes to a sustainable manufacturing process.III. Benefits and Market Impact:The introduction of the Colored Metal Steel Sheet Roll Forming Machine significantly enhances the overall efficiency and quality of steel sheet production, offering a wide array of benefits to construction professionals and manufacturers alike.1. Improved Productivity:With its advanced technology and streamlined functions, the machine enables faster production cycles, ensuring higher output and reduced lead times. This allows manufacturers to meet escalating market demands while maintaining stringent quality control.2. Cost Savings:The machine's energy-efficient operation and reduced material waste result in significant cost savings for manufacturers. Moreover, the customizable profiles cater to specific project requirements, minimizing material wastage and further optimizing resource utilization.3. Enhanced Durability:The use of high-quality colored metal steel sheets produced by this machine ensures enhanced durability and longevity of constructed structures. These steel sheets are resistant to corrosion, UV radiation, and extreme weather conditions, ensuring long-lasting performance and minimal maintenance costs.4. Aesthetically Pleasing:The availability of vibrant and customizable colors through the color coating system allows architects and designers to unleash their creativity. This feature paves the way for the development of visually appealing buildings and structures, adding value through aesthetic appeal.IV. Conclusion:The introduction of the Colored Metal Steel Sheet Roll Forming Machine signifies a groundbreaking leap forward in the construction industry. With its advanced technology and unmatched efficiency, this innovative machine promises to revolutionize the manufacturing of colored metal steel sheets, providing construction professionals with high-quality, customizable, and visually appealing solutions. As this technology gains traction, it is expected to reshape the construction landscape by empowering architects, engineers, and contractors to construct remarkable buildings that stand the test of time.

Pros and Cons of Corrugated Metal Roofing: Cost, Installation, and Benefits

If you're considering a new roof for your home or business, you might want to take a closer look at corrugated metal roofing. This type of roofing has become increasingly popular in recent years, thanks to its many advantages over traditional roofing materials like asphalt shingles or tile. In this blog post, we'll take a closer look at corrugated metal roofing, its pros and cons, and why you should consider it for your next roofing project.What is Corrugated Metal Roofing?Corrugated metal roofing is made from sheets of galvanized steel or aluminum that have been shaped into corrugated waves or ridges. These ridges are what give the roofing its distinctive look, as well as its strength and durability. The sheets are typically installed over a layer of insulation, which helps to keep your home or business warm in the winter and cool in the summer.Pros of Corrugated Metal RoofingThere are many reasons to choose corrugated metal roofing over other types of roofing materials. Here are just a few of the pros:Durability: Corrugated metal roofing is incredibly strong and durable, which means it can withstand harsh weather conditions like heavy rain, hail, and high winds. It's also resistant to fire, rot, and pests like termites.Longevity: Because of its durability, corrugated metal roofing can last for many years with minimal maintenance. In fact, many manufacturers offer warranties of up to 50 years on their roofing products.Energy Efficiency: Corrugated metal roofing is highly reflective, which means it can help to keep your home or business cool in the summer by reflecting the sun's rays away from your roof. This, in turn, can help to lower your energy bills and reduce your carbon footprint.Low Maintenance: Unlike other types of roofing materials, corrugated metal roofing requires very little maintenance. You don't need to worry about repairing or replacing shingles like you would with an asphalt roof, and you don't need to worry about moss or algae growth like you would with a tile roof.Cons of Corrugated Metal RoofingWhile there are many advantages to corrugated metal roofing, there are also a few disadvantages to consider. Here are some of the cons:Cost: Corrugated metal roofing can be more expensive than traditional roofing materials like asphalt shingles, although the cost has come down in recent years. However, when you consider the durability and longevity of corrugated metal roofing, it can actually save you money in the long run.Sound: Some people find that corrugated metal roofing is louder than other types of roofing materials when it rains or hails. However, this can be mitigated by installing a layer of insulation between the roofing and the building.Appearance: Corrugated metal roofing has a distinctive look that may not be to everyone's taste. However, there are many different styles and colors of corrugated metal roofing available, so you're sure to find something that matches your aesthetic preferences.Why You Should Consider Corrugated Metal RoofingThere are many reasons to consider corrugated metal roofing for your home or business. Here are just a few:Durability: Corrugated metal roofing is incredibly strong and durable, which means it can withstand harsh weather conditions and last for many years with minimal maintenance.Energy Efficiency: Corrugated metal roofing is highly reflective, which can help to lower your energy bills and reduce your carbon footprint.Low Maintenance: Corrugated metal roofing requires very little maintenance compared to other types of roofing materials.Appearance: Corrugated metal roofing has a distinctive look that can add character and visual interest to your home or business.If you're considering a new roof for your home or business, be sure to explore all of your options before making a decision. Corrugated metal roofing offers many advantages over other types of roofing materials, and it just might be the perfect choice for your next roofing project.Corrugated Roofing Sheet Forming MachineTo ensure your corrugated metal roofing is made to the highest quality and specifications, it's important to work with a manufacturer who uses a high-quality corrugated roofing sheet forming machine. This machine is designed to create perfectly shaped corrugations in the metal roofing sheet, which ensures a secure fit and superior durability. At Regan Industrial, we use only the best machinery and materials to create our corrugated metal roofing products, so you can be confident that you're getting the best possible product for your home or business.

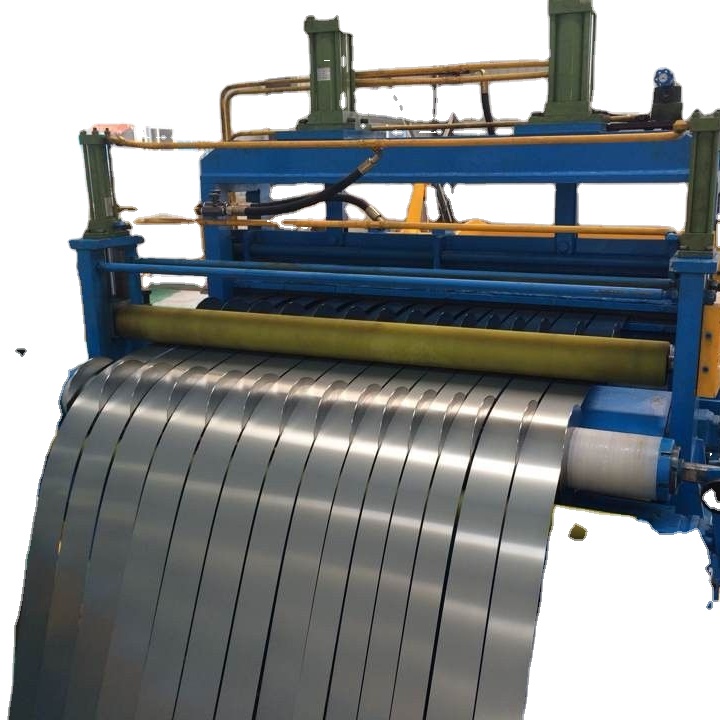

The Complete Guide to Coil Slitting Process: Techniques and Best Practices

The coil slitting process is a critical step in the manufacturing of various metal products, and it plays a crucial role in ensuring the quality and accuracy of the final product. {Company Name} is a leading manufacturer and distributor of steel products, and they have recently announced the introduction of a state-of-the-art coil slitting process at their manufacturing facility.The coil slitting process is a method of cutting wide coils of metal into smaller, narrower coils that are suitable for specific applications. This process is commonly used in the production of steel sheets, strips, and other metal products. {Company Name} has invested in the latest coil slitting technology to enhance their production capabilities and meet the growing demand for high-quality steel products in the market.With the new coil slitting process, {Company Name} is able to provide customers with a wider range of customization options for their steel products. The advanced machinery used in the process allows for precise and accurate cutting, resulting in coils that meet the exact specifications and requirements of the customer. This level of customization is essential for industries such as automotive, construction, and manufacturing, where specific dimensions and high-quality materials are crucial for the success of the final product.Furthermore, the new coil slitting process at {Company Name} allows for increased efficiency and productivity in their manufacturing operations. With the ability to produce smaller coils with minimal waste, the company can optimize their raw material usage and reduce overall production costs. This, in turn, allows {Company Name} to offer competitive pricing for their steel products while maintaining the highest standards of quality and precision.In addition to the technical capabilities of the new coil slitting process, {Company Name} also emphasizes the importance of sustainability and environmental responsibility in their manufacturing operations. The company has invested in environmentally friendly technologies and processes to minimize their carbon footprint and reduce waste in their production facilities. By implementing advanced coil slitting methods, {Company Name} is able to further enhance their sustainability efforts by reducing material waste and energy consumption.The introduction of the new coil slitting process at {Company Name} highlights their commitment to innovation and continuous improvement in their manufacturing capabilities. This investment in advanced technology will not only benefit the company in terms of increased productivity and cost-efficiency but also allow them to better serve their customers with a wider range of high-quality, customized steel products.{Company Name} is renowned for its dedication to excellence in the steel industry, and the introduction of the new coil slitting process is a testament to their ongoing efforts to push the boundaries of what is possible in steel manufacturing. With a strong focus on quality, precision, and sustainability, {Company Name} continues to set the standard for steel production and distribution, providing customers with the best-in-class products and solutions for their diverse steel needs.As the demand for high-quality steel products continues to grow in various industries, {Company Name} is well-positioned to meet and exceed the expectations of their customers with the superior capabilities of their new coil slitting process. The company's commitment to innovation and sustainability ensures that they remain a trusted partner for businesses seeking top-tier steel products and solutions in the global market.In conclusion, the introduction of the new coil slitting process at {Company Name} marks a significant milestone in their journey to provide the highest quality steel products to their customers. This investment in advanced technology not only enhances their manufacturing capabilities but also reflects their ongoing dedication to excellence, precision, and sustainability in the steel industry. With the new coil slitting process, {Company Name} is well-equipped to meet the evolving needs of their customers and continue to drive innovation in steel manufacturing for years to come.

Highly Accurate CNC Milling of Aluminum Extrusion Profiles

Aluminum Extrusion Milling Machine: Revolutionizing Precision and EfficiencyAluminum extrusion has become an integral part of various industries due to its lightweight, high strength, and versatility. From automotive to aerospace, electronics to construction, the demand for aluminum extrusion profiles is skyrocketing. However, in order to meet the ever-increasing demands, manufacturers need cutting-edge machinery and techniques. This is where aluminum CNC milling machines come into play.Precision is KeyTo produce high-quality aluminum extrusion profiles, precision is of utmost importance. Any slight deviation from the desired dimensions can lead to product failure. This is where the CNC (Computer Numerical Control) milling machines step in. These advanced machines use computer-controlled systems to execute complex milling operations with unmatched accuracy.The precision offered by aluminum CNC milling machines allows manufacturers to create intricate designs and shapes with high repeatability. From simple profiles to complex geometries, these machines can handle it all. This not only ensures consistency in the final product but also minimizes wastage, saving valuable resources and costs.High-Speed PerformanceApart from precision, speed is another crucial factor that determines the efficiency of aluminum extrusion production. Traditional machining methods are time-consuming, limiting the manufacturing capacity. In contrast, CNC milling machines offer enhanced productivity by virtue of their high-speed performance.Equipped with powerful spindles and cutting tools, CNC milling machines can quickly remove material from the aluminum billet, resulting in faster production cycles. The automated nature of these machines eliminates manual errors and speeds up the overall manufacturing process. This enables manufacturers to cater to large volumes of orders while maintaining the desired quality standards.Advanced Features for Enhanced FunctionalityCNC milling machines for aluminum extrusion profiles are equipped with a wide range of advanced features that further enhance their functionality. One such feature is the multi-axis capability. These machines can perform milling operations on multiple axes simultaneously, allowing for complex, three-dimensional profiling. This opens up a whole new world of design possibilities, expanding the horizons of aluminum extrusion applications.Furthermore, the CNC systems in these machines can be programmed to operate in a variety of modes. Whether it is contour milling, pocket milling, or face milling, the CNC milling machines can effortlessly handle all operations, ensuring seamless production processes.Sourcing High-Quality Aluminum Extrusion Milling MachinesTo experience the benefits of precision and efficiency offered by aluminum CNC milling machines, it is imperative to collaborate with reliable suppliers. When searching for OEM aluminum extrusion profile, high precision aluminum CNC milling suppliers, one name that stands out is aluminum-extrusion.At aluminum-extrusion, we specialize in providing top-notch aluminum extrusion profiles and CNC milling machines. With a focus on quality and affordability, we offer a wide range of products to cater to diverse industry requirements. Our expertise lies in delivering OEM aluminum extrusion profiles that meet the highest standards of precision and accuracy.ConclusionIn the fast-paced manufacturing industry, efficiency and precision are critical factors that can make or break a business. Aluminum extrusion milling machines offer the perfect solution to meet these demands. With their ability to deliver high precision, superior speed, and advanced functionality, these machines revolutionize the aluminum extrusion process.Collaborating with reputable suppliers like aluminum-extrusion ensures access to high-quality products that not only drive efficiency but also maintain the desired quality standards. So, embrace the power of aluminum CNC milling machines and unlock a world of possibilities for your aluminum extrusion profile manufacturing needs.

Top Quality Machinery for Forming Processes

Forming Machinery Celebrates Milestone AchievementForming Machinery, a global leader in the manufacturing of forming equipment, has recently achieved a significant milestone in its journey of providing top-quality machinery solutions to its customers. With an unwavering commitment to innovation, precision engineering, and customer satisfaction, the company has established itself as a trusted partner for businesses across various industries.With over [X] years of experience in the industry, Forming Machinery has continually pushed the boundaries of technology to deliver cutting-edge solutions that meet the evolving needs of its clientele. The company's dedication to research and development has enabled it to stay ahead of the curve and anticipate market trends, resulting in the creation of advanced, efficient, and reliable forming equipment.One of Forming Machinery's key strengths lies in its comprehensive product range, which includes [list of products]. From standard machines to custom-built solutions, the company has the capabilities to cater to a wide array of requirements, ensuring that its customers have access to the best machinery for their specific applications.The company's commitment to quality is evident in its state-of-the-art manufacturing facilities and stringent quality control measures. Every machine that bears the Forming Machinery name is a testament to the company's dedication to excellence, durability, and performance. Furthermore, the company also offers comprehensive after-sales support, spare parts availability, and technical assistance, ensuring that customers can maximize the value of their investments.In addition to its impressive product lineup, Forming Machinery takes pride in its team of highly skilled and experienced professionals. The company's engineers, technicians, and support staff are deeply passionate about their work and are driven by a shared vision of delivering unparalleled service to customers around the world. This team's expertise and dedication have been instrumental in establishing Forming Machinery as a benchmark for quality and reliability in the industry.As part of its ongoing commitment to innovation, Forming Machinery has consistently invested in research and development to drive the creation of next-generation forming equipment. The company's focus on technological advancement and continuous improvement has resulted in cutting-edge solutions that offer higher productivity, energy efficiency, and cost savings for its customers.Furthermore, Forming Machinery's dedication to sustainability is reflected in its efforts to develop eco-friendly manufacturing processes and energy-efficient machinery. By prioritizing environmental responsibility, the company aims to minimize its carbon footprint and promote sustainable practices within the industry.Looking to the future, Forming Machinery remains dedicated to upholding its reputation as a leader in the forming equipment sector. The company is steadfast in its commitment to delivering innovative solutions that exceed customer expectations, while also fostering long-term partnerships based on trust, reliability, and mutual success.As Forming Machinery celebrates this milestone achievement, it reaffirms its mission to continue setting new standards for excellence and serving as a driving force for positive change within the industry. With its unwavering dedication to quality, innovation, and customer satisfaction, the company is well-positioned to shape the future of forming machinery and make a lasting impact on businesses worldwide.

High-Quality Aluminum Profile Polishing Machine for Metal Finishing

Aluminum Profile Polishing Machine Helps Company Achieve High-Quality ProductsIn the fast-paced world of manufacturing, companies are constantly striving to enhance the quality of their products while also increasing efficiency. One crucial aspect of achieving this goal is the use of advanced machinery that can streamline production processes and improve the overall quality of final products. One company that has successfully incorporated cutting-edge technology into its operations is {Company Name}, a leading manufacturer of aluminum profiles.{Company Name} has recently implemented a state-of-the-art Aluminum Profile Polishing Machine, which has significantly improved the company's ability to produce high-quality aluminum profiles for a variety of applications. The machine, which has been carefully integrated into the company's production line, is capable of polishing aluminum profiles to a mirror-like finish, ensuring that the final products meet the highest standards of quality.The decision to invest in the Aluminum Profile Polishing Machine was driven by {Company Name}'s commitment to delivering exceptional products to its customers. By incorporating this advanced technology into its operations, the company has been able to elevate the quality of its aluminum profiles, setting it apart from its competitors in the industry.The Aluminum Profile Polishing Machine is equipped with advanced polishing techniques and precision controls, allowing {Company Name} to achieve a level of consistency and excellence that was previously unattainable. This has not only resulted in a significant improvement in the overall appearance of the aluminum profiles but has also enhanced their durability and resistance to corrosion, making them suitable for a wide range of applications in various industries.Furthermore, the integration of the Aluminum Profile Polishing Machine has had a notable impact on {Company Name}'s production efficiency. The machine's automated processes and efficient operation have helped to streamline the polishing process, reducing production lead times and increasing the company's overall output capacity. As a result, {Company Name} has been able to meet the growing demand for its high-quality aluminum profiles, without compromising on quality or consistency.The introduction of the Aluminum Profile Polishing Machine has also had a positive effect on the company's workforce. By automating certain aspects of the polishing process, {Company Name} has been able to redeploy its skilled workers to other areas of the production line, where their expertise and experience can create additional value. This has not only improved overall operational efficiency but has also enhanced employee satisfaction and morale within the organization.{Company Name} is proud to be at the forefront of technological innovation within the industry, and the successful incorporation of the Aluminum Profile Polishing Machine is a testament to the company's commitment to continuous improvement. By embracing advanced machinery and processes, {Company Name} is positioning itself as a leader in the manufacturing of high-quality aluminum profiles, meeting the ever-evolving needs of its customers and setting new standards for excellence in the industry.Moving forward, {Company Name} remains dedicated to investing in cutting-edge technology and equipment that will further enhance its production capabilities and product offerings. By staying ahead of the curve and embracing innovation, {Company Name} is poised to maintain its position as a trusted provider of premium aluminum profiles, delivering exceptional value to its customers and driving continued growth and success in the industry.