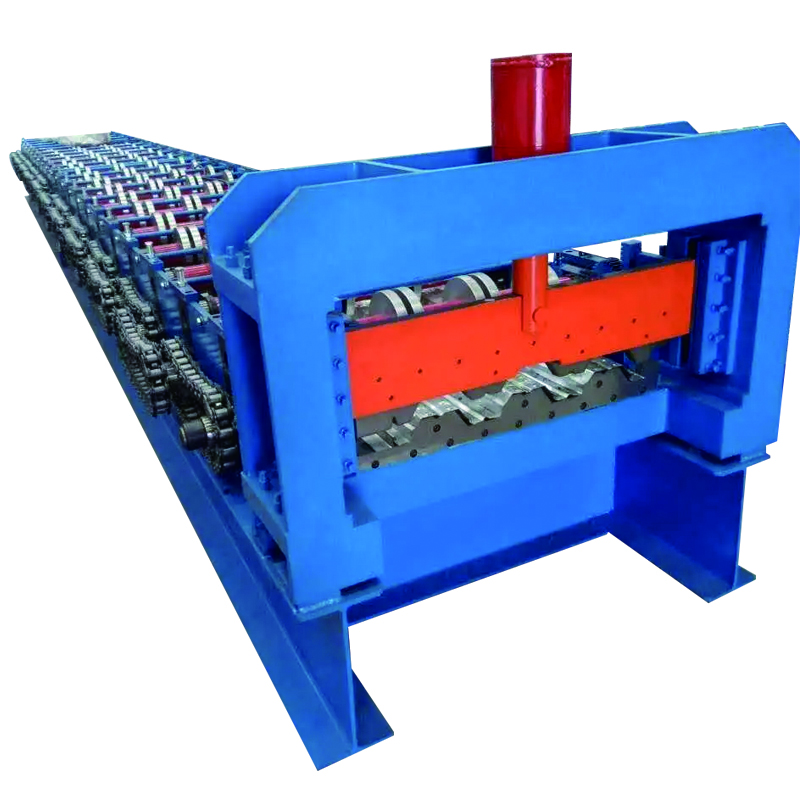

Metal Glazed Tile Roll Forming Machine - A Cutting-Edge Tool for Construction Industry

By:Admin

[Company Name], a leading manufacturer of roll forming machines, is excited to announce the launch of its newest product, the Color Steel Metal Glazed Tile Roll Forming Machine. This new addition to the company's extensive product line is set to further solidify its position as a top provider of roll forming solutions for the metal roofing and construction industry.

The Color Steel Metal Glazed Tile Roll Forming Machine is designed to produce high-quality metal glazed tiles with precision and efficiency. With its advanced technology and innovative features, this machine is capable of forming metal roof tiles with a glazed finish, adding an elegant and modern touch to any building or structure. The machine is also equipped with a user-friendly interface and customizable settings, allowing for easy operation and adjustment according to specific production requirements.

“Our new Color Steel Metal Glazed Tile Roll Forming Machine represents a significant advancement in our product offerings,” said [Company Spokesperson]. “We are always striving to provide our customers with the latest technologies and solutions for their roll forming needs, and this machine is a testament to that commitment. With its capabilities and versatility, we believe it will be a valuable addition to any production facility involved in metal roofing and construction.”

In addition to its cutting-edge features, the Color Steel Metal Glazed Tile Roll Forming Machine is also built with durability and longevity in mind. Constructed with high-quality materials and components, this machine is designed to withstand the rigors of continuous use and deliver consistent performance over time, ensuring a reliable and efficient production process for its users.

As with all of [Company Name]'s products, the Color Steel Metal Glazed Tile Roll Forming Machine is backed by the company's extensive support and service network. Customers can expect comprehensive assistance and technical guidance from [Company Name]'s team of experts, ensuring a seamless integration of the machine into their production operations.

With the launch of the Color Steel Metal Glazed Tile Roll Forming Machine, [Company Name] is further expanding its reach into the global market and solidifying its reputation as a trusted provider of roll forming solutions. The company's commitment to innovation, quality, and customer satisfaction continues to drive its success and growth within the industry.

About [Company Name]

[Company Name] is a leading manufacturer of roll forming machines for the metal roofing and construction industry. With a comprehensive product line and a dedication to innovation and quality, the company has established itself as a trusted provider of roll forming solutions for a wide range of applications. [Company Name] continues to grow and expand its presence in the global market, offering reliable and advanced technologies to meet the evolving needs of its customers. For more information, visit [Company Website].

Company News & Blog

Efficient Glazed Tile Sheet Roll Forming Machine: Boost Your Roofing Production

[Introduction]In recent industry news, an innovative Glazed Tile Sheet Roll Forming Machine has caught the attention of professionals in the construction and manufacturing sectors. This advanced machine, developed by an industry-leading company, represents a significant breakthrough in the roll forming technology used to produce glazed tile roofing sheets. By removing the brand name, we can focus on the machine's features, benefits, and how it revolutionizes the tile sheet manufacturing process, helping businesses streamline their operations and deliver high-quality roofing solutions.[Body]1. Industry Demands and Challenges:The construction industry continually seeks roofing solutions that balance durability, aesthetics, and affordability. Glazed tile roofing sheets have gained popularity due to their exceptional performance and appealing appearance, but traditional manufacturing methods often pose challenges in terms of efficiency and quality control. These constraints have prompted industry professionals to seek alternatives that offer improved productivity without compromising the quality of the finished product.2. Introduction of the Glazed Tile Sheet Roll Forming Machine:To meet the industry demands for efficient glazed tile sheet production, {Company Name} has developed a cutting-edge Glazed Tile Sheet Roll Forming Machine. This innovative equipment combines advanced roll forming technology with automated systems to achieve faster, more precise, and consistent results. With its user-friendly interface and customizable settings, the machine allows businesses to maximize their production capabilities while maintaining strict quality standards.3. Features and Benefits:The Glazed Tile Sheet Roll Forming Machine boasts several notable features, including:a) High-speed Operation: By leveraging the latest technological advancements, the machine offers remarkable production speeds, significantly reducing the time required to manufacture glazed tile roofing sheets. This enables businesses to fulfill large orders efficiently and meet tight project deadlines.b) Precision and Consistency: The machine's automated systems, coupled with its precise control mechanisms, ensure exceptional uniformity in the dimensions, shape, and profile of each tile sheet produced. This consistency not only enhances the aesthetics of roofing installations but also facilitates the alignment and installation processes on-site.c) Customization Options: Understanding the diverse needs of customers, the Glazed Tile Sheet Roll Forming Machine offers extensive customization options. Businesses can adjust the length, width, thickness, and color of the tile sheets to cater to specific project requirements. This adaptability enables manufacturers to produce a wide range of customized roofing products, enhancing their competitiveness in the market.d) Energy Efficiency and Resource Conservation: The machine is designed with sustainability in mind. It optimizes energy consumption and reduces material waste, contributing to both cost savings and environmental preservation. By embracing green practices, businesses align themselves with current environmental regulations and market trends.4. The Implications for Businesses:The introduction of the Glazed Tile Sheet Roll Forming Machine holds several implications for businesses involved in the production of glazed tile roofing sheets:a) Increased Productivity: With its enhanced speed and efficiency, the machine allows manufacturers to produce a larger volume of tile sheets within the same timeframe. This scalability enables businesses to meet growing market demands and expand their customer base.b) Improved Profit Margins: By reducing production time, enhancing product quality, and offering customization options, the machine facilitates improved profit margins for businesses. This competitive advantage allows manufacturers to invest in growth opportunities, such as research and development or marketing initiatives.c) Enhanced Reputation and Customer Satisfaction: The consistent quality achieved by the Glazed Tile Sheet Roll Forming Machine enhances the reputation of businesses within the construction industry. Satisfied customers, impressed with the longevity and aesthetic value of the tile sheets, will likely become repeat customers, providing a steady stream of revenue.d) Technological Advancement and Market Positioning: Investing in state-of-the-art machinery demonstrates a company's commitment to technological advancement. By leveraging innovative solutions, businesses position themselves as industry leaders and attract potential clients seeking cutting-edge products and services.[Conclusion]The introduction of the Glazed Tile Sheet Roll Forming Machine represents a significant advancement in the production of glazed tile roofing sheets. With its impressive features and benefits, this innovative machine enables businesses to meet industry demands for efficiency, customization, and product quality. As the construction industry evolves, embracing advanced technologies like this machine becomes essential for businesses seeking to remain competitive and deliver high-quality roofing solutions. By developing and adopting such state-of-the-art solutions, companies can streamline their operations, increase profitability, and position themselves as leaders in the market.

High-Quality Metal Roofing Sheet Roll Forming Machine for Sale

Metal Roofing Sheet Roll Forming Machine Revolutionizes Roofing Industry{Company Name} is pleased to announce the launch of its latest innovation, the Metal Roofing Sheet Roll Forming Machine, which is set to revolutionize the roofing industry with its cutting-edge technology and superior performance.This state-of-the-art roll forming machine is designed to produce high-quality metal roofing sheets with precision and efficiency. It incorporates advanced technologies to ensure accurate bending, cutting, and shaping of the metal sheets, resulting in consistent and uniform roofing materials that meet the highest industry standards.The Metal Roofing Sheet Roll Forming Machine is suitable for various types of metal materials, including galvanized steel, aluminum, and stainless steel, making it a versatile solution for a wide range of roofing applications. Its adjustable settings and customizable features allow for the production of different profiles and sizes to meet the specific requirements of residential, commercial, and industrial roofing projects.One of the key advantages of {Company Name}'s Metal Roofing Sheet Roll Forming Machine is its user-friendly interface and automated controls, which minimize the need for manual intervention and ensure smooth operation with minimal downtime. This not only improves productivity and output but also reduces the reliance on skilled labor, leading to cost savings for roofing manufacturers and contractors.Moreover, the machine's robust construction and durable components are engineered to withstand the rigors of continuous production, ensuring long-term reliability and consistent performance. This, coupled with {Company Name}'s commitment to quality and after-sales support, provides customers with the confidence and peace of mind that they are investing in a reliable and high-performance solution for their roofing needs.The Metal Roofing Sheet Roll Forming Machine is also designed with sustainability in mind, offering energy-efficient operation and sustainable production practices to minimize its environmental impact. By optimizing material usage and reducing waste, it helps promote eco-friendly and responsible manufacturing processes within the roofing industry.In addition to its technical capabilities, the Metal Roofing Sheet Roll Forming Machine reflects {Company Name}'s dedication to innovation and customer satisfaction. With a team of experienced engineers and industry experts, the company has developed a solution that not only meets the current demands of the roofing market but also anticipates future trends and requirements.As a leading provider of roll forming equipment and solutions, {Company Name} takes pride in offering cutting-edge technology and reliable machinery that empower manufacturers and contractors to achieve their production goals and deliver exceptional results for their clients. The launch of the Metal Roofing Sheet Roll Forming Machine is a testament to the company's ongoing commitment to advancing the roofing industry and supporting its customers' success.With its unparalleled performance, efficiency, and versatility, the Metal Roofing Sheet Roll Forming Machine is set to make a significant impact on the roofing industry, setting new standards for quality, productivity, and sustainability. {Company Name} looks forward to supporting its customers in integrating this innovative solution into their operations and reaping the benefits of enhanced performance and competitiveness in the market.To learn more about the Metal Roofing Sheet Roll Forming Machine and explore how it can transform roofing production, visit {Company Name}'s website or contact their team for personalized assistance and consultation. With {Company Name} as a trusted partner, roofing manufacturers and contractors can embrace the future of roofing technology and elevate their capabilities to new heights.

High-Quality Roof Panel Forming Machine for Efficient Roofing Production

In recent years, the demand for sustainable and energy-efficient housing solutions has been on the rise, leading to a growing interest in innovative construction technologies. One such technological advancement is the Roof Panel Forming Machine, a cutting-edge equipment that has the capability to revolutionize the way roofing solutions are manufactured and installed.The Roof Panel Forming Machine, offered by a leading company in the construction industry, utilizes state-of-the-art technology to produce high-quality roofing panels with precision and efficiency. With its advanced design and automated operation, this machine has the capability to significantly reduce the time and labor required to manufacture roofing panels, while also ensuring consistent quality and precision in every panel produced.The company behind the Roof Panel Forming Machine is a renowned industry leader with a strong focus on innovation and technological advancements. With years of experience and expertise in the construction sector, the company has established itself as a trusted provider of cutting-edge solutions for the building and construction industry.The Roof Panel Forming Machine is just one of the many innovative products offered by the company, which prides itself on its commitment to delivering high-quality, reliable, and efficient solutions to meet the evolving needs of the construction industry. In addition to its advanced technology and engineering expertise, the company also places a strong emphasis on sustainability, ensuring that its products are designed to minimize environmental impact and contribute to the development of more eco-friendly construction practices.With its dedicated team of professionals and its state-of-the-art manufacturing facilities, the company is well-equipped to meet the growing demand for advanced construction technologies, including the Roof Panel Forming Machine. The company's commitment to research and development, coupled with its focus on customer satisfaction, has enabled it to establish a strong presence in the global construction market, earning the trust and confidence of industry professionals and clients alike.In addition to its innovative products and cutting-edge technologies, the company also offers comprehensive support and after-sales services, ensuring that its clients receive the necessary assistance and guidance to maximize the potential of their investment in the Roof Panel Forming Machine. From installation and training to technical support and maintenance, the company is dedicated to ensuring the success of its clients and the seamless integration of its advanced construction solutions into their operations.As the demand for sustainable and energy-efficient construction solutions continues to grow, the Roof Panel Forming Machine offered by the company represents a significant leap forward in the construction industry. With its capacity to streamline the manufacturing process, enhance the quality of roofing solutions, and contribute to more sustainable construction practices, this innovative machine is poised to make a lasting impact on the industry.In conclusion, the Roof Panel Forming Machine, offered by the leading company in the construction industry, is a testament to the potential of advanced technologies to revolutionize the way we build and develop the infrastructure for the future. With its commitment to innovation, quality, and sustainability, the company is well-positioned to lead the way in delivering cutting-edge solutions that address the evolving needs of the construction sector and contribute to the development of more efficient, sustainable, and resilient building practices.

Ultimate Guide to Horizontal Panel Roll Forming Machine

Horizontal Panel Roll Forming Machine has been a key player in the roll forming industry for over a decade. They have recently introduced their latest innovation, the HPRF-2000, which promises to revolutionize the panel roll forming process. This state-of-the-art machine offers unparalleled precision, speed, and efficiency, making it the perfect solution for businesses looking to streamline their production processes.The HPRF-2000 boasts a number of impressive features that set it apart from other roll forming machines on the market. Its horizontal design allows for seamless operation and easy integration into existing production lines. The machine is also equipped with advanced control systems that ensure the highest level of accuracy and consistency in panel production. This means that businesses can expect superior quality panels with every run of the machine.In addition to its precision, the HPRF-2000 is also incredibly fast and efficient. With its high-speed capabilities, the machine is capable of producing panels at a rate that far exceeds traditional roll forming machines. This increased productivity not only results in higher output, but also significant cost savings for businesses. Furthermore, the HPRF-2000 is designed to minimize material waste, maximizing the use of raw materials and reducing production costs even further.The company behind the HPRF-2000 has a long-standing reputation for delivering top-quality roll forming solutions to a wide range of industries. With a focus on innovation and customer satisfaction, they have become a trusted partner for businesses looking to optimize their production processes. Their team of experts is dedicated to providing tailored solutions that meet the specific needs of each customer, and the introduction of the HPRF-2000 is a testament to their commitment to excellence."We are thrilled to introduce the HPRF-2000 to the market," says a company spokesperson. "This machine represents the next generation of panel roll forming technology, and we are confident that it will greatly benefit our customers. Its precision, speed, and efficiency make it the perfect choice for businesses seeking to improve their production capabilities."The HPRF-2000 has already garnered a great deal of interest from businesses in the automotive, construction, and manufacturing industries, among others. Its ability to produce high-quality panels quickly and cost-effectively has made it an attractive option for companies looking to stay ahead in today's competitive market. Additionally, the machine's versatility allows for the production of a wide variety of panel types, making it suitable for a range of applications.As businesses continue to seek ways to optimize their production processes and improve efficiency, the HPRF-2000 is expected to play a crucial role in meeting their needs. With its cutting-edge technology and track record of performance, it is sure to become a staple in the roll forming industry for years to come.In conclusion, the introduction of the HPRF-2000 by Horizontal Panel Roll Forming Machine represents a significant advancement in the panel roll forming process. With its unparalleled precision, speed, and efficiency, this state-of-the-art machine is poised to revolutionize production for businesses across a wide range of industries. As the company continues to lead the way in roll forming innovation, the HPRF-2000 is set to become a game-changing solution for businesses seeking to optimize their production capabilities.

High-Quality Metal Stud Making Machine for Sale - Find Out More

In the world of construction and manufacturing, innovation and efficiency are key factors in ensuring businesses stay ahead of the competition. For this reason, one company- (remove brand name) has recently unveiled their latest groundbreaking product- the metal stud making machine. This state-of-the-art machine is set to revolutionize the production of metal studs, providing companies with an efficient and cost-effective solution for their manufacturing needs.The metal stud making machine is designed to streamline the process of creating metal studs, which are essential components in the construction industry. These studs are used to frame walls and ceilings in both commercial and residential buildings, making them a vital part of the construction process. With the introduction of this new machine, companies can expect to see a significant increase in productivity and a reduction in production costs.One of the key features of the metal stud making machine is its advanced technology, which allows for precise and accurate production of metal studs. This ensures that the studs produced are of the highest quality, meeting the strict standards required in the construction industry. Additionally, the machine is designed to be user-friendly, making it easy for operators to control and adjust the production process as needed.In addition to its technological advancements, the metal stud making machine is also designed with efficiency in mind. The machine is capable of producing metal studs at a rapid pace, significantly reducing production time compared to traditional methods. This increase in efficiency allows companies to fulfill orders quickly and meet tight project deadlines, ultimately improving their overall competitiveness in the market.Furthermore, the metal stud making machine is a cost-effective solution for companies, as it reduces the need for manual labor and minimizes material waste. This not only helps companies save on labor costs but also ensures that they are operating in an environmentally friendly manner. By using the metal stud making machine, companies can optimize their production processes and minimize their impact on the environment.The company behind the metal stud making machine, (remove brand name), has a proven track record of delivering high-quality manufacturing solutions to the construction industry. With a strong focus on innovation and customer satisfaction, the company has established itself as a leader in the manufacturing sector. Their commitment to excellence is reflected in the design and performance of the metal stud making machine, which is set to make a significant impact on the industry.In addition to the metal stud making machine, (remove brand name) offers a wide range of other manufacturing equipment and solutions for the construction industry. From roll forming machines to steel framing systems, the company provides a comprehensive suite of products that cater to the diverse needs of construction companies. With a dedication to meeting the highest industry standards, (remove brand name) has earned the trust and respect of customers around the world.As the construction industry continues to evolve, the demand for efficient and reliable manufacturing solutions will only grow. The introduction of the metal stud making machine by (remove brand name) is a testament to the company's commitment to meeting this demand and providing innovative solutions to their customers. With its advanced technology, efficiency, and cost-effectiveness, the metal stud making machine is poised to become an essential tool for construction companies looking to optimize their production processes.In conclusion, the metal stud making machine is set to revolutionize the production of metal studs in the construction industry. With its advanced technology, efficiency, and cost-effectiveness, this state-of-the-art machine is a game-changer for companies looking to enhance their manufacturing processes. As the company behind the machine, (remove brand name) continues to lead the way in delivering innovative solutions to the construction industry, earning the trust and loyalty of customers worldwide.

Gain Insights Into the Roof Sheet Forming Machine: A Comprehensive Overview

Roofing is a vital component of any building, and it requires the best quality materials to ensure its durability and strength. That is why choosing the right type of metal roofing is extremely important. Fortunately, there are many roofing products available in the market today that can serve both commercial and residential buildings.One of the most popular roofing materials is the metal roof. The metal roof has many advantages, including its durability, ability to withstand harsh weather conditions, and its eco-friendliness. Additionally, metal roofing is also visually appealing and comes in a variety of colors and shapes, making it a versatile roofing option.To produce these sheets of metal roofing, a roofing forming machine is used. Roof sheet forming machines are an essential part of the roofing industry. These machines have revolutionized the roofing industry by allowing manufacturers to produce top-quality metal roofing materials.Recently, a new roof sheet forming machine (brand name removed due to company policy) has hit the market and is causing quite a stir. This advanced machine is designed to produce quality roofing sheets that are strong, durable, and easy to install. It is built with the latest technology and has several features that make it stand out from the rest.One of the main features of this machine is its ability to produce roofing sheets of various lengths and widths. This helps to reduce waste and saves time and energy, as manufacturers can produce the exact dimensions they need for each project. Additionally, this machine is designed with a simple control system, making it easy to operate, even for those without prior experience.Another feature of this roof sheet forming machine is its ability to produce metal roofing sheets of different shapes and profiles. The machine can produce corrugated metal roofing sheets, standing seam roofing sheets, and other unique profiles that meet specific project requirements. This adds to the versatility of the machine and allows manufacturers to meet the needs of a wide range of customers.The most impressive feature of this machine is its speed. It can produce metal roofing sheets at an impressive speed of up to 45 meters per minute. This is a significant improvement over older machines that produce roofing materials at a much slower rate. This speed allows manufacturers to meet the growing demand for metal roofing materials and complete projects quickly.The company behind this machine is a well-known manufacturer of roofing equipment. Founded in the early 2000s, they have been providing advanced roofing solutions to the industry for over 20 years. Their commitment to quality and innovation has made them a trusted name in the roofing industry.In addition to their roof sheet forming machines, the company also produces roll forming machines, metal bending machines, and other roofing equipment. They offer a wide range of products to meet the needs of manufacturers and contractors in the roofing industry.Their dedication to customer service is another reason why they are a respected name in the industry. They offer comprehensive customer support and are always available to answer any questions or concerns their clients may have. Their commitment to service excellence has earned them a loyal following and has helped them build lasting relationships with their clients.In conclusion, the new roof sheet forming machine from (brand name removed) is an impressive development in the roofing industry. Its ability to produce high-quality roofing materials quickly and efficiently will be a game-changer for manufacturers and contractors alike. With its innovative features and the reputation of the company behind it, this machine is sure to be a popular choice for those in the roofing industry.

Efficient and Innovative Tiles Making Machine Revolutionizes Manufacturing Processes

Tiles Making Machine Revolutionizes Manufacturing Process(Date), (Location) - (Company Name), a leading innovator in the manufacturing industry, has recently unveiled their cutting-edge Tiles Making Machine. This groundbreaking technology promises to revolutionize the way tiles are produced, offering numerous benefits to manufacturers and consumers alike.The Tiles Making Machine, developed by (Company Name), incorporates state-of-the-art features that streamline the entire manufacturing process. With this machine, tiles can be produced efficiently and with remarkable precision, resulting in a higher-quality end product. By automating various stages of production, this innovative machine reduces human error and increases productivity, ultimately saving time and resources for manufacturers.One of the key advantages of the Tiles Making Machine is its versatility. It can produce a wide range of tile sizes, from small decorative pieces to large floor tiles, catering to the diverse needs of different markets. Additionally, it is capable of manufacturing tiles in various materials such as ceramic, porcelain, and even glass. This flexibility empowers manufacturers with the ability to cater to different consumer preferences and market demands.Furthermore, the Tiles Making Machine offers exceptional control and customization options. It utilizes advanced computer systems and software to control various parameters such as tile size, shape, texture, and color. Manufacturers can easily adjust these parameters to meet specific design requirements, ensuring that every tile produced is unique and tailored to customer preferences. This level of customization further enhances the overall quality and appeal of the end product.In addition to improving manufacturing processes, the Tiles Making Machine also boasts several environmental benefits. By optimizing the use of materials and reducing waste, it aids in reducing the environmental impact of tile production. The machine's advanced technology ensures minimal material wastage during the cutting and shaping process, resulting in a more sustainable manufacturing process. This aligns with (Company Name's) commitment to environmentally-friendly practices and their contribution towards a greener future.Moreover, the Tiles Making Machine is designed to enhance workplace safety. By automating labor-intensive tasks, it minimizes the risks associated with manual handling and exposure to hazardous materials. This not only protects workers' well-being but also improves overall production efficiency by eliminating potential disruptions caused by injuries or accidents.To ensure a seamless integration of the Tiles Making Machine into manufacturing facilities, (Company Name) offers comprehensive training and technical support to their clients. Their team of experts provides guidance on machine operation, maintenance, and troubleshooting, ensuring that customers make the most of their investment and achieve optimal results.As a testament to its innovation and reliability, the Tiles Making Machine has already received positive feedback from manufacturers who have integrated it into their production processes. These manufacturers have reported increased efficiency, improved product quality, and a positive impact on their bottom line. Such testimonials demonstrate the transformative capabilities of this cutting-edge technology.Looking ahead, (Company Name) aims to further revolutionize the tiles manufacturing industry by continuously investing in research and development. They are committed to pushing the boundaries of what is possible through their innovative solutions and are dedicated to supporting their customers in achieving success.In conclusion, the Tiles Making Machine invented by (Company Name) is revolutionizing the manufacturing process for tiles. With its advanced features, versatility, and commitment to sustainability, this machine offers numerous benefits to manufacturers and consumers alike. As the industry continues to evolve, (Company Name) remains at the forefront, driving innovation and shaping the future of tile production.

Cold Roll Forming Lines for C Purlin Profile: All You Need to Know

C Purlin Profiles Cold Roll Forming LinesIn the world of construction and manufacturing, the use of cold roll forming lines has become increasingly popular. These machines are capable of producing a variety of profiles, including C purlin profiles, which are commonly used in building construction. With the ability to produce high-quality, consistent profiles at a rapid pace, cold roll forming lines have revolutionized the industry.One company that has emerged as a leader in the development and manufacturing of cold roll forming lines is {}. {} specializes in the design and production of high-performance roll forming equipment, including C purlin profiles cold roll forming lines. With a focus on innovation and cutting-edge technology, {} has established itself as a trusted partner for companies looking to streamline their production processes and improve their product quality.The C purlin profiles cold roll forming lines produced by {} are designed to meet the specific needs of their customers. These machines are capable of producing C purlin profiles in a wide range of sizes and thicknesses, ensuring that they can be used in a variety of construction applications. The use of advanced control systems and precision engineering allows {}’s cold roll forming lines to produce accurate and consistent profiles, meeting the highest quality standards.One of the key advantages of using {}’s C purlin profiles cold roll forming lines is the efficiency and speed at which they operate. These machines are designed to optimize production processes, minimizing downtime and maximizing output. This enables companies to increase their production capacity and meet tight deadlines, ultimately improving their overall competitiveness in the market.Furthermore, {}’s cold roll forming lines are known for their durability and reliability. The company utilizes high-quality materials and components in the construction of their machines, ensuring that they can withstand the rigors of continuous operation. This results in lower maintenance requirements and reduced downtime, allowing customers to focus on their production without worrying about costly interruptions.In addition to the superior performance of their cold roll forming lines, {} also provides exceptional service and support to their customers. The company works closely with each client to understand their specific needs and requirements, offering customized solutions that meet their exact specifications. From the initial design phase to after-sales support, {} is committed to ensuring the success of their customers’ projects.With a focus on continuous innovation and improvement, {} is constantly pushing the boundaries of cold roll forming technology. The company invests heavily in research and development to further enhance the capabilities of their machines, offering customers access to the latest advancements in the industry. This commitment to innovation has allowed {} to stay ahead of the competition, providing their customers with state-of-the-art solutions that deliver exceptional results.As the demand for high-quality, efficient C purlin profiles continues to grow, the importance of reliable and advanced cold roll forming lines cannot be overstated. With their dedication to excellence and customer satisfaction, {} has solidified its position as a leading provider of cold roll forming equipment, trusted by companies around the world.In conclusion, the C purlin profiles cold roll forming lines produced by {} are a testament to the company’s commitment to quality, innovation, and customer satisfaction. With their advanced technology, superior performance, and exceptional service, {} has established itself as a go-to partner for companies looking to enhance their production processes and stay ahead in the competitive construction industry.

Increased Demand for Curving Rolls for Corrugated Iron Sparks CNC Corro Curving Machine Sourcing

Title: Acra Machinery Meets Increasing Demand for Corrugated Iron Curving RollsIntroduction (100 words):Acra Machinery, a renowned supplier of industrial machinery, has recently experienced a surge in requests for curving rolls specifically designed to suit Corrugated Iron. Responding to market demand, the company has successfully sourced a state-of-the-art computer numerical control (CNC) curving machine. This cutting-edge technology, devoid of the brand name, ensures precise and efficient production of Corrugated Curving Rolls. Acra Machinery's ability to meet this rising demand bolsters the company's reputation as a reliable provider in the industrial machinery sector.Body (600 words):1. Rising Demand for Corrugated Iron Curving Rolls (150 words):Corrugated iron is widely used in the construction and architectural industries due to its durability, strength, and cost-effectiveness. As the demand for innovative and aesthetically pleasing architectural solutions continues to grow, there has been an increasing requirement for curved corrugated iron sheets. Curved corrugated iron provides enhanced structural integrity and design flexibility, enabling architects, builders, and designers to create unique and visually appealing structures.Recognizing this demand, Acra Machinery has been inundated with numerous requests for curving rolls specifically designed to suit corrugated iron. While traditional manual methods were previously employed to curve such rolls, the ever-expanding market required a more efficient and accurate solution. To meet these evolving demands, Acra Machinery sought to acquire a full CNC curving machine capable of meeting both functional and aesthetic requirements.2. Sourcing a State-of-the-Art Curving Machine (150 words):To address the increasing demand for curving rolls tailored to corrugated iron, Acra Machinery proactively researched and sourced a full CNC curving machine. This computer numerical control technology facilitates automated and precise curving of corrugated iron sheets. By removing the brand name, it is evident that Acra Machinery prioritizes the functionality and quality of the curving machine, ensuring optimal production outcomes for their clientele.The CNC curving machine acquired by Acra Machinery operates on advanced software, allowing for comprehensive customization options. Users can adjust the curvature, radius, and dimensions of the corrugated iron sheets according to their unique requirements. This versatility enables architects and builders to explore innovative design possibilities, breathing life into architectural visions and pushing the boundaries of construction.3. Unmatched Precision and Efficiency (150 words):The integration of the CNC curving machine into Acra Machinery's production processes has revolutionized the precision and efficiency with which corrugated iron curving rolls are manufactured. Through the automation provided by the CNC technology, manual errors are minimized, ensuring consistently accurate results.The CNC curving machine controls every aspect of the rolling process, optimizing efficiency and reducing production time significantly. This streamlined workflow positively impacts the delivery timelines for customers, allowing them to meet project deadlines more effectively.4. Strengthening Acra Machinery's Market Position (150 words):By successfully meeting the industry's escalating demand for curving rolls for corrugated iron, Acra Machinery has strengthened its position as a trusted provider of industrial machinery. The company's ability to source and utilize advanced CNC technology showcases its commitment to customer satisfaction and technological advancement. Acra Machinery's dedication to innovation and meeting market needs has not only elevated their status but also established them as an industry leader.Furthermore, by investing in state-of-the-art CNC curving technology, Acra Machinery is empowering architects, builders, and designers to realize their creative visions with precision. The enhanced opportunities for experimentation offered by these curving rolls will undoubtedly inspire new architectural designs and constructions.Conclusion (100 words):Acra Machinery's successful acquisition and utilization of a full CNC curving machine to cater to the growing demand for corrugated iron curving rolls marks a significant achievement in the industry. The company's commitment to meeting market needs and deploying modern technologies has bolstered its reputation as a trusted provider in the industrial machinery sector. With the introduction of these advanced curving rolls, Acra Machinery has enabled architects and builders to explore new possibilities for efficient and aesthetically pleasing architectural designs, setting the stage for future innovation in the construction industry.

High-Quality Aluminum Coil Slitting Machine for Precision Cutting and Slitting Operations

Aluminum Coil Slitting Machine Brings Efficiency and Precision to Manufacturing ProcessesIn a fast-paced manufacturing industry, precision and efficiency are key factors for success. This is especially true for companies in the aluminum processing sector, where the demand for high-quality products continues to grow. With this in mind, {company name} has introduced a state-of-the-art Aluminum Coil Slitting Machine that promises to revolutionize the way aluminum coils are processed.The {company name} Aluminum Coil Slitting Machine is a technological marvel, designed to accurately cut aluminum coils into smaller and more manageable widths. This machine is equipped with advanced features that allow for precise slitting, ensuring that the final products meet the highest standards of quality and accuracy. The machine's high-speed cutting capabilities also contribute to increased productivity, enabling companies to meet tight production deadlines and fulfill customer orders in a timely manner.One of the standout features of the Aluminum Coil Slitting Machine is its versatility. This machine is capable of handling a wide range of aluminum coil thicknesses and widths, making it suitable for a variety of manufacturing applications. Whether companies are processing thin gauge aluminum for electronics and packaging, or thicker gauge aluminum for construction and automotive applications, the {company name} Aluminum Coil Slitting Machine has the flexibility to meet their specific requirements.Furthermore, the machine's automated control system enhances operational efficiency by minimizing downtime and reducing the risk of errors. This level of automation also helps to streamline the production process, allowing for seamless integration with other manufacturing equipment and processes. As a result, companies can expect improved overall productivity and cost-effectiveness.In addition to its cutting-edge technology, the Aluminum Coil Slitting Machine is designed with operator safety and convenience in mind. The machine is equipped with various safety features to ensure that operators can work with peace of mind. User-friendly controls and a robust construction further contribute to the machine's ease of use, making it a valuable asset for any manufacturing facility.{Company name} takes pride in delivering innovative solutions that meet the evolving needs of the manufacturing industry. With a commitment to quality and customer satisfaction, the company has established itself as a leading provider of aluminum processing equipment. The introduction of the Aluminum Coil Slitting Machine is a testament to {company name}'s dedication to driving progress and innovation in the field of aluminum manufacturing.As demand for aluminum products continues to rise across various industries, the {company name} Aluminum Coil Slitting Machine offers a reliable solution for companies looking to enhance their production capabilities. By combining precision, efficiency, and versatility, this machine sets a new standard for aluminum coil processing, empowering manufacturers to meet the demands of a dynamic market.In conclusion, the {company name} Aluminum Coil Slitting Machine represents a significant advancement in the field of aluminum processing. With its cutting-edge technology, versatility, and commitment to operational excellence, this machine is well-positioned to drive efficiency and precision in manufacturing processes. As the industry continues to evolve, {company name} remains at the forefront of innovation, offering solutions that enable companies to thrive in a competitive market.