Rent a Wood Deck Sanding Machine for Your Next Project

By:Admin

For homeowners and contractors looking to restore the beauty of their wooden decks, {Company Name} is now offering wood deck sanding machine rentals. With these rentals, individuals can easily sand and refinish their decks, saving time and money compared to hiring professional services.

{Company Name} is a leading provider of rental equipment for construction, industrial, and residential projects. With a wide range of equipment available, {Company Name} aims to make it convenient for individuals to access the tools they need for their projects without having to make a significant investment in purchasing new equipment.

The wood deck sanding machine rental is a valuable addition to {Company Name}'s rental offerings, as it allows homeowners and contractors to tackle deck refinishing projects with ease. Whether it's removing old paint, sanding down rough surfaces, or preparing the deck for a fresh coat of stain or sealant, the rental machine provides the power and efficiency needed to achieve professional results.

"We understand the challenges that homeowners and contractors face when it comes to maintaining and restoring wooden decks. Our goal is to provide access to high-quality equipment that can make these tasks more manageable and cost-effective," said [Spokesperson], [Title] at {Company Name}. "Our wood deck sanding machine rental is designed to help individuals achieve the results they desire without having to invest in expensive equipment or hire professional services."

The wood deck sanding machine available for rent is a [Brand Name] model, known for its reliability and performance in sanding and refinishing applications. The machine features a powerful motor and a durable sanding drum that can effectively smooth out uneven surfaces, remove old coatings, and prepare the wood for refinishing. Additionally, the machine is designed for ease of use, with adjustable settings that allow users to customize the sanding process to their specific needs.

In addition to providing the rental machine, {Company Name} also offers guidance and support to individuals who may be new to deck refinishing. The team is available to provide instructions on operating the machine, as well as tips for achieving the best results. This added support ensures that renters can approach their deck refinishing projects with confidence, knowing that they have access to the resources they need to succeed.

"Renting equipment from {Company Name} is more than just getting access to the tools. It's about gaining the knowledge and support to use the equipment effectively. We want our customers to feel empowered to take on their projects and achieve professional-quality results," [Spokesperson] added.

With the availability of the wood deck sanding machine rental, homeowners can take on DIY refinishing projects at their own pace, avoiding the costs and potential scheduling constraints of hiring professional services. Contractors, on the other hand, can expand their range of services by offering deck refinishing without having to invest in additional equipment.

The convenience of having access to a reliable wood deck sanding machine rental has already attracted attention from both individual homeowners and contractors in the area. Many have taken advantage of the rental option to achieve the results they desire for their wooden decks, while appreciating the cost savings and flexibility that come with renting equipment.

As the demand for DIY home improvement projects continues to grow, {Company Name} remains committed to providing a wide range of rental equipment that can support the needs of homeowners and contractors alike. With the addition of the wood deck sanding machine rental, individuals can now confidently take on deck refinishing projects, knowing that they have the backing of a reputable rental company.

For those interested in renting the wood deck sanding machine or exploring other rental options, {Company Name} encourages individuals to contact their nearest location or visit their website for more information. With a straightforward rental process and a commitment to customer satisfaction, {Company Name} is poised to help individuals achieve their project goals effectively and affordably.

Company News & Blog

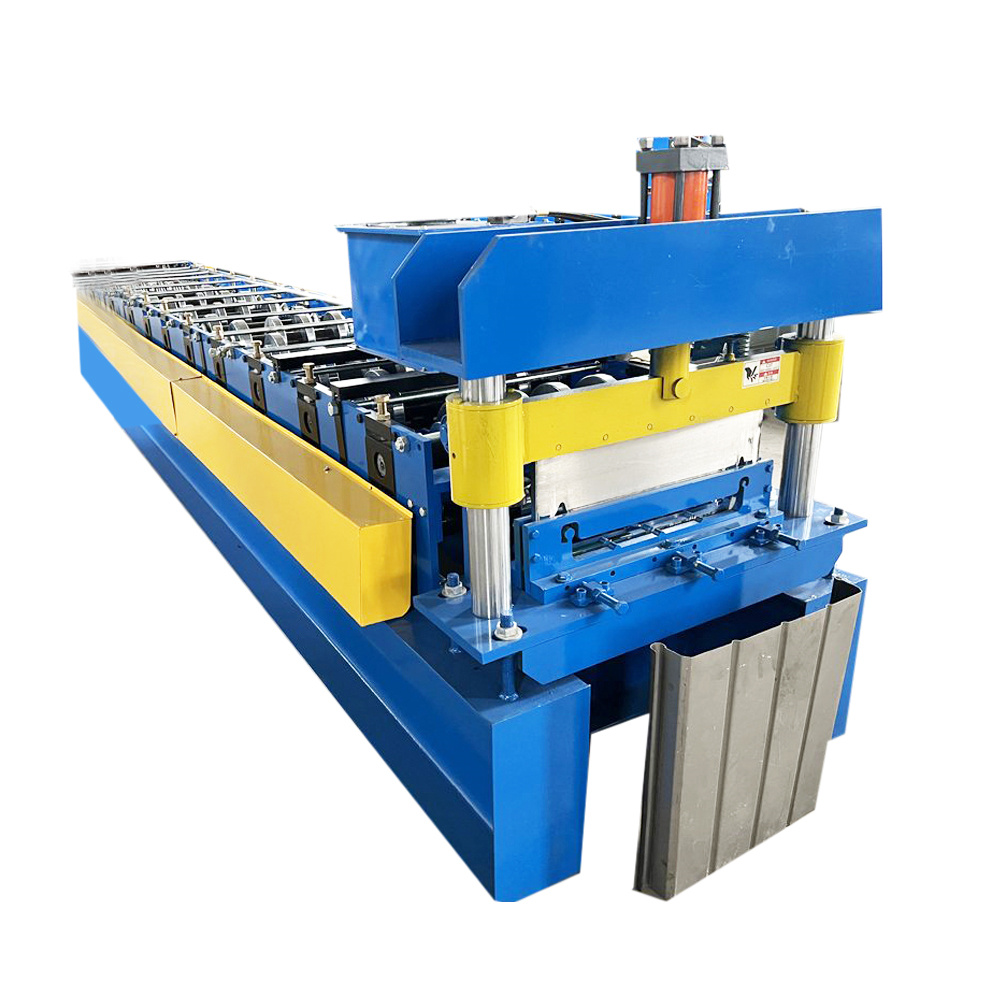

High-Quality Roll Forming Machine for Efficient Production

Roll Forming Machine Revolutionizing the Manufacturing IndustryIn the ever-evolving world of manufacturing, the demand for efficient and high-quality production processes is constantly on the rise. Companies are constantly seeking innovative solutions to streamline their manufacturing operations and stay ahead of the competition. One of the most crucial machines in this aspect is the roll forming machine, which has been gaining traction in the manufacturing industry for its high precision and flexibility.With the growing interest in roll forming machines, companies like [company name] have been at the forefront of providing cutting-edge solutions for the manufacturing industry. [Company name] has been a leading player in the roll forming machine market, providing a wide range of advanced machines that are tailored to meet the unique needs of different industries.The roll forming machine offered by [company name] boasts a number of impressive features that set it apart from traditional manufacturing methods. The machine is designed to efficiently and accurately produce metal sheets of various shapes and sizes, making it an ideal solution for a wide range of industries, from automotive to construction. With its high precision and flexibility, the roll forming machine from [company name] allows for greater customization and faster production, helping companies to meet the demands of their customers with ease.In addition to its impressive technical capabilities, the roll forming machine from [company name] also comes with a user-friendly interface that makes it easy to operate and maintain. This means that companies can maximize their production capabilities without having to invest heavily in training and maintenance costs.One of the key advantages of the roll forming machine from [company name] is its ability to produce high-quality products consistently. By using state-of-the-art technology and materials, the machine can ensure that every product meets the strictest quality standards, which is essential in industries where precision and durability are paramount.Furthermore, [company name] offers comprehensive after-sales support, guaranteeing that their customers can always count on the reliability and performance of their roll forming machine. The company's team of experts are always on hand to provide assistance and guidance, ensuring that the machine operates at its optimal level at all times.The demand for roll forming machines like the one offered by [company name] is only expected to grow as manufacturers continue to seek innovative solutions to enhance their production processes. With its cutting-edge technology and commitment to customer satisfaction, [company name] is well-positioned to meet this growing demand and further solidify its position as a leading provider of roll forming machines.In conclusion, the roll forming machine from [company name] is revolutionizing the manufacturing industry by offering a highly efficient and flexible solution for companies looking to streamline their production processes. With its advanced technology, high precision, and user-friendly design, the machine is helping manufacturers to stay ahead of the competition and meet the demands of their customers with ease. As the demand for such advanced manufacturing solutions continues to rise, [company name] is poised to play a key role in shaping the future of the manufacturing industry.

How to Choose the Right Roll Forming Machine for Your Sheet Metal Business

Sheet Metal Roll Former Revolutionizes Manufacturing IndustryIn recent years, technological advancements have completely revolutionized the manufacturing industry. One such innovation that is generating significant buzz is the Sheet Metal Roll Former, a powerful machine that has transformed the way sheet metal products are produced. By automating the fabrication process, this cutting-edge technology has improved efficiency, increased productivity, and enhanced the overall quality of sheet metal components.The Sheet Metal Roll Former, developed by a leading manufacturing solutions provider, is a state-of-the-art machine designed to shape and form sheet metal into various profiles. With its ability to produce complex geometries with precision and consistency, this roll forming system has quickly become a game-changer in the industry.One of the key advantages of the Sheet Metal Roll Former is its ability to automate the manufacturing process, reducing human error and improving productivity. Traditional methods of sheet metal fabrication involved manual labor, which was not only time-consuming but also prone to inconsistency. However, with this innovative machine, manufacturers can now automate the entire process, significantly reducing the production time and lowering the possibility of errors.Furthermore, the Sheet Metal Roll Former offers an unmatched level of versatility. It is capable of producing a wide range of profiles, shapes, and sizes, making it highly adaptable to meet the diverse needs of different industries. Whether it is for the automotive sector, construction industry, or any other application that requires precision sheet metal components, this technology has the capability to deliver high-quality products.In addition to its versatility, the Sheet Metal Roll Former also offers improved material utilization. With its precise forming capabilities, the machine ensures minimal waste during the fabrication process. This not only helps reduce costs but also contributes to the sustainability and environmental-friendliness of the manufacturing industry.The Sheet Metal Roll Former is equipped with advanced control systems that enable manufacturers to easily program and monitor the entire production process. This user-friendly interface allows operators to quickly adapt and adjust the machine settings as per the specific requirements of each project. Additionally, the system offers real-time monitoring and diagnostics, minimizing downtime and improving the overall operational efficiency.The company behind the development and manufacturing of this remarkable technology has a rich history in providing innovative solutions to the manufacturing industry. With a strong focus on research and development, the company has been at the forefront of developing cutting-edge machines and systems that enhance productivity and quality in various industries.With a team of highly skilled engineers and technicians, the company has been able to continuously improve the Sheet Metal Roll Former, ensuring that it remains at the forefront of technological advancements. From optimizing the machine's performance to developing new features that cater to the evolving needs of the industry, the company's commitment to innovation is evident in every aspect of the product.Furthermore, the company not only focuses on providing top-notch technology but also maintains a strong emphasis on customer satisfaction. With a comprehensive support system in place, including training programs, technical assistance, and regular maintenance services, the company ensures that its customers receive the necessary support throughout their experience with the Sheet Metal Roll Former. This level of customer-centricity has earned the company a stellar reputation in the industry.In conclusion, the Sheet Metal Roll Former is a groundbreaking technology that has transformed the manufacturing industry. With its automation capabilities, versatility, improved material utilization, and user-friendly interface, this machine has become an essential asset for manufacturers across various sectors. Developed by a leading manufacturing solutions provider, this state-of-the-art technology exemplifies the company's commitment to innovation and customer satisfaction. As the industry continues to evolve, the Sheet Metal Roll Former will undoubtedly play a crucial role in shaping the future of manufacturing.

Increased Demand for Curving Rolls for Corrugated Iron Sparks CNC Corro Curving Machine Sourcing

Title: Acra Machinery Meets Increasing Demand for Corrugated Iron Curving RollsIntroduction (100 words):Acra Machinery, a renowned supplier of industrial machinery, has recently experienced a surge in requests for curving rolls specifically designed to suit Corrugated Iron. Responding to market demand, the company has successfully sourced a state-of-the-art computer numerical control (CNC) curving machine. This cutting-edge technology, devoid of the brand name, ensures precise and efficient production of Corrugated Curving Rolls. Acra Machinery's ability to meet this rising demand bolsters the company's reputation as a reliable provider in the industrial machinery sector.Body (600 words):1. Rising Demand for Corrugated Iron Curving Rolls (150 words):Corrugated iron is widely used in the construction and architectural industries due to its durability, strength, and cost-effectiveness. As the demand for innovative and aesthetically pleasing architectural solutions continues to grow, there has been an increasing requirement for curved corrugated iron sheets. Curved corrugated iron provides enhanced structural integrity and design flexibility, enabling architects, builders, and designers to create unique and visually appealing structures.Recognizing this demand, Acra Machinery has been inundated with numerous requests for curving rolls specifically designed to suit corrugated iron. While traditional manual methods were previously employed to curve such rolls, the ever-expanding market required a more efficient and accurate solution. To meet these evolving demands, Acra Machinery sought to acquire a full CNC curving machine capable of meeting both functional and aesthetic requirements.2. Sourcing a State-of-the-Art Curving Machine (150 words):To address the increasing demand for curving rolls tailored to corrugated iron, Acra Machinery proactively researched and sourced a full CNC curving machine. This computer numerical control technology facilitates automated and precise curving of corrugated iron sheets. By removing the brand name, it is evident that Acra Machinery prioritizes the functionality and quality of the curving machine, ensuring optimal production outcomes for their clientele.The CNC curving machine acquired by Acra Machinery operates on advanced software, allowing for comprehensive customization options. Users can adjust the curvature, radius, and dimensions of the corrugated iron sheets according to their unique requirements. This versatility enables architects and builders to explore innovative design possibilities, breathing life into architectural visions and pushing the boundaries of construction.3. Unmatched Precision and Efficiency (150 words):The integration of the CNC curving machine into Acra Machinery's production processes has revolutionized the precision and efficiency with which corrugated iron curving rolls are manufactured. Through the automation provided by the CNC technology, manual errors are minimized, ensuring consistently accurate results.The CNC curving machine controls every aspect of the rolling process, optimizing efficiency and reducing production time significantly. This streamlined workflow positively impacts the delivery timelines for customers, allowing them to meet project deadlines more effectively.4. Strengthening Acra Machinery's Market Position (150 words):By successfully meeting the industry's escalating demand for curving rolls for corrugated iron, Acra Machinery has strengthened its position as a trusted provider of industrial machinery. The company's ability to source and utilize advanced CNC technology showcases its commitment to customer satisfaction and technological advancement. Acra Machinery's dedication to innovation and meeting market needs has not only elevated their status but also established them as an industry leader.Furthermore, by investing in state-of-the-art CNC curving technology, Acra Machinery is empowering architects, builders, and designers to realize their creative visions with precision. The enhanced opportunities for experimentation offered by these curving rolls will undoubtedly inspire new architectural designs and constructions.Conclusion (100 words):Acra Machinery's successful acquisition and utilization of a full CNC curving machine to cater to the growing demand for corrugated iron curving rolls marks a significant achievement in the industry. The company's commitment to meeting market needs and deploying modern technologies has bolstered its reputation as a trusted provider in the industrial machinery sector. With the introduction of these advanced curving rolls, Acra Machinery has enabled architects and builders to explore new possibilities for efficient and aesthetically pleasing architectural designs, setting the stage for future innovation in the construction industry.

High-quality Metal Roofing Sheet Roll Forming Machine for Sale

Metal Roofing Sheet Roll Forming Machine Revolutionizes the Roofing IndustryThe roofing industry has seen a rapid evolution in recent years, thanks to advancements in technology and machinery. One of the key innovations driving this change is the Metal Roofing Sheet Roll Forming Machine, which has quickly become a game-changer in the field of roofing manufacturing.The Metal Roofing Sheet Roll Forming Machine is a versatile and efficient piece of equipment that has revolutionized the way metal roofing sheets are produced. This machine has the capability to roll and form metal sheets into the desired shape, size, and design, allowing for greater flexibility and customization in the manufacturing process. This has resulted in an increase in the production of high-quality, precision-engineered metal roofing sheets that are durable, aesthetically pleasing, and cost-effective.One of the key features of the Metal Roofing Sheet Roll Forming Machine is its ability to produce a wide range of roofing sheet profiles, including corrugated, trapezoidal, and standing seam designs. This flexibility ensures that manufacturers can cater to a diverse range of customer needs and preferences, while also enabling them to stay competitive in the market. Additionally, the machine's high-speed production capabilities and low maintenance requirements make it an attractive investment for companies looking to streamline their production processes and improve overall efficiency.In addition to its technological advancements, the Metal Roofing Sheet Roll Forming Machine is also built with user-friendly features and safety mechanisms, ensuring a smooth and secure operation for workers. This focus on safety and ease of use has contributed to the machine's growing popularity within the industry, as manufacturers prioritize the well-being of their workers while striving for greater productivity and output.The Metal Roofing Sheet Roll Forming Machine has garnered widespread acclaim for its ability to produce roofing sheets with superior quality and precision. This has been pivotal in meeting the rising demand for high-performance metal roofing solutions in the construction and building sectors. The machine's ability to efficiently produce large quantities of roofing sheets without compromising on quality has made it a valuable asset for companies seeking to meet tight project deadlines and supply demands.In light of these advancements, [Company Name] has emerged as a leading manufacturer and supplier of Metal Roofing Sheet Roll Forming Machines. With a strong focus on research and development, [Company Name] has continually pushed the boundaries of innovation to deliver cutting-edge solutions for the roofing industry. Their commitment to quality, reliability, and customer satisfaction has positioned them as a trusted partner for companies seeking to enhance their roofing manufacturing capabilities.[Company Name] takes pride in offering a comprehensive range of Metal Roofing Sheet Roll Forming Machines, each designed to cater to specific production needs and requirements. They have successfully catered to the diverse needs of a global clientele, providing customized solutions that align with the unique specifications of their customers. Furthermore, [Company Name] remains dedicated to providing ongoing technical support, training, and maintenance services to ensure the seamless operation and longevity of their machines.With the Metal Roofing Sheet Roll Forming Machine paving the way for a new era of roofing manufacturing, [Company Name] remains committed to driving innovation and excellence within the industry. As they continue to expand their reach and influence, [Company Name] is poised to play a pivotal role in shaping the future of metal roofing production, offering game-changing solutions that empower manufacturers to thrive in an increasingly competitive market.

High-Quality Corrugated Iron Sheet Making Machine for Sale

Corrugated Iron Sheet Making Machine Revolutionizes Manufacturing IndustryIn the modern era, the manufacturing industry has seen significant advancements in technology, leading to increased efficiency and productivity. One such innovation that has revolutionized the industry is the Corrugated Iron Sheet Making Machine, a groundbreaking piece of equipment that has set new standards for the production of corrugated iron sheets. Developed by a leading manufacturing company, this state-of-the-art machine has garnered widespread attention for its cutting-edge design and capabilities.The Corrugated Iron Sheet Making Machine is a sophisticated piece of equipment that is designed to streamline the manufacturing process of corrugated iron sheets. It is utilized by numerous industries, including construction, automotive, and packaging, to produce high-quality corrugated iron sheets at an unprecedented pace. The machine’s advanced features and precise engineering have made it an indispensable tool for manufacturers looking to meet the ever-growing demand for corrugated iron sheets.The key to the machine’s success lies in its ability to automate and optimize the production process. With its advanced controls and robotics, the machine can seamlessly transform raw materials into finished corrugated iron sheets with minimal human intervention. This not only enhances productivity but also reduces the margin of error, resulting in consistently high-quality products. Additionally, the machine is capable of producing a wide range of corrugated iron sheet sizes and designs, catering to the diverse needs of different industries.The Corrugated Iron Sheet Making Machine has also proven to be environmentally friendly, as it minimizes waste and resource consumption. Its efficient use of raw materials and energy has resulted in a more sustainable manufacturing process, aligning with the growing global emphasis on eco-friendly practices. Furthermore, the machine's high-speed production capabilities contribute to reducing overall energy consumption, making it a cost-effective and environmentally sound investment for manufacturers.The company behind this groundbreaking technology, {}, has been at the forefront of the manufacturing industry for decades. With a focus on innovation and continuous improvement, the company has consistently developed cutting-edge solutions to address the evolving needs of the manufacturing sector. Leveraging its expertise in engineering and design, {} has successfully introduced the Corrugated Iron Sheet Making Machine as a game-changing product that has set new benchmarks for the industry.The company’s commitment to quality and reliability is reflected in the Corrugated Iron Sheet Making Machine, which has undergone rigorous testing and validation to ensure its performance and durability. Its robust construction and precision components are a testament to the company’s dedication to delivering superior products that withstand the rigors of industrial production. Moreover, {} provides comprehensive training and support services, ensuring that their clients can effectively integrate and optimize the machine within their manufacturing operations.The introduction of the Corrugated Iron Sheet Making Machine represents a significant milestone for the manufacturing industry, offering a glimpse into the future of automated and efficient production processes. Its impact on the industry is already evident, as manufacturers seek to adopt this transformative technology to stay ahead in an increasingly competitive market. As demand for corrugated iron sheets continues to rise, the Corrugated Iron Sheet Making Machine is poised to play a pivotal role in meeting this demand while setting new standards for efficiency and quality in manufacturing.In conclusion, the Corrugated Iron Sheet Making Machine has emerged as a game-changer for the manufacturing industry, offering unparalleled capabilities in the production of corrugated iron sheets. With its advanced technology, environmental sustainability, and the backing of a reputable company like {}, this machine is reshaping the manufacturing landscape and paving the way for a more efficient and sustainable future.

Complete Guide to Standing Seam Metal Roof Machines

[Company name], a leading manufacturer of metal roofing machines, has recently introduced its latest innovation – the Standing Seam Metal Roof Machine. This new machine is designed to offer increased efficiency and precision in the production of standing seam metal roofs, making it the perfect solution for various roofing contractors and manufacturers.The Standing Seam Metal Roof Machine is designed to produce high-quality standing seam metal roofs with ease and precision. It is equipped with state-of-the-art technology and features that make the production process faster and more efficient. The machine is capable of producing standing seam metal roofs in a variety of widths and lengths, making it suitable for a wide range of roofing projects.One of the key features of the Standing Seam Metal Roof Machine is its versatility. It is designed to be easily adjustable, allowing for quick and easy changes in panel width and length. This ensures that the machine can easily adapt to different project requirements, saving time and increasing productivity for roofing contractors and manufacturers.In addition to its versatility, the Standing Seam Metal Roof Machine is also designed with precision in mind. It is equipped with advanced controls and systems that ensure the accuracy and consistency of the finished products. This precision is essential for meeting the high standards and specifications of standing seam metal roofs, ensuring that the final product meets the requirements of the most demanding customers.Furthermore, the Standing Seam Metal Roof Machine is designed for durability and reliability. It is constructed with high-quality materials and components, making it capable of withstanding the rigors of continuous use in a production environment. This durability minimizes downtime and maintenance, ensuring that the machine can deliver consistent performance over the long term.“We are thrilled to introduce our latest innovation, the Standing Seam Metal Roof Machine,” said [Company name]'s CEO. “This machine is the result of our ongoing commitment to delivering cutting-edge solutions for the metal roofing industry. We have designed it to address the needs and challenges of our customers, providing them with a reliable and efficient solution for producing standing seam metal roofs.”[Company name] has been a trusted name in the metal roofing industry for many years. The company has a proven track record of delivering high-quality and reliable metal roofing machines that meet the needs of roofing contractors and manufacturers. The introduction of the Standing Seam Metal Roof Machine is a testament to the company's dedication to innovation and customer satisfaction.With its latest innovation, [Company name] is poised to further strengthen its position as a leading manufacturer of metal roofing machines. The Standing Seam Metal Roof Machine is set to become a game-changer in the industry, offering a level of efficiency, precision, and versatility that was previously unseen in the production of standing seam metal roofs.In conclusion, the introduction of the Standing Seam Metal Roof Machine marks a significant milestone for [Company name] and the metal roofing industry as a whole. With its advanced technology, versatility, precision, and durability, this machine is set to revolutionize the production of standing seam metal roofs, providing a reliable and efficient solution for roofing contractors and manufacturers. As [Company name] continues to push the boundaries of innovation, it is poised to further solidify its position as a trusted provider of metal roofing machines.

High-Quality Floor Tile Making Machine for Efficient Production

Floor Tile Making Machine (need remove brand name) is a cutting-edge innovation that is revolutionizing the tile manufacturing industry. This state-of-the-art machine is designed to produce high-quality floor tiles with precision and efficiency, making it an essential tool for companies looking to streamline their production processes and deliver superior products to their customers.The company behind this groundbreaking technology, {}, is a leading manufacturer of industrial machinery and equipment. With a strong focus on innovation and quality, {}, has established itself as a trusted name in the industry, and its Floor Tile Making Machine is a testament to its commitment to excellence.The Floor Tile Making Machine is equipped with advanced features that set it apart from traditional tile manufacturing equipment. Its automated process ensures consistent tile quality and reduces the likelihood of human error, resulting in a superior end product. Additionally, the machine is designed for high-speed production, allowing companies to significantly increase their output without sacrificing quality.One of the key advantages of the Floor Tile Making Machine is its versatility. It can accommodate a wide range of tile sizes and designs, giving manufacturers the flexibility to meet the diverse needs of their customers. Whether producing large-format tiles for commercial spaces or intricate designs for residential settings, this machine is capable of delivering exceptional results across the board.Another standout feature of the Floor Tile Making Machine is its user-friendly interface. With intuitive controls and easy-to-follow instructions, operators can quickly learn how to operate the machine, reducing training time and minimizing the likelihood of errors. This, in turn, enhances overall productivity and efficiency within the manufacturing process.In addition to its technological advancements, the Floor Tile Making Machine also prioritizes sustainability. It is designed to minimize waste and energy consumption, making it an environmentally friendly choice for companies looking to reduce their carbon footprint. By investing in this machine, manufacturers can demonstrate their commitment to sustainability while also reaping the benefits of cost savings in the long run.The global demand for high-quality floor tiles continues to rise, driven by factors such as urbanization, infrastructural development, and a growing focus on interior design. As a result, manufacturers are under increasing pressure to meet these demands while also maintaining high production standards. The Floor Tile Making Machine from {} offers a solution to these challenges, empowering companies to meet market demand while exceeding customer expectations.With its cutting-edge technology, commitment to quality, and focus on sustainability, the Floor Tile Making Machine is poised to transform the tile manufacturing industry. As more companies recognize the benefits of this innovative equipment, it is expected to become an essential tool for the production of high-quality floor tiles around the world.In conclusion, the Floor Tile Making Machine from {} represents a significant advancement in the tile manufacturing industry. Its advanced features, user-friendly interface, and commitment to sustainability make it a valuable asset for companies looking to enhance their production processes and deliver exceptional products to their customers. As the demand for high-quality floor tiles continues to grow, this innovative machine is set to play a pivotal role in meeting market needs and driving industry progress. With {} leading the way in innovation, the future of tile manufacturing looks brighter than ever.

High-quality C Z Shape Purlin Forming Machine for Sale - Everything You Need to Know

C Z Shape Purlin Forming Machine: Revolutionizing the Construction IndustryC Z shape purlin forming machine is a revolutionary piece of equipment that is set to transform the construction industry. This state-of-the-art machine is designed to produce high quality C and Z shaped purlins with unmatched precision and efficiency. The machine is equipped with advanced technology and cutting-edge features that make it an invaluable tool for any construction project.With the ability to produce a wide range of C and Z shaped purlins, this machine is highly versatile and can be used in a variety of construction applications. Whether it is for building warehouses, industrial buildings, or commercial structures, the C Z shape purlin forming machine is an essential piece of equipment that is redefining the way construction projects are carried out.The C Z shape purlin forming machine is designed to streamline the purlin production process, saving time and labor costs. It boasts a high level of automation, with features such as automatic feeding, punching, and cutting, that drastically reduce the need for manual intervention. This not only enhances the speed of production but also ensures consistency and precision in the purlin dimensions.In addition to its efficiency, the machine is also known for its durability and reliability. Built with high-quality materials and precision engineering, it is capable of withstanding the rigors of heavy-duty use in a construction environment. This makes it a long-term investment that offers a high return on investment for any construction company.The company behind this innovative machine is a leader in the manufacturing of construction equipment. With years of experience and a commitment to excellence, they have established themselves as a trusted provider of quality machinery for the construction industry. Their expertise and dedication to innovation have led to the development of the C Z shape purlin forming machine, which has quickly gained recognition for its performance and reliability.As a company, they are focused on meeting the evolving needs of the construction industry by delivering cutting-edge solutions that enhance efficiency and productivity. The C Z shape purlin forming machine is a testament to this commitment, as it has set new standards for purlin production in the construction sector. By offering a machine that is not only efficient but also versatile and reliable, they have positioned themselves as a key player in shaping the future of construction technology.With the demand for efficient and cost-effective construction solutions on the rise, the C Z shape purlin forming machine is poised to make a significant impact in the industry. Its ability to expedite the purlin production process while maintaining high quality standards is a game-changer for construction companies looking to stay ahead of the curve.In conclusion, the C Z shape purlin forming machine is a game-changing piece of equipment that is revolutionizing the construction industry. Its advanced technology, efficiency, and reliability make it an indispensable tool for any construction project. Coupled with the expertise and commitment to excellence of the company behind it, this machine is set to redefine the way purlins are produced and utilized in construction, setting new benchmarks in efficiency and performance.