The Complete Guide to Coil Slitting Process: Techniques and Best Practices

By:Admin

The coil slitting process is a method of cutting wide coils of metal into smaller, narrower coils that are suitable for specific applications. This process is commonly used in the production of steel sheets, strips, and other metal products. {Company Name} has invested in the latest coil slitting technology to enhance their production capabilities and meet the growing demand for high-quality steel products in the market.

With the new coil slitting process, {Company Name} is able to provide customers with a wider range of customization options for their steel products. The advanced machinery used in the process allows for precise and accurate cutting, resulting in coils that meet the exact specifications and requirements of the customer. This level of customization is essential for industries such as automotive, construction, and manufacturing, where specific dimensions and high-quality materials are crucial for the success of the final product.

Furthermore, the new coil slitting process at {Company Name} allows for increased efficiency and productivity in their manufacturing operations. With the ability to produce smaller coils with minimal waste, the company can optimize their raw material usage and reduce overall production costs. This, in turn, allows {Company Name} to offer competitive pricing for their steel products while maintaining the highest standards of quality and precision.

In addition to the technical capabilities of the new coil slitting process, {Company Name} also emphasizes the importance of sustainability and environmental responsibility in their manufacturing operations. The company has invested in environmentally friendly technologies and processes to minimize their carbon footprint and reduce waste in their production facilities. By implementing advanced coil slitting methods, {Company Name} is able to further enhance their sustainability efforts by reducing material waste and energy consumption.

The introduction of the new coil slitting process at {Company Name} highlights their commitment to innovation and continuous improvement in their manufacturing capabilities. This investment in advanced technology will not only benefit the company in terms of increased productivity and cost-efficiency but also allow them to better serve their customers with a wider range of high-quality, customized steel products.

{Company Name} is renowned for its dedication to excellence in the steel industry, and the introduction of the new coil slitting process is a testament to their ongoing efforts to push the boundaries of what is possible in steel manufacturing. With a strong focus on quality, precision, and sustainability, {Company Name} continues to set the standard for steel production and distribution, providing customers with the best-in-class products and solutions for their diverse steel needs.

As the demand for high-quality steel products continues to grow in various industries, {Company Name} is well-positioned to meet and exceed the expectations of their customers with the superior capabilities of their new coil slitting process. The company's commitment to innovation and sustainability ensures that they remain a trusted partner for businesses seeking top-tier steel products and solutions in the global market.

In conclusion, the introduction of the new coil slitting process at {Company Name} marks a significant milestone in their journey to provide the highest quality steel products to their customers. This investment in advanced technology not only enhances their manufacturing capabilities but also reflects their ongoing dedication to excellence, precision, and sustainability in the steel industry. With the new coil slitting process, {Company Name} is well-equipped to meet the evolving needs of their customers and continue to drive innovation in steel manufacturing for years to come.

Company News & Blog

High-Quality Glazed Tile Roll Forming Machine for Bamboo Material

In today's fast-paced and ever-changing world, the demand for innovative and sustainable building materials is at an all-time high. With this in mind, [Company Name] is proud to introduce our latest technological advancement in the manufacturing industry - the Bamboo Glazed Tile Roll Forming Machine. This state-of-the-art machine is designed to revolutionize the production of glazed tiles by utilizing bamboo, a natural and eco-friendly material that is not only durable but also renewable. By incorporating bamboo into the production process, we are taking a step towards sustainability and reducing our carbon footprint.[Company Name] has always been at the forefront of technological innovation, and the Bamboo Glazed Tile Roll Forming Machine is a testament to our commitment to pushing the boundaries of what is possible in the manufacturing industry. With this machine, we are not only able to produce high-quality glazed tiles at a faster rate, but we are also contributing to a more sustainable future.The use of bamboo in the production of glazed tiles is a game-changer for the industry. Known for its strength and flexibility, bamboo is an ideal material for use in construction and building materials. By harnessing the natural properties of bamboo, we are able to create glazed tiles that are not only aesthetically pleasing but also incredibly resilient.In addition to its environmental benefits, the Bamboo Glazed Tile Roll Forming Machine also offers significant cost savings for manufacturers. By utilizing bamboo, a relatively inexpensive and abundant material, we are able to reduce production costs without compromising on quality. This cost-effectiveness makes the machine an attractive investment for manufacturers looking to improve their production processes.At [Company Name], we understand the importance of sustainability and environmental responsibility. By incorporating bamboo into the production of glazed tiles, we are able to offer a more environmentally friendly alternative to traditional materials. This aligns with our commitment to reducing our impact on the environment and contributing to a more sustainable future.Furthermore, the Bamboo Glazed Tile Roll Forming Machine is a testament to our dedication to innovation and technological advancement. As a company, we are constantly seeking ways to improve our manufacturing processes and stay ahead of the curve. The introduction of this machine is a reflection of our ongoing efforts to push the boundaries of what is possible in the manufacturing industry.In conclusion, the Bamboo Glazed Tile Roll Forming Machine is a game-changing innovation that has the potential to transform the production of glazed tiles. By utilizing bamboo, a natural and sustainable material, we are not only able to create high-quality tiles, but also contribute to a more sustainable future. With this machine, [Company Name] is once again leading the way in technological innovation and demonstrating our commitment to environmental responsibility. We are excited to see the impact that this machine will have on the industry and are proud to be at the forefront of this sustainable revolution.

How to Make Roof Tiles: A Comprehensive Guide for Machine Users

Title: Revolutionary Roof Tile Making Machine Makes Waves in the Construction IndustryIntroduction:In a groundbreaking development, an innovative and state-of-the-art roof tile making machine has emerged as a game-changer in the construction industry. This groundbreaking technology, developed by a leading company in the field, has revolutionized the way roof tiles are manufactured, offering a sustainable, efficient, and cost-effective solution for construction projects worldwide.Transforming Roofing Processes:Traditional methods of manufacturing roof tiles have long been associated with labor-intensive practices that consume vast amounts of resources and contribute to environmental degradation. However, this new roof tile making machine has effectively transformed the roofing processes, ensuring minimal environmental impact while keeping up with the ever-increasing demands of the construction industry.Key Features and Technology:This cutting-edge roof tile making machine incorporates a range of features and utilizes advanced technology to streamline the production process. It offers precision molding, allowing for the creation of consistent and high-quality roof tiles. With its automated system and minimal manual labor requirements, this machine enhances operational efficiency, reducing labor costs and minimizing the risk of human error.Sustainable Materials and Practices:One of the main selling points of this roof tile making machine is its commitment to sustainability. It employs environmentally-friendly materials and practices, ensuring minimal waste generation and energy consumption. By utilizing recycled materials or eco-friendly alternatives, this machine significantly reduces the environmental footprint associated with traditional manufacturing methods.Cost-Effectiveness and Versatility:The use of this innovative roof tile making machine not only benefits the environment but also proves economically advantageous for construction companies. Its highly efficient production process, coupled with low energy consumption, enables significant cost savings. Additionally, the machine supports the creation of various roof tile designs, catering to the diverse aesthetic preferences of builders and homeowners alike.Enhanced Durability and Longevity:Roof tiles manufactured by this state-of-the-art machine are highly durable and weather-resistant, making them ideal for diverse climatic conditions. Through meticulous design and quality control measures, these tiles withstand harsh environmental factors, such as heavy rain, extreme temperatures, and strong winds. With increased longevity, these tiles offer long-term value to builders and homeowners alike.Streamlined Maintenance and Repair:An added advantage of this advanced roof tile making machine is its focus on easy maintenance and repair of the tiles it produces. With a standardized design and precise molding, any necessary repairs or replacements can be accomplished swiftly and conveniently, minimizing disruption to the building and the occupants.Global Impact and Industry Acceptance:The introduction of this innovative roof tile making machine has generated considerable interest within the construction industry globally. With its ability to transform traditional methods, this technology has disrupted the market and paved the way for a more sustainable and efficient future. Companies worldwide are recognizing its potential and adopting this technology to revolutionize their roofing processes.Conclusion:The emergence of this futuristic roof tile making machine is set to reshape the construction industry by providing a sustainable, cost-effective, and efficient solution for manufacturing high-quality roof tiles. With its focus on environmental responsibility and the incorporation of advanced technology, this machine epitomizes a new era of innovation and progress in the field. As construction companies increasingly embrace this technology, we can expect to witness a significant shift towards sustainable building practices, benefiting not only the industry but also our planet as a whole.

Latest News: Powerful Corrugation Machine Unveiled for Color Steel Glazed Tile Roof Panels

Durable Standing Seam Roof Machine for Efficient Roofing

Standing Seam Roof Machine Revolutionizes Roofing IndustryThe roofing industry has seen a revolution with the introduction of the state-of-the-art Standing Seam Roof Machine by a leading manufacturer in the field. This innovative machine has been designed with precision and advanced technology to meet the growing demands of the roofing industry.The Standing Seam Roof Machine is a game-changer for roofing professionals as it offers efficiency, durability, and unmatched precision in producing standing seam roofs. The machine features a cutting-edge design that allows for seamless and fast production of standing seam roofs, meeting the high standards of quality and performance.This revolutionary machine is the result of years of research and development by a dedicated team of engineers and experts. With an unwavering commitment to excellence, the company has set a new benchmark in the industry with its Standing Seam Roof Machine. The machine is built with high-quality materials and components, ensuring durability and long-term performance.One of the key features of the Standing Seam Roof Machine is its versatility. It is capable of producing standing seam roofs of various widths and profiles, catering to the diverse needs of roofing projects. This flexibility makes it an ideal choice for roofing contractors and professionals who require a reliable and efficient solution for their projects.In addition to its versatility, the machine is also equipped with advanced automation and control systems, allowing for precise and accurate production of standing seam roofs. This not only enhances the efficiency of the production process but also ensures the consistency of the final product.The company behind the Standing Seam Roof Machine has a long-standing reputation for delivering high-quality and innovative solutions to the roofing industry. Their commitment to excellence and customer satisfaction has earned them a trusted position in the market. With the introduction of the Standing Seam Roof Machine, they have once again solidified their leadership in the industry.The company takes pride in its customer-centric approach, offering comprehensive technical support and training to ensure that roofing professionals can fully harness the capabilities of the Standing Seam Roof Machine. Their team of technical experts is readily available to provide assistance and guidance, guaranteeing a seamless integration of the machine into the customers' operations.Furthermore, the company's dedication to sustainability is reflected in the design and production of the Standing Seam Roof Machine. It has been engineered to minimize waste, energy consumption, and environmental impact, aligning with the growing demand for eco-friendly solutions in the roofing industry.The introduction of the Standing Seam Roof Machine has garnered widespread attention in the roofing industry, with professionals recognizing its potential to streamline operations and elevate the quality of standing seam roofs. Its impact is not only limited to production efficiency but also extends to the overall performance and longevity of standing seam roofs, offering a compelling value proposition to roofing professionals.In conclusion, the Standing Seam Roof Machine is a testament to the relentless pursuit of innovation and excellence by the company. With its cutting-edge design, advanced technology, and commitment to customer satisfaction, the machine has set a new standard in the roofing industry. It represents a significant advancement that is poised to reshape the production of standing seam roofs, empowering roofing professionals to deliver exceptional results.

High-Quality Floor Decking Roll Forming Machine for Sale

Floor Decking Roll Forming Machine has been revolutionizing the construction industry with its innovative and efficient solutions. The machine, designed and manufactured by a leading company in the industry, is a game-changer in the field of floor decking and has been widely adopted by construction companies around the world.The Floor Decking Roll Forming Machine is a state-of-the-art equipment that is used to produce floor decking panels, which are essential components in building construction. The machine is designed to roll form, cut, and stack metal sheets into the desired shape and size, making the process of floor decking production faster, more accurate, and more cost-effective. With its advanced technology and precise engineering, the machine is able to produce high-quality floor decking panels that meet industry standards and specifications.The company behind the Floor Decking Roll Forming Machine is a renowned manufacturer of roll forming machines and other construction equipment. With over 20 years of experience in the industry, the company has gained a reputation for delivering top-of-the-line products that are reliable, durable, and efficient. The company's commitment to innovation and excellence has positioned it as a leader in the field, and its products are trusted by construction professionals around the world.The Floor Decking Roll Forming Machine is a testament to the company's dedication to providing cutting-edge solutions for the construction industry. Its commitment to research and development has resulted in the creation of a machine that has revolutionized the way floor decking panels are produced, making the process faster, more efficient, and more cost-effective. With its advanced features and capabilities, the machine has helped construction companies improve their productivity and streamline their operations, ultimately leading to cost savings and increased profitability.One of the key features of the Floor Decking Roll Forming Machine is its versatility. The machine is capable of producing a wide range of floor decking panels in different shapes, sizes, and thicknesses, allowing construction companies to meet the specific requirements of their projects. This versatility makes the machine an invaluable asset for construction companies of all sizes, as it enables them to take on diverse projects and deliver high-quality results.In addition to its versatility, the Floor Decking Roll Forming Machine is also known for its ease of use and maintenance. The machine is equipped with user-friendly controls and interfaces, making it easy for operators to set up and operate the machine with minimal training. Its durable construction and reliable performance also minimize the need for maintenance, reducing downtime and enhancing productivity.Furthermore, the company prides itself on its commitment to customer satisfaction. It provides comprehensive support and service for its products, ensuring that customers receive the assistance they need to maximize the performance and lifespan of their equipment. With a global network of service centers and technical experts, the company is able to provide responsive support to customers around the world, further enhancing the value of its products.In conclusion, the Floor Decking Roll Forming Machine is a groundbreaking innovation that has transformed the construction industry. With its advanced technology, versatility, and reliability, the machine has become an essential tool for construction companies seeking to improve their efficiency and productivity. Combined with the company's dedication to innovation and customer satisfaction, the Floor Decking Roll Forming Machine is sure to continue making a significant impact on the construction industry for years to come.

Steel Coil Slitter: The Ultimate Guide

Steel Coil Slitter: Enhancing Efficiency and Precision in Metal ProcessingIn the world of metal processing, precision and efficiency are essential components to ensuring high-quality products and optimal production capabilities. One company that has been at the forefront of innovation in this field is {}. With a strong commitment to excellence and a dedication to meeting the evolving needs of the industry, {} has recently introduced its latest innovation – the Steel Coil Slitter.The Steel Coil Slitter is a cutting-edge machine that has been designed to enhance efficiency and precision in the process of slitting steel coils. This state-of-the-art equipment is capable of processing large steel coils into narrower coils of various widths with exceptional accuracy and speed. By utilizing advanced technology and innovative engineering, the Steel Coil Slitter has set a new standard for performance and productivity in the metal processing industry.One of the key features of the Steel Coil Slitter is its ability to accommodate a wide range of coil widths and thicknesses, making it highly versatile and suitable for a variety of applications. This flexibility allows metal processing companies to streamline their operations and achieve greater levels of efficiency in their production processes. Additionally, the Steel Coil Slitter is equipped with precision cutting blades and advanced control systems that ensure consistent and accurate results, minimizing material waste and maximizing the yield of high-quality slit coils.Furthermore, the Steel Coil Slitter is designed with user-friendly interfaces and intuitive controls, facilitating ease of operation and reducing the need for extensive training. This user-centric approach reflects {}'s commitment to delivering innovative solutions that not only optimize performance but also simplify workflow and improve overall productivity.In addition to its impressive performance capabilities, the Steel Coil Slitter is also built with a strong emphasis on durability and reliability. {} has integrated robust construction and high-quality components into the design of the machine, ensuring that it can withstand the demands of heavy-duty industrial applications and deliver consistent results over an extended lifespan. This emphasis on long-term value and reliability underscores {}'s dedication to providing equipment that not only meets current needs but also anticipates future requirements.As a leader in the metal processing equipment industry, {} has a long-standing reputation for delivering cutting-edge solutions that empower metal fabricators, service centers, and other related businesses to achieve their production goals with precision and efficiency. The introduction of the Steel Coil Slitter further solidifies {}'s position as an innovative force in the industry, offering a solution that addresses the complexities and demands of modern metal processing operations.With a focus on continuous improvement and a deep understanding of the evolving needs of the industry, {} has remained dedicated to staying ahead of the curve through research, development, and the integration of the latest technological advancements. The Steel Coil Slitter is a testament to this ongoing commitment, providing metal processing companies with a powerful tool to enhance their capabilities and drive their success in an increasingly competitive market.In conclusion, the Steel Coil Slitter represents a significant advancement in the field of metal processing equipment, offering a compelling combination of precision, efficiency, and versatility. As {} continues to push the boundaries of innovation, it is poised to redefine the standards of excellence in the industry and empower its customers to achieve new levels of productivity and success. With the introduction of the Steel Coil Slitter, {} has once again demonstrated its dedication to delivering state-of-the-art solutions that meet the complex needs of modern metal processing operations.

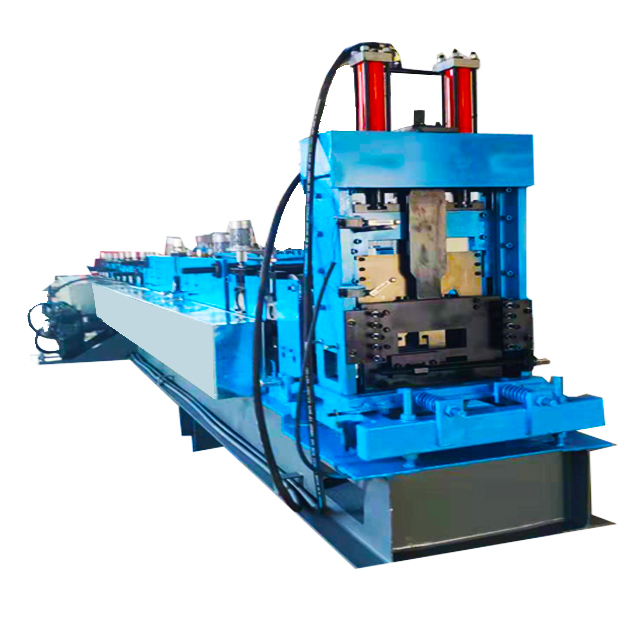

Manual Stacker For The Shape C Purline Machine - Efficient and Reliable Solution

The demand for efficient and reliable machinery in the construction industry has been on the rise, and {} has been at the forefront of meeting this demand. With a focus on innovation and quality, the company has been a trusted provider of a wide range of construction machinery and equipment. In line with their commitment to meeting the evolving needs of their customers, {} is proud to announce the launch of their new Manual Stacker for the shape C purline machine.The Manual Stacker is designed to work seamlessly with the shape C purline machine, offering a complete solution for handling and stacking purline products in a safe and efficient manner. The addition of this new equipment to {}'s product line is a testament to their dedication to providing comprehensive solutions for their customers' needs.One of the key features of the Manual Stacker is its user-friendly design, which makes it easy to operate and maintain. This allows for greater efficiency in the stacking process, saving time and labor costs for construction companies. Additionally, the Manual Stacker is built with the highest quality materials and components, ensuring its durability and long-term performance.In addition to its practical design, the Manual Stacker is also equipped with advanced safety features to protect workers and prevent accidents. With built-in safety mechanisms and ergonomic controls, operators can confidently and securely handle purline products without compromising their well-being.Furthermore, {}'s commitment to sustainability is reflected in the energy-efficient operation of the Manual Stacker. By minimizing energy consumption, the equipment helps reduce the overall environmental impact of construction projects, aligning with the industry's growing emphasis on eco-friendly practices.The launch of the Manual Stacker for the shape C purline machine further solidifies {}'s position as a leading provider of construction machinery and equipment. With a track record of delivering high-quality products and exceptional customer service, the company continues to be a trusted partner for construction companies looking to enhance their operational efficiency and productivity.In addition to their cutting-edge products, {} also offers comprehensive support services to assist customers in maximizing the value of their investments. Their team of highly trained professionals is available to provide technical guidance, maintenance, and troubleshooting to ensure that customers can operate their equipment with confidence.As the construction industry continues to evolve, {} remains at the forefront, continuously innovating to meet the changing needs of their customers. The launch of the Manual Stacker for the shape C purline machine is a testament to their unwavering commitment to providing reliable, efficient, and safe solutions for the construction industry.With a strong focus on quality, innovation, and customer satisfaction, {} is poised to continue making a significant impact in the construction machinery and equipment market. Their dedication to excellence and continuous improvement sets them apart as a formidable force in the industry, and the launch of the Manual Stacker is another testament to their ongoing success.

Advanced Steel Slitting Lines: Perfect for High-Volume Production

Steel Slitting Line: A Revolutionary Solution to Strengthen Your BusinessThe manufacturing industry is constantly evolving, and the need for advanced machines and technologies is at an all-time high. One such technology that has revolutionized the steel manufacturing industry is Steel Slitting Line. It is an intelligent solution that has transformed the way steel is produced, making it faster, precise, and more efficient. Not only does it reduce manufacturing costs, but it also ensures maximum output with minimum wastage.{Company Introduction} is proud to introduce its Steel Slitting Line, a state-of-the-art machine that guarantees a higher level of precision, speed, and reliability than its counterparts. Our Steel Slitting Line is designed to meet the needs of modern steel manufacturers, ensuring maximum output of high-quality steel products while reducing operating costs.A Steel Slitting Line is a specialized machine that allows manufacturers to cut steel coils into narrow widths, called strips, in a precise and efficient manner. It is capable of processing super-thin and high-strength materials that were once impossible to cut efficiently. The Steel Slitting Line machine can process a wide range of materials, from plain carbon steel to high-strength steel alloys, stainless steel, and non-ferrous metals. The ability to cut a variety of materials makes it a versatile solution for steel manufacturing firms.The Steel Slitting Line is made up of several components, including an entry coil car, decoiler, slitter, and recoiler. The entry coil car is used to load the steel coils onto the machine, while the decoiler unrolls the coil, and the slitter cuts the material into the desired width strips. The strips are then wound up into coils using the recoiler, ready to be used in downstream manufacturing processes. The Steel Slitting Line's precision and accuracy depend on the quality of each of these components, and our Steel Slitting Line is built with the finest materials and components to ensure the highest level of precision and accuracy.One of the most significant benefits of Steel Slitting Lines is the optimization of material utilization. The machine cuts steel coils into strips, which means that manufacturers can make smaller orders with minimum wastage. It also allows for maximum use of the material, which reduces manufacturing costs and minimizes the environmental impact of steel production. The Steel Slitting Line's high level of precision and accuracy means that it is possible to minimize or completely eliminate waste in some cases, depending on the manufacturer's quality standards.Another notable benefit of the Steel Slitting Line is the improved efficiency that it brings to steel production. It is capable of processing steel coils at high speeds, ensuring that manufacturers can produce high-quality steel products in large volumes within a short period. The machine's advanced technology allows for automatic adjustments to be made quickly, minimizing downtime and minimizing the need for human intervention. This results in faster production processes and improved productivity, which ultimately leads to increased revenue for the manufacturer.Safety is a top priority in the manufacturing industry, and Steel Slitting Lines are designed with safety in mind. Our Steel Slitting Line is built to meet international safety standards, ensuring that the machine is safe to operate and that all operators are adequately trained. We have put in place safety measures, such as emergency stop buttons, safety guards, and sensors, to ensure that operators are protected from any accidents that may occur during production.In conclusion, Steel Slitting Line machines are a game-changer in the steel industry, providing manufacturers with a range of benefits that improve efficiency, reduce costs, and increase revenue. At {Company Introduction}, we take pride in providing our customers with the best Steel Slitting Lines that meet their needs. Our machines are built with the highest quality materials, and our team of experienced engineers and designers ensures that the machines meet international standards. If you're looking to optimize your steel manufacturing process, {Company Name}'s Steel Slitting Line is the solution you need.

Efficient Automatic Roll Slitter for Accurate Cutting

Automatic Roll Slitter: Revolutionizing Manufacturing ProcessesIn today’s fast-paced and competitive manufacturing industry, efficiency and precision are essential for success. The demand for high-quality, precisely cut materials is constantly increasing, making traditional cutting methods obsolete. In light of this, the introduction of the innovative Automatic Roll Slitter by [Company Name] has completely revolutionized the cutting and slitting processes for a wide range of materials.[Company Name] is a leading provider of cutting-edge industrial equipment, specializing in the development and manufacturing of innovative solutions for the manufacturing industry. With a commitment to excellence and a focus on meeting the diverse needs of customers, the company has consistently delivered cutting-edge technology to simplify and enhance manufacturing processes.The Automatic Roll Slitter is a truly groundbreaking innovation that has set a new standard in material cutting and slitting. This advanced machine is designed to provide unparalleled precision and efficiency, making it an indispensable tool for manufacturers across various industries. From metal foils and films to textiles and paper, the Automatic Roll Slitter is capable of handling a wide range of materials with extreme accuracy.One of the key features of the Automatic Roll Slitter is its fully automated operation, which eliminates the need for manual intervention and significantly reduces the risk of errors. Equipped with state-of-the-art sensors and cutting-edge software, the machine is able to detect and adjust to changes in material tension and thickness, ensuring a consistently high level of precision with every cut. This level of automation not only minimizes the risk of human error but also enhances the overall productivity of the manufacturing process.In addition to its advanced automation capabilities, the Automatic Roll Slitter also boasts a high-speed cutting system that enables rapid and efficient processing of materials. With the ability to handle large rolls of material with ease, the machine is able to deliver quick turnaround times without compromising on quality. This makes it an ideal solution for manufacturers who require precision cutting on a large scale.Furthermore, the Automatic Roll Slitter is designed with user-friendly controls and a streamlined interface, allowing operators to easily set and adjust cutting parameters according to specific requirements. This intuitive system not only simplifies the operation of the machine but also enables operators to achieve precise and consistent results with minimal effort.The introduction of the Automatic Roll Slitter represents a significant advancement in the field of material cutting and slitting. With its cutting-edge technology and unparalleled capabilities, this innovative machine has raised the bar for precision cutting and slitting in the manufacturing industry. As a result, manufacturers are now able to achieve higher levels of productivity and quality in their operations, ultimately gaining a competitive edge in the market.[Company Name]’s commitment to innovation and excellence is evident in the development of the Automatic Roll Slitter. By delivering cutting-edge solutions that address the evolving needs of the manufacturing industry, the company continues to lead the way in revolutionizing manufacturing processes. As the demand for precision cutting and slitting continues to grow, the Automatic Roll Slitter stands as a testament to the company’s dedication to providing advanced solutions that drive progress and success for its customers.In conclusion, the Automatic Roll Slitter represents a true revolution in material cutting and slitting, offering unmatched precision, efficiency, and automation. With its advanced features, high-speed capabilities, and user-friendly interface, this innovative machine has set a new standard for manufacturing processes, empowering manufacturers to achieve higher levels of productivity and quality. As [Company Name] continues to push the boundaries of innovation, the Automatic Roll Slitter stands as a testament to the company’s commitment to delivering cutting-edge solutions that drive progress and success in the manufacturing industry.

Why Choose IBR Roofing Systems for Your Roof Sheeting Needs

When it comes to choosing a roofing system, there are numerous options available on the market. However, IBR roof systems have been gaining popularity due to their durability, strength, and versatility. This type of roofing is designed to withstand harsh weather conditions such as extreme temperatures, strong winds, and heavy rainfall.One of the main reasons IBR roof systems are a great choice is because of the Roof Sheeting Machine used to manufacture them. This machine is designed to evenly roll and cut metal sheets at high speeds, ensuring precision and accuracy in each piece. The result is a perfectly formed sheet that can be easily installed on any roofing structure.Another advantage of IBR roof systems is that they come in various thicknesses, ranging from 0.4mm to 0.8mm. This allows for customization depending on the needs of your specific roofing project. The thicker the sheet, the more durable it is, which means it will last longer and require less maintenance. Furthermore, IBR roof sheets are highly resistant to corrosion, making them ideal for coastal areas and regions with high levels of humidity.IBR roof systems are also highly versatile and can be used in a wide range of roofing applications. They can be easily installed on a variety of roofing structures, including residential homes, commercial buildings, and industrial facilities. Additionally, they can be molded and shaped to create unique roofing designs, adding to the aesthetic appeal of any building.In terms of cost-effectiveness, IBR roof systems are a great investment. They are relatively affordable compared to other roofing systems, and their durability and longevity mean that they require minimal maintenance and replacement over time. IBR roofs are also energy-efficient as they reflect the sun's rays, reducing the amount of heat absorbed by the building.Overall, IBR roof systems provide a range of benefits that make them a great choice for any roofing project. The precision and accuracy of the Roof Sheeting Machine used in their manufacturing ensure that each sheet is of the highest quality, while their strength, durability, and versatility make them a practical and cost-effective investment. Whether you are looking to install a new roof or replace an existing one, IBR roof systems are certainly worth considering.