Efficient Roll Forming Machine for R Panels - Boost Productivity in Panel Manufacturing

By:Admin

In today's fast-paced business environment, companies are increasingly relying on technology and automation to streamline their operations and stay competitive. The metal roofing industry is no exception, with many manufacturers investing in state-of-the-art equipment to improve productivity and quality.

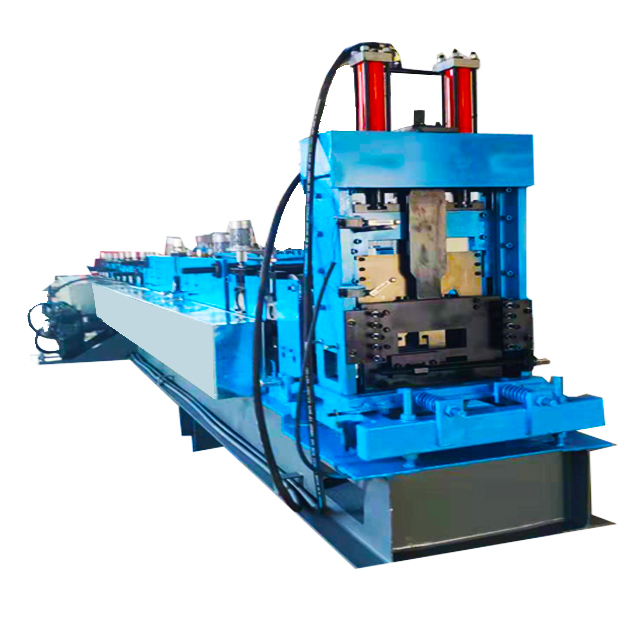

One such innovation is the R Panel Roll Forming Machine, a cutting-edge piece of equipment that has revolutionized the metal roofing production process. Developed by a leading manufacturer of roll forming machines (name removed), this machine is designed specifically for the production of R panel roofing, a popular type of metal roofing used in residential, commercial, and industrial settings.

The machine works by taking a coil of metal and forming it into the R panel shape, using a series of rollers and dies. This process is highly customizable, with options for different panel widths, rib heights, and gauges. The resulting panels are strong, durable, and weather-resistant, making them an ideal choice for roofing applications.

One of the key benefits of the R Panel Roll Forming Machine is its efficiency. With a high level of automation and precision, the machine can produce large quantities of panels quickly and consistently, reducing lead times and increasing output. This is particularly important in the metal roofing industry, where demand for fast turnaround times and tight schedules is common.

The machine is also highly versatile, with the ability to produce multiple panel profiles and custom orders. This allows manufacturers to cater to a wide range of customer needs and preferences, from simple residential roofs to complex commercial projects.

In addition to its efficiency and versatility, the R Panel Roll Forming Machine offers a number of other benefits to metal roofing manufacturers. These include:

- Reduced waste: The machine produces panels with precise dimensions, minimizing material waste and reducing costs.

- Consistent quality: With automated controls and tight tolerances, the machine ensures consistent panel quality and accuracy.

- Safety: The machine is designed with safety features that protect workers and prevent accidents, such as automatic shut-off switches.

- Ease of use: The machine's user-friendly interface and intuitive controls make it easy for operators to set up and run.

Overall, the R Panel Roll Forming Machine represents a significant advancement in the metal roofing industry, providing manufacturers with a powerful tool for improving efficiency, quality, and profitability. As the demand for metal roofing continues to grow, it is likely that more companies will turn to this innovative technology to stay ahead of the competition.

About ({Brand Name Removed})

({Brand Name Removed}) is a leading manufacturer of roll forming machines for the metal roofing and construction industries. With over 20 years of experience, the company has built a reputation for innovation, quality, and customer service. Its products are used by manufacturers and contractors around the world, offering reliable and efficient solutions for a variety of applications. The company is committed to advancing the industry through continuous research and development, and to providing exceptional value to its customers.

Company News & Blog

Highly Efficient and Durable Rain Pipe Roll Forming Machine Impresses with Innovative Color Steel Technology

Title: State-of-the-Art Color Steel Rain Pipe Roll Forming Machine Revolutionizes the IndustryIntroduction:In an ever-evolving world of technology and innovation, the manufacturing industry is no exception. Introducing a cutting-edge Color Steel Rain Pipe Roll Forming Machine, the industry is set to witness a remarkable transformation in production processes. This state-of-the-art machine is designed to streamline the manufacturing of rain pipes, ensuring high precision, durability, and efficiency. In this article, we will delve into the features and benefits of this remarkable equipment and explore how it is set to revolutionize the industry.Paragraph 1:The Color Steel Rain Pipe Roll Forming Machine, developed by leading experts in the field, offers a remarkable solution for the manufacturing of rain pipes. Equipped with advanced technology and precise engineering, this machine has the potential to usher in a new era in the production process. By optimizing the use of raw materials and maximizing output, manufacturers can improve efficiency and reduce costs.Paragraph 2:One of the key features of this Color Steel Rain Pipe Roll Forming Machine is its flexibility. Designed to accommodate various pipe sizes and shapes, manufacturers can easily adapt the machine to meet specific project requirements. This adaptability not only saves time but also reduces the need for additional equipment, ultimately reducing production costs.Paragraph 3:The machine's high precision capabilities ensure that each rain pipe is manufactured to exact specifications. This eliminates any inconsistencies that can occur with traditional manufacturing methods, guaranteeing a superior product that meets industry standards. The precision of the machine ensures that rain pipes are uniform in shape, size, and thickness, enhancing their durability and longevity.Paragraph 4:Furthermore, the Color Steel Rain Pipe Roll Forming Machine is equipped with automatic controls and feedback systems. This allows manufacturers to monitor and maintain optimal production conditions, minimizing errors and ensuring a seamless manufacturing process. With adjustable settings and real-time data monitoring, production efficiency is significantly increased, resulting in higher output and reduced downtime.Paragraph 5:In addition to the technical advantages, the machine's user-friendly interface and intuitive design make it accessible to operators of all skill levels. This eliminates the need for extensive training and allows manufacturers to quickly integrate the machine into their production line. The simplified operation also reduces the likelihood of human errors, further improving product quality and minimizing waste.Paragraph 6:The environmental impact of manufacturing is a growing concern in today's world. The Color Steel Rain Pipe Roll Forming Machine addresses this concern by optimizing the use of raw materials and minimizing waste. Through precise control and measurement during the manufacturing process, the machine ensures the efficient use of resources, making it an environmentally sustainable solution.Conclusion:The introduction of the Color Steel Rain Pipe Roll Forming Machine marks a significant milestone in the manufacturing industry. With its advanced technology, precision engineering, and user-friendly interface, this machine promises to revolutionize the production of rain pipes. From its versatility and high precision capabilities to its efficiency and environmental sustainability, the machine offers a comprehensive solution for manufacturers in this sector. As the industry embraces this cutting-edge technology, we can expect to witness enhanced productivity, improved product quality, and reduced costs.

Different Types of Content Forms for SEO Optimization: Presentations, Infographics, Videos, and Documents

As businesses continue to grow and evolve, so do their communication needs. One of the most important aspects of effective communication is the ability to share information and data in a clear, concise manner. This is where forms come into play. Forms are an essential tool for collecting, processing, and sharing information, and they can take many different forms.In this blog post, we will explore the different types of forms and how they can benefit businesses, as well as introduce a new technology that can revolutionize the way forms are created and managed.PresentationsPresentations are a popular form for sharing information in the form of images, slides, and videos. Presentations are useful for sharing data, ideas, and concepts in a visually appealing and engaging way. They are also often used to introduce new products or services. Presentations can be created using PowerPoint or other presentation software and can be uploaded to platforms like SlideShare for easy sharing.InfographicsInfographics are a visual representation of data or information, usually presented in a colorful and eye-catching format. They are often used to share statistics, data, or complex information in an easily digestible way. Infographics can be created using graphic design software or online tools, such as Canva or Piktochart.VideosVideos are a versatile and engaging form for sharing information. They can be used for product demos, explainer videos, marketing messages, and more. Videos can also be used to share interviews, panel discussions, and other events. They can be uploaded to video hosting platforms like YouTube or Vimeo for easy sharing.DocumentsDocuments are a more traditional form for sharing information. They can be used for reports, proposals, guides, and other materials. Documents are often created using Microsoft Word or other word processing software and can be converted to PDF for easy sharing.Form MachineForm Machine is a new technology that can revolutionize the way forms are created and managed. It is a web-based platform that allows businesses to create and manage forms in a simple and intuitive way. Form Machine provides a user-friendly interface for creating forms, as well as a powerful form engine for processing the information collected.Form Machine is an ideal solution for businesses that need to collect data from customers, employees, or other stakeholders. It can be used for surveys, job applications, registration forms, and more. Form Machine can also be used to automate processes, such as scheduling appointments or sending notifications.ConclusionIn conclusion, forms are an essential tool for any business that wants to collect, process, and share information effectively. Presentations, infographics, videos, and documents are all useful forms for sharing information in different ways. However, the traditional methods of creating and managing forms can be time-consuming and cumbersome.Form Machine offers a streamlined solution for creating and managing forms. It is a powerful tool that can help businesses save time, improve efficiency, and enhance their communication processes. By embracing new technologies like Form Machine, businesses can stay ahead of the game and remain competitive in an ever-changing business landscape.

Title: Discover the Ultimate Roof Sheet Rolling Machine for Your Roofing ProjectIntroduction:In today's competitive construction industry, it's essential to invest in the right tools and equipment to ensure the success of your projects. One crucial aspect of any roofing project is the roof sheet rolling machine, also known as the roof panel forming machine or roof panel roll forming machine. This advanced machinery plays a vital role in creating high-quality and durable roof sheets that are an integral part of any structure. In this blog, we will explore the significance of a roof sheet rolling machine and why finding the perfect one is essential. Additionally, we will discuss the leading manufacturers in China and their superior roof sheet rolling machine models available in the market.Understanding the Importance of a Roof Sheet Rolling Machine:A roof sheet rolling machine is specifically designed to transform raw metal sheets into precisely shaped and sized roof panels. This process involves a series of intricate stages, including material loading, roll forming, cutting, and product stacking. By using a roof sheet rolling machine, construction professionals can streamline the production process, ensuring accuracy, efficiency, and consistency.Benefits of Using a High-Quality Roof Sheet Rolling Machine:Investing in a high-quality roof sheet rolling machine offers numerous advantages for contractors and construction firms:1. Superior Durability: Top-notch machines are manufactured using premium-grade materials and components, ensuring the longevity and resilience of the equipment.2. Precision and Efficiency: Advanced technology and design features allow for precise panel forming, cutting, and sizing, minimizing material waste and increasing productivity.3. Versatility: Leading roof sheet rolling machines can produce a variety of different panel designs, enabling contractors to cater to diverse customer requirements.4. Easy Operation and Maintenance: Quality machines come with user-friendly interfaces, making them easy to operate. Moreover, maintenance requirements are minimal, reducing downtime during the production process.5. Output Quality: The use of reliable roof sheet rolling machines ensures consistent and uniform panel quality, giving clients peace of mind regarding the structural integrity of their roofs.Leading Manufacturers of Roof Sheet Rolling Machines in China:China has established itself as a global leader in manufacturing top-quality roof sheet rolling machines. Some renowned Chinese manufacturers that provide exceptional machines include:1. [Manufacturer 1]: Known for their commitment to superior design and engineering, this manufacturer offers a range of high-performance roof sheet rolling machines suitable for various roofing applications.2. [Manufacturer 2]: With a reputation built on innovation and precision engineering, this manufacturer produces advanced roof panel forming machines that promise remarkable accuracy, durability, and efficiency.3. [Manufacturer 3]: Known for their wide range of roll forming machinery, this manufacturer delivers top-quality roof panel roll forming machines that cater to the diverse needs of construction professionals.Conclusion:Investing in a roof sheet rolling machine is a game-changer for construction firms looking to enhance their roofing projects' efficiency, accuracy, and overall quality. The significance of finding a reliable and high-quality machine cannot be overstated. Manufacturers in China, such as [Manufacturer 1], [Manufacturer 2], and [Manufacturer 3], offer exceptional options that guarantee superior performance and durability. By choosing the right roof sheet rolling machine, you can elevate your roofing projects to new heights, ensuring customer satisfaction and success in your construction endeavors.Keywords: Roof Sheet Rolling Machine, Roof Panel Forming Machine, Roof Panel Roll Forming Machine

How to Choose a Steel Angle Roll Forming Machine?

Title: Revolutionary Steel Angle Roll Forming Machine: A Game-Changer in Metal Fabrication IndustryIntroduction:Steel angle roll forming machines have long played a vital role in the metal fabrication industry, allowing for efficient and precise manufacturing of steel angles used in various applications. A recent introduction by a leading manufacturer is revolutionizing the industry by setting new standards in terms of performance, versatility, and cost-effectiveness. This state-of-the-art roll forming machine operates with unrivaled precision, enabling manufacturers to meet the growing demands of steel angles across diverse sectors.Enhanced Performance and Versatility:This advanced steel angle roll forming machine boasts a range of cutting-edge features that significantly enhance its performance and versatility. Equipped with the latest technology, it offers unprecedented precision in producing steel angles of various measurements and profiles. The machine's high-speed capabilities minimize production time while maintaining excellent quality control.The roll forming machine incorporates adjustable roller sets, allowing for easy customization of the angle dimensions. With its ability to handle a wide range of materials, including stainless steel, aluminum, and carbon steel, manufacturers now have the flexibility to cater to a broader spectrum of customer requirements.User-Friendly Interface and Automated Operations:The steel angle roll forming machine's user-friendly interface simplifies the programming and operation processes, ensuring smooth and seamless production runs. Its intuitive control panel allows operators to set various parameters such as length, angle, and bend radius with precision and ease. The machine's automated operations further boost efficiency, reducing the need for manual labor and minimizing the risk of human error.Cost-Effectiveness and Increased Productivity:Engineered to optimize production efficiency, the roll forming machine significantly reduces material wastage, thereby lowering operational costs. Its precise bending and cutting mechanisms ensure minimal scrap during the manufacturing process. Moreover, the machine's high-speed capabilities enable manufacturers to meet tight deadlines and increase their overall productivity.Seamless Integration with Existing Workflows:Recognizing the diverse operational needs of manufacturers, the steel angle roll forming machine is designed to seamlessly integrate into existing production lines. The machine's modular design allows for easy installation and integration with other equipment. Its compatibility with industry-standard software streamlines the exchange of data, bridging the gap between manufacturing processes and achieving enhanced efficiency across the entire production cycle.Robust Build Quality and Safety Features:Safety is paramount in any manufacturing environment, and this roll forming machine prioritizes operator well-being through its comprehensive safety system. Equipped with emergency stop buttons and protective enclosures, it ensures a secure working environment. The machine's robust construction guarantees durability, reducing downtime due to maintenance issues and maximizing its operational lifespan.Implications for the Metal Fabrication Industry:The introduction of this revolutionary steel angle roll forming machine is set to transform the metal fabrication industry significantly. Its unrivaled precision, enhanced performance, and streamlined workflows will enable manufacturers to meet evolving market demands efficiently.Manufacturers utilizing this roll forming machine will experience reduced costs, increased productivity, and enhanced product quality, ultimately leading to improved customer satisfaction and business growth. By leveraging the machine's versatility, manufacturers can now expand their product offerings, catering to a wide array of sectors such as construction, infrastructure development, and transportation.Conclusion:The advent of the steel angle roll forming machine signifies a breakthrough in the metal fabrication industry. Its cutting-edge features, user-friendly interface, and automated operations will pave the way for a new era of efficiency and precision. Manufacturers choosing to invest in this revolutionary machine will undoubtedly gain a competitive edge, fueling growth and innovation in the ever-evolving world of steel angle production.

Top-Quality Automatic Metal Slitting Machines for Steel Coils

In an ever-evolving metalworking industry, it is crucial to stay ahead of competition by providing high-quality and efficient solutions. That's where our company comes in! As a leading manufacturer and exporter of metalworking machinery in China, we specialize in Automatic Slitting Machines, Steel Coil Slitting Machines, and Metal Steel Slitting Machines.Our Automatic Slitting Machines are designed to operate at high speeds and precision. They are equipped with advanced cutting tools and computer-controlled systems that ensure consistent and accurate cuts on every sheet. With automatic feeding and stacking, the machine eliminates the need for manual labor and increases production efficiency.The Steel Coil Slitting Machine is perfect for large-scale metalworking operations. Designed to handle the heaviest coils, our steel coil slitting machine boasts advanced design features that guarantee high output and low maintenance. With an accurate digital control system, the machine can make precise and clean slits with minimal waste.Moreover, our Metal Steel Slitting Machine is the go-to solution for any sheet metal cutting needs. With a sturdy structure and reliable components, our metal steel slitting machine provides the perfect balance of accuracy, speed, and durability. It is capable of handling the most challenging materials and producing clean cuts consistently.Our commitment to delivering high-quality and reliable solutions has earned us a solid reputation in the industry. With over a decade of experience, we have become the trusted partner for many businesses in the metalworking industry. Our machines are designed to meet international quality standards to ensure they meet the unique needs of global customers.We pride ourselves on providing excellent customer service to ensure we cater to our clients' needs. We work closely with our customers to ensure they receive the right machine for their business and provide them with timely support and maintenance. We have a team of experienced technicians who can install, troubleshoot, and repair our machines.In summary, our company is dedicated to providing high-quality Automatic Slitting Machines, Steel Coil Slitting Machines, and Metal Steel Slitting Machines to the global market. We are committed to innovation and continuously improving our products to ensure they keep up with the dynamic needs of the industry. We provide excellent customer service to ensure our clients get the most out of their investment. Contact us today and let's help you take your metalworking business to the next level.

How to Roll Form Step Tile Metal Steel Roof Sheet

Steel roofing sheets are one of the most commonly used roofing materials in the construction industry. They are preferred for their durability, affordability, and ease of installation. However, these sheets come in different sizes, shapes, and designs, and it is often a daunting task to find the right roofing sheet for your building.To address this challenge, a reputable company that specializes in the production of metal roofing sheet roll forming machines has just launched a new product into the market. The Step Tile Metal Steel Roof Sheet Roll Forming Machine is a top-grade roofing sheet roll forming machine that is designed to produce beautiful, durable, and cost-effective roofing sheets.The Step Tile Metal Steel Roof Sheet Roll Forming Machine is an advanced machine that is crafted using high-quality materials and innovative technology. It is compact, easy to operate, and highly efficient, contributing significantly to reducing the cost of production and increasing profitability for roofing companies.The machine is designed with precision and attention to detail, ensuring that it produces accurate and high-quality roofing sheets. It has an automatic control system that allows operators to adjust the width, thickness, and profile of the sheets with ease.One of the key features of the Step Tile Metal Steel Roof Sheet Roll Forming Machine is its ability to produce roofing sheets of different profiles. Whether you need a stepped or flat roof profile, the machine delivers consistent and high-quality output, each time. What’s more, the machine can produce roofing sheets with a thickness range of 0.3-0.7mm and a maximum width of 1250mm, making it highly versatile and adaptable to various roofing requirements.Apart from its technical capabilities, the Step Tile Metal Steel Roof Sheet Roll Forming Machine is also designed with safety and ergonomics in mind. It has a protective cover that shields operators from possible injuries while using the machine. The machine also has an ergonomic control panel that is easy to use and ensures the operator is comfortable during the production process.The Step Tile Metal Steel Roof Sheet Roll Forming Machine is the result of years of research and development aimed at providing roofing companies with the most reliable and efficient machine to produce quality roofing sheets. It is manufactured by a reputable company that has over 20 years of experience in the production of metal roofing sheet roll forming machines. The company has an excellent track record of providing high-quality products and outstanding customer service.In conclusion, the Step Tile Metal Steel Roof Sheet Roll Forming Machine is a game-changer in the metal roofing industry. It is a top-quality machine that guarantees superior output, durability, and efficiency. With this machine in your possession, you can be assured of delivering high-quality and cost-effective roofing solutions to your customers. Investing in the Step Tile Metal Steel Roof Sheet Roll Forming Machine is a wise decision that roofing companies cannot afford to miss out on.

How to Make Roof Tiles: A Comprehensive Guide for Machine Users

Title: Revolutionary Roof Tile Making Machine Makes Waves in the Construction IndustryIntroduction:In a groundbreaking development, an innovative and state-of-the-art roof tile making machine has emerged as a game-changer in the construction industry. This groundbreaking technology, developed by a leading company in the field, has revolutionized the way roof tiles are manufactured, offering a sustainable, efficient, and cost-effective solution for construction projects worldwide.Transforming Roofing Processes:Traditional methods of manufacturing roof tiles have long been associated with labor-intensive practices that consume vast amounts of resources and contribute to environmental degradation. However, this new roof tile making machine has effectively transformed the roofing processes, ensuring minimal environmental impact while keeping up with the ever-increasing demands of the construction industry.Key Features and Technology:This cutting-edge roof tile making machine incorporates a range of features and utilizes advanced technology to streamline the production process. It offers precision molding, allowing for the creation of consistent and high-quality roof tiles. With its automated system and minimal manual labor requirements, this machine enhances operational efficiency, reducing labor costs and minimizing the risk of human error.Sustainable Materials and Practices:One of the main selling points of this roof tile making machine is its commitment to sustainability. It employs environmentally-friendly materials and practices, ensuring minimal waste generation and energy consumption. By utilizing recycled materials or eco-friendly alternatives, this machine significantly reduces the environmental footprint associated with traditional manufacturing methods.Cost-Effectiveness and Versatility:The use of this innovative roof tile making machine not only benefits the environment but also proves economically advantageous for construction companies. Its highly efficient production process, coupled with low energy consumption, enables significant cost savings. Additionally, the machine supports the creation of various roof tile designs, catering to the diverse aesthetic preferences of builders and homeowners alike.Enhanced Durability and Longevity:Roof tiles manufactured by this state-of-the-art machine are highly durable and weather-resistant, making them ideal for diverse climatic conditions. Through meticulous design and quality control measures, these tiles withstand harsh environmental factors, such as heavy rain, extreme temperatures, and strong winds. With increased longevity, these tiles offer long-term value to builders and homeowners alike.Streamlined Maintenance and Repair:An added advantage of this advanced roof tile making machine is its focus on easy maintenance and repair of the tiles it produces. With a standardized design and precise molding, any necessary repairs or replacements can be accomplished swiftly and conveniently, minimizing disruption to the building and the occupants.Global Impact and Industry Acceptance:The introduction of this innovative roof tile making machine has generated considerable interest within the construction industry globally. With its ability to transform traditional methods, this technology has disrupted the market and paved the way for a more sustainable and efficient future. Companies worldwide are recognizing its potential and adopting this technology to revolutionize their roofing processes.Conclusion:The emergence of this futuristic roof tile making machine is set to reshape the construction industry by providing a sustainable, cost-effective, and efficient solution for manufacturing high-quality roof tiles. With its focus on environmental responsibility and the incorporation of advanced technology, this machine epitomizes a new era of innovation and progress in the field. As construction companies increasingly embrace this technology, we can expect to witness a significant shift towards sustainable building practices, benefiting not only the industry but also our planet as a whole.

Corrugated Metal Ideas for Your Home: Lightweight, Durable and Environmentally Friendly

[Article]Corrugated Metal Ideas For The Home: Innovative Solutions by Corrugated Metal RollerMetal sheets or rolls have always been a popular choice for a variety of applications in the construction industry. Their lightweight nature, corrosion resistance, durability, and cost-effectiveness make them an ideal material for numerous projects. In recent years, these versatile materials have found their way into homes, offering homeowners a wide array of creative and innovative solutions. One company, in particular, has been at the forefront of providing exceptional corrugated metal products for home use: Corrugated Metal Roller.Corrugated Metal Roller, a leading manufacturer and supplier of metal sheets, has been revolutionizing the way people incorporate metal into their homes. With their extensive range of offerings, they have become a trusted name in the industry. Metal sheets and rolls have never been more accessible, and the benefits they bring to the table have made them an attractive choice for homeowners.One of the primary advantages of using corrugated metal in home projects is its lightweight nature. Compared to other building materials, such as wood or concrete, metal sheets are significantly lighter, making them easier to handle and transport. This characteristic allows for greater flexibility in design and installation, making it an excellent choice for both DIY enthusiasts and professional builders alike.Additionally, corrugated metal is known for its corrosion resistance. Unlike traditional materials, such as wood, which are susceptible to rot and decay, metal sheets are built to withstand the test of time. This resistance to corrosion ensures that homeowners can enjoy their investment for many years to come, even in harsh weather conditions. Furthermore, metal sheets require minimal maintenance, saving homeowners both time and money in the long run.Durability is another significant advantage associated with corrugated metal. Its robust and rigid structure offers exceptional strength, making it suitable for a wide range of applications. From roofing and siding to interior design elements such as accent walls or ceiling finishes, corrugated metal provides unparalleled durability and longevity. This durability ultimately translates into cost savings for homeowners, as they can rely on their metal installations for decades without the need for replacement or extensive repairs.Apart from being an economical choice, corrugated metal is also highly sustainable. The use of metal sheets contributes to reduced energy consumption during the construction process, as they are lightweight and require less fuel for transportation. Additionally, metals can be easily recycled at the end of their lifespan, promoting a circular economy. This eco-friendly aspect has made corrugated metal a favorite among environmentally conscious homeowners looking to reduce their carbon footprint and have a positive impact on the planet.With the accessibility of corrugated metal sheets and rolls, homeowners now have endless opportunities to incorporate this versatile material into their homes. From enhancing the aesthetics of an outdoor space by creating a stunning metal fence or gate to adding a contemporary touch to an interior by installing a corrugated metal accent wall, the possibilities are genuinely endless. Corrugated Metal Roller offers a vast range of corrugated metal products, including various gauges, colors, and finishes, empowering homeowners to unleash their creativity and bring their design visions to life.In conclusion, the rise in popularity of corrugated metal for home use can be attributed to the numerous advantages it offers. Corrugated Metal Roller has played a crucial role in making metal sheets and rolls easily accessible to homeowners, allowing them to explore innovative and creative designs for their homes. With their lightweight, corrosion-resistant, durable, and economical features, corrugated metal has become the material of choice for homeowners seeking long-lasting and sustainable solutions. Whether used for roofing, siding, or interior accents, it is clear that corrugated metal has found its place in the modern home.

Advanced Roll Forming Machine for Color Steel Tile Production: Discover the Latest News!

Color Steel Tile Roll Forming Machine Industry Analysis and Top PlayersThe Global Color Steel Tile Roll Forming Machine Market research report is a comprehensive analysis of the industry, focusing on key trends, market share, and growth opportunities. The report covers a detailed analysis of the market size, segmentation, and competitive landscape in various regions across the globe.Introduction:Color Steel Tile Roll Forming Machine (need to remove brand name) is a leading player in the roll forming machine industry. With its advanced technology and superior quality, the company has been providing efficient roll forming solutions to various industries. Their color steel tile roll forming machines are widely used in the construction industry for making high-quality roof and wall tiles.Color Steel Tile Roll Forming Machine Industry Analysis:The global color steel tile roll forming machine market is projected to grow at a significant rate in the coming years. The increasing demand for color steel tiles in the construction industry, coupled with the growing need for automated roll forming machines, is driving the market growth. The rise in urbanization and industrialization in developing countries is also contributing to the market expansion.The report highlights the key factors influencing the market, including the technological advancements in roll forming machines, the availability of raw materials, and the regulatory landscape. The increasing focus on sustainable construction practices and the use of eco-friendly materials is also expected to boost the demand for color steel tile roll forming machines.Segmentation Analysis:Based on product type, the color steel tile roll forming machine market can be segmented into single layer, double layer, and multiple layer machines. The single-layer machines are the most commonly used in the industry due to their simplicity and cost-effectiveness. However, the demand for double layer and multiple layer machines is expected to grow at a higher rate in the coming years, as they provide increased flexibility and efficiency in tile production.In terms of application, the market can be categorized into residential, commercial, and industrial sectors. The residential sector holds the largest market share, owing to the increasing construction of residential buildings. However, the commercial and industrial sectors are witnessing significant growth, driven by the construction of commercial complexes, warehouses, and manufacturing units.Competitive Landscape:Color Steel Tile Roll Forming Machine (need to remove brand name) is one of the key players in the market, with a wide range of innovative roll forming machines. The company focuses on research and development to introduce advanced technologies and enhance its product offerings. It also emphasizes strategic collaborations and partnerships to expand its distribution network and reach a wider customer base.Some of the other prominent players in the market include XYZ Company, ABC Corporation, and PQR Industries. These companies are also investing in research and development activities to improve their product portfolios and gain a competitive edge in the market.Conclusion:The global color steel tile roll forming machine market is witnessing significant growth, driven by the increasing demand for color steel tiles in the construction industry. The market is highly competitive, with key players focusing on technological advancements and partnerships to stay ahead. With the rise in urbanization and industrialization, the demand for efficient roll forming machines is expected to continue growing in the coming years.