High-quality Cable Tray Forming Machine for Efficient Production - Your Ultimate Guide

By:Admin

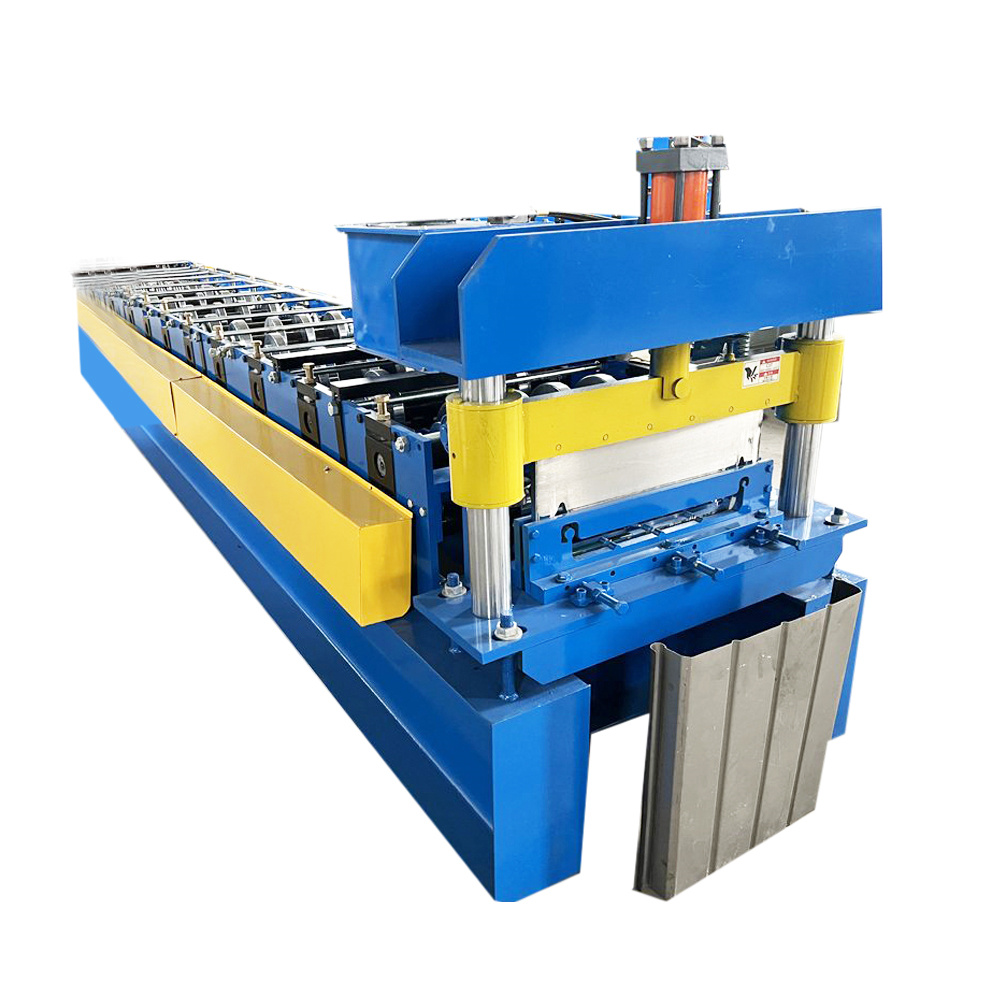

In recent years, there has been a significant increase in demand for cable tray systems across various industries. With the rise in infrastructure development, the need for efficient cable management solutions has become more critical than ever. In response to this growing demand, {company} has developed a state-of-the-art Cable Tray Forming Machine that is set to revolutionize the manufacturing industry.

{Company} is a leading provider of innovative solutions for the production of cable tray systems. With a strong focus on research and development, the company has continuously worked towards improving the efficiency and quality of their products. The Cable Tray Forming Machine is a testament to their commitment to innovation and excellence.

The Cable Tray Forming Machine is designed to streamline the manufacturing process of cable tray systems, offering a range of benefits for manufacturers. The machine is capable of producing cable trays of various sizes and configurations, catering to the diverse needs of different industries. With its advanced technology, the machine can produce high-quality cable trays with precision and efficiency, reducing production time and costs for manufacturers.

One of the key features of the Cable Tray Forming Machine is its versatility. The machine is equipped with interchangeable tooling, allowing manufacturers to produce different types of cable trays using the same equipment. This flexibility not only increases the efficiency of production but also enables manufacturers to meet the specific requirements of their clients with ease.

Furthermore, the Cable Tray Forming Machine is designed for ease of use, with a user-friendly interface and intuitive controls. This makes it accessible for operators of varying skill levels, minimizing the need for extensive training and ensuring a smooth transition to automated manufacturing processes.

In addition to its operational benefits, the Cable Tray Forming Machine is also designed with sustainability in mind. The machine is energy-efficient, reducing the carbon footprint of the manufacturing process. This aligns with {company}'s commitment to environmental responsibility and sustainable practices.

{Company} has also established a comprehensive support system for the Cable Tray Forming Machine, providing technical assistance, maintenance, and training to ensure the smooth operation of the equipment. This commitment to customer support reflects the company's dedication to supporting manufacturers in optimizing their production processes.

The introduction of the Cable Tray Forming Machine is set to bring significant advancements to the manufacturing industry. By improving the efficiency, quality, and sustainability of cable tray production, the machine offers a competitive edge for manufacturers seeking to meet the growing demand for cable management solutions.

Furthermore, the machine's versatility and user-friendly design make it a valuable asset for manufacturers looking to diversify their product offerings and adapt to evolving market needs. With the support and expertise of {company}, manufacturers can take advantage of the benefits offered by the Cable Tray Forming Machine to stay ahead in the industry.

As the demand for cable tray systems continues to grow, the Cable Tray Forming Machine presents an opportunity for manufacturers to enhance their production capabilities and meet the needs of the market effectively. With its innovative technology and commitment to quality, {company} is set to revolutionize the manufacturing industry with this groundbreaking solution.

Company News & Blog

Roll Forming Machines for Metal Roof and Drywall Studs and Track

If you are involved in the construction industry, you probably know how important it is to have the right equipment to get the job done quickly and efficiently. One of the most essential pieces of equipment that you need is a metal stud making machine.There are many different types of metal stud making machines on the market, but the most popular ones are those that are designed to produce high-quality metal studs and tracks used in drywall installation and house making. These machines are known for their precision, accuracy, and speed, making them the perfect tools for any construction project.One of the best things about metal stud making machines is that they are incredibly versatile. They can be used to produce a wide range of metal studs and tracks, including those made from steel, aluminum, and other metals. This means that you can use them for a variety of different projects, from small-scale jobs like installing a new drywall partition to large commercial construction projects.Metal stud making machines come in a range of sizes and configurations to meet the needs of different construction businesses. Some machines are designed to be portable, while others are more stationary. Some machines are designed to produce only metal studs, while others can produce both studs and tracks.To ensure that you are getting the best metal stud making machine for your needs, it is important to do your research and compare different models and brands. Look for a machine that is easy to use, has a high level of automation, and can produce high-quality metal studs quickly and efficiently.One popular brand of metal stud making machines is Alibaba. Their drywall stud roll forming machine is designed to produce high-quality studs and tracks for drywall installation and house framing. This machine is easy to operate and can produce metal studs and tracks in a range of different sizes and configurations.Another popular brand of metal stud making machine is Jobsite Roll Forming Equipment. Their machines are designed to produce metal studs and tracks for a range of different applications, including both residential and commercial construction projects. These machines are known for their precision and speed, making them the perfect choice for any construction business.In conclusion, if you are in the construction industry and looking to invest in a metal stud making machine, there are plenty of options to choose from. Whether you are looking for a portable machine or a more stationary model, there is sure to be a machine that fits your needs. Just be sure to do your research and compare different brands and models to find the best machine for your construction business.

New Machine Helps Build Safer Roads with W Beam Crash Barriers" can be rewritten as "Innovative Machine Streamlines Construction of W Beam Crash Barriers for Safer Roads".

W Beam Crash Barrier Machine Proves to be a Game-Changer In the Construction IndustryIn today's time, safety has become one of the major concerns while constructing infrastructure. Road safety barriers are effective tools that can help prevent accidents, save lives, and minimize the damage done during a crash. A W Beam Crash Barrier Machine has revolutionized the construction industry by delivering an efficient and reliable way of constructing crash barriers.The W Beam Crash Barrier Machine is a specialized machine that is designed to construct W beam guardrails that are properly aligned to the road and also at an optimal height that ensures the safety of the vehicles. This machine is designed to simplify the process of manufacturing and installing crash barriers, reducing the manpower required and increasing the speed of construction.With years of research and development in the field of road safety barriers, the W Beam Crash Barrier Machine has become the go-to machine for construction companies around the world. Its features include high-speed production capacity, precise installation, and compatibility with a range of materials that can be used for construction.One of the most significant advantages of using the W Beam Crash Barrier Machine is the speed at which it operates. This machine has a high-speed production capacity that can produce up to 1.2 meters of crash barrier per second. This is significantly faster than traditional manufacturing methods, making it an ideal choice for large-scale construction projects.Another important feature of the W Beam Crash Barrier Machine is its precise installation capabilities. The machine has a built-in sensor system that ensures that the crash barriers are installed at the correct height and are properly aligned with the road. This helps to reduce accidents and improve overall road safety.The machine is also compatible with a range of materials used for construction, including steel, aluminum, and other metals. This gives the construction company the flexibility to choose the material that is most appropriate for their specific project and budget.The W Beam Crash Barrier Machine is also designed with safety in mind. It has a range of safety features such as emergency stop buttons, automatic shut-off mechanisms, and safety guards to ensure that the operator and other construction workers are protected from any potential hazards.One of the leading manufacturers of W Beam Crash Barrier Machine is a company {} with headquarters in China. The company has a vast experience of 22 years in the manufacturing of roll forming machines and has a strong reputation for providing quality machines to the construction industry.The company's commitment to quality and innovation is reflected in the W Beam Crash Barrier Machine. The machine is made using only the highest quality materials and is manufactured to the strictest industry standards. This ensures that the machine is reliable, safe, and efficient.In addition to providing high-quality machines, the company also offers exceptional after-sales support to its customers. They have a team of experienced technicians who are available to provide training and technical support to ensure that their customers get the most out of their machines.The W Beam Crash Barrier Machine has proven to be a game-changer in the construction industry. Its speed, efficiency, and safety features make it an ideal choice for construction companies looking to improve their processes and deliver high-quality projects.In conclusion, the W Beam Crash Barrier Machine is an innovative machine that has revolutionized the construction industry. Its high-speed production capacity, precise installation capabilities, and compatibility with a range of materials have made it an ideal choice for construction companies around the world. Furthermore, with the commitment to quality and innovation by the manufacturer, the W Beam Crash Barrier Machine continues to provide exceptional value to its users.

Revolutionary 3D Printer Utilizing Aluminium Extrusion Technology

Aluminium Extrusion 3D Printer Revolutionizing Manufacturing ProcessesIn recent years, the field of additive manufacturing has been rapidly evolving, with numerous advancements being made to enhance the capabilities and efficiency of 3D printers. One groundbreaking innovation that has garnered significant attention is the Aluminium Extrusion 3D Printer developed by a pioneering company that focuses on revolutionizing the manufacturing industry.Introducing lightweight and versatile materials into 3D printing has always been a challenge. However, this newly developed Aluminium Extrusion 3D Printer eliminates the boundaries faced by traditional printing methods by allowing for the creation of complex and intricate designs using aluminium as the primary printing material. This breakthrough technology brings forth a multitude of possibilities for various industries, ranging from aerospace and automotive to construction and consumer products.The construction of this cutting-edge printer involves utilizing high-quality components and state-of-the-art engineering techniques. The company behind this remarkable innovation has ensured that their printer is equipped with the latest advancements in the field of 3D printing technology. This includes a robust frame made from durable materials, precise extrusion systems, and advanced software for seamless operation.One significant advantage of the Aluminium Extrusion 3D Printer is its ability to fabricate large-scale prototypes and parts with exceptional precision. The printer's large build volume allows for the creation of objects up to 2 meters in length, eliminating the need for assembly or welding of multiple parts. This capability greatly reduces manufacturing time and costs, making it an attractive choice for industries looking to streamline their production processes.Moreover, the aluminium material used in the printing process offers several advantages over traditional printing materials. Aluminium has superior strength-to-weight ratio, excellent thermal conductivity, and high corrosion resistance. These properties make it an ideal choice for industries where lightweight structures and high-performance components are crucial. With the Aluminium Extrusion 3D Printer, manufacturers can now easily incorporate aluminium into their designs without compromising the structural integrity or performance of the final product.Furthermore, the Aluminium Extrusion 3D Printer is equipped with an advanced slicing software that ensures precise layer-by-layer deposition of aluminium. This software incorporates complex algorithms to optimize support structures and minimize material waste, resulting in cost-effective and sustainable manufacturing processes. Additionally, it allows for intricate geometries and intricate designs to be printed with minimal post-processing requirements, saving both time and resources.The impact of this Aluminium Extrusion 3D Printer on various industries cannot be overstated. In the aerospace industry, where weight reduction is critical, the ability to 3D print lightweight aluminium components opens up a realm of possibilities for optimizing fuel efficiency. Automotive manufacturers can leverage this technology to fabricate stronger and lighter parts, improving overall performance and reducing emissions. In the construction industry, the Aluminium Extrusion 3D Printer enables the rapid production of customized building components with unparalleled precision, revolutionizing the way structures are built.As the Aluminium Extrusion 3D Printer revolutionizes the manufacturing industry, this pioneering company continues to push the boundaries of 3D printing technology. Their commitment to innovation and dedication to quality ensures that manufacturers across various industries will benefit from this revolutionary printer. With its unparalleled capabilities and immense potential, the Aluminium Extrusion 3D Printer is set to reshape the manufacturing landscape and open up a new era of possibilities.

How Automatic Guardrail Roll Forming Machine Can Improve Road Safety?

Highway Guardrail Machine: The Future of Road SafetyRoad safety is a critical issue all over the world, and governments are continually looking for ways to ensure that the roads are safe for drivers and pedestrians alike. One of the essential elements of road safety is the implementation of guardrails on high traffic roads to prevent accidents. Guardrails act as a barrier to protect drivers and passengers from accidents by absorbing the impact of an out-of-control vehicle. Installing guardrails on the highways can be a daunting task, often requiring a lot of time, manpower, and resources. However, with the introduction of the latest technology, highway guardrail machines have made this process efficient and cost-effective.One such company leading the charge in this regard is the Highway Guardrail Machine (HGM) company. Helping to revolutionize the way we approach highway guardrail installation, HGM designs and manufactures machines that make the task easier and more efficient. The company is dedicated to providing innovative, reliable, and high-quality manufacturing services, with the aim of improving road safety and reducing the risk of injury and death on the highways.The HGM AdvantageOne of the main advantages of using HGM products is the machines' versatility, durability, and ease of use. Compared to traditional installation methods, HGM highway guardrail machines can be used to install guardrails continuously, thus reducing the chances of gaps and breaks that may compromise safety. The machines can be adjusted according to the terrain, making them suitable for use in a variety of environments. Additionally, because HGM machines are designed for precision, they can install guardrails with minimal damage to the surrounding landscape, thus minimizing environmental impact.The machines also offer significant advantages in terms of cost-effectiveness. Because of their precision and efficiency, HGM highway guardrail machines require less labor and time to install guardrails, which translates to lower costs. This is particularly beneficial for governments or any company managing road construction projects that are working on a budget. Furthermore, the machines can pay for themselves quickly, as they require less maintenance and repairs than traditional systems.HGM Company VisionHGM's primary goal is to create a safer environment for both drivers and pedestrians by providing innovative solutions for highway guardrail installation. The company recognizes the importance of guardrails in reducing accidents and aims to make the installation process more effective, efficient, and environmentally friendly. HGM's modern machines also provide a safer working environment for the workers installing the guardrails by reducing the need for manual labor, which can be dangerous in high traffic areas.The company's commitment to quality assurance is demonstrated by its strict adherence to safety regulations and best practices. HGM machines undergo rigorous quality control procedures before they are released to the market, ensuring that they meet the highest standards of performance, safety, and reliability. Additionally, the company invests heavily in research and development to ensure that its products remain cutting-edge and meet growing market demands.ConclusionHighway Guardrail Machine is a leading company that designs and manufactures innovative highway guardrail machines. The company's products offer significant advantages in terms of efficiency, safety, and cost-effectiveness, making the installation of guardrails on highways more effective and accessible. The company's focus on innovation, sustainability, and safety ensures that it remains at the forefront of the industry and provides the most effective solutions for the ever-growing demand for highway guardrails.Together with their customers and the community, HGM is committed to creating a safer future by providing innovative solutions for highway guardrail installation. Interested parties can find out more about HGM's products and services on their website. In conclusion, HGM is helping to make the roads safer by providing cutting-edge highway guardrail machines.

How Glazed Steel Roofing Tile Corrugating Machines Improve Color Steel Production

Color Steel Glazed Steel Roofing Tile Corrugating Machine Enters the MarketThe demand for high-quality and durable roofing materials is on the rise in various parts of the world. One of the most popular roofing materials, especially in areas that experience harsh weather conditions, is color steel glazed steel roofing tiles. These tiles not only provide excellent insulation but also add aesthetic appeal to any structure.To meet the increasing demand for color steel glazed steel roofing tiles, () introduces a new corrugating machine. The machine adopts the latest technology, from uncoiling and feeding to curving and cutting, to produce high-quality and perfect roofing tiles. The tiles have a glossy appearance, offering an elegant and sophisticated look to your residential or commercial building.The new machine produces roofing tiles that are suitable for different installation needs. Whether you need tiles for large warehouses, shopping malls, or residential homes, the machine can adjust to your specifications. You can select various sizes, colors, and patterns to customize the roofing tiles to suit your needs.The roofing tiles produced by () are strong, durable, and resistant to harsh weather conditions. They can withstand high winds, heavy rainfall, and hailstorms. They are also corrosion-resistant, making them perfect for buildings in coastal areas.Apart from their functional benefits, the color steel glazed steel roofing tiles produced by () also provide thermal insulation, noise reduction, and fire resistance. They are energy-efficient, reducing your heating or cooling costs throughout the year.The company's production line uses high-quality materials and advanced technology to ensure that they produce roofing tiles of the highest quality. They have a team of experienced engineers and technicians who carry out regular maintenance and quality checks to ensure that all machines are in top condition.The new corrugating machine is easy to operate, making it perfect for both small-scale and large-scale production. The machine is fully automated, reducing human error and improving the overall output. You can set the machine to produce a certain number of roofing tiles at a particular time, ensuring that your production schedule is on track.() has a reputation for producing high-quality and long-lasting roofing materials, from tiles to metal sheets and galvanized steel pipes. They have won various awards and recognition for their quality products, including the ISO 9001 certification.In addition to their quality products, () also offers excellent customer service. They have a team of dedicated customer service representatives who are always ready to assist with any inquiries or concerns. They offer free consultation services to help you choose the right roofing materials for your project.The new corrugating machine is expected to increase the company's production capacity, meeting the growing demand for color steel glazed steel roofing tiles. The machine is also expected to enrich their product line, enabling them to cater to a wider range of customers.Overall, the introduction of the new corrugating machine by () is a game-changer in the roofing industry. It offers a new level of efficiency, quality, and affordability, making it ideal for contractors, architects, and property owners who want durable and stylish roofing tiles. With their commitment to quality and customer service, () is poised to become a market leader in the roofing industry.

How Glazed Tile Manufacturing Machine Can Transform Your Tile Production

Glazed Tile Manufacturing Machine Offers High-Quality and Efficient ProductionIn the world of construction, glazed tiles are becoming increasingly popular due to their durability, versatility, and aesthetic appeal. With the demand for high-quality glazed tiles on the rise, manufacturers are seeking ways to improve their production processes and ensure consistent quality in their products. This is where the Glazed Tile Manufacturing Machine comes in, offering a reliable and efficient solution for producing glazed tiles in large quantities.The Glazed Tile Manufacturing Machine, which is developed and manufactured by one of the leading engineering companies in the industry, is a state-of-the-art production system that combines cutting-edge technology and advanced machinery to create high-quality glazed tiles. Its fully automated operation minimizes the need for manual labor, allowing for increased efficiency and productivity in the production process.The machine is highly customizable, with various options for tile size, thickness, color, and texture. This allows manufacturers to produce a wide range of glazed tiles to meet the specific needs of their customers. The Glazed Tile Manufacturing Machine can produce up to 10,000 tiles per day, making it a cost-effective solution for large-scale production and reducing the need for multiple machines.The advanced technology used in the Glazed Tile Manufacturing Machine ensures consistent quality in each tile produced. The machine is equipped with sensors and advanced software that monitor every step of the production process, from mixing the raw materials to firing the tiles in the kiln. This ensures that each tile meets the required standards of quality, strength, and durability.The Glazed Tile Manufacturing Machine is also designed with ease of use and maintenance in mind. Its user-friendly interface and intuitive control system make it easy for operators to monitor and adjust the production process as needed. The machine also requires minimal maintenance, with automated cleaning and lubrication systems that help to prevent wear and tear on its components.One of the leading users of the Glazed Tile Manufacturing Machine is {} – a company that specializes in producing high-quality glazed tiles for the construction industry. According to the company's spokesperson, the Glazed Tile Manufacturing Machine has been instrumental in improving their production efficiency and product quality. "Since we started using the Glazed Tile Manufacturing Machine, we have been able to produce more tiles in less time, while maintaining consistent quality. This has helped us to meet the growing demand for our products and stay competitive in the market," said the spokesperson.In addition to its operational benefits, the Glazed Tile Manufacturing Machine is also environmentally friendly. Its advanced production processes and energy-efficient design help to reduce energy consumption and minimize waste in the production process. This makes it a sustainable solution for manufacturers who are looking to reduce their carbon footprint and promote eco-friendly practices.In conclusion, the Glazed Tile Manufacturing Machine is a game-changer for manufacturers in the construction industry who are looking to improve their production processes and keep up with the growing demand for glazed tiles. With its advanced technology, customizable options, and user-friendly design, the machine offers a reliable and efficient solution for producing high-quality glazed tiles in large quantities. As the construction industry continues to grow, the Glazed Tile Manufacturing Machine will undoubtedly play a pivotal role in meeting the demand for durable and versatile glazed tiles.

Revolutionary Roof Sheeting Machine Provides Mobile Solution for Easy Installation

Title: Revolutionary Mobile Roof Sheeting Machine Revolutionizes Construction IndustryIntroduction:In a significant breakthrough for the construction industry, a revolutionary Mobile Roof Sheeting Machine has been introduced by an industry-leading company. This groundbreaking innovation is set to streamline roofing processes and improve efficiency, ultimately transforming the way buildings are constructed. With its cutting-edge technology and versatile capabilities, this machinery promises to revolutionize the roofing industry as we know it.1. The Need for Innovation in Roofing Construction:The construction industry has always relied on innovative technologies to enhance its processes. One area that needed attention was the roofing sector, which often struggled with time-consuming manual labor and significant safety risks. The traditional methods of roofing installation required extensive human intervention, making the process prone to errors and accidents. Recognizing this need for innovation, the company developed the Mobile Roof Sheeting Machine.2. The Mobile Roof Sheeting Machine: A Game-Changer in Roofing Technology:The Mobile Roof Sheeting Machine is a state-of-the-art, automated device designed to precisely and efficiently install roofing sheets onto buildings. It is equipped with advanced features that eliminate the need for manual labor and enhance safety on construction sites. This cutting-edge machinery not only improves the speed of the roofing process but also ensures greater accuracy and reduces the risk of human error.The machine's user-friendly interface allows for easy operation, while its intelligent control system ensures seamless sheet alignment and placement. With its robotic arms and automated functions, the machine can easily navigate complex roof structures, reducing the need for human interaction and ultimately enhancing overall productivity.3. Versatility and Adaptability:One of the significant advantages of the Mobile Roof Sheeting Machine is its versatility. It can be used for various roofing materials, such as metal, asphalt, or composite sheets, making it an ideal solution for different construction projects. Its adaptability to a range of roof configurations, including flat, pitched, and curved roofs, highlights its versatility and reliance on modern technology.4. Enhanced Efficiency and Safety:The implementation of the Mobile Roof Sheeting Machine brings multiple benefits, primarily improving efficiency and safety on construction sites. By automating the roofing process, the machine significantly reduces installation time, allowing projects to be completed faster and more efficiently. This not only leads to cost savings but also minimizes disruption to surrounding areas.Moreover, the machine's automation eliminates the need for workers to manually handle heavy roofing materials, reducing the risk of injuries and accidents. The engineered safety features, including sensors and emergency stop mechanisms, ensure a safe working environment for all personnel involved.5. Environmental Impact:In addition to its efficiency and safety advantages, the Mobile Roof Sheeting Machine also contributes to sustainability in the construction industry. With increased accuracy and reduced material waste, the inefficient use of roofing materials is minimized. Furthermore, the precision and consistency of the machine's placement prevent leaks and water damage, extending the longevity of roofs and reducing the need for repairs or replacements.Conclusion:The introduction of the Mobile Roof Sheeting Machine marks a significant milestone in the construction industry. With its advanced technology, versatility, efficiency, and safety features, this innovative machinery promises to revolutionize the way buildings are roofed. Its potential to save time, reduce human error, and enhance sustainability makes it an invaluable asset for any construction project. As this cutting-edge technology continues to gain traction, it is poised to transform the roofing industry, setting new standards and improving safety and efficiency on construction sites worldwide.

Efficient and Controlled Solar Support Forming Machine for Solar Panel Mounting Brackets

Solar energy is a rapidly growing sector worldwide. With the demand for renewable energy sources soaring, the need for efficient and economical solar panel mounting solutions is higher than ever. The revolution of the solar energy industry also brought a new demand for equipment, and one of the most sought-after tools is the Solar Panel Mounting Bracket Roll Forming Machine. LOTOS 2O19 Solar Support Forming Machine has been introduced as a practical solution for creating solar panel mounting brackets without any hassle.The LOTOS 2O19 Solar Support Forming Machine is an excellent piece of machinery that can make the job of creating solar panel mounting brackets easier and faster. It is easy to control and handle, thanks to its advanced electrical controlling cabinet. The cabinet uses the latest technology, making the machine reliable and accurate. Its precision control system allows the operator to produce high-quality mounting brackets at a faster rate.The Solar Panel Mounting Bracket Roll Forming Machine is a game-changer for those who are looking to streamline their solar panel installation processes. The machine can roll form steel into solar panel mounting brackets with a uniform shape and size. The brackets are formed in long continuous lengths that are cut to the desired length, making the installation process faster and more efficient.The machine's utility is not just limited to the solar panel industry; it can also be used in fabrication and construction sites. The color steel solar mounting structure roll forming machine can be utilized for making various kinds of metal products such as roof trusses, studs, and decking. The machine's versatility makes it a valuable asset in any metal fabrication industry.One of the significant advantages of the LOTOS 2O19 Solar Support Forming Machine is that it is easy to operate, even for those with little knowledge of engineering processes. The machine comes with a user manual that is easy to follow and understand. The manual also provides useful tips on various maintenance routines to keep the machine working and in good condition. The easy-to-use interface allows even inexperienced operators to create high-quality mounting brackets in a matter of minutes.In conclusion, the LOTOS 2O19 Solar Support Forming Machine is a practical investment for anyone involved in the solar panel industry or metal fabrication. Its ability to roll form steel into solar panel mounting brackets at a uniform shape and size makes the installation process faster, more efficient, and reliable. Its versatility also makes it an essential tool in other industries that require metal fabrication services. The inclusion of the keywords Color Steel Solar Mounting Structure Roll Forming Machine in this blog will help in its SEO optimization, which can be helpful in reaching out to the target audience.

Corrugated Roof Tile Barrel Sheet Profiling Machine: Everything You Need to Know

Innovative Corrugated Roof Tile Barrel Sheet Profiling Machine Revolutionizes Manufacturing ProcessThe manufacturing industry is constantly evolving, with new technological advancements revolutionizing the way products are made. One such innovation is the Corrugated Roof Tile Barrel Sheet Profiling Machine, which has been developed by a leading company in the industry.This groundbreaking machine is designed to streamline the production of corrugated roof tiles, barrel sheets, and other similar roofing products. It utilizes advanced profiling technology to accurately shape and cut metal sheets, resulting in a precise and high-quality finished product. The use of this machine has dramatically reduced production time and labor costs, making it a game-changer for manufacturers in the roofing industry.The Corrugated Roof Tile Barrel Sheet Profiling Machine is equipped with a state-of-the-art control system, allowing for easy and precise operation. This ensures that each product is consistently manufactured to the highest standards, meeting the strict requirements of the industry. The machine is also highly versatile, capable of producing a wide range of designs and sizes to meet the diverse needs of customers.In addition to its advanced technological features, the machine is also designed with safety and efficiency in mind. It is equipped with safety guards and emergency stop mechanisms to protect operators and prevent accidents. Furthermore, the machine’s energy-efficient design helps reduce energy consumption, making it a sustainable choice for manufacturers.The company behind this innovative machine has a long history of excellence in the manufacturing industry. With a strong focus on research and development, they have consistently delivered cutting-edge solutions to meet the evolving needs of their customers. Their commitment to quality and innovation has earned them a reputation as a trusted leader in the industry.In addition to the Corrugated Roof Tile Barrel Sheet Profiling Machine, the company offers a wide range of other manufacturing equipment and solutions. From roll forming machines to metal cutting systems, they are dedicated to providing comprehensive and custom-tailored solutions to their clients. Their team of skilled engineers and technicians work closely with customers to develop the perfect manufacturing solution for their specific needs.Through their dedication to excellence and innovation, the company has established a strong global presence, serving clients in various industries around the world. Their commitment to quality and customer satisfaction has earned them numerous accolades and recognition within the industry.The introduction of the Corrugated Roof Tile Barrel Sheet Profiling Machine is yet another example of the company’s commitment to innovation and progress. By offering a groundbreaking solution to streamline the manufacturing process, they are helping their clients stay ahead of the competition and meet the growing demands of the market.In conclusion, the Corrugated Roof Tile Barrel Sheet Profiling Machine represents a significant advancement in the manufacturing industry. Its cutting-edge technology, precision engineering, and commitment to safety and efficiency make it a valuable asset for manufacturers in the roofing industry. As the company continues to push the boundaries of innovation, we can expect to see more groundbreaking solutions that will shape the future of manufacturing.

Standing Seam Roll Forming Machine: Advanced Technology for Efficient Metal Panel Manufacturing

Standing Seam Roll Forming Machine Empowers Companies to Enhance Their OperationsStanding seam roofs have been in demand for their sleek and modern appearance, as well as robust durability. These quintessential roofs require efficient machinery that will produce panels with impeccable precision, swiftly and consistently. With the advancement of technology, several reliable machines have been built, including the Standing Seam Roll Forming Machine, which offers top-notch performance and versatility.This high-quality equipment is designed by an industry-leading company focused on manufacturing roll forming machines with optimal technical support. The company has been in operation for years, and with their vast experience, they have created automated systems that meet their clients' unique needs. This Standing Seam Roll Forming Machine uses excellent technology to whip up roofing panels that are top-performing and visually appealing, which makes it a go-to solution for roofing companies.The Standing Seam Roll Forming Machine is electronically controlled and adjustable, making it efficient for creating panels of various sizes and shapes. It is also highly customizable and can be made to fit specific needs instantly without interfering with the machine's quality performance. It is engineered to handle a range of materials, as well as a vast variety of thicknesses, including aluminum, steel, and copper. Additionally, with the consistency in panel production, companies can save money by reducing waste and increasing productivity.The machine is powered using an electric motor, which makes it less cost-prohibitive due to the low cost of electricity. Further, it requires little in terms of maintenance, and its unique design allows for optimum power consumption by utilizing minimal electricity. With very few moving parts, the machine is straightforward to assemble and use. Also, it is built with high-quality materials, which ensures that it remains durable and lasts an extended period, even with minimal maintenance.The Standing Seam Roll Forming Machine comes with efficient technical support from the manufacturer. The engineers are available to offer technical expertise that assists clients in improving their operations. Moreover, clients receive continuous support in matters related to the machines' maintenance and repairs, and spare parts are readily available.Overall, the Standing Seam Roll Forming Machine is an indispensable asset for any roofing company. It is a smart investment that enhances operations, reduces production costs, and boosts profitability. It is reliable, efficient, and cost-friendly, and it ensures that companies remain competitive in their respective markets. Moreover, it is environmentally friendly due to its low power usage, as well as the ability to reduce waste and increase productivity.In conclusion, companies looking to improve their roofing operations ought to consider investing in the Standing Seam Roll Forming Machine. With a high quality, durable design, and customizable features, this machine provides the kind of precision and speed that will satisfy customers and boost productivity. Thanks to its robust engineering and excellent technical support, it is precisely the equipment that roofing companies need to stay on top of their game in the competitive roofing industry.