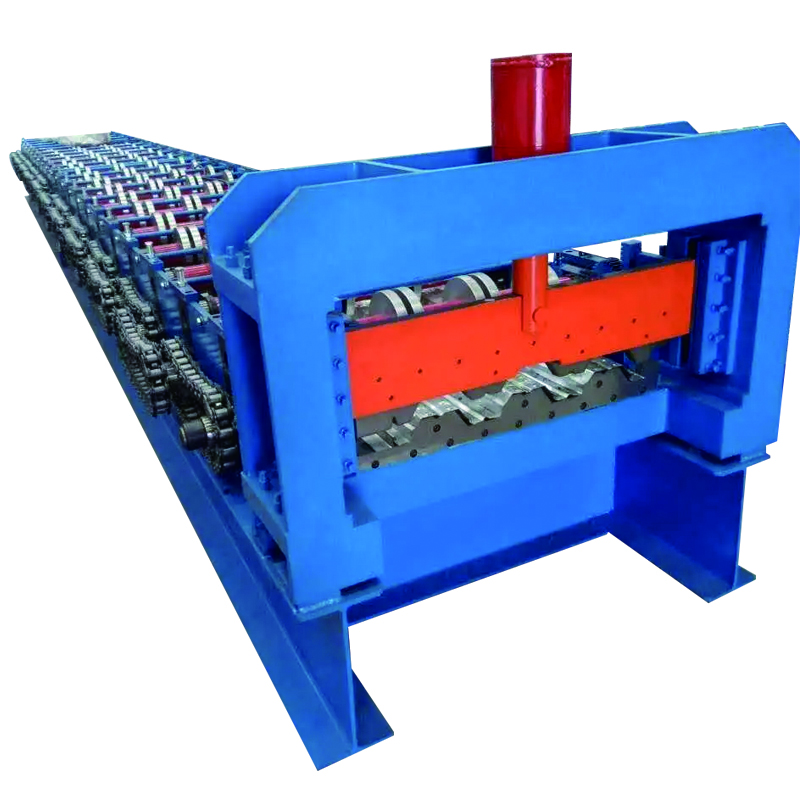

High-Quality Roll Forming Machine for Tiles at Competitive Prices

By:Admin

The Tile Roll Forming Machine is the result of extensive research and development, as well as collaboration with industry experts to ensure that it meets the needs and demands of modern construction projects. The machine is equipped with state-of-the-art technology and features a user-friendly interface, making it easy for operators to control and adjust settings to achieve the desired tile profiles.

One of the key benefits of the Tile Roll Forming Machine is its ability to produce tiles with consistent dimensions and precise shapes, ensuring that they fit seamlessly together when installed on a roof. This level of precision is crucial for both the aesthetic appeal and the structural integrity of the roof, providing peace of mind for builders and homeowners alike.

In addition to its precision, the Tile Roll Forming Machine is also designed for high-speed production, allowing for efficient and cost-effective manufacturing of large quantities of tiles. This is especially important for meeting the demands of large-scale construction projects, where tight deadlines and budgets are common challenges.

Furthermore, the machine is built with durability in mind, utilizing high-quality materials and components to withstand the rigors of continuous operation in a manufacturing environment. This ensures minimal downtime for maintenance and repairs, contributing to overall productivity and profitability for the users.

The Tile Roll Forming Machine also offers versatility in terms of the types of tiles it can produce. Whether it's traditional clay tiles, concrete tiles, or metal tiles, the machine is capable of accommodating various materials and specifications, making it a valuable asset for manufacturers serving diverse markets and customers.

{Company Name} is committed to providing comprehensive support for their customers, including training, technical assistance, and spare parts availability to ensure that the Tile Roll Forming Machine operates at its optimal performance throughout its lifespan. This dedication to customer satisfaction has been a cornerstone of {Company Name}'s success, earning them a reputation for reliable and responsive service.

With the launch of the Tile Roll Forming Machine, {Company Name} is poised to make a significant impact on the roofing industry, offering a solution that addresses the evolving needs of modern construction. As sustainability and energy efficiency continue to be priorities for builders and homeowners, the ability to produce durable, high-quality roofing materials has never been more important, and the Tile Roll Forming Machine delivers on this promise.

In conclusion, the Tile Roll Forming Machine from {Company Name} represents a significant advancement in the manufacturing of roofing tiles, offering a combination of precision, speed, and versatility that is unmatched in the industry. With a track record of excellence and a commitment to customer satisfaction, {Company Name} is well-positioned to meet the growing demand for high-quality roofing materials, supporting the construction industry for years to come.

Company News & Blog

High-Quality Replacement Roof Tiles for Your Cambridge Property - PE7 Area

Title: The Ultimate Guide to Roof Tiles: Types, Installation, and MaintenanceIntroduction:When it comes to protecting our homes, a well-maintained roof is essential. The type of roof tiles we choose plays a vital role in enhancing the aesthetics, durability, and overall value of our property. In this comprehensive guide, we will delve into the world of roof tiles, covering various types, the installation process, and essential maintenance tips. Whether you are a homeowner or a roofing professional, this blog post is here to acquaint you with everything you need to know about roof tiles!Types of Roof Tiles:1. Concrete Roof Tiles: These affordable and low-maintenance tiles are known for their durability and ability to withstand harsh weather conditions. Concrete roof tiles come in a variety of colors and styles, offering flexibility in design choices.2. Clay Roof Tiles: Clay roof tiles exude elegance and sophistication, enhancing the curb appeal of any property. Made from natural clay and kiln-fired, these tiles offer superior durability while reflecting heat effectively.3. Slate Roof Tiles: Known for their distinctive appearance, slate roof tiles are strong, fire-resistant, and highly durable. With a lifespan of over a century, these tiles offer exceptional longevity. Slate tiles are available in a range of colors and can be shaped to suit different architectural styles.4. Metal Roof Tiles: With their lightweight composition, metal roof tiles are ideal for various architectural designs. They are resistant to rust, insects, and UV radiation, making them an excellent option for long-lasting roofing solutions.Installation Process:Installing roof tiles requires a systematic approach to ensure proper functionality and longevity. Here are the key steps involved in the installation process:1. Inspection: Before installing any roof tiles, a preliminary inspection is crucial to identify any underlying issues or damage that require repairs.2. Roof Surface Preparation: The roof surface must be clean, free from debris, and properly waterproofed. This step includes installing underlayment to provide additional protection against moisture and improve thermal insulation.3. Tile Layout: Based on the selected tile pattern and design, layout lines are marked to guide the installation process and ensure precision.4. Tile Installation: Each tile is installed carefully, and proper fastening techniques are used to prevent tile shifting or damage during severe weather conditions. Contractor-grade adhesives and sealants are commonly employed for added stability.5. Ridge and Hip Installation: The finishing touches of installing ridge and hip tiles contribute to the overall aesthetic appeal and improve the roof's water shedding ability.Roof Tile Maintenance Tips:Regular maintenance is crucial to prolonging the life of your roof tiles and preventing major repairs. Here are some essential maintenance tips to consider:1. Inspect: Schedule periodic inspections to identify and address any visible or potential issues promptly.2. Clean Gutters: Clearing debris from gutters and downspouts ensures proper water flow and prevents overflowing, which can lead to roof leaks and damage.3. Trim Overhanging Trees: Overhanging branches can scrape and damage roof tiles during strong winds. Regular trimming will minimize this risk.4. Moss and Algae Removal: Moss and algae can compromise roof tiles' integrity and cause discoloration. Safely remove them to maintain the aesthetics and longevity of your roof.5. Professional Maintenance: Engage professional roofing contractors for comprehensive maintenance checks, especially for intricate tasks such as tile realignment and fixing damaged or cracked tiles.Conclusion:Choosing the right roof tiles, understanding the installation process, and implementing regular maintenance practices are key to ensuring a safe, durable, and attractive roof. From concrete and clay to slate and metal, various roof tile options are available to suit different styles and budgets. Whether you reside in Cambridge or the PE7 region, be sure to consult trusted roofing professionals who offer reliable replacement roof tiles for your project. Remember, a well-maintained roof not only protects your home but also adds value and visual appeal for years to come.Keywords: roof tiles, replacement, Cambridge, PE7, installation, maintenance, concrete, clay, slate, metal

Wide Coil Slitter Operator Jobs in Oldbury - Experience in Metals Environment Required

Title: Wide Coil Slitter Operator Jobs Available in Oldbury's Metal IndustryIntroduction:Oldbury, a key industrial area known for its metal manufacturing, is currently seeking experienced wide coil slitters to join its thriving workforce. This exciting opportunity offers rotating shifts and the chance to work within a dynamic metals environment. Interested applicants are encouraged to apply and become a part of Oldbury's esteemed metal coil slitting industry.Oldbury's Thriving Metal Industry:Oldbury has long been renowned for its robust metal manufacturing industry. The demand for high-quality metal products, particularly in the automotive and construction sectors, has contributed to the growth and success of the region. As a result, the need for skilled workers, such as wide coil slitters, has become paramount.The Role of a Wide Coil Slitter Operator:A wide coil slitter operator plays a crucial role in the metal manufacturing process. Working within a metals environment, their primary responsibility is to operate machinery that cuts wide metal coils into narrower strips of desired sizes. This process involves precise measurements, attention to detail, and adherence to safety protocols. The slitter operator ensures that the metal coils are prepared and cut according to specific requirements, meeting the industry's high standards.Job Requirements and Shift Pattern:To be considered for this role, prospective candidates must possess experience working within a metals environment. This experience should ideally include previous work as a wide coil slitter operator. The ability to work effectively and efficiently within a team is essential, as operators often collaborate with colleagues to ensure seamless production.The job itself requires undertaking rotating shifts, with two sets of shifts available: 6-2 and 2-10. This flexibility allows for optimal workflow and accommodates personal schedules.Benefits of the Role:Working as a wide coil slitter operator in Oldbury offers numerous advantages. The position provides an opportunity to work within a dynamic and constantly evolving industry, contributing to the production of essential components used in various sectors. Moreover, the rotating shift pattern allows for a healthy work-life balance, as individuals can adjust their schedules accordingly.Oldbury's metal industry boasts a supportive and inclusive work environment. Employees can expect consistent training, career development opportunities, and competitive remuneration packages. Those seeking job security and professional growth will find this industry and role particularly appealing.How to Apply:To apply for this exciting opportunity, interested individuals should submit their applications through the Jobcentre Plus Universal Jobmatch platform. The application process will include providing relevant professional experiences, skills, and contact information. Candidates are encouraged to apply promptly, as these positions often fill quickly due to the strong demand within the metal manufacturing industry.Conclusion:Oldbury's metal industry is actively seeking experienced wide coil slitter operators to join its esteemed workforce. The demand for high-quality metal products continues to grow, making this an excellent opportunity for individuals with experience in metals environments. The rotating shift pattern and inclusive work environment further enhance the appeal of this position. Interested applicants should take advantage of this opportunity and apply promptly to secure their place within this thriving industry.

Bag&Baggage Productions Utilizes Advanced Projector for Cutting-Edge Theater Experience

Bag&Baggage Productions (B&B), a theater company based in Hillsboro, Oregon, has recently installed a state-of-the-art projector in their new multipurpose venue, The Vault. The BenQ LK970 Blue Core Laser 4K projector was selected for its ability to project ultra-realistic set backgrounds, significantly reducing the scale, cost, and manual labor required for set designs. Aside from enhancing the company's productions and performances, the projector also allows B&B to explore creative new avenues, such as creating immersive digital projection laboratories and film festivals for area digital content creators. This is a major step forward for the company, which has been actively looking for ways to evolve and innovate in an ever-changing digital world. The LK970 Blue Core Laser 4K projector, known for its ultra-high resolution and brightness, has been used in various commercial applications such as large-scale events and museums. In the context of theater productions, it has been proven to be an effective tool for creating vivid, lifelike visual backdrops, providing an immersive experience for audiences. This innovative projection technology not only saves time and effort in making physical sets but also allows theater companies to push the boundaries of what is possible on stage. By harnessing the power of digital projection, Bag&Baggage Productions can now create unique and unforgettable productions that will keep audiences coming back for more. As a company dedicated to providing the best theatrical experiences for its audiences, Bag&Baggage Productions has taken a bold step forward by investing in cutting-edge projection technology. By installing the BenQ LK970 Blue Core Laser 4K projector, they have not only enhanced their production capabilities but also set a new standard for theater companies striving to stay ahead of the curve. In conclusion, the installation of the LK970 Blue Core Laser 4K projector by Bag&Baggage Productions is a significant development for the theater industry, showcasing the potential of technology in enhancing the creative process in a cost-effective and efficient manner. With the introduction of this technology, theater companies can now create more immersive, memorable, and visually stunning productions, setting new benchmarks for the art form. Keywords: Bag&Baggage Productions, LK970 Blue Core Laser 4K projector, horizontal barrel vault panel production equipment, theater productions, digital projection, visual display solutions, immersive experience, cutting-edge technology, cost-effective, efficient.

High-Quality Roof Panel Roll Forming Machine for Steel Metal Roof Panels - Roofing Sheet Roll Former, 5 Ton Capacity

PLC Steel Metal Roof Panel Roll Forming Machine: The Game Changer For Roofing Sheet ProductionIn the construction industry, metal roofing sheets provide the perfect alternative to traditional roofing materials. It is no secret that traditional roofing materials are prone to various types of damage that require repair and maintenance, costing both time and money. On the other hand, metal roofing sheets offer superior durability, resistance to weather elements, and long-lasting performance, making them the preferred option for homeowners and contractors alike. However, the production of metal roofing sheets can be a complex process. This is where the PLC Steel Metal Roof Panel Roll Forming Machine comes in handy. This cutting-edge technology offers the perfect solution for businesses involved in the production of metal roofing sheets.What is a PLC Steel Metal Roof Panel Roll Forming Machine?A PLC Steel Metal Roof Panel Roll Forming Machine is an automated production line that transforms metal sheets into roofing panels. It applies the principle of roll forming to shape the sheets into the desired roofing panel design. With this machine, it is possible to create a wide variety of roofing panel designs, from corrugated panels to standing seam panels.This machine features a Programmable Logic Controller (PLC) that ensures precise, accurate, and repeatable production processes. The PLC controls the machine's operations, including the feeder, roll forming process, and cutting system. It also features an Human Machine Interface (HMI) that enables operators to monitor and control the machine during production.How does a PLC Steel Metal Roof Panel Roll Forming Machine work?The PLC Steel Metal Roof Panel Roll Forming Machine is a multi-step process that involves various stages, including:1. Metal sheet loading - This involves inserting the metal sheets into the machine's feeder.2. Sheet leveling - This stage ensures that the metal sheets are uniform and flat before they enter the roll forming process.3. Roll forming - This is the heart of the process. The metal sheets pass through a series of rollers that shape them into the desired roofing panel design.4. Cutting - Once the metal sheets have been formed into the roofing panel, the machine's cutting system cuts the panel to the desired length.5. Stacking - Finally, the roofing panels are stacked and ready for delivery.Advantages of using a PLC Steel Metal Roof Panel Roll Forming Machine1. Improved efficiency - The PLC Steel Metal Roof Panel Roll Forming Machine is designed to handle large volumes of metal sheets, enabling businesses to produce more roofing panels in a shorter time.2. Precise and accurate - The PLC controls the machine's operations, ensuring consistent and repeatable results.3. Reduced labor costs - The automated process eliminates the need for manual labor, reducing labor costs and increasing productivity.4. Customizable - The machine can be tailored to produce a wide variety of roofing panel designs, depending on the client's requirements.5. Reduced waste - The roll forming process ensures minimal waste, optimizing material usage and reducing costs.6. Enhanced safety - The machine's automated system ensures that the production process is safe for operators.In conclusion, the PLC Steel Metal Roof Panel Roll Forming Machine is a game-changer for metal roofing sheet production. It offers improved efficiency, accuracy, and customizability, reducing costs and increasing productivity. With this technology in hand, businesses can produce high-quality metal roofing sheets that meet their clients' needs and exceed their expectations.

Revolutionary Horizontal Profiled Panel Production Line Boosts Efficiency and Quality

Horizontal Profiled Panel Production Line Presents New Innovations in Manufacturing TechnologyWith a continuous focus on innovation and advanced manufacturing solutions, {Company Name}, a leading global provider of industrial machinery, is proud to introduce its state-of-the-art Horizontal Profiled Panel Production Line. This cutting-edge equipment offers significant advancements in the manufacturing process, promising improved efficiency, durability, and flexibility.The Horizontal Profiled Panel Production Line represents the culmination of years of research, development, and expertise in the field of industrial machinery. Designed to meet the diverse needs of various industries, this production line incorporates advanced technologies to streamline the manufacturing process of profiled panels, optimizing productivity and performance.One of the key features of this new production line is its horizontal orientation, which sets it apart from traditional vertical profiled panel lines. This configuration offers numerous benefits, including enhanced stability and balance during the manufacturing process. By utilizing a horizontal layout, {Company Name} has dramatically minimized vibrations and improved accuracy, leading to a significant reduction in material waste and ensuring consistent product quality.Moreover, the Horizontal Profiled Panel Production Line boasts a range of innovative components that further enhance its efficiency. Equipped with precision cutting tools and advanced laser-guided systems, the line ensures the precise and seamless shaping of panels. This precision allows for seamless integration of various profiled panel types, ranging from corrugated and trapezoidal to architectural and decorative panels. Such flexibility enables manufacturers to cater to the specific requirements of their customers while maintaining superior quality standards.The new production line also incorporates cutting-edge automation technologies to streamline the manufacturing process. Integrated robotic systems enable efficient material handling and reduce the need for human intervention, thereby increasing productivity and minimizing the risk of errors. Additionally, real-time monitoring systems and advanced quality control methods ensure continuous feedback and enable timely adjustments, guaranteeing that each panel meets the highest industry standards.In line with {Company Name}'s commitment to sustainability, the Horizontal Profiled Panel Production Line incorporates energy-saving features, reducing power consumption and minimizing the overall environmental impact. Through efficient energy management systems and smart utilization of resources, the line not only fulfills stringent environmental regulations but also enables manufacturers to significantly reduce operational costs.Furthermore, the Horizontal Profiled Panel Production Line is designed with user-friendliness in mind. An intuitive interface and user-friendly controls allow operators to easily navigate the production process, minimizing downtime and maximizing productivity. To ensure seamless integration into existing manufacturing facilities, {Company Name} offers extensive technical support and customization options according to the specific requirements of each customer.As a global leader in industrial machinery, {Company Name} has an extensive presence and a strong track record of delivering high-quality equipment to industries worldwide. The introduction of the Horizontal Profiled Panel Production Line further solidifies the company's commitment to pushing the boundaries of manufacturing technology and providing innovative solutions to its customers.In conclusion, {Company Name}'s revolutionary Horizontal Profiled Panel Production Line represents a significant leap in manufacturing technology. Through its horizontal orientation, innovative components, automation features, sustainability initiatives, and user-friendly design, this production line offers numerous benefits to manufacturers, including improved efficiency, product quality, and customization options. With this cutting-edge equipment, {Company Name} continues to empower industries across the globe to enhance their production capabilities and achieve unparalleled success.

Roll Forming Machines for Metal Roof and Drywall Studs and Track

If you are involved in the construction industry, you probably know how important it is to have the right equipment to get the job done quickly and efficiently. One of the most essential pieces of equipment that you need is a metal stud making machine.There are many different types of metal stud making machines on the market, but the most popular ones are those that are designed to produce high-quality metal studs and tracks used in drywall installation and house making. These machines are known for their precision, accuracy, and speed, making them the perfect tools for any construction project.One of the best things about metal stud making machines is that they are incredibly versatile. They can be used to produce a wide range of metal studs and tracks, including those made from steel, aluminum, and other metals. This means that you can use them for a variety of different projects, from small-scale jobs like installing a new drywall partition to large commercial construction projects.Metal stud making machines come in a range of sizes and configurations to meet the needs of different construction businesses. Some machines are designed to be portable, while others are more stationary. Some machines are designed to produce only metal studs, while others can produce both studs and tracks.To ensure that you are getting the best metal stud making machine for your needs, it is important to do your research and compare different models and brands. Look for a machine that is easy to use, has a high level of automation, and can produce high-quality metal studs quickly and efficiently.One popular brand of metal stud making machines is Alibaba. Their drywall stud roll forming machine is designed to produce high-quality studs and tracks for drywall installation and house framing. This machine is easy to operate and can produce metal studs and tracks in a range of different sizes and configurations.Another popular brand of metal stud making machine is Jobsite Roll Forming Equipment. Their machines are designed to produce metal studs and tracks for a range of different applications, including both residential and commercial construction projects. These machines are known for their precision and speed, making them the perfect choice for any construction business.In conclusion, if you are in the construction industry and looking to invest in a metal stud making machine, there are plenty of options to choose from. Whether you are looking for a portable machine or a more stationary model, there is sure to be a machine that fits your needs. Just be sure to do your research and compare different brands and models to find the best machine for your construction business.

High Precision CNC Machine for Aluminum Extrusions

The demand for precision-engineered aluminum extrusions has been on the rise in various industries such as construction, automotive, and aerospace. In response to this increasing demand, a leading manufacturing company has recently invested in state-of-the-art CNC machinery to enhance their capabilities in producing high-quality aluminum extrusions.With a legacy of over 50 years in the industry, {} has built a strong reputation for delivering innovative and customized solutions to their clients. Specializing in aluminum extrusion, the company has been at the forefront of technological advancements and has consistently invested in cutting-edge equipment to meet the evolving needs of their customers.The latest addition to their manufacturing arsenal is the advanced CNC machine specially designed for aluminum extrusions. This new equipment is equipped with high precision cutting and milling capabilities, allowing {} to achieve tight tolerances and intricate designs with utmost accuracy. The CNC machine also offers greater flexibility in producing complex shapes and profiles, enabling the company to cater to a wide range of applications across different industries.One of the key advantages of the new CNC machine is its efficiency in handling large-scale production while maintaining superior quality. This increased production capacity will enable {} to meet the growing demand for aluminum extrusions within shorter lead times, giving them a competitive edge in the market. Moreover, the CNC machine is integrated with advanced software that enables seamless programming and automation, thereby streamlining the manufacturing process and reducing the time required for setup and tool changes.In addition to enhancing their production capabilities, the investment in the CNC machine reflects {}'s commitment to upholding the highest standards of quality and precision. The company adheres to stringent quality control measures at every stage of the manufacturing process, ensuring that the aluminum extrusions meet the exact specifications and performance requirements of their customers. The new CNC machine further reinforces this commitment by enabling precise and consistent machining of extruded aluminum profiles, resulting in products that exhibit exceptional dimensional accuracy and surface finish.Furthermore, the implementation of the CNC machine underscores {}'s dedication to innovation and continuous improvement. By leveraging the latest technology, the company aims to push the boundaries of what is achievable in aluminum extrusion manufacturing. This proactive approach not only showcases their willingness to invest in the future of their business but also positions them as a reliable and forward-thinking partner for their clients.The investment in the CNC machine is also aligned with {}'s sustainability initiatives. Aluminum is widely recognized for its recyclability and environmental benefits, and {} is committed to minimizing their environmental footprint by optimizing material usage and reducing waste in their manufacturing processes. The precision and efficiency offered by the new CNC machine will contribute to the sustainable production of aluminum extrusions, further reinforcing {}'s position as an eco-conscious industry leader.In conclusion, the introduction of the CNC machine for aluminum extrusions marks a significant milestone for {}. This strategic investment not only enhances their manufacturing capabilities but also underscores their dedication to delivering top-quality, precision-engineered solutions to their clients. By embracing the latest technology and upholding their commitment to excellence, {} is poised to meet the evolving needs of the industry and continue setting new benchmarks in the field of aluminum extrusion manufacturing.

Glazed Tile Roll Forming Machine - Industrial Steel Rolling Machines for Metal Roofing Sheet Production

Title: ZhongTuoCN Revolutionizes Roofing Industry with Advanced Glazed Tile Roll Forming MachineIntroduction:ZhongTuoCN, a renowned leader in the steel rolling machine industry, has unveiled its latest product, the Color Steel Glazed Roof Tile Roll Forming Machine. This advanced machinery has revolutionized the roofing industry by enabling the efficient production of high-quality metal glazed tiles. With its cutting-edge technology and precision engineering, ZhongTuoCN is empowering manufacturers to meet growing demands for durable and aesthetically pleasing roofing solutions.1. Meeting the Rising Demand for Glazed Roofing Tiles:The demand for glazed roofing tiles has been steadily increasing due to their exceptional durability, weather resistance, and stunning visual appeal. Recognizing this trend, ZhongTuoCN's engineers have developed a state-of-the-art roll forming machine specifically designed to cater to this niche segment. Manufacturers can now produce glazed tiles efficiently, ensuring timely delivery and meeting customer expectations.2. Cutting-Edge Technology Enhances Efficiency:The Color Steel Glazed Roof Tile Roll Forming Machine stands out for its advanced features, guaranteeing optimal efficiency. Equipped with state-of-the-art automation technology, this innovative machine minimizes human intervention, reducing labor costs and increasing productivity. With high-speed forming capabilities, it guarantees a smooth and streamlined production process, allowing manufacturers to meet large-scale orders efficiently.3. Unparalleled Precision and Durability:ZhongTuoCN's Glazed Tile Roll Forming Machine is meticulously engineered to deliver unmatched precision and durability. Its robust frame, constructed from high-quality steel, ensures long-term stability and reliability. The rollers are made from top-grade materials, facilitating seamless tile formation without any deformities. This ensures that every finished tile exhibits consistent dimensions and exceptional surface quality.4. Flexibility in Tile Design and Customization:In addition to its standard features, the Color Steel Glazed Roof Tile Roll Forming Machine provides manufacturers with unparalleled flexibility in tile design and customization. By incorporating adjustable features in the machine, manufacturers can easily tailor the dimensions, profile, and curvature of the glazed tiles to meet various customer requirements. This adaptability sets ZhongTuoCN's machinery apart from its competitors and allows clients to offer unique and personalized roofing solutions.5. Strict Quality Control and After-Sales Support:ZhongTuoCN prioritizes quality control throughout the manufacturing process. Each component of the Glazed Tile Roll Forming Machine undergoes stringent testing to ensure optimal performance and durability. Additionally, ZhongTuoCN provides comprehensive after-sales support, including installation guidance, training programs, and 24/7 technical assistance. This commitment to customer satisfaction has earned the company an excellent reputation in the industry.Conclusion:With the introduction of the Color Steel Glazed Roof Tile Roll Forming Machine, ZhongTuoCN has reaffirmed its position as a pioneer in the steel rolling machine industry. This cutting-edge technology guarantees exceptional efficiency, precision, and customization options for manufacturers in the roofing sector. By empowering clients to meet the rising demand for glazed tiles, ZhongTuoCN is revolutionizing the roofing industry and offering an unparalleled solution for businesses worldwide.

Quickly Changeable C/Z Purlin Roll Forming Machine: Efficient Steel Purlin Production

Title: Revolutionary CZ Interchangeable Purlin Roll Forming Machine Streamlines Steel ProductionIntroduction:In the ever-evolving realm of steel manufacturing, advancements in technology continue to redefine the way we produce essential building components. The latest innovation making waves in the industry is the CZ Interchangeable Purlin Roll Forming Machine. Designed to expedite the production process and enhance efficiency, this state-of-the-art machine effortlessly molds steel C and Z purlins of various sizes and thicknesses.Seamless Purlin Roll Transition:Traditionally, switching between C and Z purlin roll forming required cumbersome manual adjustments and downtime. However, the CZ Interchangeable Purlin Roll Forming Machine eliminates these inefficiencies by seamlessly transitioning between the two types of purlins. This groundbreaking technology significantly reduces production downtime, streamlining operations and increasing overall productivity.Precision Performance:The CZ Interchangeable Purlin Roll Forming Machine is renowned for its precision performance. Equipped with cutting-edge technology and automated processes, it delivers unparalleled accuracy and consistency in producing C and Z purlins. This ensures structural integrity and reliable performance of the final products, meeting the stringent quality standards demanded by the construction industry.Enhanced Flexibility:One of the most compelling features of the CZ Interchangeable Purlin Roll Forming Machine is its ability to produce purlins of varying sizes and thicknesses. Whether it's a small-scale residential project or a large commercial construction, this versatile machine can adapt to the requirements of any project, thereby expanding manufacturers' capabilities and market reach. Effortless Operation:Designed with user convenience in mind, the CZ Interchangeable Purlin Roll Forming Machine offers both manual and automatic adjustment options, catering to the diverse needs of manufacturers. Users can easily switch between modes depending on the complexity of the project, ensuring seamless operation and reducing the chances of error.Efficiency and Time-Saving:The CZ Interchangeable Purlin Roll Forming Machine revolutionizes the production process by reducing manual labor and maximizing efficiency. By automating key stages, this machine eliminates human error while significantly expediting production timelines. Manufacturers can now meet tight project deadlines without compromising on quality, thereby boosting overall customer satisfaction.Cost-Effective Solution:The CZ Interchangeable Purlin Roll Forming Machine is not only efficient but also cost-effective. With the ability to adapt to various project requirements, manufacturers no longer need to invest in separate machines for different purlin types. This reduces capital expenditure, maintenance costs, and overheads, enhancing profitability and competitiveness in the market.Sustainable Manufacturing:In today's environmentally conscious world, the CZ Interchangeable Purlin Roll Forming Machine aligns with the industry's commitment to sustainable manufacturing practices. By dramatically reducing material waste and energy consumption, this machine helps manufacturers meet their sustainability goals without compromising productivity or product quality.Conclusion:The CZ Interchangeable Purlin Roll Forming Machine represents a paradigm shift in steel production, offering manufacturers an advanced and versatile tool. With its ability to effortlessly switch between C and Z purlins, while accommodating various sizes and thicknesses, this machine sets a new standard for precision and efficiency in the industry. By streamlining operations, reducing downtime, and enhancing overall productivity, this innovative machine promises a bright future for the steel manufacturing sector.

The Distinction between Slitting Machines and Cut-to-Length Machines for Steel Coils

Title: Maximizing Efficiency and Cost Savings: Understanding the Difference Between Slitting Machines and Cut-to-Length MachinesIntroduction:In today's fast-paced manufacturing industry, optimizing production processes while minimizing costs is essential to remain competitive. When it comes to cutting steel coils to specific dimensions, both slitting machines and cut-to-length machines play a crucial role in achieving these objectives. In this blog post, we will explore the differences between these two machines and how they can help you streamline your manufacturing operations. Keywords: slitting machine, cut-to-length machine, steel coils, production processes, cost savings, manufacturing operations1. Understanding the Slitting Machine:A slitting machine is specifically designed to cut wide steel coils into narrower strips. It is ideal for applications that require multiple narrow coils of varying widths. The slitting process involves unwinding the master coil, passing it through rotating circular knives, and rewinding the slit strips onto individual smaller coils. By adjusting the slitter's settings, you can achieve precise dimensions according to your specific requirements. This versatility makes slitting machines a popular choice for various industries, including automotive, construction, and steel fabrication. 2. Exploring the Cut-to-Length Machine:On the other hand, a cut-to-length machine is primarily used to cut steel coils into individual sheets of predetermined lengths. This machine eliminates the need for rewinding smaller coils, ensuring that the desired dimensions are produced efficiently in a single pass. Cut-to-length machines are highly advantageous when it comes to producing accurately-sized sheets for applications such as roofing, flooring, and paneling. By choosing the suitable settings, you can achieve consistent cuts, reducing material waste and improving overall productivity.3. Cost Savings and Material Efficiency:By applying slitting and cut-to-length techniques to the manufacturing process, you can significantly reduce material costs and inventory. Using standard-size steel coils allows you to take advantage of bulk purchasing at lower prices. By slitting or cutting these coils to precise dimensions, you eliminate the need for specialized coil sizes, thereby reducing inventory expenses. Furthermore, both techniques minimize material waste, allowing you to efficiently utilize every part of the coil, resulting in additional cost savings.4. Factors Influencing Machine Selection:When deciding whether to invest in a slitting machine or a cut-to-length machine, several factors need to be considered. These factors include the desired end product, production volume, speed requirements, material thickness, and available floor space. For businesses with higher production volumes and a requirement for multiple narrow strips, a slitting machine would be a preferred choice. Conversely, if you primarily need accurately sized sheets with consistent lengths, a cut-to-length machine would be more suitable.5. Enhancing Production Efficiency:Both slitting and cut-to-length machines offer significant advantages in enhancing production efficiency. These machines are often equipped with advanced features such as automated controls, precision cutting tools, and real-time monitoring systems. These features enable faster setup times, reduce operator errors, and enhance overall productivity. Additionally, the integration of these machines with other process automation technologies can further streamline the production line, leading to optimized efficiency.Conclusion:Slitting machines and cut-to-length machines play a vital role in the manufacturing industry by enabling cost-effective customization of steel coils. Understanding their differences and choosing the right machine for your specific production requirements is crucial. The utilization of these machines can lead to substantial cost savings, improved material efficiency, and streamlined manufacturing operations. By investing in the appropriate machinery and adopting efficient production techniques, businesses can thrive in today's competitive marketplace.Keywords: slitting machine, cut-to-length machine, steel coils, production requirements, cost-effective customization, manufacturing operations, streamlined productivity.