Advanced Steel Slitting Lines: Perfect for High-Volume Production

By:Admin

The manufacturing industry is constantly evolving, and the need for advanced machines and technologies is at an all-time high. One such technology that has revolutionized the steel manufacturing industry is Steel Slitting Line. It is an intelligent solution that has transformed the way steel is produced, making it faster, precise, and more efficient. Not only does it reduce manufacturing costs, but it also ensures maximum output with minimum wastage.

{Company Introduction} is proud to introduce its Steel Slitting Line, a state-of-the-art machine that guarantees a higher level of precision, speed, and reliability than its counterparts. Our Steel Slitting Line is designed to meet the needs of modern steel manufacturers, ensuring maximum output of high-quality steel products while reducing operating costs.

A Steel Slitting Line is a specialized machine that allows manufacturers to cut steel coils into narrow widths, called strips, in a precise and efficient manner. It is capable of processing super-thin and high-strength materials that were once impossible to cut efficiently. The Steel Slitting Line machine can process a wide range of materials, from plain carbon steel to high-strength steel alloys, stainless steel, and non-ferrous metals. The ability to cut a variety of materials makes it a versatile solution for steel manufacturing firms.

The Steel Slitting Line is made up of several components, including an entry coil car, decoiler, slitter, and recoiler. The entry coil car is used to load the steel coils onto the machine, while the decoiler unrolls the coil, and the slitter cuts the material into the desired width strips. The strips are then wound up into coils using the recoiler, ready to be used in downstream manufacturing processes. The Steel Slitting Line's precision and accuracy depend on the quality of each of these components, and our Steel Slitting Line is built with the finest materials and components to ensure the highest level of precision and accuracy.

One of the most significant benefits of Steel Slitting Lines is the optimization of material utilization. The machine cuts steel coils into strips, which means that manufacturers can make smaller orders with minimum wastage. It also allows for maximum use of the material, which reduces manufacturing costs and minimizes the environmental impact of steel production. The Steel Slitting Line's high level of precision and accuracy means that it is possible to minimize or completely eliminate waste in some cases, depending on the manufacturer's quality standards.

Another notable benefit of the Steel Slitting Line is the improved efficiency that it brings to steel production. It is capable of processing steel coils at high speeds, ensuring that manufacturers can produce high-quality steel products in large volumes within a short period. The machine's advanced technology allows for automatic adjustments to be made quickly, minimizing downtime and minimizing the need for human intervention. This results in faster production processes and improved productivity, which ultimately leads to increased revenue for the manufacturer.

Safety is a top priority in the manufacturing industry, and Steel Slitting Lines are designed with safety in mind. Our Steel Slitting Line is built to meet international safety standards, ensuring that the machine is safe to operate and that all operators are adequately trained. We have put in place safety measures, such as emergency stop buttons, safety guards, and sensors, to ensure that operators are protected from any accidents that may occur during production.

In conclusion, Steel Slitting Line machines are a game-changer in the steel industry, providing manufacturers with a range of benefits that improve efficiency, reduce costs, and increase revenue. At {Company Introduction}, we take pride in providing our customers with the best Steel Slitting Lines that meet their needs. Our machines are built with the highest quality materials, and our team of experienced engineers and designers ensures that the machines meet international standards. If you're looking to optimize your steel manufacturing process, {Company Name}'s Steel Slitting Line is the solution you need.

Company News & Blog

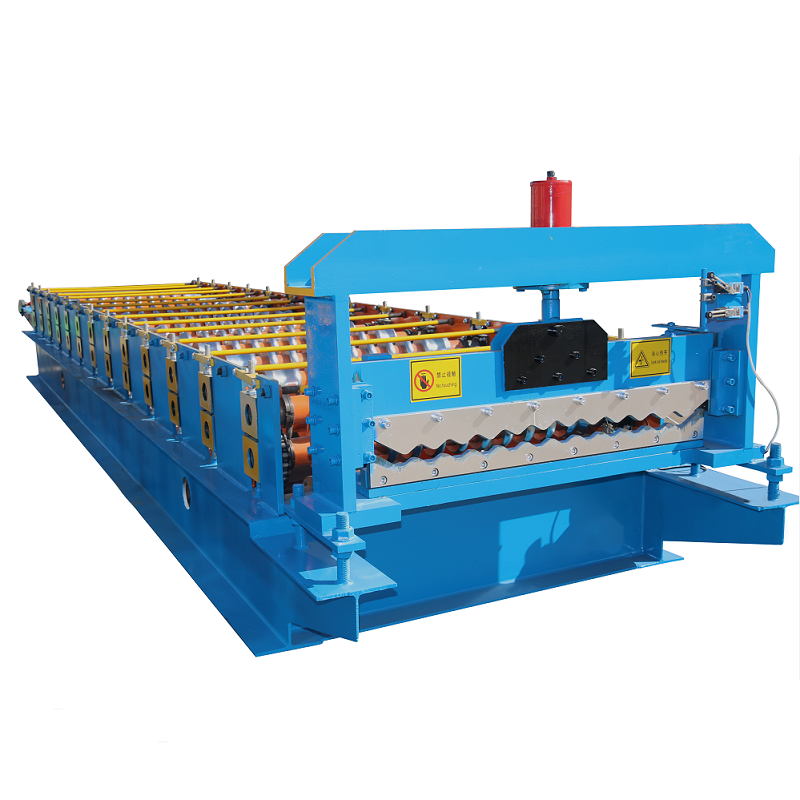

Efficient Corrugated Roof Sheet Manufacturing Machines Now Available for Purchase

Title: Innovation Takes the Roofing Industry to New Heights: Corrugated Roof Sheet Manufacturing Machine Revolutionizes ProductionIntroduction:The global roofing industry has witnessed a remarkable transformation with the introduction of cutting-edge manufacturing technology. The latest breakthrough comes in the form of a highly advanced Corrugated Roof Sheet Manufacturing Machine (CRSMM), empowering companies to meet growing demand for durable and aesthetically pleasing roofing solutions. This revolutionary machine represents a significant leap forward in terms of efficiency, productivity, and overall quality in the production of corrugated roof sheets.Redefining Efficiency:The CRSMM is designed to streamline the entire manufacturing process, making it highly efficient and cost-effective for companies operating in the roofing industry. By automating key steps, such as material cutting, shaping, and forming, this advanced machinery significantly reduces production time and labor costs. It ensures precision in every stage, resulting in consistently high-quality roof sheets that meet market standards and customer expectations.Uncompromising Quality:The new generation of CRSMM is equipped with advanced technology that enables manufacturers to produce top-of-the-line corrugated roof sheets. The machine employs high-quality materials and robust engineering to fabricate sheets that offer exceptional durability, strength, and weather resistance. This cutting-edge technology also ensures dimensional accuracy, allowing for easy installation and long-lasting performance under diverse weather conditions.Versatile Range of Products:Despite its advanced technology, the CRSMM is highly versatile and can be customized to produce a wide range of corrugated roof sheets. From standard sizes to special dimensions, the machine accommodates different roofing specifications, catering to the unique needs of each construction project. With the ability to manufacture various profiles, colors, and coatings, this machine provides businesses with unparalleled flexibility to meet the ever-evolving demands of the roofing industry.Sustainable Manufacturing:As environmental concerns continue to grow, the CRSMM embraces sustainable manufacturing practices. This advanced machinery uses energy-efficient components and optimized processes to minimize the ecological footprint of the production line. By reducing material waste and optimizing resource usage, the CRSMM aligns with global sustainability goals, contributing to a greener future for the roofing industry.Market Impact and Future Prospects:The introduction of the CRSMM is set to revolutionize the roofing industry, presenting new opportunities for growth and innovation. Manufacturers can now produce high-quality roof sheets at a faster pace, efficiently meeting rising market demand. This advanced machinery also enhances product quality and consistency, fostering customer satisfaction and brand reputation.Moreover, the versatility of the CRSMM allows companies to expand their product offerings and tap into diverse market segments. In an era where architectural designs are becoming increasingly imaginative and varied, the machine enables manufacturers to deliver customized roofing solutions that cater to the unique needs of every project.Looking ahead, the CRSMM is expected to undergo continuous advancements, integrating artificial intelligence and machine learning technologies. This will further improve its efficiency, precision, and automation, revolutionizing the roofing industry as we know it. The continued development of the CRSMM will undoubtedly play a pivotal role in shaping the future of construction and infrastructure development worldwide.Conclusion:The Corrugated Roof Sheet Manufacturing Machine is transforming the roofing industry by revolutionizing the production of high-quality, durable, and aesthetically pleasing roof sheets. With its unmatched efficiency, versatility, and sustainability, this advanced machinery is set to redefine industry standards and provide manufacturers with a competitive edge. As technology evolves, the CRSMM will continue to pave the way for innovative solutions that meet the demands of a rapidly changing construction landscape, driving the growth and development of the roofing industry into the future.

Standing Seam Roll Forming Machine: Advanced Technology for Efficient Metal Panel Manufacturing

Standing Seam Roll Forming Machine Empowers Companies to Enhance Their OperationsStanding seam roofs have been in demand for their sleek and modern appearance, as well as robust durability. These quintessential roofs require efficient machinery that will produce panels with impeccable precision, swiftly and consistently. With the advancement of technology, several reliable machines have been built, including the Standing Seam Roll Forming Machine, which offers top-notch performance and versatility.This high-quality equipment is designed by an industry-leading company focused on manufacturing roll forming machines with optimal technical support. The company has been in operation for years, and with their vast experience, they have created automated systems that meet their clients' unique needs. This Standing Seam Roll Forming Machine uses excellent technology to whip up roofing panels that are top-performing and visually appealing, which makes it a go-to solution for roofing companies.The Standing Seam Roll Forming Machine is electronically controlled and adjustable, making it efficient for creating panels of various sizes and shapes. It is also highly customizable and can be made to fit specific needs instantly without interfering with the machine's quality performance. It is engineered to handle a range of materials, as well as a vast variety of thicknesses, including aluminum, steel, and copper. Additionally, with the consistency in panel production, companies can save money by reducing waste and increasing productivity.The machine is powered using an electric motor, which makes it less cost-prohibitive due to the low cost of electricity. Further, it requires little in terms of maintenance, and its unique design allows for optimum power consumption by utilizing minimal electricity. With very few moving parts, the machine is straightforward to assemble and use. Also, it is built with high-quality materials, which ensures that it remains durable and lasts an extended period, even with minimal maintenance.The Standing Seam Roll Forming Machine comes with efficient technical support from the manufacturer. The engineers are available to offer technical expertise that assists clients in improving their operations. Moreover, clients receive continuous support in matters related to the machines' maintenance and repairs, and spare parts are readily available.Overall, the Standing Seam Roll Forming Machine is an indispensable asset for any roofing company. It is a smart investment that enhances operations, reduces production costs, and boosts profitability. It is reliable, efficient, and cost-friendly, and it ensures that companies remain competitive in their respective markets. Moreover, it is environmentally friendly due to its low power usage, as well as the ability to reduce waste and increase productivity.In conclusion, companies looking to improve their roofing operations ought to consider investing in the Standing Seam Roll Forming Machine. With a high quality, durable design, and customizable features, this machine provides the kind of precision and speed that will satisfy customers and boost productivity. Thanks to its robust engineering and excellent technical support, it is precisely the equipment that roofing companies need to stay on top of their game in the competitive roofing industry.

Advanced Steel Slitting Lines: Perfect for High-Volume Production

Steel Slitting Line: A Revolutionary Solution to Strengthen Your BusinessThe manufacturing industry is constantly evolving, and the need for advanced machines and technologies is at an all-time high. One such technology that has revolutionized the steel manufacturing industry is Steel Slitting Line. It is an intelligent solution that has transformed the way steel is produced, making it faster, precise, and more efficient. Not only does it reduce manufacturing costs, but it also ensures maximum output with minimum wastage.{Company Introduction} is proud to introduce its Steel Slitting Line, a state-of-the-art machine that guarantees a higher level of precision, speed, and reliability than its counterparts. Our Steel Slitting Line is designed to meet the needs of modern steel manufacturers, ensuring maximum output of high-quality steel products while reducing operating costs.A Steel Slitting Line is a specialized machine that allows manufacturers to cut steel coils into narrow widths, called strips, in a precise and efficient manner. It is capable of processing super-thin and high-strength materials that were once impossible to cut efficiently. The Steel Slitting Line machine can process a wide range of materials, from plain carbon steel to high-strength steel alloys, stainless steel, and non-ferrous metals. The ability to cut a variety of materials makes it a versatile solution for steel manufacturing firms.The Steel Slitting Line is made up of several components, including an entry coil car, decoiler, slitter, and recoiler. The entry coil car is used to load the steel coils onto the machine, while the decoiler unrolls the coil, and the slitter cuts the material into the desired width strips. The strips are then wound up into coils using the recoiler, ready to be used in downstream manufacturing processes. The Steel Slitting Line's precision and accuracy depend on the quality of each of these components, and our Steel Slitting Line is built with the finest materials and components to ensure the highest level of precision and accuracy.One of the most significant benefits of Steel Slitting Lines is the optimization of material utilization. The machine cuts steel coils into strips, which means that manufacturers can make smaller orders with minimum wastage. It also allows for maximum use of the material, which reduces manufacturing costs and minimizes the environmental impact of steel production. The Steel Slitting Line's high level of precision and accuracy means that it is possible to minimize or completely eliminate waste in some cases, depending on the manufacturer's quality standards.Another notable benefit of the Steel Slitting Line is the improved efficiency that it brings to steel production. It is capable of processing steel coils at high speeds, ensuring that manufacturers can produce high-quality steel products in large volumes within a short period. The machine's advanced technology allows for automatic adjustments to be made quickly, minimizing downtime and minimizing the need for human intervention. This results in faster production processes and improved productivity, which ultimately leads to increased revenue for the manufacturer.Safety is a top priority in the manufacturing industry, and Steel Slitting Lines are designed with safety in mind. Our Steel Slitting Line is built to meet international safety standards, ensuring that the machine is safe to operate and that all operators are adequately trained. We have put in place safety measures, such as emergency stop buttons, safety guards, and sensors, to ensure that operators are protected from any accidents that may occur during production.In conclusion, Steel Slitting Line machines are a game-changer in the steel industry, providing manufacturers with a range of benefits that improve efficiency, reduce costs, and increase revenue. At {Company Introduction}, we take pride in providing our customers with the best Steel Slitting Lines that meet their needs. Our machines are built with the highest quality materials, and our team of experienced engineers and designers ensures that the machines meet international standards. If you're looking to optimize your steel manufacturing process, {Company Name}'s Steel Slitting Line is the solution you need.

C Shape Purlin Forming Machine: Latest News and Updates Revealed

article about the significance of the C Shape Purlin Forming Machine in the construction industry.C Shape Purlin Forming Machine Significantly Boosting The Construction IndustryThe construction industry has emerged as one of the most important industries contributing to the growth and development of the economy. With the rising demand for commercial and residential properties, the construction industry is poised for growth and expansion. However, the industry needs to innovate and adopt modern technologies to keep up with changing market trends. This is where the C Shape Purlin Forming Machine comes into play.The company, (brand name removed), is a leading manufacturer of C Shape Purlin Forming Machine that has revolutionized the construction industry. The machine is designed to create durable and high-quality C-shaped, cold-formed steel channels for use in various construction projects. With advanced technology, the C Shape Purlin Forming Machine offers numerous benefits to the construction industry, including:1. Cost-effectiveThe C Shape Purlin Forming Machine uses raw materials that are cost-effective and easily available in the market. The machine's production process requires no welding, thus saving labor time and cost compared to other traditional construction methods. The machine's high efficiency helps to reduce production costs, making the process more affordable and accessible to buyers.2. High-quality productsThe C Shape Purlin Forming Machine produces high-quality and durable C-shaped steel channels that are perfect for construction projects. The machine uses advanced manufacturing technologies to ensure the products meet strict quality standards. The C shaped steel channels produced have a high strength-to-weight ratio, making them ideal for use in various building projects.3. VersatilityThe C Shape Purlin Forming Machine is versatile and can be used to create channels perfect for various applications. The C channel profiles can be customized to fit any design, making them suitable for use in different types of structures. They are commonly used in buildings, factories, warehouses, and other constructions.4. Time-savingUsing the C Shape Purlin Forming Machine significantly reduces the time required to produce C-shaped steel channels for construction projects. The machine produces several channels in one go, making it possible to complete projects much faster. The high efficiency also reduces labor needs, minimizing the time required to construct buildings using these materials.5. DurabilityThe C Shape Purlin Forming Machine produces durable and long-lasting steel channels that are resistant to corrosion and decay. These high-quality channels ensure a long-lasting construction that is strong and sturdy, making them perfect for use in construction projects.It is clear that the C Shape Purlin Forming Machine has revolutionized the construction industry, providing an innovative solution to meet the growing demand for durable, cost-effective, and high-quality steel channels. The technology has enabled manufacturers to produce channels that can meet any design requirement, offering versatile building solutions to the construction industry.The applications of C Shape Purlin Forming Machine in construction industry:1. Roofs and WallsC-shaped steel channels are commonly used to form roofs and walls in buildings. The channels' high strength-to-weight ratio makes them ideal for use in roofing structures, providing a strong and sturdy surface that can withstand different weather conditions. The channels also create a robust wall surface, enhancing the building's durability.2. Frame StructuresThe C Shape Purlin Forming Machine produces steel channels that are ideal for use in frame structures. The channels' strength and durability make them perfect for forming the skeleton of a building frame, enhancing its stability and sturdiness. The channels also provide a cost-effective solution, reducing the building's construction time and labor costs.3. Structural BeamsC-shaped steel channels produced by the C Shape Purlin Forming Machine can act as structural beams for buildings, providing support for other elements such as floors, walls, and roofs. The channels' strength ensures that they can withstand heavy loads and high-pressure levels, making them ideal for use in large buildings.ConclusionThe C Shape Purlin Forming Machine has revolutionized the construction industry, providing an innovative solution to meet the growing demand for durable, cost-effective, and high-quality steel channels. The machine's versatility, cost-effectiveness, and efficiency have made it a popular choice for builders across different countries. As the construction industry continues to grow, the C Shape Purlin Forming Machine will remain an essential tool for builders seeking efficient and reliable construction solutions.

Efficient Quick Interchangeable Purlin Roll Forming Machine for C/Z Shapes

If you are in the market for a high-quality roll forming machine that can produce both C and Z shape purlins without the need for changing rollers, then the Quick Interchangeable C/Z Purlin Roll Forming Machine is the ideal solution for you. Designed with efficiency and ease of operation in mind, this machine has quickly become a popular choice for many industries.One of the key features of this machine is its quick interchangeable capability. This means that you can easily switch between producing C and Z shaped purlins without the need for any additional tooling or equipment. This feature not only saves time but also makes it more convenient for operators to use.The roll forming process is an important aspect of this machine. The materials are fed into the machine and then go through a series of rollers that gradually shape and form them into the desired C or Z purlin profile. What makes this machine unique is that it offers a high level of accuracy and precision, ensuring that each purlin produced is consistent in shape and size.Additionally, this machine can also punch holes into the purlins as they are being formed. This feature is especially useful in industries such as construction, where holes are required for fixing the purlins to the building structure.The Quick Interchangeable C/Z Purlin Roll Forming Machine is also built to meet strict European standards. It is made from high-quality materials that are sturdy and highly durable, allowing it to withstand heavy usage and long-term wear and tear.In terms of its operation, this machine is easy to use and requires minimal maintenance. It also has a high production capacity, making it suitable for a range of applications and industries.In conclusion, the Quick Interchangeable C/Z Purlin Roll Forming Machine is a versatile, efficient, and highly reliable machine that is ideal for producing both C and Z shaped purlins. Its quick interchangeable feature, high production capacity, and ability to punch holes make it a popular choice in industries such as construction and manufacturing. It is built to meet European standards and is easy to use, making it a great investment for businesses looking to improve their production capabilities.

Roll Forming Machines for Drywall and House Making: Metal Studs, Tracks and Dumplings

and Roll Forming Equipment.Metal Roof Roll Machine For Drywall – Top Quality House Making MachineIf you are looking for a top-quality house making machine, look no further than the metal roof roll machine for drywall. This versatile machine is capable of producing all the components needed for constructing a sturdy, reliable house, including metal studs, tracks, roofing, and more.One of the primary advantages of the metal roof roll machine for drywall is its ability to generate metal studs and tracks using a specialized technique known as roll forming. In this technique, sheets of metal are fed through a series of rollers that gradually bend the metal into the desired shape. This produces a durable, strong, and uniform product that is perfectly suited for use in residential and commercial construction.The metal stud and track roll forming machine from Alibaba is an excellent example of this type of equipment. It is capable of producing high-quality metal studs and tracks in a variety of sizes and configurations, making it suitable for a wide range of construction applications. Whether you are building a small residential property or a large commercial complex, this machine can help you create the perfect metal framing to get the job done.Other Benefits of Steel FramingIn addition to being strong, durable, and reliable, steel framing also offers a number of other advantages for construction projects. For example, steel is much lighter than traditional building materials like bricks and concrete, which can help reduce the overall weight of a building and make it easier to erect. It is also non-combustible, which can help reduce the risk of fires in buildings.Steel framing is also extremely flexible, allowing contractors to create customized designs and incorporate a wide range of materials and finishes into their projects. And because it is produced using sophisticated manufacturing processes like roll forming, it is possible to create extremely precise, uniform components that are easy to install and require very little maintenance.Finding the Right Metal Stud Making MachineIf you are interested in using roll forming equipment to produce metal studs and tracks for your construction projects, it is important to choose the right machine for your needs. Look for equipment that offers a high level of precision and flexibility, and that is capable of producing a wide range of different shapes and sizes.Also, be sure to choose a machine that is backed by a reputable manufacturer with a track record of producing high-quality equipment. This will ensure that you receive reliable, long-lasting equipment that meets your needs and exceeds your expectations.ConclusionOverall, the metal roof roll machine for drywall is a top-quality house making machine that is capable of producing a wide range of components for any construction project. Whether you are constructing a single-family home or a large commercial complex, this equipment is the perfect tool for ensuring that your building is strong, durable, and reliable. So if you are in the market for a metal stud making machine or roll forming equipment, look no further than the metal roof roll machine for drywall – the best choice for your construction needs!

Comprehensive Roll Forming Solutions in China: Experts in Cold Roll Forming Machines for Various Applications

Roll forming is a process used to mold metal into various shapes by passing it through a series of rollers. The roll forming machine is a crucial tool in this process, facilitating the shaping of the metal with ease and accuracy. Steel stud roll forming machines are an essential type of roll forming machine designed specifically for the construction industry. In this blog, we will explore the importance of steel stud roll forming machines and their benefits.What is a Steel Stud Roll Forming Machine?A steel stud roll forming machine is a type of roll forming equipment that is used to manufacture steel studs. Steel studs are vital components in the construction of buildings and other structures. They are primarily used as framing elements to support walls, ceilings, and floors, providing strength and stability to the overall structure.A steel stud roll forming machine is a necessary tool in creating these steel studs. It is designed to take a flat steel plate or sheet and transform it into a steel stud by passing it through a series of rollers. These rollers shape the steel into a specific profile or cross-section, making sure it is precisely cut and molded to your specifications.Benefits of Using Steel Stud Roll Forming MachineUsing a steel stud roll forming machine has many benefits, including:1. EfficiencySteel stud roll forming machines are incredibly efficient in creating precise shapes and sizes of steel studs. They operate at high speeds, significantly reducing the time required to manufacture studs and ensuring production is cost-effective.2. ConsistencyThe use of steel stud roll forming machines ensures consistent production of steel studs with uniform dimensions and shapes. It eliminates any variations that may occur when using alternative tools, providing an optimal level of quality control.3. High-Quality OutputThe steel stud roll forming process ensures that the final product is of the highest quality. The resulting steel studs are strong, durable, and exhibit excellent tolerance and surface finish.4. VersatilitySteel stud roll forming machines can be used to manufacture a variety of cross-sections for steel studs. They can be customized to create different profile shapes and sizes, allowing for the production of different types of studs for varying applications.5. Energy EfficientModern steel stud roll forming machines are designed to save energy by adopting environmentally-friendly practices. As a result, they reduce energy costs and minimize the carbon emissions generated in the manufacturing process.ConclusionSteel stud roll forming machines are an essential tool in the construction industry, enabling the production of steel studs to be efficient, consistent, and high-quality. They offer numerous benefits, including efficiency, precision, consistency, and versatility while reducing energy costs and making the manufacturing process more eco-friendly.Looking for a steel stud roll forming machine for your next construction project? MTC is a leading cold roll former manufacturer in China, providing a one-stop roll forming solution, from consultation to final training, for many different applications where roll forming machines can make a difference. Contact MTC today and get your state-of-the-art steel stud roll forming machine!

Efficient Slitting And Cutting Machine Simplifies Industrial Operations

Title: Innovative Slitting and Cutting Machine Revolutionizes Industrial ProcessesIntroduction:In today's manufacturing landscape, technological advancements continue to shape industries and transform production processes. Companies are constantly seeking innovative solutions to enhance efficiency and improve overall productivity. The Slitting and Cutting Machine, developed by an industry-leading company, has emerged as a groundbreaking solution that revolutionizes cutting-edge industrial processes. This groundbreaking machine addresses the challenges of precision, speed, and versatility, positioning the manufacturing industry on a path to unprecedented growth and success.Precision and Accuracy:The Slitting and Cutting Machine is designed with precision and accuracy as its primary goals. Incorporating cutting-edge technology and state-of-the-art components, it has the ability to achieve highly precise cuts on various materials, including metal sheets, plastic films, and textiles. Equipped with advanced sensors and intelligent software, this machine ensures that each cut made is consistent and error-free, eliminating the inconsistencies that conventional machines often encounter. This level of precision minimizes material waste and enhances production quality, ultimately boosting enterprises' bottom line.Speed and Efficiency:One of the key advantages of the Slitting and Cutting Machine is its ability to operate at high speeds, significantly increasing production efficiency. With an integrated servo motor system and advanced control algorithms, this machine can rapidly process large quantities of material within a short timeframe. By minimizing downtime and maximizing output, it empowers businesses to stay ahead in an increasingly competitive market. Furthermore, its user-friendly interface and customizable settings allow operators to easily adjust cutting parameters and optimize performance, ensuring seamless integration into existing production workflows.Versatility and Adaptability:The Slitting and Cutting Machine offers remarkable flexibility and adaptability across a wide range of industrial applications. It can efficiently handle materials of varying thicknesses and dimensions, accommodating diverse production requirements. Furthermore, its modular design enables quick tool changeovers, allowing for a seamless transition between different materials and cutting patterns. As a result, the machine empowers enterprises to diversify their product offerings, explore new markets, and meet the ever-changing demands of customers, enhancing their overall competitiveness and growth potential.Safety and Reliability:The Slitting and Cutting Machine prioritizes safety and reliability, boasting numerous built-in features to ensure a secure operational environment. It is equipped with comprehensive safety measures, including emergency stop buttons, intelligent sensors, and protective barriers to prevent accidents and injuries. Additionally, the machine's robust construction and high-quality components guarantee long-term reliability and durability, reducing maintenance costs and enhancing overall operational efficiency.Conclusion:The Slitting and Cutting Machine, developed by an industry-leading company, represents a significant milestone in the realm of manufacturing. Its precision, speed, versatility, safety features, and reliability make it the go-to solution for businesses seeking to optimize their production processes and gain a competitive edge. With this innovative machine at their disposal, enterprises can streamline operations, reduce waste, enhance overall product quality, and explore new opportunities for growth. The Slitting and Cutting Machine paves the way for a more efficient and prosperous industrial landscape, while solidifying the position of its manufacturer as a pioneer in cutting-edge technology.

Highly Accurate CNC Milling of Aluminum Extrusion Profiles

Aluminum Extrusion Milling Machine: Revolutionizing Precision and EfficiencyAluminum extrusion has become an integral part of various industries due to its lightweight, high strength, and versatility. From automotive to aerospace, electronics to construction, the demand for aluminum extrusion profiles is skyrocketing. However, in order to meet the ever-increasing demands, manufacturers need cutting-edge machinery and techniques. This is where aluminum CNC milling machines come into play.Precision is KeyTo produce high-quality aluminum extrusion profiles, precision is of utmost importance. Any slight deviation from the desired dimensions can lead to product failure. This is where the CNC (Computer Numerical Control) milling machines step in. These advanced machines use computer-controlled systems to execute complex milling operations with unmatched accuracy.The precision offered by aluminum CNC milling machines allows manufacturers to create intricate designs and shapes with high repeatability. From simple profiles to complex geometries, these machines can handle it all. This not only ensures consistency in the final product but also minimizes wastage, saving valuable resources and costs.High-Speed PerformanceApart from precision, speed is another crucial factor that determines the efficiency of aluminum extrusion production. Traditional machining methods are time-consuming, limiting the manufacturing capacity. In contrast, CNC milling machines offer enhanced productivity by virtue of their high-speed performance.Equipped with powerful spindles and cutting tools, CNC milling machines can quickly remove material from the aluminum billet, resulting in faster production cycles. The automated nature of these machines eliminates manual errors and speeds up the overall manufacturing process. This enables manufacturers to cater to large volumes of orders while maintaining the desired quality standards.Advanced Features for Enhanced FunctionalityCNC milling machines for aluminum extrusion profiles are equipped with a wide range of advanced features that further enhance their functionality. One such feature is the multi-axis capability. These machines can perform milling operations on multiple axes simultaneously, allowing for complex, three-dimensional profiling. This opens up a whole new world of design possibilities, expanding the horizons of aluminum extrusion applications.Furthermore, the CNC systems in these machines can be programmed to operate in a variety of modes. Whether it is contour milling, pocket milling, or face milling, the CNC milling machines can effortlessly handle all operations, ensuring seamless production processes.Sourcing High-Quality Aluminum Extrusion Milling MachinesTo experience the benefits of precision and efficiency offered by aluminum CNC milling machines, it is imperative to collaborate with reliable suppliers. When searching for OEM aluminum extrusion profile, high precision aluminum CNC milling suppliers, one name that stands out is aluminum-extrusion.At aluminum-extrusion, we specialize in providing top-notch aluminum extrusion profiles and CNC milling machines. With a focus on quality and affordability, we offer a wide range of products to cater to diverse industry requirements. Our expertise lies in delivering OEM aluminum extrusion profiles that meet the highest standards of precision and accuracy.ConclusionIn the fast-paced manufacturing industry, efficiency and precision are critical factors that can make or break a business. Aluminum extrusion milling machines offer the perfect solution to meet these demands. With their ability to deliver high precision, superior speed, and advanced functionality, these machines revolutionize the aluminum extrusion process.Collaborating with reputable suppliers like aluminum-extrusion ensures access to high-quality products that not only drive efficiency but also maintain the desired quality standards. So, embrace the power of aluminum CNC milling machines and unlock a world of possibilities for your aluminum extrusion profile manufacturing needs.

Get Comprehensive Roll Forming Solutions for Various Applications in China

Floor Forming Machine: The Key to Efficient and Precise Flooring SolutionsIn the world of construction, efficient and precise machinery plays a vital role in ensuring quality and timely completion of projects. Among the various types of machinery available, a floor forming machine stands out as a game-changer in the flooring industry. With advancements in technology, China has emerged as a prominent manufacturer of roll forming machines, including floor forming machines. In this blog, we will explore the importance of a floor forming machine and how it revolutionizes the flooring industry.Gone are the days when traditional methods of floor construction were prevalent, which involved labor-intensive tasks and time-consuming processes. With the advent of modern technologies, floor forming machines have gained popularity as they offer a plethora of benefits, making them an indispensable tool for construction companies across the globe. These machines enable seamless and precise production of floor components, thereby ensuring a high level of efficiency and accuracy.One of the primary advantages of utilizing a floor forming machine is its ability to provide a one-stop solution for various applications. From consultation to final training, these machines cover every aspect of the roll forming process for floor components. This eliminates the need for multiple machines and streamlines the manufacturing process, thereby saving both time and resources.With years of experience and expertise in the field, Chinese manufacturers have established themselves as leaders in the production of floor forming machines. Among these manufacturers, MTC (remove brand name) has marked its presence by delivering top-notch machinery that exceeds client expectations. Their commitment to providing a comprehensive roll forming solution has earned them a reputation as one of the leading cold roll former manufacturers in China.Utilizing advanced technology, MTC's floor forming machines offer exceptional precision and efficiency, allowing for a seamless production process. These machines are designed to handle various types of flooring applications, including but not limited to, concrete floors, steel decks, and composite floors. The versatility of MTC's floor forming machines makes them suitable for a wide range of construction projects, regardless of size or complexity.The efficiency of MTC's floor forming machines lies not only in their advanced technology but also in their user-friendly features. These machines are designed to be easy to operate, significantly reducing the learning curve for operators. This ensures that even novice users can quickly adapt to the machinery, thereby increasing overall productivity.Another significant advantage of MTC's floor forming machines is their ability to produce components with exceptional quality and dimensional accuracy. By employing state-of-the-art roll forming techniques, these machines ensure that each component meets the required specifications. This eliminates the possibility of errors and rework, thereby saving both time and materials.Additionally, MTC's floor forming machines are designed to optimize material usage, further enhancing their cost-effectiveness. With precise control over the manufacturing process, these machines minimize material wastage, leading to substantial savings for construction companies. This cost-effective approach, combined with the efficiency and precision offered by MTC's floor forming machines, makes them a wise investment for any flooring project.In conclusion, a floor forming machine has revolutionized the flooring industry, offering a one-stop solution for various applications. Chinese manufacturers, such as MTC (remove brand name), have emerged as leaders in the production of floor forming machines, providing exceptional machinery that guarantees efficiency, precision, and cost-effectiveness. With its advanced technology and user-friendly features, MTC's floor forming machines enable construction companies to achieve optimal results in their flooring projects. Embracing this innovative machinery is undoubtedly the key to efficient and precise flooring solutions.