Durable and Efficient Roller for Corrugated Roof Installation

By:Admin

Established in 1995, our company is a leading manufacturer and supplier of premium quality roofing products for commercial and residential use. With years of experience in the industry, we have gained a reputation for delivering top-notch and innovative solutions for our customers' roofing needs. Our commitment to quality, durability, and customer satisfaction has made us a trusted name in the construction and roofing sector.

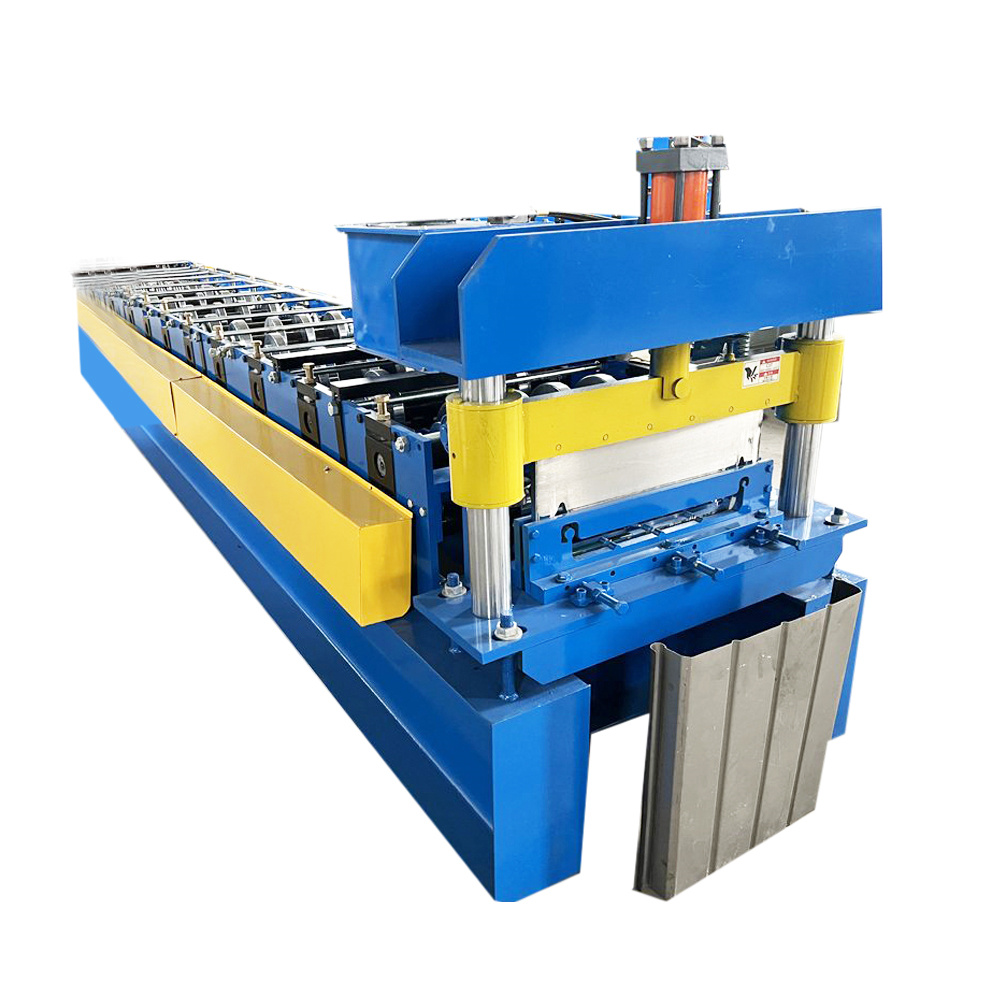

[Roller For Corrugated Roof]

In line with our dedication to providing the best roofing solutions, we are proud to introduce our latest innovation - the Roller for Corrugated Roof. This new product is designed to provide efficient and effective installation of corrugated roofing materials, ensuring a seamless and professional finish for every roofing project.

The Roller for Corrugated Roof is engineered to streamline the installation process, allowing for quick and easy application of corrugated roofing panels. Its innovative design eliminates the need for manual fastening of each panel, significantly reducing installation time and labor costs. This roller is compatible with a wide range of corrugated roofing materials, making it a versatile and practical tool for roofing contractors and DIY enthusiasts alike.

The durable construction of the Roller for Corrugated Roof ensures long-lasting performance, making it a valuable investment for any roofing professional. Its ergonomic design and lightweight construction enable effortless handling and maneuverability, enhancing efficiency and productivity on the job site. Additionally, the roller's smooth rolling action creates a consistent and secure bond between the roofing panels and the underlying structure, resulting in a pristine and professional-looking finish.

Our commitment to quality is reflected in the meticulous engineering and testing that goes into every product we manufacture. The Roller for Corrugated Roof is no exception, as it has undergone rigorous quality assurance measures to ensure its reliability, performance, and durability. Rest assured that when you choose our roller, you are investing in a product that meets the highest standards of quality and excellence.

Furthermore, we understand the importance of environmental sustainability in today's construction industry. That's why the Roller for Corrugated Roof is designed with eco-friendly materials and production processes, minimizing its impact on the environment. We take pride in offering roofing solutions that not only meet the demands of our customers but also contribute to a greener and more sustainable future for all.

As a customer-centric company, we are dedicated to providing exceptional service and support to our clients. Whether you are a roofing contractor, builder, architect, or DIY enthusiast, our team is committed to helping you find the right roofing solutions for your specific needs. The introduction of the Roller for Corrugated Roof is just one example of our ongoing efforts to empower our customers with innovative and practical tools for their roofing projects.

In conclusion, the Roller for Corrugated Roof is a game-changing addition to our lineup of roofing products. Its ability to streamline the installation process, improve efficiency, and deliver professional results makes it a must-have tool for anyone involved in roofing projects. With our unwavering dedication to quality, innovation, and customer satisfaction, we are confident that the Roller for Corrugated Roof will set a new standard for corrugated roofing installation. We look forward to seeing the positive impact this product will have on the industry and the satisfaction it will bring to our customers.

Company News & Blog

Revolutionary Automatic Length Cutting Machine: Enhancing Precision and Efficiency

In today's fast-paced world, the manufacturing sector is always on the lookout for innovative technologies that can improve their production process, while ensuring quality and efficiency. One such technology that has gained significant attention in recent times is the Automatic Length Cutting Machine.The Automatic Length Cutting Machine is a revolutionary device that helps manufacturers achieve faster and more accurate cutting of materials such as wires, pipes, and tubes. With its advanced features and intuitive controls, this machine has become a popular choice for industries ranging from automotive to aerospace, and from construction to electrical.One company that has been at the forefront of developing cutting-edge machines for the manufacturing industry is based in a country with a strong manufacturing tradition. The company has been in operation for over two decades and has become a trusted name in the industry.The company offers a comprehensive range of machines designed for maximum efficiency and productivity, including the Automatic Length Cutting Machine. This state-of-the-art device is equipped with precision cutting blades that can cut through a wide range of materials, making it ideal for use in a variety of industries.One of the key features of this machine is its ability to process multiple cuts with high speed and accuracy, making it a valuable asset for companies looking to improve their output and streamline their production process. Additionally, it has an automatic feed system that ensures a constant flow of materials, eliminating the need for manual intervention and reducing the risk of errors.The Automatic Length Cutting Machine offered by the company has been designed keeping in mind the needs of modern manufacturers. It is equipped with user-friendly controls that allow for easy operation and can be customized to suit the specific requirements of each client.Additionally, the machine has a compact design, making it easy to install and operate in even the most confined spaces. This feature has helped companies increase their utilization of floor space, enabling them to accommodate more machines and boost their overall productivity.One of the key benefits of the Automatic Length Cutting Machine is its ability to cut materials in various shapes and sizes. This feature has made it a popular choice among manufacturers of pipes, wires, and tubes, who require specific dimensions to meet industry standards.The advanced blade system of the Automatic Length Cutting Machine ensures that each cut is precise and accurate, reducing the amount of scrap material generated during the cutting process. This feature has helped companies save on raw material costs, while improving their overall efficiency.With its superior quality and advanced features, it is easy to see why the Automatic Length Cutting Machine has become such a popular choice for manufacturers across the globe. The machine not only improves productivity but also reduces waste, making it an economical and sustainable solution for businesses of all sizes.In conclusion, the Automatic Length Cutting Machine has revolutionized the manufacturing industry, enabling companies to achieve faster and more accurate cutting of materials. With its advanced features and user-friendly controls, this machine has become an essential part of the modern manufacturing process. The company that offers this innovative machine has made a significant contribution to the industry, helping businesses improve their output and streamline their production process. With its continued commitment to developing cutting-edge technologies, the company is set to remain a major player in the manufacturing sector for years to come.

High-Quality Roll Forming Machine for Wall Panel Manufacturing

Wall Panel Roll Forming MachineIn recent years, there has been a significant increase in demand for metal wall panels in various industries, including construction, automotive, and aerospace. To meet this growing demand, the need for efficient and high-quality wall panel roll forming machines has become more essential than ever. With this in mind, (company name) has recently launched its latest innovation in the form of a state-of-the-art Wall Panel Roll Forming Machine, designed to revolutionize the production of metal wall panels.The Wall Panel Roll Forming Machine boasts a range of advanced features that set it apart from traditional roll forming machines. One of the key highlights of this machine is its ability to produce wall panels with exceptional precision and consistency. This is achieved through the use of advanced technology and precision engineering, ensuring that every panel produced meets the highest quality standards.Furthermore, the Wall Panel Roll Forming Machine is designed for maximum efficiency, with a high-speed production capability that allows for increased output without compromising on quality. This means that manufacturers can now produce a greater volume of wall panels in a shorter amount of time, ultimately leading to improved productivity and profitability.In addition to its impressive performance capabilities, this machine also offers a high level of versatility. It is capable of producing a wide range of wall panel profiles, allowing manufacturers to cater to diverse customer requirements. This flexibility is further enhanced by the machine's easy-to-use control system, which allows for quick and seamless adjustments to be made to the panel production process.To further complement its cutting-edge technology, the Wall Panel Roll Forming Machine is also designed with a strong focus on durability and reliability. It is constructed using high-quality materials and components, ensuring that it can withstand the rigors of continuous, heavy-duty operation. This not only extends the machine's lifespan but also minimizes the need for maintenance, reducing downtime and associated costs.In line with (company name)'s commitment to customer satisfaction, the Wall Panel Roll Forming Machine is backed by comprehensive service and support. From installation and training to ongoing technical assistance, the company's team of experts is on hand to ensure that customers can maximize the potential of their investment.With the launch of the Wall Panel Roll Forming Machine, (company name) has once again demonstrated its position as a leading innovator in the roll forming industry. By combining cutting-edge technology with a focus on performance, versatility, and reliability, this new machine is set to redefine the production of metal wall panels and set a new standard for efficiency and quality.About (company name):(Company name) is a renowned manufacturer of roll forming machines, with a strong track record of delivering high-performance solutions to customers around the world. With a commitment to innovation, quality, and service, the company has established itself as a trusted partner for businesses seeking to enhance their production capabilities. As a provider of comprehensive roll forming solutions, (company name) is dedicated to meeting the evolving needs of its customers and driving the industry forward through continuous improvement and innovation.In summary, the Wall Panel Roll Forming Machine from (company name) represents a significant advancement in the production of metal wall panels. With its cutting-edge technology, exceptional performance, and comprehensive support, it is poised to make a lasting impact on the industry and set new benchmarks for efficiency and quality.

High-Quality Metal Roll Forming Systems for Efficient Production

Metal roll forming systems have seen a surge in demand over the past few years, as the construction and manufacturing industries continue to grow at a rapid pace. Companies are constantly looking for ways to increase efficiency and productivity, and metal roll forming systems offer a solution that meets these needs.One company that has been leading the way in providing high-quality metal roll forming systems is {}. Since its inception, {} has built a strong reputation for delivering innovative and reliable metal forming solutions to its customers. With a focus on customer satisfaction and technological advancement, {} has become a trusted name in the industry.{} offers a wide range of metal roll forming systems that are designed to meet the specific needs of various industries. Whether it's for roofing, siding, or automotive applications, {} has the expertise and experience to provide top-of-the-line solutions. The company's commitment to quality and precision has made it a preferred choice for many companies looking to enhance their manufacturing capabilities.One of the key factors that sets {} apart from its competitors is its dedication to research and development. The company's team of engineers and technicians are constantly working to improve and innovate its metal roll forming systems, ensuring that they remain at the forefront of technology. By staying ahead of the curve, {} is able to offer its customers the most cutting-edge solutions for their metal forming needs.In addition to its technological prowess, {} also takes pride in its customer-centric approach. The company works closely with its clients to understand their specific requirements and provide custom solutions that address their unique challenges. Whether it's a small-scale project or a large-scale production line, {} has the expertise and resources to deliver tailored metal roll forming systems that exceed expectations.Furthermore, {} places a strong emphasis on quality control and assurance throughout the manufacturing process. The company adheres to strict standards and guidelines to ensure that every metal roll forming system that leaves its facility is of the highest quality. This commitment to excellence has earned {} a reputation for reliability and durability, further solidifying its position as a leader in the industry.As the demand for metal roll forming systems continues to grow, {} remains dedicated to meeting the evolving needs of its customers. The company is constantly exploring new opportunities and expanding its capabilities to better serve the market. With its unwavering commitment to innovation and customer satisfaction, {} is well-positioned to remain a driving force in the metal forming industry for years to come.In conclusion, metal roll forming systems have become an essential component of modern manufacturing and construction processes, and {} has proven itself to be a leading provider of these systems. With its focus on innovation, quality, and customer satisfaction, {} has established itself as a trusted partner for companies looking to enhance their metal forming capabilities. As the industry continues to evolve, {} is well-equipped to provide top-of-the-line solutions that meet the ever-changing needs of its customers.

High Quality Rolling Forming Machine for Efficient Track Production

The track rolling forming machine is a crucial piece of equipment for many industries, and it is an invaluable tool for companies looking to streamline their production processes. This machine is used to create custom tracks for a variety of applications, including heavy machinery and industrial equipment.{Company Name} is a leading provider of track rolling forming machines, and they are known for their high-quality and reliable equipment. The company has been in business for over 20 years, and they have a strong reputation for delivering top-notch products and exceptional customer service.The track rolling forming machine offered by {Company Name} is designed to meet the specific needs of their customers. The machine is capable of creating tracks in a wide range of sizes and materials, and it can be customized to meet the unique requirements of each customer. This flexibility makes the machine an ideal choice for companies looking to improve their production processes and increase their overall efficiency.One of the key features of the track rolling forming machine is its advanced technology. The machine is equipped with state-of-the-art controls and automation systems, which allow for precise and efficient track forming. This technology also helps to reduce downtime and maximize productivity, making it an invaluable asset for companies with high production demands.In addition to its advanced technology, the track rolling forming machine offered by {Company Name} is also designed with durability and longevity in mind. The machine is built to withstand the rigors of industrial use, and it is constructed from high-quality materials that are designed to last. This means that companies can rely on their machine to perform consistently and reliably, even in demanding production environments.The track rolling forming machine from {Company Name} is also backed by comprehensive customer support and service. The company offers installation, training, and ongoing maintenance to ensure that their customers can get the most out of their equipment. This level of support is crucial for companies looking to maximize the return on their investment and ensure that their production processes run smoothly and efficiently.{Company Name} is proud to offer their track rolling forming machine to companies across the globe, and they have a strong track record of delivering exceptional results for their customers. The machine has been used in a wide range of applications, from agriculture to construction, and it has consistently proven to be a valuable asset for companies looking to improve their production processes.Overall, the track rolling forming machine offered by {Company Name} is a top-of-the-line piece of equipment that is designed to meet the specific needs of their customers. With its advanced technology, durability, and comprehensive customer support, the machine is an ideal choice for companies looking to streamline their production processes and improve their overall efficiency.

Comprehensive Roll Forming Solutions in China: Experts in Cold Roll Forming Machines for Various Applications

Roll forming is a process used to mold metal into various shapes by passing it through a series of rollers. The roll forming machine is a crucial tool in this process, facilitating the shaping of the metal with ease and accuracy. Steel stud roll forming machines are an essential type of roll forming machine designed specifically for the construction industry. In this blog, we will explore the importance of steel stud roll forming machines and their benefits.What is a Steel Stud Roll Forming Machine?A steel stud roll forming machine is a type of roll forming equipment that is used to manufacture steel studs. Steel studs are vital components in the construction of buildings and other structures. They are primarily used as framing elements to support walls, ceilings, and floors, providing strength and stability to the overall structure.A steel stud roll forming machine is a necessary tool in creating these steel studs. It is designed to take a flat steel plate or sheet and transform it into a steel stud by passing it through a series of rollers. These rollers shape the steel into a specific profile or cross-section, making sure it is precisely cut and molded to your specifications.Benefits of Using Steel Stud Roll Forming MachineUsing a steel stud roll forming machine has many benefits, including:1. EfficiencySteel stud roll forming machines are incredibly efficient in creating precise shapes and sizes of steel studs. They operate at high speeds, significantly reducing the time required to manufacture studs and ensuring production is cost-effective.2. ConsistencyThe use of steel stud roll forming machines ensures consistent production of steel studs with uniform dimensions and shapes. It eliminates any variations that may occur when using alternative tools, providing an optimal level of quality control.3. High-Quality OutputThe steel stud roll forming process ensures that the final product is of the highest quality. The resulting steel studs are strong, durable, and exhibit excellent tolerance and surface finish.4. VersatilitySteel stud roll forming machines can be used to manufacture a variety of cross-sections for steel studs. They can be customized to create different profile shapes and sizes, allowing for the production of different types of studs for varying applications.5. Energy EfficientModern steel stud roll forming machines are designed to save energy by adopting environmentally-friendly practices. As a result, they reduce energy costs and minimize the carbon emissions generated in the manufacturing process.ConclusionSteel stud roll forming machines are an essential tool in the construction industry, enabling the production of steel studs to be efficient, consistent, and high-quality. They offer numerous benefits, including efficiency, precision, consistency, and versatility while reducing energy costs and making the manufacturing process more eco-friendly.Looking for a steel stud roll forming machine for your next construction project? MTC is a leading cold roll former manufacturer in China, providing a one-stop roll forming solution, from consultation to final training, for many different applications where roll forming machines can make a difference. Contact MTC today and get your state-of-the-art steel stud roll forming machine!

Different Types of Content Forms for SEO Optimization: Presentations, Infographics, Videos, and Documents

As businesses continue to grow and evolve, so do their communication needs. One of the most important aspects of effective communication is the ability to share information and data in a clear, concise manner. This is where forms come into play. Forms are an essential tool for collecting, processing, and sharing information, and they can take many different forms.In this blog post, we will explore the different types of forms and how they can benefit businesses, as well as introduce a new technology that can revolutionize the way forms are created and managed.PresentationsPresentations are a popular form for sharing information in the form of images, slides, and videos. Presentations are useful for sharing data, ideas, and concepts in a visually appealing and engaging way. They are also often used to introduce new products or services. Presentations can be created using PowerPoint or other presentation software and can be uploaded to platforms like SlideShare for easy sharing.InfographicsInfographics are a visual representation of data or information, usually presented in a colorful and eye-catching format. They are often used to share statistics, data, or complex information in an easily digestible way. Infographics can be created using graphic design software or online tools, such as Canva or Piktochart.VideosVideos are a versatile and engaging form for sharing information. They can be used for product demos, explainer videos, marketing messages, and more. Videos can also be used to share interviews, panel discussions, and other events. They can be uploaded to video hosting platforms like YouTube or Vimeo for easy sharing.DocumentsDocuments are a more traditional form for sharing information. They can be used for reports, proposals, guides, and other materials. Documents are often created using Microsoft Word or other word processing software and can be converted to PDF for easy sharing.Form MachineForm Machine is a new technology that can revolutionize the way forms are created and managed. It is a web-based platform that allows businesses to create and manage forms in a simple and intuitive way. Form Machine provides a user-friendly interface for creating forms, as well as a powerful form engine for processing the information collected.Form Machine is an ideal solution for businesses that need to collect data from customers, employees, or other stakeholders. It can be used for surveys, job applications, registration forms, and more. Form Machine can also be used to automate processes, such as scheduling appointments or sending notifications.ConclusionIn conclusion, forms are an essential tool for any business that wants to collect, process, and share information effectively. Presentations, infographics, videos, and documents are all useful forms for sharing information in different ways. However, the traditional methods of creating and managing forms can be time-consuming and cumbersome.Form Machine offers a streamlined solution for creating and managing forms. It is a powerful tool that can help businesses save time, improve efficiency, and enhance their communication processes. By embracing new technologies like Form Machine, businesses can stay ahead of the game and remain competitive in an ever-changing business landscape.

Promotional Corrugated Pipe Machine and PC Solid, Transparent Sheet Manufacturing Line for Sale

Title: Unleashing the Innovation: Corrugated Sheet Manufacturing Machine Revolutionizes the Production ProcessIntroduction:In today's competitive industrial landscape, staying ahead is crucial for any business to thrive. The manufacturing industry continuously seeks innovative solutions to optimize production processes and enhance product quality. One such revolutionary machine, the Corrugated Sheet Manufacturing Machine, has taken the market by storm. In this blog post, we will delve into the various features and benefits of this powerhouse device and explore its applications across diverse industries.Understanding the Corrugated Sheet Manufacturing Machine:Developed by an industry-leading machinery manufacturer, this Corrugated Sheet Manufacturing Machine is designed to produce high-quality corrugated sheets efficiently and effectively. The machine utilizes state-of-the-art technology and cutting-edge automation processes to meet the requirements of various industries worldwide.Key Features and Specifications of the Machine:1. Increased Productivity:The Corrugated Sheet Manufacturing Machine boasts high production capacity, enabling businesses to meet increasing market demands effectively. With its advanced capabilities, it can produce corrugated sheets at an impressive speed, resulting in reduced lead times and increased profitability.2. Precision and Accuracy:The machine's advanced control systems ensure precise formation and cutting of corrugated sheets, guaranteeing uniform thickness and flawless finishes. This level of precision allows manufacturers to maintain the highest quality standards, meeting customer expectations consistently.3. Flexible Customization:One of the most significant advantages of this machine is its ability to adapt to different production requirements. Manufacturers can adjust settings to produce sheets of varying widths, materials, and thicknesses. This flexibility makes it suitable for a wide range of applications across diverse industries.4. Energy Efficiency:The Corrugated Sheet Manufacturing Machine incorporates energy-saving features, making it an eco-friendly choice. The machine optimizes power consumption while maintaining high productivity, reducing both operational costs and environmental impact.Applications of Corrugated Sheets:Corrugated sheets produced using this innovative machine find applications across multiple industries. Some key applications include:1. Packaging Industry:Corrugated sheets are widely used for packaging purposes due to their durability and lightweight design. The machine's ability to produce sheets of different sizes and materials allows packaging companies to cater to various customer requirements efficiently.2. Construction Sector:Corrugated sheets are utilized for roofing, wall cladding, and insulation purposes in the construction industry. With the machine's flexibility in producing custom sizes and thicknesses, construction companies can easily source corrugated sheets that meet their specific project needs.3. Advertising and Signage:The transparent, durable, and lightweight properties of corrugated sheets make them ideal for advertising and signage applications. The machine's precision enables the production of high-quality sheets suitable for printing eye-catching graphics, ensuring maximum visibility for promotional materials.Conclusion:The Corrugated Sheet Manufacturing Machine has revolutionized the production process in various industries, offering increased productivity, precision, and flexibility. With its ability to produce corrugated sheets of different sizes, materials, and thicknesses, the machine caters to the unique requirements of diverse industries.Investing in this innovative machine can empower businesses to stay ahead in the market, cut down costs, and enhance overall product quality. By incorporating the Corrugated Sheet Manufacturing Machine into their operations, manufacturers can unlock new opportunities for growth, sustainability, and customer satisfaction.Keywords: Corrugated Sheet Manufacturing Machine, Corrugated sheets, production process, innovation, precision, flexibility, applications, packaging industry, construction sector, advertising, signage.

Forming Machine for Stud and Track: What You Need to Know

Stud And Track Forming Machine is a vital piece of equipment in the construction industry. This machine is used to produce studs and tracks, which are essential components in the construction of various structures such as walls, ceilings, and roofs. The machine is capable of producing high-quality studs and tracks with precision and efficiency, making it an indispensable tool for contractors and builders.{Company} is a leading manufacturer of stud and track forming machines, with a track record of producing top-quality equipment for the construction industry. With a strong commitment to innovation and customer satisfaction, {Company} has established itself as a reliable provider of specialized machinery for the construction sector. The company's stud and track forming machines are known for their robust construction, high productivity, and user-friendly operation, making them the preferred choice for many construction professionals.The stud and track forming machine produced by {Company} is designed to meet the specific requirements of modern construction projects. The machine is equipped with advanced technology and features that enable it to produce studs and tracks of varying shapes and sizes. This flexibility is key to meeting the diverse needs of construction projects, where different types of studs and tracks may be required to accommodate specific design and engineering requirements.One of the key advantages of using the stud and track forming machine from {Company} is its high level of precision and accuracy. The machine is engineered to produce studs and tracks with tight tolerances, ensuring that the components fit together seamlessly during the construction process. This precision is critical for ensuring the structural integrity and stability of the building, making the {Company}'s machine an essential tool for ensuring high-quality construction outcomes.Moreover, {Company} offers a wide range of customization options for its stud and track forming machine, allowing contractors and builders to tailor the equipment to their specific needs. This includes the ability to produce studs and tracks from different materials, such as steel and aluminum, as well as the flexibility to create custom profiles and dimensions. This level of customization ensures that the stud and track forming machine can be adapted to the unique requirements of different construction projects, further enhancing its value and versatility.In addition to its advanced technical capabilities, the stud and track forming machine from {Company} is also known for its high productivity and efficiency. The machine is designed to maximize output while minimizing downtime, allowing construction professionals to meet tight deadlines and maintain project schedules. This level of productivity is crucial for ensuring the profitability and success of construction projects, making the {Company}'s machine a valuable asset for contractors and builders.Furthermore, {Company} prides itself on providing excellent customer service and technical support for its stud and track forming machines. The company offers comprehensive training and maintenance services to ensure that customers can maximize the performance and longevity of their equipment. This commitment to customer support has earned {Company} a reputation for reliability and trustworthiness, further solidifying its position as a preferred supplier of stud and track forming machines in the construction industry.In conclusion, the stud and track forming machine from {Company} is a highly advanced and reliable piece of equipment that is essential for modern construction projects. With its precision, customization options, productivity, and customer support, the machine offers a complete solution for producing high-quality studs and tracks for various construction applications. As the construction industry continues to evolve, the demand for advanced and versatile machinery like the stud and track forming machine from {Company} is only expected to grow, further cementing the company's position as a leader in the field.

C Purlin Machine with Punching Hole Device: An Overview

C Purlin Machine With Punching Hole Device Leads the Innovation in Metal Forming IndustryThe metal forming industry is constantly evolving, and the demand for efficient and advanced machinery is growing rapidly. In response to this demand, a leading manufacturer of metal forming machinery has introduced a groundbreaking C Purlin Machine with a Punching Hole Device, setting a new standard for innovation and efficiency in the industry.The C Purlin Machine with Punching Hole Device is designed to streamline the production process of C-shaped steel purlins, a critical component in the construction of steel buildings, warehouses, and other structures. This machine not only shapes the steel into the desired C profile, but it also features a built-in punching hole device that allows for precise and efficient hole punching, saving time and labor costs.The company behind this innovative machine has a long-standing reputation for excellence in the design and manufacturing of metal forming equipment, with a commitment to pushing the boundaries of technological advancement in the industry. The introduction of the C Purlin Machine with Punching Hole Device is a testament to their dedication to providing cutting-edge solutions for the evolving needs of their customers.One of the most noteworthy features of this new machine is its advanced punching hole device, which is capable of creating precise and consistent holes in the steel purlins. This is a critical capability for many construction projects, as it ensures that the purlins can be easily assembled and installed with other components of the structure. The punching hole device is fully automated, allowing for high-speed and accurate hole punching, resulting in a significant boost to overall production efficiency.In addition to its innovative punching hole device, the C Purlin Machine is also designed for versatility and ease of use. It is capable of processing a wide range of steel materials, making it suitable for a variety of applications in the construction industry. The machine can be quickly and easily adjusted to accommodate different sizes and thicknesses of steel, providing a high level of flexibility for manufacturers.Furthermore, the machine is equipped with a user-friendly control system that allows for easy operation and monitoring of the production process. This intuitive interface streamlines the setup and operation of the machine, reducing the need for extensive training and minimizing the potential for error. This ease of use contributes to the overall efficiency of the production process, as it allows operators to maximize their productivity with minimal downtime.The introduction of the C Purlin Machine with Punching Hole Device represents a significant leap forward in the metal forming industry, offering a solution that combines precision, efficiency, and versatility in a single machine. It is poised to revolutionize the way steel purlins are manufactured, providing manufacturers with a competitive edge in an increasingly demanding market.As the global demand for steel structures continues to grow, the need for advanced and efficient metal forming machinery is more critical than ever. The introduction of the C Purlin Machine with Punching Hole Device addresses this need head-on, offering a solution that is engineered to meet the evolving requirements of the industry. With this innovative machine, manufacturers can expect to achieve higher levels of productivity, cost savings, and overall operational efficiency.In conclusion, the C Purlin Machine with Punching Hole Device is a game-changer in the metal forming industry, setting a new standard for innovation and performance. As the industry continues to adapt to the changing landscape of construction and manufacturing, this groundbreaking machine represents a significant step forward in the evolution of metal forming technology. With its advanced capabilities and user-friendly design, it is poised to make a lasting impact on the way steel purlins are produced, paving the way for a more efficient and competitive industry.