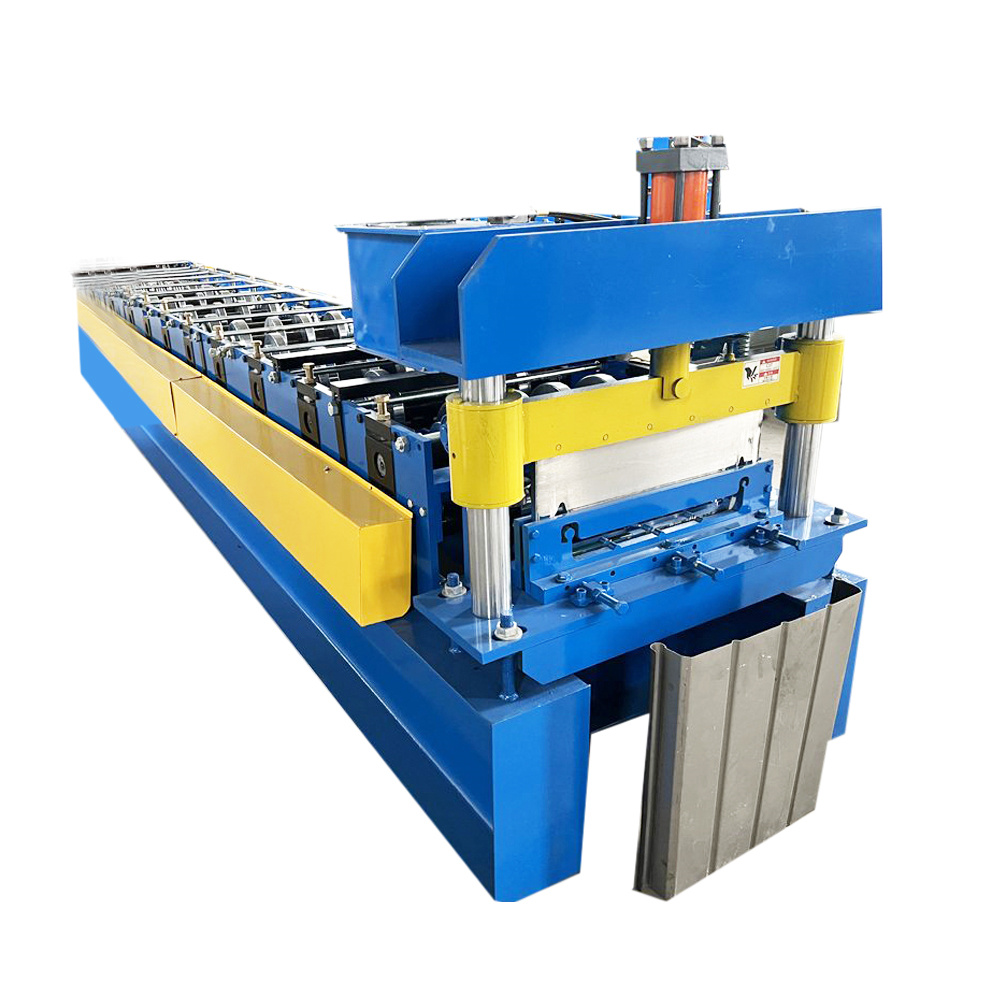

Durable and Efficient Sheet Metal Roller for Corrugated Materials

By:Admin

In the world of manufacturing and construction, the use of sheet metal is widespread. It is a versatile material that can be used for a variety of applications, from roofing and siding to automotive and aviation. However, the process of shaping and corrugating sheet metal has historically been time-consuming and labor-intensive. That is, until now.

Thanks to the innovation and ingenuity of the team at {{Company Name Removed}}, a new corrugated sheet metal roller has been introduced to revolutionize the industry. This cutting-edge technology promises to streamline the process of shaping and corrugating sheet metal, ultimately saving time and money for manufacturers and construction professionals.

The {{Company Name Removed}} corrugated sheet metal roller is equipped with advanced features designed to enhance efficiency and precision. Its automated system ensures consistent and uniform corrugations, eliminating the need for manual adjustments and reducing the risk of errors. This level of reliability allows for increased productivity and higher output, giving companies a competitive edge in the market.

Furthermore, the corrugated sheet metal roller is built for durability and longevity. Its robust construction and high-quality materials make it a reliable investment for any business. With proper maintenance and care, this machine is designed to withstand the rigors of heavy-duty use, ensuring consistent performance over time.

One of the most impressive aspects of the {{Company Name Removed}} corrugated sheet metal roller is its user-friendly interface. The intuitive controls and digital display make it easy for operators to set parameters and monitor the machine's operation. This simplifies the production process and reduces the need for extensive training, allowing businesses to quickly integrate this technology into their workflow.

In addition to its technical capabilities, the {{Company Name Removed}} corrugated sheet metal roller is also designed with safety in mind. Its protective measures and emergency shutdown features prioritize the well-being of workers, minimizing the risk of accidents and injuries in the workplace. This commitment to safety reflects the company's dedication to providing holistic solutions for its customers.

With the introduction of the {{Company Name Removed}} corrugated sheet metal roller, the industry is poised for a significant transformation. Manufacturers and construction professionals can expect to experience a marked improvement in their operations, from increased productivity and efficiency to enhanced product quality and consistency. This innovative technology has the potential to elevate the standard of sheet metal processing, setting a new benchmark for the industry.

{{Company Name Removed}} is proud to be at the forefront of this revolution in sheet metal manufacturing. As a leading provider of innovative machinery and equipment, the company is committed to pushing the boundaries of what is possible in the industry. With a focus on research and development, {{Company Name Removed}} continues to invest in new technologies that can optimize production processes and deliver tangible benefits to its customers.

In closing, the introduction of the {{Company Name Removed}} corrugated sheet metal roller represents a significant milestone in the evolution of the industry. By combining advanced technology, reliable performance, and user-friendly design, this machine is poised to redefine the way sheet metal is processed and utilized. As manufacturers and construction professionals embrace this innovation, they can look forward to a future of enhanced productivity, efficiency, and success.

Company News & Blog

High Quality Color Steel Glazed Tile Profiling Equipment for Sale

Color Steel Glazed Tile Profiling Equipment Revolutionizes the IndustryIn the fast-paced world of construction, innovation and technology continue to play a crucial role in driving the industry forward. Among the latest advancements in the field is the Color Steel Glazed Tile Profiling Equipment, a revolutionary machine that promises to transform the way steel glazed tiles are manufactured. Developed by a leading company in the industry, this state-of-the-art equipment is set to make a significant impact on the market.The Color Steel Glazed Tile Profiling Equipment is designed to streamline the production process of steel glazed tiles, offering efficiency and precision like never before. With its advanced technology and automated features, the equipment is capable of producing high-quality tiles at a rapid pace, allowing manufacturers to meet the growing demand for these products in a timely manner.One of the key highlights of the Color Steel Glazed Tile Profiling Equipment is its ability to create a wide range of tile profiles with ease. Whether it's a traditional design or a custom shape, the machine is able to produce tiles that meet the exact specifications of the customer. This level of flexibility is a game-changer for manufacturers, as it enables them to cater to diverse customer needs without compromising on quality or efficiency.Moreover, the equipment is equipped with cutting-edge control systems that ensure precise and consistent output. This not only guarantees the uniformity of the tiles but also minimizes material wastage, leading to cost savings for the manufacturer. Additionally, the machine's user-friendly interface makes it easy to operate and maintain, further enhancing its appeal to businesses of all sizes.With its ability to boost productivity and reduce production costs, the Color Steel Glazed Tile Profiling Equipment is poised to create a significant impact on the market. Its introduction marks a new era in the manufacturing of steel glazed tiles, providing a competitive edge to companies that embrace this innovative technology.The company behind the development of this groundbreaking equipment, {Company Name}, has established itself as a leading player in the industry. With a strong commitment to research and development, the company has consistently introduced cutting-edge solutions that address the evolving needs of its customers. The Color Steel Glazed Tile Profiling Equipment is a testament to the company's dedication to innovation and its vision to drive positive change in the construction industry.{Company Name} has a proven track record of delivering high-quality products and exceptional service to its clients. Its team of experienced engineers and technicians have worked tirelessly to bring the Color Steel Glazed Tile Profiling Equipment to life, leveraging their expertise to create a machine that sets new standards in the industry. The company's strong focus on precision engineering and attention to detail is evident in the superior performance and reliability of the equipment.Furthermore, {Company Name} is committed to providing comprehensive support to its customers, offering training, technical assistance, and maintenance services to ensure the seamless operation of the Color Steel Glazed Tile Profiling Equipment. This dedication to customer satisfaction has earned the company a reputation for excellence and reliability in the market.As the construction industry continues to evolve, the demand for advanced manufacturing solutions like the Color Steel Glazed Tile Profiling Equipment is set to grow. With its ability to enhance efficiency, quality, and versatility, this innovative machine is poised to become a game-changer for manufacturers of steel glazed tiles. Backed by the expertise and commitment of {Company Name}, the equipment is primed to lead the industry into a new era of production excellence.In conclusion, the Color Steel Glazed Tile Profiling Equipment represents a significant leap forward in the manufacturing of steel glazed tiles. Its advanced technology, precision engineering, and user-friendly features position it as a transformative solution for companies seeking to optimize their production processes. With {Company Name} at the helm, this innovative equipment is poised to make a lasting impact on the industry and redefine the standards for quality and efficiency.

How to Use a Roll Former for R Panels: Tips and Advice

R Panel roll former, a roll forming machine designed for producing metal panels with a 1 1/4" high ribbed profile, has become the latest addition to the advanced range of machinery offered by {company name}. This new machine is set to revolutionize the metal roofing and siding industry, providing a more efficient and cost-effective solution for manufacturing high-quality metal panels.With years of experience in the design and manufacturing of roll forming machinery, {company name} has established a strong reputation for providing innovative and reliable solutions for the metal construction industry. The addition of the R Panel roll former to their product lineup is a testament to their commitment to continuously improving and diversifying their offerings.The R Panel roll former is equipped with state-of-the-art technology, allowing for precision and accuracy in the production of metal panels. Its high-speed capabilities and advanced controls make it a viable option for manufacturers looking to increase their production output without compromising on quality. The machine’s ability to produce panels with consistent ribbed profiles ensures that the end product meets the industry’s stringent standards.In addition to its high-speed capabilities, the R Panel roll former is also designed with user-friendly features that facilitate easy operation and maintenance. Its intuitive controls and ergonomic design make it accessible to operators of all levels of expertise, minimizing the need for extensive training and reducing the likelihood of errors during operation.One of the key advantages of the R Panel roll former is its versatility. It is capable of processing a wide range of metal materials, including steel, aluminum, and copper, enabling manufacturers to cater to various project requirements and customer preferences. This flexibility allows for greater customization and adaptability, further enhancing the machine’s appeal to a wide audience of manufacturers.Furthermore, the R Panel roll former is designed with efficiency in mind. Its streamlined production process and minimal material waste contribute to cost savings for manufacturers, making it a valuable investment for boosting operational efficiency and profitability. The machine’s efficient use of resources aligns with {company name}’s commitment to sustainable and eco-friendly manufacturing practices.{company name}’s dedication to delivering high-quality machinery is complemented by their comprehensive support services. In addition to providing top-of-the-line equipment, they offer technical assistance, training, and after-sales support to ensure that their customers are equipped with the knowledge and resources to maximize the potential of their investments. This holistic approach to customer service sets {company name} apart as a trusted partner in the metal construction industry.The introduction of the R Panel roll former underscores {company name}’s forward-looking approach to meeting the evolving needs of the metal construction industry. By integrating cutting-edge technology and user-centric design, they have positioned themselves as a leader in providing innovative solutions for metal panel manufacturing.With its superior capabilities, versatility, and commitment to efficiency, the R Panel roll former is poised to make a significant impact on the metal roofing and siding industry. Its integration into {company name}’s product lineup is a testament to the company’s dedication to driving progress and offering value to manufacturers seeking to elevate their production capabilities.As {company name} continues to push the boundaries of roll forming technology, the R Panel roll former stands as a powerful example of their ongoing commitment to excellence and innovation. With its potential to enhance productivity, quality, and customization in metal panel manufacturing, this new machine is set to transform the industry and empower manufacturers to achieve greater success in their operations.

Top-Quality Automatic Metal Slitting Machines for Steel Coils

In an ever-evolving metalworking industry, it is crucial to stay ahead of competition by providing high-quality and efficient solutions. That's where our company comes in! As a leading manufacturer and exporter of metalworking machinery in China, we specialize in Automatic Slitting Machines, Steel Coil Slitting Machines, and Metal Steel Slitting Machines.Our Automatic Slitting Machines are designed to operate at high speeds and precision. They are equipped with advanced cutting tools and computer-controlled systems that ensure consistent and accurate cuts on every sheet. With automatic feeding and stacking, the machine eliminates the need for manual labor and increases production efficiency.The Steel Coil Slitting Machine is perfect for large-scale metalworking operations. Designed to handle the heaviest coils, our steel coil slitting machine boasts advanced design features that guarantee high output and low maintenance. With an accurate digital control system, the machine can make precise and clean slits with minimal waste.Moreover, our Metal Steel Slitting Machine is the go-to solution for any sheet metal cutting needs. With a sturdy structure and reliable components, our metal steel slitting machine provides the perfect balance of accuracy, speed, and durability. It is capable of handling the most challenging materials and producing clean cuts consistently.Our commitment to delivering high-quality and reliable solutions has earned us a solid reputation in the industry. With over a decade of experience, we have become the trusted partner for many businesses in the metalworking industry. Our machines are designed to meet international quality standards to ensure they meet the unique needs of global customers.We pride ourselves on providing excellent customer service to ensure we cater to our clients' needs. We work closely with our customers to ensure they receive the right machine for their business and provide them with timely support and maintenance. We have a team of experienced technicians who can install, troubleshoot, and repair our machines.In summary, our company is dedicated to providing high-quality Automatic Slitting Machines, Steel Coil Slitting Machines, and Metal Steel Slitting Machines to the global market. We are committed to innovation and continuously improving our products to ensure they keep up with the dynamic needs of the industry. We provide excellent customer service to ensure our clients get the most out of their investment. Contact us today and let's help you take your metalworking business to the next level.

Efficient and Innovative Horizontal Barrel Vault Panel Production Equipment

Title: Revolutionary Horizontal Barrel Vault Panel Production Equipment Revolutionizes Construction IndustryIntroduction:In an effort to boost efficiency and revolutionize the construction industry, a leading manufacturer has introduced a groundbreaking Horizontal Barrel Vault Panel Production Equipment. This cutting-edge technology, developed in partnership with a renowned construction firm, promises to streamline the production process, reduce costs, and improve the quality of building materials. With its innovative design and advanced features, this equipment is set to transform construction practices globally.Paragaph 1:The Horizontal Barrel Vault Panel Production Equipment, developed by [Company Name], is poised to tackle key challenges faced by the construction industry. Traditional methods of panel production involve extensive labor, increased costs, and time-consuming processes. However, this revolutionary equipment aims to revolutionize the sector by automating the production of barrel vault panels, offering standardized dimensions, and enhancing material quality.Paragraph 2:By integrating state-of-the-art technology, the equipment simplifies the complex process of barrel vault panel production. It boasts a user-friendly interface that allows operators to effortlessly control the entire production line, ensuring consistent quality throughout the manufacturing process. The advanced automation features significantly reduce the need for human intervention, minimizing errors, and enhancing overall productivity. Furthermore, the equipment's modular design enables easy customization and expansion, accommodating the diverse requirements of construction projects.Paragraph 3:Manufactured using high-grade materials, the Horizontal Barrel Vault Panel Production Equipment guarantees long-lasting durability and robustness, ensuring uninterrupted production cycles. Its cutting-edge technology enables the precise molding of barrel vault panels, resulting in exceptional dimensional accuracy and structural integrity. These panels, once produced, can be effortlessly integrated into various construction projects, such as residential, commercial, and industrial buildings.Paragraph 4:The implementation of this equipment on construction sites will have a significant positive impact on the industry. Firstly, it reduces production costs by eliminating excessive labor and waste. With its efficient operations, the equipment ensures savings on both time and material resources, enabling construction firms to complete projects within budget and on schedule. Moreover, the standardized dimensions of the barrel vault panels contribute to faster construction processes and simplified logistics, further reducing project timelines.Paragraph 5:Environmental sustainability is a key concern in the construction industry, and the Horizontal Barrel Vault Panel Production Equipment aligns with global sustainability goals. Through its use of advanced technology, the equipment significantly reduces waste generation and increases energy efficiency. The production process also incorporates eco-friendly materials, minimizing the environmental impact of construction projects. These factors make the equipment an attractive choice for companies aiming to adopt green practices and contribute to a more sustainable future.Paragraph 6:In conclusion, the Horizontal Barrel Vault Panel Production Equipment, manufactured by [Company Name], represents a groundbreaking advancement in the construction industry. It combines cutting-edge technology, quality materials, and an intuitive design to streamline panel production, reduce costs, and enhance the overall efficiency of construction projects. As the industry embraces this revolutionary equipment, it is poised to redefine construction practices and contribute to a sustainable and prosperous future.Word Count: 493 words

Manual Stacker For The Shape C Purline Machine Purline Machine: A Handy Tool for Easy Stacking

Manual Stacker for the Shape C Purline Machine Improves Efficiency and Accuracy in Material HandlingIn the ever-evolving manufacturing industry, companies are constantly looking for innovative solutions to improve efficiency and accuracy in their production processes. One such solution that has caught the attention of industry professionals is the Manual Stacker for the Shape C Purline Machine. This advanced equipment is designed to streamline material handling and enhance overall productivity in manufacturing facilities.The Manual Stacker for the Shape C Purline Machine is a game-changer for companies involved in the production of C-shaped purlins. These purlins are essential structural elements used in the construction of buildings and other structures. The machine's ability to handle these materials with precision and speed makes it an invaluable asset to manufacturing operations.The Manual Stacker is seamlessly integrated with the Shape C Purline Machine, creating a powerful tandem that enhances the overall production process. With its user-friendly interface and advanced technology, the Manual Stacker offers unmatched efficiency and accuracy in material handling. This results in significant time and cost savings for companies using this equipment.One of the primary advantages of the Manual Stacker is its ability to handle heavy loads with ease. This impressive lifting capacity allows for the transportation of large quantities of materials, reducing the need for manual labor and minimizing the risk of workplace injuries. Additionally, the Stacker's ergonomic design ensures operator comfort and safety, further contributing to a positive work environment.Moreover, the Manual Stacker is equipped with advanced features that facilitate seamless integration with the Shape C Purline Machine. This includes precise positioning and alignment capabilities, ensuring that materials are handled with the utmost accuracy. As a result, manufacturers can expect consistently high-quality output, minimizing material wastage and rework.The Manual Stacker also boasts a user-friendly interface that allows for easy operation and control. This intuitive system enables operators to efficiently maneuver the equipment, leading to improved productivity and reduced downtime. Additionally, the Stacker's advanced automation capabilities further optimize the material handling process, allowing for uninterrupted production cycles.In a competitive industry where time is of the essence, the Manual Stacker for the Shape C Purline Machine offers a significant time advantage. Its efficient material handling capabilities enable manufacturers to meet demanding production schedules and fulfill customer orders in a timely manner. This ultimately contributes to enhanced customer satisfaction and loyalty.As a leading manufacturer of industrial equipment, our company is proud to introduce the Manual Stacker for the Shape C Purline Machine. With our commitment to technological innovation and continuous improvement, we strive to provide our customers with cutting-edge solutions that empower their manufacturing operations. The Manual Stacker is a testament to our dedication to delivering reliable, high-performance equipment that meets the evolving needs of the industry.In conclusion, the Manual Stacker for the Shape C Purline Machine is a revolutionary tool that has the potential to transform the material handling process in the manufacturing industry. Its unparalleled efficiency and accuracy set a new standard for productivity, providing companies with a competitive edge in their respective markets. As manufacturing operations continue to evolve, the Manual Stacker stands out as a must-have solution for companies looking to optimize their production processes. With its advanced technology and ergonomic design, this equipment has undoubtedly earned its place as a game-changer in the industry.

Top Quality Machinery for Forming Processes

Forming Machinery Celebrates Milestone AchievementForming Machinery, a global leader in the manufacturing of forming equipment, has recently achieved a significant milestone in its journey of providing top-quality machinery solutions to its customers. With an unwavering commitment to innovation, precision engineering, and customer satisfaction, the company has established itself as a trusted partner for businesses across various industries.With over [X] years of experience in the industry, Forming Machinery has continually pushed the boundaries of technology to deliver cutting-edge solutions that meet the evolving needs of its clientele. The company's dedication to research and development has enabled it to stay ahead of the curve and anticipate market trends, resulting in the creation of advanced, efficient, and reliable forming equipment.One of Forming Machinery's key strengths lies in its comprehensive product range, which includes [list of products]. From standard machines to custom-built solutions, the company has the capabilities to cater to a wide array of requirements, ensuring that its customers have access to the best machinery for their specific applications.The company's commitment to quality is evident in its state-of-the-art manufacturing facilities and stringent quality control measures. Every machine that bears the Forming Machinery name is a testament to the company's dedication to excellence, durability, and performance. Furthermore, the company also offers comprehensive after-sales support, spare parts availability, and technical assistance, ensuring that customers can maximize the value of their investments.In addition to its impressive product lineup, Forming Machinery takes pride in its team of highly skilled and experienced professionals. The company's engineers, technicians, and support staff are deeply passionate about their work and are driven by a shared vision of delivering unparalleled service to customers around the world. This team's expertise and dedication have been instrumental in establishing Forming Machinery as a benchmark for quality and reliability in the industry.As part of its ongoing commitment to innovation, Forming Machinery has consistently invested in research and development to drive the creation of next-generation forming equipment. The company's focus on technological advancement and continuous improvement has resulted in cutting-edge solutions that offer higher productivity, energy efficiency, and cost savings for its customers.Furthermore, Forming Machinery's dedication to sustainability is reflected in its efforts to develop eco-friendly manufacturing processes and energy-efficient machinery. By prioritizing environmental responsibility, the company aims to minimize its carbon footprint and promote sustainable practices within the industry.Looking to the future, Forming Machinery remains dedicated to upholding its reputation as a leader in the forming equipment sector. The company is steadfast in its commitment to delivering innovative solutions that exceed customer expectations, while also fostering long-term partnerships based on trust, reliability, and mutual success.As Forming Machinery celebrates this milestone achievement, it reaffirms its mission to continue setting new standards for excellence and serving as a driving force for positive change within the industry. With its unwavering dedication to quality, innovation, and customer satisfaction, the company is well-positioned to shape the future of forming machinery and make a lasting impact on businesses worldwide.

Efficient and Innovative Roll Forming Machines for Panel Manufacturing

In today’s market, the need for quality and efficient panel roll forming machines has never been more apparent. As the construction industry continues to grow and evolve, manufacturers are looking to create products that can meet the needs of their clients while also maximizing productivity and profitability. One company that has successfully taken on this challenge is {company name}, a leading provider of roll forming technology.With over 20 years of experience in the industry, {company name} has established itself as a trusted name in roll forming machinery. They specialize in developing innovative solutions that can create a variety of profiles, including panel roll forming machines that are designed to handle a wide range of materials, such as steel, aluminum, and copper.One of their most popular machines is the panel roll forming machine. This machine is designed to produce panels that are used in a variety of applications, from roofing and siding to vehicle bodies and shipping containers. It allows manufacturers to create panels in a range of sizes, thicknesses, and shapes, making it an incredibly versatile machine.The panel roll forming machine offered by {company name} is known for its efficiency and ease of use. It is capable of producing panels at high speed, allowing manufacturers to achieve high levels of productivity. In addition, the machine is equipped with user-friendly controls, making it easy for operators to set up and run the machine.One of the key advantages of {company name}’s panel roll forming machine is its quality. Each machine is built to the highest standards, ensuring that it is durable and reliable. This not only reduces the risk of downtime and costly repairs but also ensures that the finished panels meet the required specifications.Another benefit of the panel roll forming machine from {company name} is its flexibility. The machine can be customized to meet the specific needs of each manufacturer, allowing for the creation of panels that are tailored to their unique requirements. This can help manufacturers to differentiate themselves in the market and provide their clients with a product that stands out from the competition.{Company name} also provides comprehensive support to their clients. This includes installation, training, and ongoing maintenance and support. Their team of experts can help manufacturers get the most out of their new machines, ensuring that they are able to achieve maximum productivity and profitability.In addition to their high-quality panel roll forming machine, {company name} also offers a range of other roll forming machines, including those for producing roofing and siding profiles, metal framing, and more. With their innovative solutions, dedication to quality, and commitment to customer support, {company name} is a company that is poised to continue to grow and thrive in the years ahead.As the construction industry continues to expand, the demand for high-quality roll forming machinery is only going to increase. Manufacturers will need to find innovative solutions that can help them keep up with demand while ensuring that they are able to achieve maximum efficiency and profitability. With {company name}’s panel roll forming machine, they have found a solution that meets all of these requirements and more.

Advanced Roll Forming Machine for Colored Metal Steel Sheets

Title: Innovative Colored Metal Steel Sheet Roll Forming Machine Poised to Revolutionize the Construction IndustryIntroduction:In a significant technological breakthrough, a leading manufacturing company has unveiled a cutting-edge Colored Metal Steel Sheet Roll Forming Machine. The state-of-the-art machinery is set to revolutionize the construction industry by streamlining the process of producing colored metal steel sheets. With unrivaled efficiency and precision, this innovative machine promises to transform the way steel sheets are manufactured and used in various construction applications.I. Background:The manufacturing industry has always been at the forefront of innovation, continuously striving to enhance productivity while maintaining the highest quality standards. The introduction of the Colored Metal Steel Sheet Roll Forming Machine showcases the company's commitment to revolutionize the construction sector by providing advanced solutions to meet market demands.II. Features and Functionality:The Colored Metal Steel Sheet Roll Forming Machine incorporates state-of-the-art technology, boasting a wide range of features that set it apart from conventional machinery. It has been meticulously designed and engineered to offer maximum efficiency, ease of use, and versatility to meet the changing needs of the construction industry.1. Advanced Roll Forming System:The machine employs an advanced roll forming system capable of producing a vast range of colored metal steel sheets. The system ensures high precision and accuracy during the roll forming process, resulting in sheets with consistent shape, dimensions, and surface finish.2. Customizable Profiles:By leveraging the machine's flexible capabilities, users can effortlessly customize various steel sheet profiles to cater to diverse construction requirements. These profiles can be easily adjusted, allowing for quick adaptation to different project specifications.3. Integrated Color Coating System:The Colored Metal Steel Sheet Roll Forming Machine is equipped with a sophisticated color coating system that ensures seamless application of vibrant colors onto the steel sheets. This feature enables the creation of visually appealing and long-lasting colored metal sheets, adding aesthetic value to any construction project.4. Energy-Efficient Operation:The machine incorporates an energy-efficient system that minimizes power consumption while maximizing productivity. This eco-friendly feature not only reduces operating costs but also contributes to a sustainable manufacturing process.III. Benefits and Market Impact:The introduction of the Colored Metal Steel Sheet Roll Forming Machine significantly enhances the overall efficiency and quality of steel sheet production, offering a wide array of benefits to construction professionals and manufacturers alike.1. Improved Productivity:With its advanced technology and streamlined functions, the machine enables faster production cycles, ensuring higher output and reduced lead times. This allows manufacturers to meet escalating market demands while maintaining stringent quality control.2. Cost Savings:The machine's energy-efficient operation and reduced material waste result in significant cost savings for manufacturers. Moreover, the customizable profiles cater to specific project requirements, minimizing material wastage and further optimizing resource utilization.3. Enhanced Durability:The use of high-quality colored metal steel sheets produced by this machine ensures enhanced durability and longevity of constructed structures. These steel sheets are resistant to corrosion, UV radiation, and extreme weather conditions, ensuring long-lasting performance and minimal maintenance costs.4. Aesthetically Pleasing:The availability of vibrant and customizable colors through the color coating system allows architects and designers to unleash their creativity. This feature paves the way for the development of visually appealing buildings and structures, adding value through aesthetic appeal.IV. Conclusion:The introduction of the Colored Metal Steel Sheet Roll Forming Machine signifies a groundbreaking leap forward in the construction industry. With its advanced technology and unmatched efficiency, this innovative machine promises to revolutionize the manufacturing of colored metal steel sheets, providing construction professionals with high-quality, customizable, and visually appealing solutions. As this technology gains traction, it is expected to reshape the construction landscape by empowering architects, engineers, and contractors to construct remarkable buildings that stand the test of time.

The Basics of Slitting Process in Sheet Metal: Everything You Need to Know

The slitting process in sheet metal is a crucial step in the manufacturing of various products and components. This process involves taking a large roll of sheet metal and cutting it into smaller, more manageable strips. These strips are then further processed to create a wide range of finished products, from automotive parts to household appliances to construction materials.One company at the forefront of the sheet metal slitting process is {}. With their state-of-the-art facilities and cutting-edge technology, they are able to offer precision slitting services that meet the diverse needs of their clients. Their emphasis on quality, efficiency, and innovation has made them a leader in the industry.The slitting process begins with the uncoiling of the metal roll, which is then fed through a set of rollers that straighten the material and ensure a consistent thickness. The metal is then fed through a set of circular blades that cut it into narrower strips. These strips are then recoiled for further processing or shipped out as-is, depending on the specific requirements of the customer.One of the key advantages of the slitting process is its ability to produce consistent, high-quality strips of metal with tight tolerances. This is essential for many applications where precision is paramount. Additionally, the ability to quickly and efficiently process large rolls of metal into smaller strips allows for greater flexibility and cost savings in the manufacturing process.In addition to their cutting-edge technology, {} is known for their exceptional customer service and quick turnaround times. They work closely with their clients to understand their unique needs and specifications, and are able to tailor their slitting services to meet these requirements. This level of personalized attention has helped them forge long-lasting relationships with their customers and establish a reputation for reliability and excellence.Furthermore, {} is committed to sustainability and environmental responsibility in their operations. They have implemented various measures to minimize waste and reduce the environmental impact of their manufacturing processes. This includes the responsible disposal of scrap metal and the use of energy-efficient machinery, as well as a focus on recycling and reusing materials whenever possible.As a result of their dedication to quality, innovation, and sustainability, {} has become a trusted partner for companies across a wide range of industries. Their precision slitting services have been crucial in the production of components for automobiles, appliances, HVAC systems, and more. Their ability to deliver high-quality products in a timely manner has made them an invaluable resource for their clients, helping them stay competitive in today's ever-evolving marketplace.Looking ahead, {} is poised to continue leading the way in the sheet metal slitting industry. With ongoing investments in technology and a steadfast commitment to meeting the needs of their customers, they are well-positioned for continued growth and success. As industries continue to demand high-quality, precision-cut sheet metal, {} will be there to deliver the solutions they need.

Manual Stacker For The Shape C Purline Machine - Efficient and Reliable Solution

The demand for efficient and reliable machinery in the construction industry has been on the rise, and {} has been at the forefront of meeting this demand. With a focus on innovation and quality, the company has been a trusted provider of a wide range of construction machinery and equipment. In line with their commitment to meeting the evolving needs of their customers, {} is proud to announce the launch of their new Manual Stacker for the shape C purline machine.The Manual Stacker is designed to work seamlessly with the shape C purline machine, offering a complete solution for handling and stacking purline products in a safe and efficient manner. The addition of this new equipment to {}'s product line is a testament to their dedication to providing comprehensive solutions for their customers' needs.One of the key features of the Manual Stacker is its user-friendly design, which makes it easy to operate and maintain. This allows for greater efficiency in the stacking process, saving time and labor costs for construction companies. Additionally, the Manual Stacker is built with the highest quality materials and components, ensuring its durability and long-term performance.In addition to its practical design, the Manual Stacker is also equipped with advanced safety features to protect workers and prevent accidents. With built-in safety mechanisms and ergonomic controls, operators can confidently and securely handle purline products without compromising their well-being.Furthermore, {}'s commitment to sustainability is reflected in the energy-efficient operation of the Manual Stacker. By minimizing energy consumption, the equipment helps reduce the overall environmental impact of construction projects, aligning with the industry's growing emphasis on eco-friendly practices.The launch of the Manual Stacker for the shape C purline machine further solidifies {}'s position as a leading provider of construction machinery and equipment. With a track record of delivering high-quality products and exceptional customer service, the company continues to be a trusted partner for construction companies looking to enhance their operational efficiency and productivity.In addition to their cutting-edge products, {} also offers comprehensive support services to assist customers in maximizing the value of their investments. Their team of highly trained professionals is available to provide technical guidance, maintenance, and troubleshooting to ensure that customers can operate their equipment with confidence.As the construction industry continues to evolve, {} remains at the forefront, continuously innovating to meet the changing needs of their customers. The launch of the Manual Stacker for the shape C purline machine is a testament to their unwavering commitment to providing reliable, efficient, and safe solutions for the construction industry.With a strong focus on quality, innovation, and customer satisfaction, {} is poised to continue making a significant impact in the construction machinery and equipment market. Their dedication to excellence and continuous improvement sets them apart as a formidable force in the industry, and the launch of the Manual Stacker is another testament to their ongoing success.