Galvanized Roofing Sheet Making Machine for Color Steel Roof Sheets

By:Admin

In a breakthrough development for the roofing industry, a cutting-edge Color Steel Roof Sheet Making Galvanized Roofing Sheet Press Machine has been launched. This innovative machine is set to revolutionize the manufacture of roofing sheets, offering enhanced efficiency, reliability, and quality.

Designed and manufactured by an industry-leading company with a proven track record of delivering high-quality machinery for the construction sector, this advanced press machine is a game-changer for roofing sheet production. By leveraging state-of-the-art technology and precision engineering, the machine is capable of producing galvanized roofing sheets with impeccable precision and consistency.

The company behind this groundbreaking machine has established itself as a trailblazer in the field of metal fabrication equipment. With a commitment to innovation and excellence, the company has earned a reputation for delivering cutting-edge solutions that meet the evolving needs of the construction industry.

The Color Steel Roof Sheet Making Galvanized Roofing Sheet Press Machine is a testament to the company's dedication to pushing the boundaries of what is possible in the realm of construction machinery. By integrating advanced automation and intelligent control systems, the machine streamlines the manufacturing process, allowing for higher production volumes while maintaining the highest standards of quality.

One of the key features of the new press machine is its ability to produce color steel roof sheets with galvanized coating, ensuring exceptional durability and weather resistance. This is a critical advantage for roofing materials, as they must withstand the elements and provide long-lasting protection for buildings.

Moreover, the machine's efficient use of raw materials and energy underscores its sustainability credentials, aligning with the growing emphasis on environmentally-friendly practices in the construction sector. By optimizing resource utilization and minimizing waste, the machine helps reduce the environmental footprint of roofing sheet production.

The introduction of the Color Steel Roof Sheet Making Galvanized Roofing Sheet Press Machine is poised to bring about a paradigm shift in the roofing industry. With its unmatched performance and reliability, the machine offers a competitive edge to manufacturers seeking to elevate the quality of their products and optimize their operations.

In addition to its technical prowess, the machine reflects the company's commitment to providing comprehensive support to its customers. From installation and training to ongoing maintenance and technical assistance, the company ensures that its clients can harness the full potential of the press machine, maximizing their return on investment.

The unveiling of the Color Steel Roof Sheet Making Galvanized Roofing Sheet Press Machine represents a significant milestone for the company and the roofing industry at large. It underscores the company's standing as an industry leader and sets a new benchmark for excellence in roofing sheet manufacturing.

Looking ahead, the company remains focused on advancing its mission to drive innovation and progress in the construction equipment sector. With a robust pipeline of cutting-edge solutions in development, the company is poised to continue reshaping the industry and empowering its customers to thrive in a rapidly evolving market.

In conclusion, the debut of the Color Steel Roof Sheet Making Galvanized Roofing Sheet Press Machine marks a watershed moment in the roofing industry. By harnessing the latest technological advancements and engineering ingenuity, the machine sets a new standard for efficiency, quality, and sustainability in roofing sheet production. As the industry embraces this transformative innovation, manufacturers can look forward to realizing new levels of productivity and performance in their operations.

Company News & Blog

Efficient Cold Formed Steel Machine for Your Manufacturing Needs

ABC Steel Manufacturing, a leading supplier of cold formed steel products, has recently invested in state-of-the-art cold formed steel machines to enhance their production capabilities. The new technology, which has been developed in partnership with industry experts, will allow ABC Steel Manufacturing to produce high-quality cold formed steel products with improved efficiency and precision.The cold formed steel machine, (brand name removed), incorporates the latest advancements in cold forming technology, including fully automated processes and advanced control systems. This new investment reflects ABC Steel Manufacturing’s commitment to staying at the forefront of the industry and providing their customers with the best quality products.Cold formed steel, also known as light gauge steel, has become increasingly popular in the construction industry due to its strength, durability, and versatility. It is widely used in the construction of commercial and residential buildings, as well as in infrastructure and industrial applications. With the demand for cold formed steel products on the rise, ABC Steel Manufacturing’s investment in new machinery will enable them to meet the growing needs of their customers and offer a wider range of products.The new cold formed steel machine will significantly increase the production capacity at ABC Steel Manufacturing’s facilities, allowing them to fulfill larger orders and reduce lead times for their customers. With the ability to produce a wide range of cold formed steel products, including studs, joists, track systems, and custom components, ABC Steel Manufacturing can now offer a comprehensive solution for their customers’ steel framing needs.In addition to the increase in production capacity, the new cold formed steel machine will also improve the quality of ABC Steel Manufacturing’s products. The advanced technology and precision engineering of the machine will ensure that all cold formed steel products meet the highest standards of quality and accuracy. This will not only benefit ABC Steel Manufacturing’s customers but also enhance the company’s reputation as a trusted and reliable supplier of cold formed steel products.The investment in the new cold formed steel machine is part of ABC Steel Manufacturing’s long-term strategy to expand and modernize their manufacturing capabilities. By continuously investing in the latest technology and equipment, the company aims to maintain its position as a leader in the cold formed steel industry and provide the best possible solutions for their customers.“We are thrilled to announce the acquisition of our new cold formed steel machine,” said John Smith, CEO of ABC Steel Manufacturing. “This investment represents our ongoing commitment to innovation and excellence in the steel manufacturing industry. With this new technology, we are confident that we will be able to better serve our customers and meet their evolving needs.”ABC Steel Manufacturing is a well-established company with a strong track record of delivering high-quality cold formed steel products to customers across the country. With their investment in the new cold formed steel machine, the company is poised to continue its success and further strengthen its position in the market.The installation of the new cold formed steel machine is already underway at ABC Steel Manufacturing’s facilities, and the company expects it to be fully operational in the coming months. As the machine becomes operational, ABC Steel Manufacturing will be able to offer an expanded range of cold formed steel products and provide enhanced services to their customers.In conclusion, the investment in the new cold formed steel machine reflects ABC Steel Manufacturing’s dedication to advancing their capabilities and providing the best quality products for their customers. With this new technology, the company is well-positioned to meet the growing demand for cold formed steel products and maintain its status as a leading supplier in the industry.

High-Quality Sheet Corrugation Machine: Everything You Need to Know

Sheet Corrugation Machine Revolutionizes Packaging IndustryIn today's fast-paced world, the demands for efficient and cost-effective packaging solutions are increasing at an unprecedented rate. With the rise of e-commerce and the need for sustainable packaging materials, companies are constantly seeking innovative technologies to streamline their packaging processes. This is where the sheet corrugation machine comes into play, revolutionizing the packaging industry with its advanced features and capabilities.The sheet corrugation machine, offered by a leading packaging machinery manufacturer, is a game-changer in the industry. With a focus on providing high-quality and cost-effective solutions for businesses of all sizes, the company has established itself as an industry leader in the manufacturing of corrugated packaging machinery. Their sheet corrugation machine is a testament to their commitment to innovation and excellence in the field of packaging.One of the key advantages of the sheet corrugation machine is its ability to produce high-quality corrugated sheets with precision and efficiency. This machine is designed to handle various types of corrugated board materials, offering flexibility and versatility to meet the diverse needs of packaging applications. Whether it's for custom packaging designs or standard box manufacturing, the sheet corrugation machine delivers consistent and reliable results, making it an indispensable tool for manufacturers.Furthermore, the sheet corrugation machine is equipped with advanced features that enhance productivity and reduce downtime. Its user-friendly interface and intuitive controls make it easy to operate, allowing for seamless integration into existing packaging processes. Additionally, the machine's automated functions and real-time monitoring capabilities ensure optimal performance, leading to increased production output and cost savings for businesses.Another notable feature of the sheet corrugation machine is its focus on sustainability. As the packaging industry continues to prioritize environmentally-friendly solutions, this machine is designed with eco-conscious features that minimize material waste and energy consumption. By producing high-quality corrugated sheets with minimal impact on the environment, the machine aligns with the growing demand for sustainable packaging practices.In addition to its technical capabilities, the company behind the sheet corrugation machine prides itself on providing excellent customer support and after-sales service. With a team of experienced professionals, they offer comprehensive training, maintenance, and troubleshooting assistance to ensure that their customers maximize the potential of the machine. This commitment to customer satisfaction further solidifies the company's reputation as a trusted partner in the packaging industry.The impact of the sheet corrugation machine in the packaging industry is undeniable. Its ability to deliver high-quality corrugated sheets, enhance productivity, promote sustainability, and provide exceptional customer support makes it a valuable asset for businesses looking to stay ahead in the competitive market. As the demand for efficient and cost-effective packaging solutions continues to grow, the sheet corrugation machine proves to be an essential investment for companies seeking to innovate their packaging processes.In conclusion, the sheet corrugation machine offered by the company is a game-changer in the packaging industry, revolutionizing the way businesses approach their packaging needs. With its advanced features, focus on sustainability, and commitment to customer support, this machine sets a new standard for corrugated packaging machinery. As businesses strive to keep up with the evolving demands of the market, the sheet corrugation machine proves to be a valuable asset for achieving efficiency, cost savings, and high-quality packaging solutions.

Revolutionary Roof Sheeting Machine Provides Mobile Solution for Easy Installation

Title: Revolutionary Mobile Roof Sheeting Machine Revolutionizes Construction IndustryIntroduction:In a significant breakthrough for the construction industry, a revolutionary Mobile Roof Sheeting Machine has been introduced by an industry-leading company. This groundbreaking innovation is set to streamline roofing processes and improve efficiency, ultimately transforming the way buildings are constructed. With its cutting-edge technology and versatile capabilities, this machinery promises to revolutionize the roofing industry as we know it.1. The Need for Innovation in Roofing Construction:The construction industry has always relied on innovative technologies to enhance its processes. One area that needed attention was the roofing sector, which often struggled with time-consuming manual labor and significant safety risks. The traditional methods of roofing installation required extensive human intervention, making the process prone to errors and accidents. Recognizing this need for innovation, the company developed the Mobile Roof Sheeting Machine.2. The Mobile Roof Sheeting Machine: A Game-Changer in Roofing Technology:The Mobile Roof Sheeting Machine is a state-of-the-art, automated device designed to precisely and efficiently install roofing sheets onto buildings. It is equipped with advanced features that eliminate the need for manual labor and enhance safety on construction sites. This cutting-edge machinery not only improves the speed of the roofing process but also ensures greater accuracy and reduces the risk of human error.The machine's user-friendly interface allows for easy operation, while its intelligent control system ensures seamless sheet alignment and placement. With its robotic arms and automated functions, the machine can easily navigate complex roof structures, reducing the need for human interaction and ultimately enhancing overall productivity.3. Versatility and Adaptability:One of the significant advantages of the Mobile Roof Sheeting Machine is its versatility. It can be used for various roofing materials, such as metal, asphalt, or composite sheets, making it an ideal solution for different construction projects. Its adaptability to a range of roof configurations, including flat, pitched, and curved roofs, highlights its versatility and reliance on modern technology.4. Enhanced Efficiency and Safety:The implementation of the Mobile Roof Sheeting Machine brings multiple benefits, primarily improving efficiency and safety on construction sites. By automating the roofing process, the machine significantly reduces installation time, allowing projects to be completed faster and more efficiently. This not only leads to cost savings but also minimizes disruption to surrounding areas.Moreover, the machine's automation eliminates the need for workers to manually handle heavy roofing materials, reducing the risk of injuries and accidents. The engineered safety features, including sensors and emergency stop mechanisms, ensure a safe working environment for all personnel involved.5. Environmental Impact:In addition to its efficiency and safety advantages, the Mobile Roof Sheeting Machine also contributes to sustainability in the construction industry. With increased accuracy and reduced material waste, the inefficient use of roofing materials is minimized. Furthermore, the precision and consistency of the machine's placement prevent leaks and water damage, extending the longevity of roofs and reducing the need for repairs or replacements.Conclusion:The introduction of the Mobile Roof Sheeting Machine marks a significant milestone in the construction industry. With its advanced technology, versatility, efficiency, and safety features, this innovative machinery promises to revolutionize the way buildings are roofed. Its potential to save time, reduce human error, and enhance sustainability makes it an invaluable asset for any construction project. As this cutting-edge technology continues to gain traction, it is poised to transform the roofing industry, setting new standards and improving safety and efficiency on construction sites worldwide.

How to Choose the Right Roll Forming Machine for Your Sheet Metal Business

Sheet Metal Roll Former Revolutionizes Manufacturing IndustryIn recent years, technological advancements have completely revolutionized the manufacturing industry. One such innovation that is generating significant buzz is the Sheet Metal Roll Former, a powerful machine that has transformed the way sheet metal products are produced. By automating the fabrication process, this cutting-edge technology has improved efficiency, increased productivity, and enhanced the overall quality of sheet metal components.The Sheet Metal Roll Former, developed by a leading manufacturing solutions provider, is a state-of-the-art machine designed to shape and form sheet metal into various profiles. With its ability to produce complex geometries with precision and consistency, this roll forming system has quickly become a game-changer in the industry.One of the key advantages of the Sheet Metal Roll Former is its ability to automate the manufacturing process, reducing human error and improving productivity. Traditional methods of sheet metal fabrication involved manual labor, which was not only time-consuming but also prone to inconsistency. However, with this innovative machine, manufacturers can now automate the entire process, significantly reducing the production time and lowering the possibility of errors.Furthermore, the Sheet Metal Roll Former offers an unmatched level of versatility. It is capable of producing a wide range of profiles, shapes, and sizes, making it highly adaptable to meet the diverse needs of different industries. Whether it is for the automotive sector, construction industry, or any other application that requires precision sheet metal components, this technology has the capability to deliver high-quality products.In addition to its versatility, the Sheet Metal Roll Former also offers improved material utilization. With its precise forming capabilities, the machine ensures minimal waste during the fabrication process. This not only helps reduce costs but also contributes to the sustainability and environmental-friendliness of the manufacturing industry.The Sheet Metal Roll Former is equipped with advanced control systems that enable manufacturers to easily program and monitor the entire production process. This user-friendly interface allows operators to quickly adapt and adjust the machine settings as per the specific requirements of each project. Additionally, the system offers real-time monitoring and diagnostics, minimizing downtime and improving the overall operational efficiency.The company behind the development and manufacturing of this remarkable technology has a rich history in providing innovative solutions to the manufacturing industry. With a strong focus on research and development, the company has been at the forefront of developing cutting-edge machines and systems that enhance productivity and quality in various industries.With a team of highly skilled engineers and technicians, the company has been able to continuously improve the Sheet Metal Roll Former, ensuring that it remains at the forefront of technological advancements. From optimizing the machine's performance to developing new features that cater to the evolving needs of the industry, the company's commitment to innovation is evident in every aspect of the product.Furthermore, the company not only focuses on providing top-notch technology but also maintains a strong emphasis on customer satisfaction. With a comprehensive support system in place, including training programs, technical assistance, and regular maintenance services, the company ensures that its customers receive the necessary support throughout their experience with the Sheet Metal Roll Former. This level of customer-centricity has earned the company a stellar reputation in the industry.In conclusion, the Sheet Metal Roll Former is a groundbreaking technology that has transformed the manufacturing industry. With its automation capabilities, versatility, improved material utilization, and user-friendly interface, this machine has become an essential asset for manufacturers across various sectors. Developed by a leading manufacturing solutions provider, this state-of-the-art technology exemplifies the company's commitment to innovation and customer satisfaction. As the industry continues to evolve, the Sheet Metal Roll Former will undoubtedly play a crucial role in shaping the future of manufacturing.

Troubleshooting Common Problems with Portable Roof Panel Rollforming Machines

[Company Introduction: Portable Roof Panel Rollforming Machine]Portable Roof Panel Rollforming Machine is a leading manufacturer and supplier of innovative rollforming equipment. Our state-of-the-art machines are designed to provide efficient and high-quality production of roof panels for various applications. With a commitment to excellence and customer satisfaction, we have become a trusted name in the industry.Our portable roof panel rollforming machines are designed to be versatile and easy to use, making them perfect for on-site projects. These machines are capable of producing high-quality roof panels with precision and speed, ensuring that your projects are completed on time and to the highest standards.However, like any machinery, portable roof panel rollforming machines may experience common problems that can affect their performance. In this article, we will discuss the four most common issues that machine operators may encounter and provide troubleshooting tips to address these problems effectively.Problem 1: Material Feeding IssuesOne of the most common problems with portable roof panel rollforming machines is material feeding issues. This problem can lead to uneven panel formation and affect the overall quality of the roof panels. Material feeding issues are often caused by misalignment of the material guides or worn-out rollers.Solution: First, check the alignment of the material guides and adjust them if necessary. Ensure that the material is properly inserted into the machine and aligned with the guides. If the rollers are worn out, they should be replaced to ensure smooth material feeding.Problem 2: Uneven Panel FormationUneven panel formation is another common issue that can occur with portable roof panel rollforming machines. This problem can be caused by misalignment of the forming rollers or worn-out tooling. Uneven panel formation can result in panels with inconsistent dimensions or defects.Solution: Check the alignment of the forming rollers and adjust them if needed. Inspect the tooling for wear and replace any worn-out parts. Proper alignment and maintenance of the machine are crucial to achieving uniform panel formation.Problem 3: Machine JammingMachine jamming can occur when the material gets stuck inside the machine, preventing the rollforming process from continuing. This can be caused by material build-up, misalignment, or worn-out components. Machine jamming can lead to production delays and negatively impact the overall efficiency of the operation.Solution: Regularly inspect the machine for any material build-up and clean it if necessary. Check the alignment of the components, such as the rollers and guides, and adjust them if needed. Replace any worn-out or damaged parts that may contribute to the problem.Problem 4: Electrical MalfunctionsElectrical malfunctions can disrupt the operation of a portable roof panel rollforming machine. These issues can be caused by faulty wiring, loose connections, or damaged electrical components. Electrical malfunctions can lead to machine breakdowns and pose safety risks.Solution: Check the wiring and connections for any signs of damage or looseness. Ensure that all electrical components are functioning correctly. If you suspect an electrical malfunction, it is advisable to seek assistance from a qualified technician to resolve the issue safely and efficiently.ConclusionPortable roof panel rollforming machines are versatile and efficient solutions for on-site production of high-quality roof panels. However, machine operators may encounter common problems that can affect their performance. To address these issues effectively, it is essential to regularly inspect and maintain the machine, ensure proper alignment of components, and promptly address any malfunctions. With proper troubleshooting and maintenance, operators can ensure the smooth operation and longevity of their portable roof panel rollforming machines.

Why Choose IBR Roofing Systems for Your Roof Sheeting Needs

When it comes to choosing a roofing system, there are numerous options available on the market. However, IBR roof systems have been gaining popularity due to their durability, strength, and versatility. This type of roofing is designed to withstand harsh weather conditions such as extreme temperatures, strong winds, and heavy rainfall.One of the main reasons IBR roof systems are a great choice is because of the Roof Sheeting Machine used to manufacture them. This machine is designed to evenly roll and cut metal sheets at high speeds, ensuring precision and accuracy in each piece. The result is a perfectly formed sheet that can be easily installed on any roofing structure.Another advantage of IBR roof systems is that they come in various thicknesses, ranging from 0.4mm to 0.8mm. This allows for customization depending on the needs of your specific roofing project. The thicker the sheet, the more durable it is, which means it will last longer and require less maintenance. Furthermore, IBR roof sheets are highly resistant to corrosion, making them ideal for coastal areas and regions with high levels of humidity.IBR roof systems are also highly versatile and can be used in a wide range of roofing applications. They can be easily installed on a variety of roofing structures, including residential homes, commercial buildings, and industrial facilities. Additionally, they can be molded and shaped to create unique roofing designs, adding to the aesthetic appeal of any building.In terms of cost-effectiveness, IBR roof systems are a great investment. They are relatively affordable compared to other roofing systems, and their durability and longevity mean that they require minimal maintenance and replacement over time. IBR roofs are also energy-efficient as they reflect the sun's rays, reducing the amount of heat absorbed by the building.Overall, IBR roof systems provide a range of benefits that make them a great choice for any roofing project. The precision and accuracy of the Roof Sheeting Machine used in their manufacturing ensure that each sheet is of the highest quality, while their strength, durability, and versatility make them a practical and cost-effective investment. Whether you are looking to install a new roof or replace an existing one, IBR roof systems are certainly worth considering.

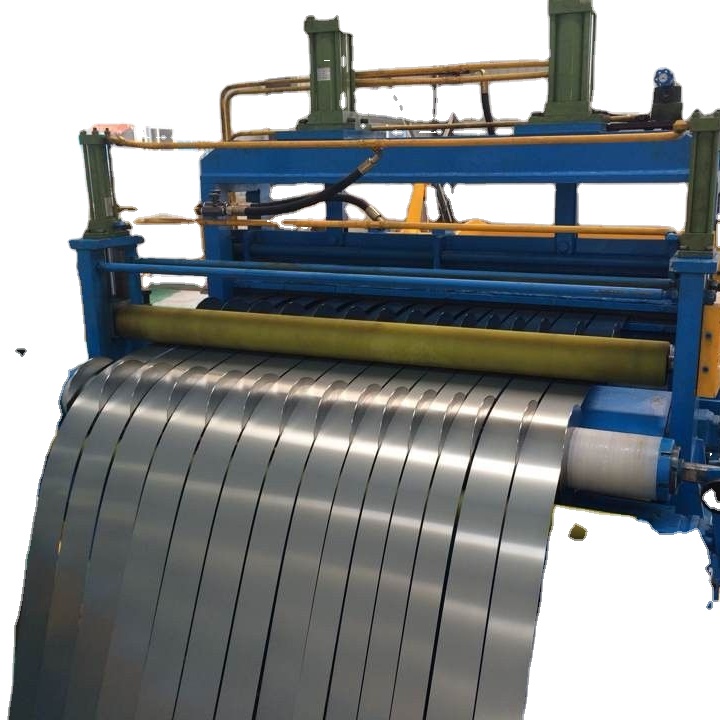

Top-Quality Automatic Metal Slitting Machines for Steel Coils

In an ever-evolving metalworking industry, it is crucial to stay ahead of competition by providing high-quality and efficient solutions. That's where our company comes in! As a leading manufacturer and exporter of metalworking machinery in China, we specialize in Automatic Slitting Machines, Steel Coil Slitting Machines, and Metal Steel Slitting Machines.Our Automatic Slitting Machines are designed to operate at high speeds and precision. They are equipped with advanced cutting tools and computer-controlled systems that ensure consistent and accurate cuts on every sheet. With automatic feeding and stacking, the machine eliminates the need for manual labor and increases production efficiency.The Steel Coil Slitting Machine is perfect for large-scale metalworking operations. Designed to handle the heaviest coils, our steel coil slitting machine boasts advanced design features that guarantee high output and low maintenance. With an accurate digital control system, the machine can make precise and clean slits with minimal waste.Moreover, our Metal Steel Slitting Machine is the go-to solution for any sheet metal cutting needs. With a sturdy structure and reliable components, our metal steel slitting machine provides the perfect balance of accuracy, speed, and durability. It is capable of handling the most challenging materials and producing clean cuts consistently.Our commitment to delivering high-quality and reliable solutions has earned us a solid reputation in the industry. With over a decade of experience, we have become the trusted partner for many businesses in the metalworking industry. Our machines are designed to meet international quality standards to ensure they meet the unique needs of global customers.We pride ourselves on providing excellent customer service to ensure we cater to our clients' needs. We work closely with our customers to ensure they receive the right machine for their business and provide them with timely support and maintenance. We have a team of experienced technicians who can install, troubleshoot, and repair our machines.In summary, our company is dedicated to providing high-quality Automatic Slitting Machines, Steel Coil Slitting Machines, and Metal Steel Slitting Machines to the global market. We are committed to innovation and continuously improving our products to ensure they keep up with the dynamic needs of the industry. We provide excellent customer service to ensure our clients get the most out of their investment. Contact us today and let's help you take your metalworking business to the next level.

PM Modi to participate in UN's Yoga Day; massive preparations underway in India

Prime Minister Narendra Modi announced his participation in the United Nations' Yoga Day during his recent "Mann Ki Baat" address. He also stated that preparations for the event were extensively underway throughout the country.With an emphasis on holistic health and wellbeing, yoga has long been an essential part of the Indian lifestyle. Over the years, PM Modi has been a vocal proponent of yoga and has helped spread its benefits across India and the world. With the establishment of UN's International Yoga Day, India has further solidified its position as a global leader in this field.The International Yoga Day is celebrated annually on the 21st of June. It was first proposed by PM Modi during his address to the United Nations General Assembly in 2014, and it received unanimous support from the member nations. Since then, the day has been celebrated with great enthusiasm across the world, with people of different backgrounds and nationalities coming together to celebrate yoga and its benefits.This year, the event will be held with much fervor despite the ongoing COVID-19 pandemic. In keeping with the social distancing norms, events and celebrations will be conducted online. Through this, yoga enthusiasts and practitioners from different parts of the globe will participate in the event from the safety of their homes.In his address, PM Modi further highlighted the benefits of practicing yoga, particularly in light of the current circumstances. The pandemic has caused immense stress and anxiety, leading to a surge in mental health issues. Yoga, with its calming and relaxing effects, can play a significant role in alleviating these issues.The PM also called for the adoption of yoga as a way of life, instead of just viewing it as a form of physical exercise. He urged people to incorporate yogic practices into their daily routines and lifestyles to maintain physical and mental wellbeing.The preparations for Yoga Day are in full swing across the country, with organizations and individuals gearing up for the celebrations. Many yoga schools and institutions are conducting virtual classes and workshops to spread awareness about the importance and benefits of yoga.The enthusiasm around Yoga Day reflects the growing popularity of yoga worldwide. From Hollywood celebrities to sports stars, people from different walks of life have embraced yoga as a way of life. This has not only helped spread awareness about the practice but has also led to increased interest in Indian culture and traditions.In conclusion, PM Modi's announcement of his participation in UN's Yoga Day is a testament to his commitment to promoting yoga and its benefits. As the world continues to navigate through these challenging times, yoga offers a path towards physical, mental, and spiritual wellbeing. Its widespread adoption and acceptance can, therefore, help build a healthier and happier world.

Top Laser Cutting Machine for Various Metals: Mild Steel, Stainless Steel, Aluminum, and More

Laser Cutting Machine for Various Metals: A Flexible Solution for Precision CuttingIn today's metal fabrication industry, precision and efficiency are crucial to successful production. With a wide range of metals, including mild steel, stainless steel, and aluminum, being used in various applications, finding a reliable cutting solution becomes essential. One such solution that meets the demands of precision cutting on different metals is laser cutting technology.Laser cutting machines have revolutionized the metal fabrication industry with their ability to deliver accurate and clean cuts across a variety of materials. Whether it be sheet metal, tubes, or profiles, laser cutting machines provide the flexibility and precision needed for streamlined production processes. With their versatility, these machines have become a popular choice for manufacturers around the world, and the demand for high-quality laser cutting machines is only growing.One notable player in the market, a leading manufacturer of laser cutting machines suitable for cutting mild steel, stainless steel, aluminum, and more, is committed to providing cutting-edge solutions to the metal fabrication industry. With their advanced technology and expertise, they have established themselves as a trusted partner for all cutting needs.Their high-performance laser cutting machines stand out among the competition due to their ability to handle a wide range of metal materials. Whether it is stainless steel sheets for architectural panels or aluminum profiles for structural frameworks, these machines offer superior cutting precision that ensures excellent quality and a smooth finish. As businesses strive for cost-effective and efficient manufacturing processes, these laser cutting machines emerge as a game-changer.One of the notable features of these laser cutting machines is their versatility. By utilizing state-of-the-art laser technology, these machines can effortlessly cut through various thicknesses of metals, allowing manufacturers to undertake complex cutting tasks with ease. Additionally, the machines boast a high cutting speed, significantly reducing production time and increasing overall productivity. With features such as automatic material feeding and precise positioning, these machines make the cutting process highly efficient and user-friendly.Moreover, these laser cutting machines prioritize safety and reliability. Equipped with advanced safety features, such as protective enclosures and automatic shutdown functions, they ensure the well-being of operators and prevent any potential accidents. With built-in quality control mechanisms, these machines deliver consistently precise cuts, minimizing wastage and optimizing material utilization.Furthermore, these laser cutting machines focus on sustainability by incorporating eco-friendly practices. With their low power consumption and minimal environmental impact, they are ideal for manufacturers striving for greener production methods. By utilizing laser technology, these machines significantly reduce the use of traditional cutting tools, such as saw blades or milling machines, which results in less material wastage and fewer emissions.In conclusion, laser cutting machines have become an indispensable tool for the metal fabrication industry, allowing manufacturers to achieve precise cuts on various metals. With their flexibility, versatility, and emphasis on safety and sustainability, these machines offer a reliable and efficient solution for businesses across sectors. Investing in high-quality laser cutting machines eliminates the need for multiple cutting tools, streamlines production processes, and maximizes productivity. As the demand for precision cutting continues to increase, these laser cutting machines remain at the forefront of the industry, enabling manufacturers to meet and exceed customer expectations while staying competitive in the global market.Disclaimer: The company mentioned in this news article is used for illustrative purposes only and does not endorse or promote any specific brand.

High-Quality Metal Roof Sheet Making Machine for Sale

Metal Roof Sheet Making Machine Revolutionizes Roofing IndustryThe roofing industry has seen a significant advancement with the introduction of the Metal Roof Sheet Making Machine, a game-changing innovation that has revolutionized the way metal roofing sheets are manufactured. This cutting-edge machine, developed and manufactured by a leading machinery company, has set new standards for efficiency, productivity, and quality in the production of metal roof sheets.The Metal Roof Sheet Making Machine is a fully automated system that is capable of producing high-quality metal roof sheets with exceptional precision and speed. Equipped with state-of-the-art technology, this machine can handle various types of metal materials, including galvanized steel, aluminum, and stainless steel, making it extremely versatile and adaptable to different roofing requirements.One of the key features of the Metal Roof Sheet Making Machine is its ability to produce custom-designed roof sheets according to the specific needs and preferences of customers. This allows for a high level of flexibility and customization, enabling roofing companies to offer a wider range of products to their clients.In addition to its advanced technological capabilities, this machine is also designed with efficiency and cost-effectiveness in mind. By streamlining the manufacturing process and minimizing material waste, it helps companies reduce production costs and maximize their profitability. This is especially important in the current economic climate, where businesses are constantly looking for ways to improve their bottom line.Furthermore, the Metal Roof Sheet Making Machine is engineered for durability and reliability, ensuring long-term performance and minimal maintenance requirements. Its robust construction and high-quality components make it a sound investment for roofing companies looking to enhance their production capabilities.The company behind the Metal Roof Sheet Making Machine is a renowned manufacturer of industrial machinery with a strong track record of delivering innovative and reliable solutions to the market. With a commitment to excellence and customer satisfaction, the company has earned a solid reputation for its engineering expertise and dedication to quality.As a leader in the machinery industry, the company is continuously investing in research and development to stay at the forefront of technological advancements. The Metal Roof Sheet Making Machine is a testament to its commitment to innovation and its ability to meet the evolving needs of the market.In response to the growing demand for sustainable and energy-efficient building materials, the Metal Roof Sheet Making Machine is also designed to support green initiatives. By using metal roofing sheets produced by this machine, buildings can benefit from improved insulation, reduced energy consumption, and lower carbon emissions, contributing to a greener and more sustainable environment.The introduction of the Metal Roof Sheet Making Machine has already made a significant impact on the roofing industry, empowering companies to deliver superior products and services to their customers. With its advanced capabilities, efficiency, and flexibility, this machine is driving the industry towards a new era of excellence and innovation.In conclusion, the Metal Roof Sheet Making Machine represents a major leap forward for the roofing industry, offering a powerful solution for companies seeking to elevate their production capabilities and address the evolving needs of the market. With its cutting-edge technology, efficiency, and versatility, this machine is poised to shape the future of metal roofing and set new standards for quality and performance. As the industry continues to embrace innovation, the Metal Roof Sheet Making Machine stands out as a game-changing asset that is redefining the way metal roof sheets are manufactured.