High Efficiency Horizontal Roof Panel Forming Machine for Faster Production

By:Admin

The roofing industry is constantly evolving with technological advancements and innovative solutions. One such solution is the Horizontal Roof Panel Forming Machine, developed by a leading manufacturer in the industry.

The company, with over 20 years of experience in the production of advanced roofing equipment, has recently unveiled their latest offering - the Horizontal Roof Panel Forming Machine. This state-of-the-art machine is designed to revolutionize the way roof panels are manufactured, offering increased efficiency, precision, and customization options.

The Horizontal Roof Panel Forming Machine is equipped with advanced features that set it apart from traditional panel forming machines. It is capable of forming large roof panels with precision and speed, reducing production time and costs for manufacturers. The machine also allows for seamless customization, enabling the production of panels in various shapes, sizes, and patterns to meet the specific requirements of different roofing projects.

In addition to its impressive functionality, the Horizontal Roof Panel Forming Machine is also built with user-friendly features, making it easy to operate and maintain. This facilitates a smooth and hassle-free manufacturing process for users, ensuring maximum productivity and minimal downtime.

The company's commitment to innovation and quality is evident in the design and production of the Horizontal Roof Panel Forming Machine. Through extensive research and development, they have created a machine that meets the highest industry standards and exceeds the expectations of roofing professionals.

The launch of the Horizontal Roof Panel Forming Machine represents a significant milestone for the company, further establishing their position as a leading provider of cutting-edge roofing equipment. With a strong focus on customer satisfaction and continuous improvement, the company continues to invest in research and development to bring innovative solutions to the market.

To complement the Horizontal Roof Panel Forming Machine, the company also offers comprehensive training and support services to ensure that customers can maximize the benefits of this advanced technology. This includes training programs, technical assistance, and ongoing maintenance services to keep the machine operating at peak performance.

As the roofing industry continues to evolve, the demand for efficient and versatile manufacturing solutions is on the rise. The Horizontal Roof Panel Forming Machine is well-positioned to meet this demand, offering a reliable and cost-effective solution for manufacturers looking to enhance their production capabilities.

In conclusion, the introduction of the Horizontal Roof Panel Forming Machine by the company represents a significant advancement in the roofing industry. With its advanced features, user-friendly design, and commitment to quality, this machine is set to revolutionize the way roof panels are manufactured. As the industry continues to evolve, the company remains at the forefront of innovation, delivering cutting-edge solutions to meet the changing needs of roofing professionals.

Company News & Blog

High-Quality Glazed Tile Forming Machine: A Complete Guide

Color Steel Glazed Tile Forming Machine: Revolutionizing the Roofing IndustryIn recent years, there has been a growing demand for durable, high-quality roofing materials that are not only aesthetically pleasing but also offer superior protection against the elements. In response to this demand, the Color Steel Glazed Tile Forming Machine has emerged as a game-changer in the roofing industry, revolutionizing the way roofing materials are manufactured and installed.The Color Steel Glazed Tile Forming Machine, developed by [Company Name], is a state-of-the-art piece of equipment that is designed to produce color steel glazed tiles with precision and efficiency. These tiles, also known as glazed roofing tiles, are made from high-quality color steel and are coated with a layer of glaze that not only enhances their appearance but also provides an added layer of protection against corrosion, UV radiation, and extreme weather conditions.One of the key advantages of the Color Steel Glazed Tile Forming Machine is its ability to produce tiles of various shapes, sizes, and colors, allowing for a high degree of customization to meet the specific needs and preferences of customers. The machine is equipped with advanced technology and automated processes that ensure the consistent production of high-quality tiles while minimizing material wastage and production time.Furthermore, the Color Steel Glazed Tile Forming Machine is designed to be user-friendly and low-maintenance, making it suitable for use in a wide range of manufacturing settings, from small-scale roofing material production facilities to large-scale industrial operations. Its versatility and efficiency have made it an attractive investment for businesses looking to modernize their roofing material manufacturing processes and improve their overall product quality.[Company Name] has built a solid reputation as a leading manufacturer and supplier of innovative machinery for the construction and building materials industry. With a commitment to research and development, as well as a focus on customer satisfaction, the company has continuously pushed the boundaries of technological innovation to develop products that meet the evolving needs of the market.The Color Steel Glazed Tile Forming Machine is a testament to [Company Name]'s dedication to excellence and its ability to provide cutting-edge solutions that drive progress in the industry. By offering a reliable and efficient way to produce high-quality color steel glazed tiles, the machine has become a valuable asset for businesses seeking to meet the growing demand for durable and visually appealing roofing materials.The impact of the Color Steel Glazed Tile Forming Machine extends beyond the manufacturing process, as its use has also led to significant improvements in the overall quality and performance of glazed roofing tiles. These tiles have become increasingly popular among homeowners, architects, and builders due to their exceptional durability, resistance to fading, and ability to enhance the visual appeal of any structure.As the construction industry continues to evolve, the demand for roofing materials that offer both form and function will only continue to grow. With the Color Steel Glazed Tile Forming Machine, [Company Name] has positioned itself at the forefront of this trend, providing businesses with the tools they need to stay ahead of the competition and meet the expectations of an increasingly discerning market.In conclusion, the Color Steel Glazed Tile Forming Machine represents a significant advancement in the roofing industry, offering a reliable, efficient, and cost-effective solution for the production of high-quality color steel glazed tiles. With its cutting-edge technology and user-friendly design, the machine has transformed the way roofing materials are manufactured and has set a new standard for excellence in the industry. As the demand for durable and visually appealing roofing materials continues to grow, the Color Steel Glazed Tile Forming Machine is poised to play a pivotal role in shaping the future of the industry.

Single Layer Color Steel Roll Forming Machine: All You Need to Know

Introducing a Revolutionary Single Layer Color Steel Roll Forming MachineThe [Company Name] is proud to announce the launch of their latest innovation in the field of metal forming equipment - the Single Layer Color Steel Roll Forming Machine. This state-of-the-art machine promises to revolutionize the process of creating color steel roofing and wall panels, offering unmatched precision, efficiency, and reliability.With a strong focus on research and development, [Company Name] has been at the forefront of metal forming technology for over a decade. The company's team of engineers and designers have worked tirelessly to create a machine that addresses the most common challenges faced by manufacturers in the industry. The result is a cutting-edge roll forming machine that sets new standards for quality and performance.One of the key features of the Single Layer Color Steel Roll Forming Machine is its advanced design, which allows for the rapid and precise shaping of color steel sheets. This is achieved through a combination of high-quality materials, innovative engineering, and precision manufacturing techniques. The machine is also equipped with a range of advanced control systems, enabling operators to fine-tune the production process and produce panels of the highest quality with minimal waste.In addition to its superior performance, the Single Layer Color Steel Roll Forming Machine also offers unparalleled flexibility. It is capable of producing a wide variety of panel designs, allowing manufacturers to meet the diverse needs of their customers. Whether it's a simple corrugated panel or a complex architectural profile, this machine can handle it with ease. This level of versatility is a game-changer for manufacturers, enabling them to take on a wider range of projects and expand their capabilities.Furthermore, the machine is designed with ease of use in mind. Its intuitive interface and user-friendly controls make it simple for operators to set up and operate the machine, reducing the need for extensive training and minimizing the risk of errors. This not only saves time and money but also ensures consistent quality in every panel produced.The launch of the Single Layer Color Steel Roll Forming Machine represents a major milestone for [Company Name]. It reflects the company's commitment to innovation and its dedication to providing the industry with the most advanced and reliable equipment available. With this new machine, [Company Name] is poised to set new benchmarks for quality, efficiency, and customer satisfaction in the metal forming industry.In order to ensure that customers can make the most of this groundbreaking technology, [Company Name] is offering comprehensive support and after-sales service. This includes installation assistance, training programs, and ongoing maintenance and technical support. This further underscores the company's commitment to customer success and satisfaction.As the global demand for high-quality color steel panels continues to grow, the launch of the Single Layer Color Steel Roll Forming Machine couldn't have come at a better time. Manufacturers in various industries, from construction to automotive, are now able to access a solution that will enable them to stay ahead of the competition and meet the evolving needs of their clients.In conclusion, the Single Layer Color Steel Roll Forming Machine from [Company Name] is a game-changing innovation that is set to redefine the way color steel panels are manufactured. With its cutting-edge technology, unmatched versatility, and user-friendly design, this machine is poised to become an indispensable asset for manufacturers around the world. For those looking to take their metal forming capabilities to the next level, the Single Layer Color Steel Roll Forming Machine is the ultimate solution.

High-Quality Roof Panel Machine for Snap Lock Panels

Snap Lock Roof Panel Machine revolutionizes the roofing industryIn a major breakthrough for the roofing industry, a leading company has introduced a state-of-the-art Snap Lock Roof Panel Machine that is set to revolutionize the way roofs are installed and maintained. This remarkable piece of equipment has the potential to change the landscape of the roofing industry by streamlining the installation process and improving the overall quality and longevity of roofs.The Snap Lock Roof Panel Machine, developed by the innovative team at the company, is designed to produce high-quality snap lock roof panels that are not only durable and long-lasting, but also easy to install. This machine is equipped with advanced technology and precision engineering to ensure that the roof panels produced are of the highest standard and meet the specific requirements of each project.The company behind this groundbreaking technology is a leading manufacturer and supplier of roofing solutions, with a strong reputation for delivering top-quality products to customers across the globe. With a commitment to innovation and excellence, the company has consistently pushed the boundaries of what is possible in the roofing industry, and the introduction of the Snap Lock Roof Panel Machine is a testament to their dedication to driving advancements in the field.One of the key features of the Snap Lock Roof Panel Machine is its versatility and efficiency. The machine is capable of producing a wide range of snap lock roof panels in various sizes and designs, allowing for greater flexibility and customization in roofing projects. Furthermore, the automated nature of the machine ensures high levels of productivity, with the ability to produce a large volume of panels in a short amount of time, ultimately reducing installation time and labor costs for the customer.In addition to its impressive operational capabilities, the Snap Lock Roof Panel Machine also prioritizes durability and resilience in its output. The roof panels produced by this machine are constructed from high-quality materials that are engineered to withstand the harshest weather conditions and provide long-term protection for any structure. This focus on durability not only ensures the longevity of the roof, but also reduces the need for frequent maintenance and repairs, ultimately saving time and money for the customer in the long run.The introduction of the Snap Lock Roof Panel Machine marks a significant advancement in the roofing industry, and its potential impact is already being felt by industry professionals and customers alike. By offering a more efficient, cost-effective, and durable roofing solution, this machine is poised to set a new standard for roof installation and maintenance, and is expected to be widely adopted by contractors and builders looking to deliver superior results to their clients.As the demand for innovative and reliable roofing solutions continues to grow, the company is proud to lead the way with the Snap Lock Roof Panel Machine. With a strong commitment to pushing the boundaries of what is possible in the industry, the company is confident that this machine will not only meet the needs of today's roofing projects, but also set the stage for future advancements in the field.In conclusion, the introduction of the Snap Lock Roof Panel Machine represents a significant milestone in the roofing industry, offering a game-changing solution for contractors, builders, and customers. With its advanced technology, versatility, and focus on durability, this machine is set to transform the way roofs are installed and maintained, and is poised to become a standard-bearer for excellence in the field. As the company continues to push the boundaries of innovation and quality, the Snap Lock Roof Panel Machine stands as a testament to their commitment to delivering superior roofing solutions to customers around the world.

Glazed Tile Roll Forming Machine - Industrial Steel Rolling Machines for Metal Roofing Sheet Production

Title: ZhongTuoCN Revolutionizes Roofing Industry with Advanced Glazed Tile Roll Forming MachineIntroduction:ZhongTuoCN, a renowned leader in the steel rolling machine industry, has unveiled its latest product, the Color Steel Glazed Roof Tile Roll Forming Machine. This advanced machinery has revolutionized the roofing industry by enabling the efficient production of high-quality metal glazed tiles. With its cutting-edge technology and precision engineering, ZhongTuoCN is empowering manufacturers to meet growing demands for durable and aesthetically pleasing roofing solutions.1. Meeting the Rising Demand for Glazed Roofing Tiles:The demand for glazed roofing tiles has been steadily increasing due to their exceptional durability, weather resistance, and stunning visual appeal. Recognizing this trend, ZhongTuoCN's engineers have developed a state-of-the-art roll forming machine specifically designed to cater to this niche segment. Manufacturers can now produce glazed tiles efficiently, ensuring timely delivery and meeting customer expectations.2. Cutting-Edge Technology Enhances Efficiency:The Color Steel Glazed Roof Tile Roll Forming Machine stands out for its advanced features, guaranteeing optimal efficiency. Equipped with state-of-the-art automation technology, this innovative machine minimizes human intervention, reducing labor costs and increasing productivity. With high-speed forming capabilities, it guarantees a smooth and streamlined production process, allowing manufacturers to meet large-scale orders efficiently.3. Unparalleled Precision and Durability:ZhongTuoCN's Glazed Tile Roll Forming Machine is meticulously engineered to deliver unmatched precision and durability. Its robust frame, constructed from high-quality steel, ensures long-term stability and reliability. The rollers are made from top-grade materials, facilitating seamless tile formation without any deformities. This ensures that every finished tile exhibits consistent dimensions and exceptional surface quality.4. Flexibility in Tile Design and Customization:In addition to its standard features, the Color Steel Glazed Roof Tile Roll Forming Machine provides manufacturers with unparalleled flexibility in tile design and customization. By incorporating adjustable features in the machine, manufacturers can easily tailor the dimensions, profile, and curvature of the glazed tiles to meet various customer requirements. This adaptability sets ZhongTuoCN's machinery apart from its competitors and allows clients to offer unique and personalized roofing solutions.5. Strict Quality Control and After-Sales Support:ZhongTuoCN prioritizes quality control throughout the manufacturing process. Each component of the Glazed Tile Roll Forming Machine undergoes stringent testing to ensure optimal performance and durability. Additionally, ZhongTuoCN provides comprehensive after-sales support, including installation guidance, training programs, and 24/7 technical assistance. This commitment to customer satisfaction has earned the company an excellent reputation in the industry.Conclusion:With the introduction of the Color Steel Glazed Roof Tile Roll Forming Machine, ZhongTuoCN has reaffirmed its position as a pioneer in the steel rolling machine industry. This cutting-edge technology guarantees exceptional efficiency, precision, and customization options for manufacturers in the roofing sector. By empowering clients to meet the rising demand for glazed tiles, ZhongTuoCN is revolutionizing the roofing industry and offering an unparalleled solution for businesses worldwide.

Highly Efficient and Durable Rain Pipe Roll Forming Machine Impresses with Innovative Color Steel Technology

Title: State-of-the-Art Color Steel Rain Pipe Roll Forming Machine Revolutionizes the IndustryIntroduction:In an ever-evolving world of technology and innovation, the manufacturing industry is no exception. Introducing a cutting-edge Color Steel Rain Pipe Roll Forming Machine, the industry is set to witness a remarkable transformation in production processes. This state-of-the-art machine is designed to streamline the manufacturing of rain pipes, ensuring high precision, durability, and efficiency. In this article, we will delve into the features and benefits of this remarkable equipment and explore how it is set to revolutionize the industry.Paragraph 1:The Color Steel Rain Pipe Roll Forming Machine, developed by leading experts in the field, offers a remarkable solution for the manufacturing of rain pipes. Equipped with advanced technology and precise engineering, this machine has the potential to usher in a new era in the production process. By optimizing the use of raw materials and maximizing output, manufacturers can improve efficiency and reduce costs.Paragraph 2:One of the key features of this Color Steel Rain Pipe Roll Forming Machine is its flexibility. Designed to accommodate various pipe sizes and shapes, manufacturers can easily adapt the machine to meet specific project requirements. This adaptability not only saves time but also reduces the need for additional equipment, ultimately reducing production costs.Paragraph 3:The machine's high precision capabilities ensure that each rain pipe is manufactured to exact specifications. This eliminates any inconsistencies that can occur with traditional manufacturing methods, guaranteeing a superior product that meets industry standards. The precision of the machine ensures that rain pipes are uniform in shape, size, and thickness, enhancing their durability and longevity.Paragraph 4:Furthermore, the Color Steel Rain Pipe Roll Forming Machine is equipped with automatic controls and feedback systems. This allows manufacturers to monitor and maintain optimal production conditions, minimizing errors and ensuring a seamless manufacturing process. With adjustable settings and real-time data monitoring, production efficiency is significantly increased, resulting in higher output and reduced downtime.Paragraph 5:In addition to the technical advantages, the machine's user-friendly interface and intuitive design make it accessible to operators of all skill levels. This eliminates the need for extensive training and allows manufacturers to quickly integrate the machine into their production line. The simplified operation also reduces the likelihood of human errors, further improving product quality and minimizing waste.Paragraph 6:The environmental impact of manufacturing is a growing concern in today's world. The Color Steel Rain Pipe Roll Forming Machine addresses this concern by optimizing the use of raw materials and minimizing waste. Through precise control and measurement during the manufacturing process, the machine ensures the efficient use of resources, making it an environmentally sustainable solution.Conclusion:The introduction of the Color Steel Rain Pipe Roll Forming Machine marks a significant milestone in the manufacturing industry. With its advanced technology, precision engineering, and user-friendly interface, this machine promises to revolutionize the production of rain pipes. From its versatility and high precision capabilities to its efficiency and environmental sustainability, the machine offers a comprehensive solution for manufacturers in this sector. As the industry embraces this cutting-edge technology, we can expect to witness enhanced productivity, improved product quality, and reduced costs.

Glazed Metal Tile Roll Forming Machine for Color Steel Roofing

Color Steel Glazed Metal Tile Roll Forming Machine Revolutionizes Roofing IndustryThe roofing industry has witnessed a significant revolution with the introduction of the latest Color Steel Glazed Metal Tile Roll Forming Machine from . This cutting-edge technology promises to redefine the way metal tiles are produced and installed, marking a significant advancement in the industry.With a commitment to innovation and excellence, has developed the Color Steel Glazed Metal Tile Roll Forming Machine to meet the growing demand for high-quality, durable, and visually appealing metal roofing tiles. This advanced machine is designed to streamline the production process and enhance the overall quality and efficiency of metal tile manufacturing.The Color Steel Glazed Metal Tile Roll Forming Machine boasts a range of impressive features that set it apart from traditional roll forming equipment. From its precise and automated operation to its ability to produce a wide variety of metal tile designs, this machine offers a level of versatility and performance that is unparalleled in the industry.One of the key highlights of the Color Steel Glazed Metal Tile Roll Forming Machine is its ability to produce glazed metal tiles with outstanding accuracy and consistency. The machine is equipped with state-of-the-art technology that enables it to create perfectly formed metal tiles with a smooth glazed finish, ensuring a flawless and aesthetically pleasing result every time.Furthermore, the Color Steel Glazed Metal Tile Roll Forming Machine is designed to be user-friendly and easy to operate, making it suitable for both large-scale manufacturers and smaller roofing companies. Its efficient and cost-effective production process allows businesses to meet customer demand while maintaining high standards of quality and craftsmanship.In addition to its advanced production capabilities, the Color Steel Glazed Metal Tile Roll Forming Machine is also engineered with durability and longevity in mind. Built to withstand rigorous use and demanding production schedules, this machine is designed to be a reliable and long-lasting investment for any roofing business.The introduction of this innovative technology is poised to have a significant impact on the roofing industry. By offering an efficient and high-quality solution for metal tile production, the Color Steel Glazed Metal Tile Roll Forming Machine has the potential to elevate the standards of metal roofing and provide businesses with a competitive edge in the market.As the demand for metal roofing continues to grow, is proud to be at the forefront of innovation, providing cutting-edge solutions that meet the evolving needs of the industry. With the Color Steel Glazed Metal Tile Roll Forming Machine, the company reaffirms its commitment to delivering excellence and driving progress in the field of roofing technology.In conclusion, the Color Steel Glazed Metal Tile Roll Forming Machine represents a significant milestone in the roofing industry, ushering in a new era of efficiency, quality, and productivity. With its advanced features and unmatched performance, this machine is set to shape the future of metal tile production and installation, setting a new standard for excellence in the industry. As the roofing industry continues to evolve, remains dedicated to meeting the demands of the market and providing innovative solutions that empower businesses to thrive and succeed.

High Efficiency Horizontal Roof Panel Forming Machine for Faster Production

Introducing the Advanced Horizontal Roof Panel Forming MachineThe roofing industry is constantly evolving with technological advancements and innovative solutions. One such solution is the Horizontal Roof Panel Forming Machine, developed by a leading manufacturer in the industry.The company, with over 20 years of experience in the production of advanced roofing equipment, has recently unveiled their latest offering - the Horizontal Roof Panel Forming Machine. This state-of-the-art machine is designed to revolutionize the way roof panels are manufactured, offering increased efficiency, precision, and customization options.The Horizontal Roof Panel Forming Machine is equipped with advanced features that set it apart from traditional panel forming machines. It is capable of forming large roof panels with precision and speed, reducing production time and costs for manufacturers. The machine also allows for seamless customization, enabling the production of panels in various shapes, sizes, and patterns to meet the specific requirements of different roofing projects.In addition to its impressive functionality, the Horizontal Roof Panel Forming Machine is also built with user-friendly features, making it easy to operate and maintain. This facilitates a smooth and hassle-free manufacturing process for users, ensuring maximum productivity and minimal downtime.The company's commitment to innovation and quality is evident in the design and production of the Horizontal Roof Panel Forming Machine. Through extensive research and development, they have created a machine that meets the highest industry standards and exceeds the expectations of roofing professionals.The launch of the Horizontal Roof Panel Forming Machine represents a significant milestone for the company, further establishing their position as a leading provider of cutting-edge roofing equipment. With a strong focus on customer satisfaction and continuous improvement, the company continues to invest in research and development to bring innovative solutions to the market.To complement the Horizontal Roof Panel Forming Machine, the company also offers comprehensive training and support services to ensure that customers can maximize the benefits of this advanced technology. This includes training programs, technical assistance, and ongoing maintenance services to keep the machine operating at peak performance.As the roofing industry continues to evolve, the demand for efficient and versatile manufacturing solutions is on the rise. The Horizontal Roof Panel Forming Machine is well-positioned to meet this demand, offering a reliable and cost-effective solution for manufacturers looking to enhance their production capabilities.In conclusion, the introduction of the Horizontal Roof Panel Forming Machine by the company represents a significant advancement in the roofing industry. With its advanced features, user-friendly design, and commitment to quality, this machine is set to revolutionize the way roof panels are manufactured. As the industry continues to evolve, the company remains at the forefront of innovation, delivering cutting-edge solutions to meet the changing needs of roofing professionals.

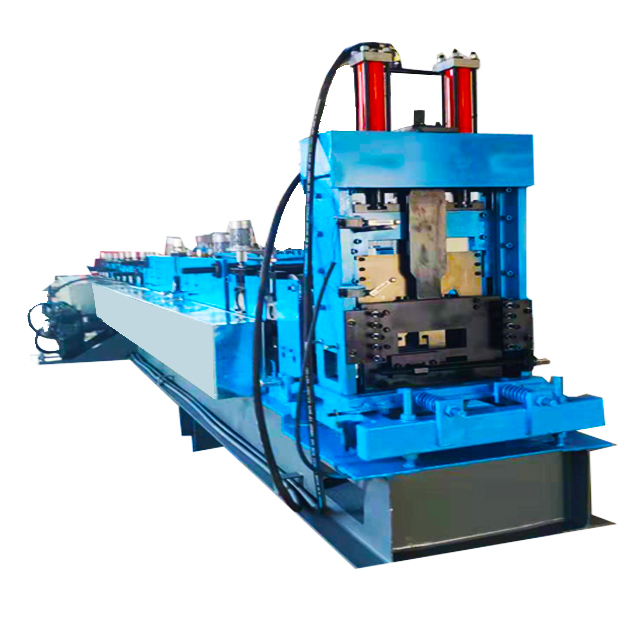

High-quality C Z Shape Purlin Forming Machine for Sale - Everything You Need to Know

C Z Shape Purlin Forming Machine: Revolutionizing the Construction IndustryC Z shape purlin forming machine is a revolutionary piece of equipment that is set to transform the construction industry. This state-of-the-art machine is designed to produce high quality C and Z shaped purlins with unmatched precision and efficiency. The machine is equipped with advanced technology and cutting-edge features that make it an invaluable tool for any construction project.With the ability to produce a wide range of C and Z shaped purlins, this machine is highly versatile and can be used in a variety of construction applications. Whether it is for building warehouses, industrial buildings, or commercial structures, the C Z shape purlin forming machine is an essential piece of equipment that is redefining the way construction projects are carried out.The C Z shape purlin forming machine is designed to streamline the purlin production process, saving time and labor costs. It boasts a high level of automation, with features such as automatic feeding, punching, and cutting, that drastically reduce the need for manual intervention. This not only enhances the speed of production but also ensures consistency and precision in the purlin dimensions.In addition to its efficiency, the machine is also known for its durability and reliability. Built with high-quality materials and precision engineering, it is capable of withstanding the rigors of heavy-duty use in a construction environment. This makes it a long-term investment that offers a high return on investment for any construction company.The company behind this innovative machine is a leader in the manufacturing of construction equipment. With years of experience and a commitment to excellence, they have established themselves as a trusted provider of quality machinery for the construction industry. Their expertise and dedication to innovation have led to the development of the C Z shape purlin forming machine, which has quickly gained recognition for its performance and reliability.As a company, they are focused on meeting the evolving needs of the construction industry by delivering cutting-edge solutions that enhance efficiency and productivity. The C Z shape purlin forming machine is a testament to this commitment, as it has set new standards for purlin production in the construction sector. By offering a machine that is not only efficient but also versatile and reliable, they have positioned themselves as a key player in shaping the future of construction technology.With the demand for efficient and cost-effective construction solutions on the rise, the C Z shape purlin forming machine is poised to make a significant impact in the industry. Its ability to expedite the purlin production process while maintaining high quality standards is a game-changer for construction companies looking to stay ahead of the curve.In conclusion, the C Z shape purlin forming machine is a game-changing piece of equipment that is revolutionizing the construction industry. Its advanced technology, efficiency, and reliability make it an indispensable tool for any construction project. Coupled with the expertise and commitment to excellence of the company behind it, this machine is set to redefine the way purlins are produced and utilized in construction, setting new benchmarks in efficiency and performance.

Manual Stacker For The Shape C Purline Machine Purline Machine: A Handy Tool for Easy Stacking

Manual Stacker for the Shape C Purline Machine Improves Efficiency and Accuracy in Material HandlingIn the ever-evolving manufacturing industry, companies are constantly looking for innovative solutions to improve efficiency and accuracy in their production processes. One such solution that has caught the attention of industry professionals is the Manual Stacker for the Shape C Purline Machine. This advanced equipment is designed to streamline material handling and enhance overall productivity in manufacturing facilities.The Manual Stacker for the Shape C Purline Machine is a game-changer for companies involved in the production of C-shaped purlins. These purlins are essential structural elements used in the construction of buildings and other structures. The machine's ability to handle these materials with precision and speed makes it an invaluable asset to manufacturing operations.The Manual Stacker is seamlessly integrated with the Shape C Purline Machine, creating a powerful tandem that enhances the overall production process. With its user-friendly interface and advanced technology, the Manual Stacker offers unmatched efficiency and accuracy in material handling. This results in significant time and cost savings for companies using this equipment.One of the primary advantages of the Manual Stacker is its ability to handle heavy loads with ease. This impressive lifting capacity allows for the transportation of large quantities of materials, reducing the need for manual labor and minimizing the risk of workplace injuries. Additionally, the Stacker's ergonomic design ensures operator comfort and safety, further contributing to a positive work environment.Moreover, the Manual Stacker is equipped with advanced features that facilitate seamless integration with the Shape C Purline Machine. This includes precise positioning and alignment capabilities, ensuring that materials are handled with the utmost accuracy. As a result, manufacturers can expect consistently high-quality output, minimizing material wastage and rework.The Manual Stacker also boasts a user-friendly interface that allows for easy operation and control. This intuitive system enables operators to efficiently maneuver the equipment, leading to improved productivity and reduced downtime. Additionally, the Stacker's advanced automation capabilities further optimize the material handling process, allowing for uninterrupted production cycles.In a competitive industry where time is of the essence, the Manual Stacker for the Shape C Purline Machine offers a significant time advantage. Its efficient material handling capabilities enable manufacturers to meet demanding production schedules and fulfill customer orders in a timely manner. This ultimately contributes to enhanced customer satisfaction and loyalty.As a leading manufacturer of industrial equipment, our company is proud to introduce the Manual Stacker for the Shape C Purline Machine. With our commitment to technological innovation and continuous improvement, we strive to provide our customers with cutting-edge solutions that empower their manufacturing operations. The Manual Stacker is a testament to our dedication to delivering reliable, high-performance equipment that meets the evolving needs of the industry.In conclusion, the Manual Stacker for the Shape C Purline Machine is a revolutionary tool that has the potential to transform the material handling process in the manufacturing industry. Its unparalleled efficiency and accuracy set a new standard for productivity, providing companies with a competitive edge in their respective markets. As manufacturing operations continue to evolve, the Manual Stacker stands out as a must-have solution for companies looking to optimize their production processes. With its advanced technology and ergonomic design, this equipment has undoubtedly earned its place as a game-changer in the industry.