High-Quality C Purlin Roll Forming Machine: A Complete Guide

By:Admin

Company Introduction:

Established in 2005, our company has been a pioneer in the field of metalworking machinery. Our dedication to continuous innovation and customer satisfaction has propelled us to become a leading manufacturer of roll forming machines. With a strong focus on research and development, we have consistently introduced cutting-edge technologies to the market, earning us a reputation for excellence and reliability.

News Content:

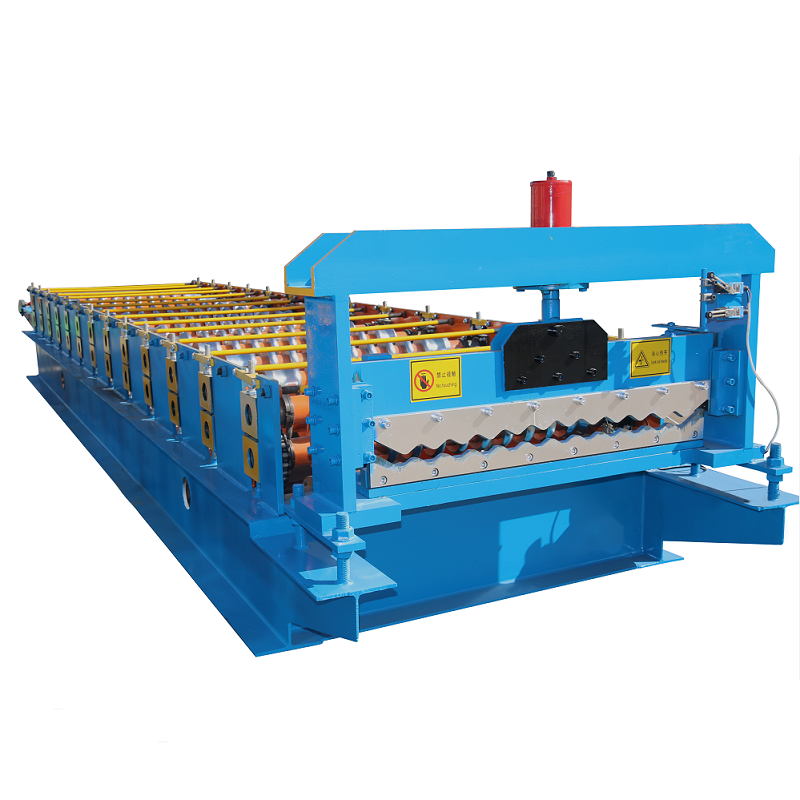

The Manual C Purlin Roll Forming Machine is a testament to our commitment to providing advanced solutions for our customers. This state-of-the-art machine is the ideal choice for businesses or individuals seeking to produce C purlins with precision and efficiency. With its manual operation, it offers an intuitive and user-friendly experience, making it accessible to operators of all skill levels.

What sets this machine apart is its ability to produce high-quality C purlins with consistency. The precision engineering of the roll forming process ensures that each purlin meets the required specifications, whether it's for residential, commercial, or industrial construction projects. This level of accuracy is essential for ensuring the structural integrity and stability of buildings, making it a valuable asset for any metalworking operation.

In addition to its performance, the Manual C Purlin Roll Forming Machine is designed with practicality in mind. Its compact size and efficient operation make it a space-saving and cost-effective solution for small to medium-sized enterprises. Furthermore, its manual operation eliminates the need for complex programming or extensive training, allowing operators to quickly familiarize themselves with the machine and start producing C purlins without unnecessary delays.

The versatility of the Manual C Purlin Roll Forming Machine extends to its ability to accommodate a wide range of material thicknesses and widths, offering operators the flexibility to meet various project requirements. This adaptability is essential in the ever-changing construction industry, where diverse purlin specifications are often necessary to meet specific building designs and structural demands.

As a testament to our ongoing commitment to customer satisfaction, the Manual C Purlin Roll Forming Machine is backed by our comprehensive technical support and training services. Our team of experts is readily available to provide guidance on machine operation, maintenance, and troubleshooting, ensuring that our customers can maximize the machine's capabilities and achieve optimal results.

In conclusion, the Manual C Purlin Roll Forming Machine represents a significant advancement in the field of metalworking machinery. Its combination of high-performance capabilities, user-friendly operation, and versatility makes it a valuable addition to any metalworking operation. As we continue to uphold our tradition of innovation and excellence, we are confident that this machine will deliver exceptional value to our customers and contribute to the success of their construction projects.

Company News & Blog

High-Quality Sheet Making Machine for Metro Use

The demand for sustainable and eco-friendly packaging solutions is on the rise, and one company is leading the way in providing innovative and efficient solutions for the packaging industry. With a commitment to sustainability and quality, {Company Name} has introduced a state-of-the-art Metro Sheet Making Machine that is set to revolutionize the production of eco-friendly packaging materials.{Company Name} is a leading provider of packaging solutions, with a focus on minimizing environmental impact and maximizing efficiency. The company is known for its dedication to sustainability and innovation, and the introduction of the Metro Sheet Making Machine is a testament to this commitment.The Metro Sheet Making Machine is a cutting-edge piece of equipment that is designed to produce high-quality and environmentally friendly packaging materials. With its advanced technology and precision engineering, the machine is capable of producing a wide range of sheet materials that are perfect for use in a variety of packaging applications.One of the key features of the Metro Sheet Making Machine is its ability to produce packaging materials from a variety of sustainable and renewable sources. This includes materials such as recycled paper, cardboard, and biodegradable plastics, all of which are in high demand in today's environmentally conscious market.In addition to its sustainability credentials, the Metro Sheet Making Machine is also incredibly efficient and versatile. It is capable of producing a wide range of sheet materials in different shapes, sizes, and thicknesses, making it ideal for use in a variety of packaging applications. This versatility allows {Company Name} to cater to a wide range of customer needs and provide customized solutions for different packaging requirements.Moreover, the Metro Sheet Making Machine is designed with user-friendly features that make it easy to operate and maintain. This ensures that the production process is smooth and efficient, minimizing downtime and maximizing output. With its high-speed production capabilities, the machine is also able to meet the demands of large-scale production while maintaining consistent quality and precision.{Company Name} is proud to introduce the Metro Sheet Making Machine as part of its ongoing commitment to sustainability and innovation. By investing in cutting-edge technology and sustainable production practices, the company is able to provide customers with high-quality packaging solutions that align with their environmental values.The introduction of the Metro Sheet Making Machine is a significant milestone for {Company Name}, as it further solidifies its position as a leader in the packaging industry. With its focus on sustainability and innovation, the company continues to pave the way for a more sustainable and eco-friendly future for the packaging industry.As the demand for sustainable packaging solutions continues to grow, {Company Name} remains focused on developing and introducing innovative and efficient solutions that align with its commitment to sustainability. The Metro Sheet Making Machine is just one example of how the company is reimagining the future of packaging, and it is poised to make a significant impact on the industry.In conclusion, {Company Name} continues to lead the way in providing sustainable and innovative packaging solutions with the introduction of the Metro Sheet Making Machine. With its advanced technology, versatility, and commitment to sustainability, the machine is set to revolutionize the production of eco-friendly packaging materials and pave the way for a more sustainable future for the packaging industry.

Quickly Changeable C/Z Purlin Roll Forming Machine: Efficient Steel Purlin Production

Title: Revolutionary CZ Interchangeable Purlin Roll Forming Machine Streamlines Steel ProductionIntroduction:In the ever-evolving realm of steel manufacturing, advancements in technology continue to redefine the way we produce essential building components. The latest innovation making waves in the industry is the CZ Interchangeable Purlin Roll Forming Machine. Designed to expedite the production process and enhance efficiency, this state-of-the-art machine effortlessly molds steel C and Z purlins of various sizes and thicknesses.Seamless Purlin Roll Transition:Traditionally, switching between C and Z purlin roll forming required cumbersome manual adjustments and downtime. However, the CZ Interchangeable Purlin Roll Forming Machine eliminates these inefficiencies by seamlessly transitioning between the two types of purlins. This groundbreaking technology significantly reduces production downtime, streamlining operations and increasing overall productivity.Precision Performance:The CZ Interchangeable Purlin Roll Forming Machine is renowned for its precision performance. Equipped with cutting-edge technology and automated processes, it delivers unparalleled accuracy and consistency in producing C and Z purlins. This ensures structural integrity and reliable performance of the final products, meeting the stringent quality standards demanded by the construction industry.Enhanced Flexibility:One of the most compelling features of the CZ Interchangeable Purlin Roll Forming Machine is its ability to produce purlins of varying sizes and thicknesses. Whether it's a small-scale residential project or a large commercial construction, this versatile machine can adapt to the requirements of any project, thereby expanding manufacturers' capabilities and market reach. Effortless Operation:Designed with user convenience in mind, the CZ Interchangeable Purlin Roll Forming Machine offers both manual and automatic adjustment options, catering to the diverse needs of manufacturers. Users can easily switch between modes depending on the complexity of the project, ensuring seamless operation and reducing the chances of error.Efficiency and Time-Saving:The CZ Interchangeable Purlin Roll Forming Machine revolutionizes the production process by reducing manual labor and maximizing efficiency. By automating key stages, this machine eliminates human error while significantly expediting production timelines. Manufacturers can now meet tight project deadlines without compromising on quality, thereby boosting overall customer satisfaction.Cost-Effective Solution:The CZ Interchangeable Purlin Roll Forming Machine is not only efficient but also cost-effective. With the ability to adapt to various project requirements, manufacturers no longer need to invest in separate machines for different purlin types. This reduces capital expenditure, maintenance costs, and overheads, enhancing profitability and competitiveness in the market.Sustainable Manufacturing:In today's environmentally conscious world, the CZ Interchangeable Purlin Roll Forming Machine aligns with the industry's commitment to sustainable manufacturing practices. By dramatically reducing material waste and energy consumption, this machine helps manufacturers meet their sustainability goals without compromising productivity or product quality.Conclusion:The CZ Interchangeable Purlin Roll Forming Machine represents a paradigm shift in steel production, offering manufacturers an advanced and versatile tool. With its ability to effortlessly switch between C and Z purlins, while accommodating various sizes and thicknesses, this machine sets a new standard for precision and efficiency in the industry. By streamlining operations, reducing downtime, and enhancing overall productivity, this innovative machine promises a bright future for the steel manufacturing sector.

High Precision CNC Machine for Aluminum Extrusions

The demand for precision-engineered aluminum extrusions has been on the rise in various industries such as construction, automotive, and aerospace. In response to this increasing demand, a leading manufacturing company has recently invested in state-of-the-art CNC machinery to enhance their capabilities in producing high-quality aluminum extrusions.With a legacy of over 50 years in the industry, {} has built a strong reputation for delivering innovative and customized solutions to their clients. Specializing in aluminum extrusion, the company has been at the forefront of technological advancements and has consistently invested in cutting-edge equipment to meet the evolving needs of their customers.The latest addition to their manufacturing arsenal is the advanced CNC machine specially designed for aluminum extrusions. This new equipment is equipped with high precision cutting and milling capabilities, allowing {} to achieve tight tolerances and intricate designs with utmost accuracy. The CNC machine also offers greater flexibility in producing complex shapes and profiles, enabling the company to cater to a wide range of applications across different industries.One of the key advantages of the new CNC machine is its efficiency in handling large-scale production while maintaining superior quality. This increased production capacity will enable {} to meet the growing demand for aluminum extrusions within shorter lead times, giving them a competitive edge in the market. Moreover, the CNC machine is integrated with advanced software that enables seamless programming and automation, thereby streamlining the manufacturing process and reducing the time required for setup and tool changes.In addition to enhancing their production capabilities, the investment in the CNC machine reflects {}'s commitment to upholding the highest standards of quality and precision. The company adheres to stringent quality control measures at every stage of the manufacturing process, ensuring that the aluminum extrusions meet the exact specifications and performance requirements of their customers. The new CNC machine further reinforces this commitment by enabling precise and consistent machining of extruded aluminum profiles, resulting in products that exhibit exceptional dimensional accuracy and surface finish.Furthermore, the implementation of the CNC machine underscores {}'s dedication to innovation and continuous improvement. By leveraging the latest technology, the company aims to push the boundaries of what is achievable in aluminum extrusion manufacturing. This proactive approach not only showcases their willingness to invest in the future of their business but also positions them as a reliable and forward-thinking partner for their clients.The investment in the CNC machine is also aligned with {}'s sustainability initiatives. Aluminum is widely recognized for its recyclability and environmental benefits, and {} is committed to minimizing their environmental footprint by optimizing material usage and reducing waste in their manufacturing processes. The precision and efficiency offered by the new CNC machine will contribute to the sustainable production of aluminum extrusions, further reinforcing {}'s position as an eco-conscious industry leader.In conclusion, the introduction of the CNC machine for aluminum extrusions marks a significant milestone for {}. This strategic investment not only enhances their manufacturing capabilities but also underscores their dedication to delivering top-quality, precision-engineered solutions to their clients. By embracing the latest technology and upholding their commitment to excellence, {} is poised to meet the evolving needs of the industry and continue setting new benchmarks in the field of aluminum extrusion manufacturing.

Advanced Laser Cutting Machine for Precision Cutting - Coil/Sheet/CNC

A laser cutting machine is an innovative piece of equipment that has revolutionized the manufacturing industry. The LXN Revolution, a laser cutting machine by a well-known company, is one of the most sought after cutting machines in the market today. This machine caters to the cutting needs of different industries, from sheet cutting to coil cutting and CNC machining. The machine has made precision cutting quick and effortless, making it a reliable tool in modern manufacturing processes.Sheet and coil cutting machines, in particular, are essential in the manufacturing industry as they allow for mass production capabilities. The LXN Revolution laser cutting machine has made sheet and coil cutting more efficient than ever before, providing high-quality cuts at faster speeds than traditional cutting machines. This machine works by using a beam of a powerful laser to cut through a range of materials. Materials such as sheet metal, stainless steel, and aluminum are commonly cut using this machine.One of the reasons why the LXN Revolution laser cutting machine is a game-changer is its precision. This machine can create intricate cuts with pinpoint accuracy. As a result, manufacturers can achieve precise shapes, sizes, and designs with minimal errors. This high level of precision ensures that every piece of material that passes through the machine gets cut as intended, reducing the chances of waste materials and saving time and resources.Moreover, the LXN Revolution laser cutting machine has made the cutting of coils easier and more efficient than ever before. It can handle different types of coils with varying thicknesses and widths, making it highly versatile. The machine can also create several cuts from a single coil, which saves time and energy. As a result, manufacturers can increase their production output without sacrificing quality.In conclusion, the LXN Revolution laser cutting machine is a versatile and efficient machine that caters to the cutting needs of different industries. With its precision cutting capabilities, it has made sheet and coil cutting machines more efficient than ever before. Its versatility and capabilities can help manufacturers increase their production output while maintaining the high-quality levels of their products. If you are in the manufacturing industry, investing in this machine is a game-changer.

Premium Steel Sheets: Cut-to-Length, Shear and Slitter Cut Services at Unbeatable Prices!

Title: Enhance Your Project's Efficiency and Quality with Hot Rolled Slitter Steel SheetsIntroductionIn today's fast-paced construction and manufacturing industries, the demand for high-quality steel sheets that can be customized to specific requirements is at an all-time high. Hot rolled steel sheets have become an exceptionally popular choice due to their durability and versatility.This blog aims to shed light on the benefits and applications of hot rolled steel sheets and the key role played by slitter cutting services in meeting the varied needs of different projects. So, let's delve deeper into the world of hot rolled slitter steel sheets!Understanding Hot Rolled Steel SheetsHot rolled steel sheets are produced through a process involving heating steel slabs above their recrystallization temperature, followed by cooling them to room temperature. This technique results in a flexible, strong, and malleable steel product that can be further processed to various specifications. The hot rolling process eliminates impurities, while the controlled cooling ensures uniformity and consistency in the sheet's strength.Applications and Advantages1. Versatility: One of the primary benefits of hot rolled steel sheets lies in their versatility. From automotive manufacturing and construction to machinery fabrication and shipbuilding, these sheets find application across a wide range of industries. Their strength and malleability allow for seamless forming and shaping, making them suitable for diverse projects.2. Durability: Hot rolled steel sheets are known for their exceptional durability. They can withstand heavy loads, extreme temperatures, and harsh environments, ensuring a longer lifespan for your projects. Whether it's a structural application or a component in heavy machinery, hot rolled steel sheets provide the necessary strength and resilience.3. Cost-effectiveness: With their cost-effective production process, hot rolled steel sheets offer excellent value for money. Affordable and readily available, they are a preferred choice for projects that demand a high-volume supply of steel sheets without compromising on quality.The Role of Slitter Cutting ServicesTo maximize the benefits of hot rolled steel sheets, slitter cutting services come into play. Slitter cut refers to the process of cutting wide coils of steel into narrower strips, catering to specific project requirements. This technique ensures precision and accuracy, ensuring that the sheets are tailored to the desired dimensions.Importance of Slitter Cutting1. Customization: Slitter cutting enables customization by accommodating different project needs. Sheets can be cut into a variety of widths, lengths, and thicknesses, ensuring an exact fit for your project requirements. This flexibility eliminates the need for additional processing and minimizes waste, thereby optimizing overall efficiency and cost-effectiveness.2. Simplicity and Time Efficiency: Slitter cutting services streamline the manufacturing process by providing ready-to-use steel strips. This eliminates the need for additional cutting and reduces the time and effort spent in modifying the sheets on-site. Better time management and enhanced simplicity contribute to meeting project deadlines and improving overall work efficiency.3. Precision and Quality: Slitter cutting techniques ensure precise and accurate cuts, resulting in high-quality steel strips. The accurate dimensions obtained through slitter cutting services reduce the risk of errors and ensure a perfect fit for your project's requirements. This level of precision translates into improved structural integrity and better overall performance.ConclusionHot rolled slitter steel sheets offer a range of benefits that meet the demands of various industries. Their versatility, durability, and cost-effectiveness make them an ideal choice for your projects. By employing slitter cutting services, you can further enhance the efficiency and quality of your projects. Customization, time efficiency, and precision are some of the significant advantages that slitter cutting brings to the table.When sourcing steel sheets, consider partnering with a reliable supplier offering hot rolled slitter steel sheets. By doing so, you can rest assured that you will receive quality products that are tailored to your exact requirements. Remember, investing in high-quality materials and services ensures the success and longevity of your projects in the long run.So, why wait? Embrace the versatility and reliability of hot rolled slitter steel sheets for your next construction or manufacturing project, and witness the remarkable difference it can make!

C/Z/U Channel Interchangeable Roll Forming Machine - Find Out More on China-Glorious.com Today

Introduction:Roll forming is the process of shaping metals into custom cross-section profiles, and it is widely used in various industries, including construction, automotive, and appliances. The roll forming machines are designed to automate this process, and they come in different types depending on the desired profile and material. In this blog, we will discuss the C channel rolling machine, its features, benefits, and applications.What is a C Channel Rolling Machine?A C channel rolling machine is a roll forming machine that is designed to produce C channel profiles from coils of sheet metal. The machine consists of several roll stations, where each station progressively shapes the metal into the desired C channel profile. The machine's design allows for the interchangeability of the C, Z, and U channels, producing different sizes and shapes according to the customer's needs.Features of the C Channel Rolling Machine:- Interchangeable channel profiles: The C channel rolling machine can produce various channel profiles, including C, Z, and U channels, by interchanging the roller stations.- High precision and efficiency: The rolling machine has a digital control system that ensures high precision and consistency in the production process.- Customizable sizes and shapes: The machine can produce C channel profiles of different sizes and shapes, depending on the customer's requirements.- Easy to operate: The C channel rolling machine is user-friendly and easy to operate, making it suitable for both small and large-scale production.Benefits of using a C Channel Rolling Machine:- Cost-effective: The machine's automated process reduces labor costs and material waste, resulting in cost savings.- High production output: The C channel rolling machine has a high production output, allowing for the efficient and timely completion of large orders.- Customizable profiles: The flexibility of the machine allows for the production of customized C channel profiles, meeting individual customer needs.- High-quality output: The digital control system ensures high precision in the production process, resulting in a high-quality output.Applications of the C Channel Rolling Machine:The C channel rolling machine is widely used in various industries, including:- Construction: C channel profiles are used in the construction industry for building frameworks, supports, and columns.- Automotive: C channel profiles are used in vehicle frames, exhaust systems, and roof rails.- Appliances: C channel profiles are used in the production of refrigerators, air conditioners, and washing machines.Conclusion:The C channel rolling machine is a versatile and cost-effective roll forming machine, suitable for the production of C, Z, and U channel profiles. Its customizable sizes and shapes, high precision, and efficiency make it ideal for various applications in different industries. If you are looking for a reliable machine for your C channel production needs, the C channel rolling machine is a worthy investment.

How Automatic Guardrail Roll Forming Machine Can Improve Road Safety?

Highway Guardrail Machine: The Future of Road SafetyRoad safety is a critical issue all over the world, and governments are continually looking for ways to ensure that the roads are safe for drivers and pedestrians alike. One of the essential elements of road safety is the implementation of guardrails on high traffic roads to prevent accidents. Guardrails act as a barrier to protect drivers and passengers from accidents by absorbing the impact of an out-of-control vehicle. Installing guardrails on the highways can be a daunting task, often requiring a lot of time, manpower, and resources. However, with the introduction of the latest technology, highway guardrail machines have made this process efficient and cost-effective.One such company leading the charge in this regard is the Highway Guardrail Machine (HGM) company. Helping to revolutionize the way we approach highway guardrail installation, HGM designs and manufactures machines that make the task easier and more efficient. The company is dedicated to providing innovative, reliable, and high-quality manufacturing services, with the aim of improving road safety and reducing the risk of injury and death on the highways.The HGM AdvantageOne of the main advantages of using HGM products is the machines' versatility, durability, and ease of use. Compared to traditional installation methods, HGM highway guardrail machines can be used to install guardrails continuously, thus reducing the chances of gaps and breaks that may compromise safety. The machines can be adjusted according to the terrain, making them suitable for use in a variety of environments. Additionally, because HGM machines are designed for precision, they can install guardrails with minimal damage to the surrounding landscape, thus minimizing environmental impact.The machines also offer significant advantages in terms of cost-effectiveness. Because of their precision and efficiency, HGM highway guardrail machines require less labor and time to install guardrails, which translates to lower costs. This is particularly beneficial for governments or any company managing road construction projects that are working on a budget. Furthermore, the machines can pay for themselves quickly, as they require less maintenance and repairs than traditional systems.HGM Company VisionHGM's primary goal is to create a safer environment for both drivers and pedestrians by providing innovative solutions for highway guardrail installation. The company recognizes the importance of guardrails in reducing accidents and aims to make the installation process more effective, efficient, and environmentally friendly. HGM's modern machines also provide a safer working environment for the workers installing the guardrails by reducing the need for manual labor, which can be dangerous in high traffic areas.The company's commitment to quality assurance is demonstrated by its strict adherence to safety regulations and best practices. HGM machines undergo rigorous quality control procedures before they are released to the market, ensuring that they meet the highest standards of performance, safety, and reliability. Additionally, the company invests heavily in research and development to ensure that its products remain cutting-edge and meet growing market demands.ConclusionHighway Guardrail Machine is a leading company that designs and manufactures innovative highway guardrail machines. The company's products offer significant advantages in terms of efficiency, safety, and cost-effectiveness, making the installation of guardrails on highways more effective and accessible. The company's focus on innovation, sustainability, and safety ensures that it remains at the forefront of the industry and provides the most effective solutions for the ever-growing demand for highway guardrails.Together with their customers and the community, HGM is committed to creating a safer future by providing innovative solutions for highway guardrail installation. Interested parties can find out more about HGM's products and services on their website. In conclusion, HGM is helping to make the roads safer by providing cutting-edge highway guardrail machines.

High Precision Profile Cutting Machine for Metal Fabrication

Metal Profile Cutting Machine Revolutionizes Manufacturing IndustryIn the fast-paced world of manufacturing, precision and efficiency are key factors in producing high-quality products. This is why the introduction of the Metal Profile Cutting Machine by {Company Name} has revolutionized the industry, bringing about a new level of precision and speed in metal cutting.{Company Name} has been a leading manufacturer of industrial cutting tools for over a decade, specializing in providing innovative solutions for various industries such as automotive, aerospace, and construction. Their latest offering, the Metal Profile Cutting Machine, is set to change the game for manufacturers looking to streamline their operations and improve productivity.The Metal Profile Cutting Machine is designed to cut metal profiles with high precision and speed, making it an ideal tool for manufacturers who require intricate and accurate cuts in their production process. Whether it's cutting steel, aluminum, or other types of metal, this machine is capable of delivering exceptional results with minimal waste and maximum efficiency.One of the key features of the Metal Profile Cutting Machine is its advanced CNC technology, which allows for automated cutting processes that are highly accurate and repeatable. This means that manufacturers can rely on the machine to consistently produce high-quality cuts, leading to improved product quality and reduced rework.Furthermore, the Metal Profile Cutting Machine is equipped with a user-friendly interface that makes it easy for operators to program and monitor the cutting process. This not only saves time and effort but also ensures that the machine can be operated by individuals with varying levels of experience.Another major advantage of the Metal Profile Cutting Machine is its flexibility in handling a wide range of profiles and thicknesses. Whether it's cutting thin sheets or thick plates, this machine can adapt to various cutting requirements, making it a versatile tool for manufacturers with diverse needs.In addition to its technical capabilities, {Company Name} also provides comprehensive support and service for the Metal Profile Cutting Machine, ensuring that customers receive the necessary training and assistance to maximize the machine's potential. This commitment to customer satisfaction sets {Company Name} apart from its competitors and reinforces its reputation as a trusted partner in the manufacturing industry.The introduction of the Metal Profile Cutting Machine has already garnered attention from industry insiders, with many experts praising its potential to revolutionize the way metal cutting is done. Manufacturers who have adopted the machine have reported significant improvements in their production processes, citing its ability to increase productivity and reduce material waste.With the Metal Profile Cutting Machine, {Company Name} has solidified its position as an industry leader in providing cutting-edge solutions for the manufacturing sector. As the demand for high-quality and precise metal cutting continues to grow, this machine is expected to become an indispensable tool for manufacturers looking to stay ahead of the competition.In conclusion, the Metal Profile Cutting Machine by {Company Name} represents a new era in metal cutting technology, offering unprecedented precision, efficiency, and versatility for manufacturers. As the manufacturing industry continues to evolve, this machine is poised to play a pivotal role in shaping the future of metal fabrication, setting new standards for excellence and innovation.

Complete Guide to Standing Seam Metal Roof Machines

[Company name], a leading manufacturer of metal roofing machines, has recently introduced its latest innovation – the Standing Seam Metal Roof Machine. This new machine is designed to offer increased efficiency and precision in the production of standing seam metal roofs, making it the perfect solution for various roofing contractors and manufacturers.The Standing Seam Metal Roof Machine is designed to produce high-quality standing seam metal roofs with ease and precision. It is equipped with state-of-the-art technology and features that make the production process faster and more efficient. The machine is capable of producing standing seam metal roofs in a variety of widths and lengths, making it suitable for a wide range of roofing projects.One of the key features of the Standing Seam Metal Roof Machine is its versatility. It is designed to be easily adjustable, allowing for quick and easy changes in panel width and length. This ensures that the machine can easily adapt to different project requirements, saving time and increasing productivity for roofing contractors and manufacturers.In addition to its versatility, the Standing Seam Metal Roof Machine is also designed with precision in mind. It is equipped with advanced controls and systems that ensure the accuracy and consistency of the finished products. This precision is essential for meeting the high standards and specifications of standing seam metal roofs, ensuring that the final product meets the requirements of the most demanding customers.Furthermore, the Standing Seam Metal Roof Machine is designed for durability and reliability. It is constructed with high-quality materials and components, making it capable of withstanding the rigors of continuous use in a production environment. This durability minimizes downtime and maintenance, ensuring that the machine can deliver consistent performance over the long term.“We are thrilled to introduce our latest innovation, the Standing Seam Metal Roof Machine,” said [Company name]'s CEO. “This machine is the result of our ongoing commitment to delivering cutting-edge solutions for the metal roofing industry. We have designed it to address the needs and challenges of our customers, providing them with a reliable and efficient solution for producing standing seam metal roofs.”[Company name] has been a trusted name in the metal roofing industry for many years. The company has a proven track record of delivering high-quality and reliable metal roofing machines that meet the needs of roofing contractors and manufacturers. The introduction of the Standing Seam Metal Roof Machine is a testament to the company's dedication to innovation and customer satisfaction.With its latest innovation, [Company name] is poised to further strengthen its position as a leading manufacturer of metal roofing machines. The Standing Seam Metal Roof Machine is set to become a game-changer in the industry, offering a level of efficiency, precision, and versatility that was previously unseen in the production of standing seam metal roofs.In conclusion, the introduction of the Standing Seam Metal Roof Machine marks a significant milestone for [Company name] and the metal roofing industry as a whole. With its advanced technology, versatility, precision, and durability, this machine is set to revolutionize the production of standing seam metal roofs, providing a reliable and efficient solution for roofing contractors and manufacturers. As [Company name] continues to push the boundaries of innovation, it is poised to further solidify its position as a trusted provider of metal roofing machines.