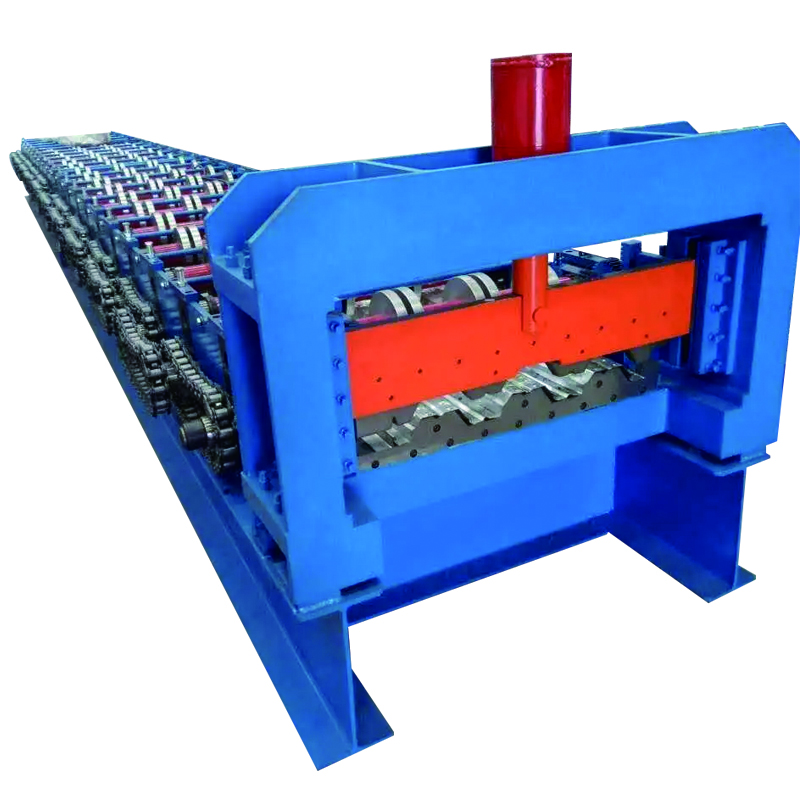

High-quality Corrugated Iron Rolling Machine for Sale - Find Out More Here

By:Admin

Recently, {Company Name} unveiled its latest creation - the Corrugated Iron Rolling Machine. This state-of-the-art piece of equipment represents a significant advancement in the industry and is set to revolutionize the way corrugated iron is produced.

The Corrugated Iron Rolling Machine is a cutting-edge piece of machinery that is designed to streamline the process of creating corrugated iron sheets. With its advanced technology and precision engineering, this machine is capable of producing high-quality corrugated iron sheets with unparalleled efficiency and accuracy.

One of the key features of the Corrugated Iron Rolling Machine is its versatility. The machine is capable of handling a wide range of materials, including steel, aluminum, and other metals, allowing for flexibility in production and ensuring that the needs of a diverse customer base can be met.

In addition to its impressive capabilities, the Corrugated Iron Rolling Machine is also designed with user-friendliness in mind. With intuitive controls and a user-friendly interface, the machine is easy to operate, making it accessible to operators of all skill levels.

Furthermore, the Corrugated Iron Rolling Machine is engineered with a focus on durability and reliability. Constructed from high-quality materials and built to the highest standards, this machine is designed to withstand the rigors of industrial use, ensuring longevity and consistent performance.

{Company Name} has a long-standing reputation for delivering superior products, and the Corrugated Iron Rolling Machine is no exception. With its cutting-edge technology, versatility, user-friendly design, and robust construction, this machine is poised to set a new standard for corrugated iron production.

In a statement, the CEO of {Company Name} expressed his enthusiasm for the Corrugated Iron Rolling Machine, stating, "We are proud to introduce this groundbreaking piece of equipment to the market. The Corrugated Iron Rolling Machine is the result of years of research, development, and innovation, and we believe it has the potential to greatly benefit our customers and the industry as a whole."

The unveiling of the Corrugated Iron Rolling Machine represents a significant milestone for {Company Name}. It is a testament to their ongoing commitment to pushing the boundaries of innovation and setting new benchmarks for excellence in the manufacturing industry.

As the industry continues to evolve, {Company Name} remains dedicated to staying at the forefront of technological advancement and providing cutting-edge solutions to their customers. With the introduction of the Corrugated Iron Rolling Machine, {Company Name} has once again demonstrated their leadership and expertise in the field, and is poised to make a lasting impact on the industry.

Company News & Blog

Steel Cut To Length Roofing Sheet Roll Forming Machine: All You Need to Know

Metal Steel Cut To Length Roofing Sheet Roll Forming Machine Revolutionizes Manufacturing ProcessesThe metal roofing industry has experienced a significant transformation with the introduction of the advanced Metal Steel Cut To Length Roofing Sheet Roll Forming Machine. This state-of-the-art equipment has been designed to revolutionize the manufacturing processes, optimizing cutting and forming metal sheets for roofing applications.The Metal Steel Cut To Length Roofing Sheet Roll Forming Machine is equipped with the latest technology and precision engineering, offering a range of benefits that are set to redefine the way metal roofing sheets are produced. With its ability to cut and form metal sheets to precise dimensions with minimal waste, this innovative machine is not only increasing productivity but also reducing production costs for manufacturers."One of the key features of the Metal Steel Cut To Length Roofing Sheet Roll Forming Machine is its precision cutting capabilities," said a spokesperson for the company. "The machine is designed to accurately cut metal sheets to specified lengths, ensuring a high level of consistency and quality across the board. This level of precision is essential in the production of roofing sheets, as it allows for seamless installation and enhanced durability."In addition to its cutting capabilities, the Metal Steel Cut To Length Roofing Sheet Roll Forming Machine also excels in forming metal sheets into the desired shape and profile. This versatility makes it a valuable asset for manufacturers, as it eliminates the need for multiple machines and processes, streamlining production and improving overall efficiency.Furthermore, the machine's advanced control system allows for precise adjustments and customization, catering to the unique requirements of different roofing sheet designs. This flexibility opens up new possibilities for manufacturers to expand their product offerings and meet the evolving demands of the market.The Metal Steel Cut To Length Roofing Sheet Roll Forming Machine also boasts a user-friendly interface, making it easy for operators to set up and monitor the production process. Its automated features and intuitive controls reduce the need for manual intervention, further enhancing productivity and ensuring consistent output.The introduction of this cutting-edge machine comes at a time when the demand for metal roofing materials is on the rise. With its durability, energy efficiency, and aesthetic appeal, metal roofing has become a popular choice for residential, commercial, and industrial applications. As a result, manufacturers are seeking innovative solutions to meet the growing need for high-quality metal roofing products.The company behind the Metal Steel Cut To Length Roofing Sheet Roll Forming Machine has a long-standing reputation for delivering cutting-edge solutions to the metal manufacturing industry. With a strong focus on research and development, the company has continuously pushed the boundaries of technology to bring advanced machinery to the market."Our goal is to empower manufacturers with the tools they need to stay ahead in a competitive market," the spokesperson explained. "The Metal Steel Cut To Length Roofing Sheet Roll Forming Machine is a testament to our commitment to innovation, and we are confident that it will make a significant impact on the metal roofing industry."As manufacturers embrace the capabilities of the Metal Steel Cut To Length Roofing Sheet Roll Forming Machine, the industry is entering a new era of efficiency, productivity, and quality. With its ability to streamline production processes, reduce waste, and deliver precision-engineered roofing sheets, this innovative machine is set to shape the future of metal roofing manufacturing.

CNC Aluminum Profile: Tips for Affordable and Quality Aluminum Profiles

Title: Revolutionary Cnc Aluminum Profile Taking Manufacturing Efficiency to New HeightsIntroduction:In a breakthrough development, a leading manufacturing company has recently unveiled its cutting-edge Cnc Aluminum Profile, designed to transform the industrial sector with its unmatched precision, durability, and efficiency. This innovative product is set to revolutionize manufacturing processes across various industries, ensuring higher productivity and superior quality fabrication.Unveiling the Cnc Aluminum Profile:The Cnc Aluminum Profile, developed by the forward-thinking engineers at (company name), is a result of intensive research and testing. This ground-breaking technology offers a wide range of advantages that will redefine the manufacturing landscape. With a focus on precision, reliability, and longevity, the Cnc Aluminum Profile is set to elevate industrial operations to new levels of performance.Unmatched Precision:The Cnc Aluminum Profile boasts precision engineering that allows for highly accurate and intricate cutting, shaping, and machining operations. The profile’s advanced computer numerical control (CNC) mechanism ensures millimeter-level precision, reducing human error and minimizing wastage. With this exceptional precision, manufacturers will witness a significant improvement in product quality and consistency.Enhanced Durability:Manufacturers often face the challenge of keeping manufacturing equipment operational and efficient for extended periods. The Cnc Aluminum Profile addresses this concern with its construction using high-grade aluminum alloy, capable of withstanding high stress levels and continuous usage. This superior durability ensures extended equipment lifespan, reducing maintenance costs and downtime for businesses.Improved Efficiency:One of the key highlights of the Cnc Aluminum Profile is its ability to streamline and enhance manufacturing processes. With computer-controlled algorithms, this technology significantly reduces manual labor, resulting in improved operational efficiency and reduced time-to-market. The profile’s high-speed machining capability allows for faster production cycles, increasing productivity and overall output.Versatility Across Industries:The versatility of the Cnc Aluminum Profile makes it suitable for various industries ranging from automotive and aerospace to construction and consumer goods. The profile’s adaptability to different manufacturing requirements and specifications ensures it can be seamlessly integrated into existing production lines, facilitating smooth transitions without disrupting the manufacturing workflow.Sustainable Manufacturing:In addition to its significant advantages in productivity and quality, the Cnc Aluminum Profile embraces sustainability in manufacturing. The profile's energy-efficient design reduces power consumption and minimizes environmental impact. Additionally, the technology's precise material utilization minimizes waste, making it an eco-friendly solution to drive sustainable manufacturing practices globally.Implementation in Manufacturing Companies:Several prominent manufacturing companies have already begun integrating the Cnc Aluminum Profile into their production processes. Initial results have been overwhelmingly positive, demonstrating improved operational efficiency, higher product quality, and increased profitability. The successful implementation of this technology further underscores the potential benefits it can bring to companies across industries.Conclusion:The introduction of the Cnc Aluminum Profile represents a paradigm shift in the manufacturing sector. Its precision, durability, and efficiency make it a game-changing technology that promises to optimize production processes, increase output, and elevate product quality. With its versatility and adaptability, the Cnc Aluminum Profile is set to become an integral part of manufacturing operations worldwide, cementing its position as a catalyst for innovation and progress in the industrial landscape.

Sheet Metal Roll Forming Machine for Horizontal Barrel Corrugated Sheets News Update

Title: Revolutionary Horizontal Barrel Corrugated Sheet Roll Forming Machine Set to Transform the Metal Manufacturing IndustryIntroduction:In a bid to revolutionize the metal manufacturing industry, an innovative company has introduced the groundbreaking Horizontal Barrel Corrugated Sheet Roll Forming Machine. This cutting-edge technology promises to offer unprecedented efficiency and accuracy, thus reducing production time and costs. With its seamless design and state-of-the-art features, this ingenious machine is poised to redefine the future of metal forming processes.Developed by a renowned company specializing in advanced machinery, the Horizontal Barrel Corrugated Sheet Roll Forming Machine aims to address the limitations of traditional roll forming methodologies. By incorporating advanced technological advancements, this revolutionary equipment exhibits remarkable capabilities, translating into enhanced productivity for metal manufacturers.Features and Technical Advancements:The Horizontal Barrel Corrugated Sheet Roll Forming Machine boasts a myriad of impressive features that make it stand out in the industry. A few of these notable features include:1. Innovative Design: The machine incorporates a horizontal barrel configuration, allowing for easier feeding and achieving a more precise corrugated sheet formation. This unique design ensures flawless output with minimal material wastage.2. High-Speed Production: Equipped with cutting-edge control systems, this machine offers faster production speeds compared to conventional roll forming equipment. This increased efficiency translates into higher output volumes and reduced production timelines.3. Customization: The machine offers flexible settings, enabling manufacturers to easily adjust the dimensions, thickness, and corrugation patterns of the sheets according to their specific requirements. This adaptability ensures the production of tailor-made metal sheets for various applications.4. Enhanced Accuracy: The precision engineering of the machine ensures consistently accurate dimensions, resulting in high-quality corrugated sheets that meet industry standards. This accuracy minimizes the need for additional processing or rectification, further streamlining the manufacturing process.Implications for the Metal Manufacturing Industry:The introduction of the Horizontal Barrel Corrugated Sheet Roll Forming Machine is set to have far-reaching implications for the metal manufacturing industry. Its numerous advantages and technical advancements hold significant potential to transform the way metal sheets are produced, offering benefits such as:1. Increased Efficiency and Cost Savings: The machine's faster production speeds and reduced material wastage significantly improve overall manufacturing efficiency. This, in turn, leads to substantial cost savings for metal manufacturers, making them more competitive in the market.2. Streamlined Supply Chain: The machine's customization capabilities enable manufacturers to swiftly adjust production parameters, resulting in shorter lead times and quicker response to customer demands. This streamlined supply chain ensures better customer satisfaction and increased market competitiveness.3. Improved Product Quality: With its heightened accuracy and precision, the Horizontal Barrel Corrugated Sheet Roll Forming Machine eliminates variations and defects often encountered in traditional manufacturing processes. The production of consistently high-quality metal sheets enhances product reliability and durability.4. Sustainability and Resource Optimization: The reduced material wastage, achieved through the machine's seamless design and precision engineering, significantly contributes to environmental sustainability. By optimizing resource utilization, metal manufacturing companies can significantly reduce their carbon footprint.Conclusion:The introduction of the Horizontal Barrel Corrugated Sheet Roll Forming Machine marks a significant milestone in the evolution of the metal manufacturing industry. With its innovative design, advanced features, and multiple benefits such as increased efficiency, reduced costs, and improved product quality, this revolutionary machine is set to redefine the future of metal forming processes. As more companies adopt this cutting-edge technology, the industry can expect to witness enhanced productivity, sustainability, and competitiveness.

High-Quality Glazed Tile Forming Machine: A Complete Guide

Color Steel Glazed Tile Forming Machine: Revolutionizing the Roofing IndustryIn recent years, there has been a growing demand for durable, high-quality roofing materials that are not only aesthetically pleasing but also offer superior protection against the elements. In response to this demand, the Color Steel Glazed Tile Forming Machine has emerged as a game-changer in the roofing industry, revolutionizing the way roofing materials are manufactured and installed.The Color Steel Glazed Tile Forming Machine, developed by [Company Name], is a state-of-the-art piece of equipment that is designed to produce color steel glazed tiles with precision and efficiency. These tiles, also known as glazed roofing tiles, are made from high-quality color steel and are coated with a layer of glaze that not only enhances their appearance but also provides an added layer of protection against corrosion, UV radiation, and extreme weather conditions.One of the key advantages of the Color Steel Glazed Tile Forming Machine is its ability to produce tiles of various shapes, sizes, and colors, allowing for a high degree of customization to meet the specific needs and preferences of customers. The machine is equipped with advanced technology and automated processes that ensure the consistent production of high-quality tiles while minimizing material wastage and production time.Furthermore, the Color Steel Glazed Tile Forming Machine is designed to be user-friendly and low-maintenance, making it suitable for use in a wide range of manufacturing settings, from small-scale roofing material production facilities to large-scale industrial operations. Its versatility and efficiency have made it an attractive investment for businesses looking to modernize their roofing material manufacturing processes and improve their overall product quality.[Company Name] has built a solid reputation as a leading manufacturer and supplier of innovative machinery for the construction and building materials industry. With a commitment to research and development, as well as a focus on customer satisfaction, the company has continuously pushed the boundaries of technological innovation to develop products that meet the evolving needs of the market.The Color Steel Glazed Tile Forming Machine is a testament to [Company Name]'s dedication to excellence and its ability to provide cutting-edge solutions that drive progress in the industry. By offering a reliable and efficient way to produce high-quality color steel glazed tiles, the machine has become a valuable asset for businesses seeking to meet the growing demand for durable and visually appealing roofing materials.The impact of the Color Steel Glazed Tile Forming Machine extends beyond the manufacturing process, as its use has also led to significant improvements in the overall quality and performance of glazed roofing tiles. These tiles have become increasingly popular among homeowners, architects, and builders due to their exceptional durability, resistance to fading, and ability to enhance the visual appeal of any structure.As the construction industry continues to evolve, the demand for roofing materials that offer both form and function will only continue to grow. With the Color Steel Glazed Tile Forming Machine, [Company Name] has positioned itself at the forefront of this trend, providing businesses with the tools they need to stay ahead of the competition and meet the expectations of an increasingly discerning market.In conclusion, the Color Steel Glazed Tile Forming Machine represents a significant advancement in the roofing industry, offering a reliable, efficient, and cost-effective solution for the production of high-quality color steel glazed tiles. With its cutting-edge technology and user-friendly design, the machine has transformed the way roofing materials are manufactured and has set a new standard for excellence in the industry. As the demand for durable and visually appealing roofing materials continues to grow, the Color Steel Glazed Tile Forming Machine is poised to play a pivotal role in shaping the future of the industry.

Advanced Glazed Roof Tile Making Machine Equipment for Colored Cold Steel

Colored Cold Steel Glazed Roof Tile Making Machine Equipment Revolutionizes Roofing IndustryThe roofing industry has witnessed a significant transformation with the introduction of the Colored Cold Steel Glazed Roof Tile Making Machine Equipment. This innovative technology, developed by \textit{(company name)}, is set to revolutionize the way roofs are manufactured, installed, and maintained.Traditional roofing materials and methods have been prone to various issues such as leaks, corrosion, and limited design options. However, the Colored Cold Steel Glazed Roof Tile Making Machine Equipment overcomes these challenges with its cutting-edge features and advanced manufacturing process.One of the key advantages of this equipment is its ability to produce colored cold steel glazed roof tiles. These tiles not only provide superior protection against the elements but also enhance the aesthetic appeal of any building. With a wide range of colors and finishes available, architects and homeowners can now have greater flexibility in choosing the perfect roof design to complement their overall building aesthetics.The manufacturing process of these tiles involves the use of high-quality cold steel, which ensures their durability and longevity. Unlike traditional roofing materials, such as asphalt shingles or clay tiles, the glazed roof tiles produced by this equipment are resistant to cracking, fading, and warping. This greatly reduces maintenance costs and extends the lifespan of the roof, making it a more cost-effective and sustainable option in the long run.Furthermore, the Colored Cold Steel Glazed Roof Tile Making Machine Equipment is designed to streamline the installation process. Its automated features and precision engineering allow for quick and efficient assembly, minimizing labor costs and reducing the time required for roof installation. This is especially beneficial for large-scale roofing projects or areas with tight deadlines.In addition to its manufacturing and installation advantages, this equipment also offers significant environmental benefits. The use of cold steel, a recyclable material, reduces the carbon footprint associated with traditional roofing materials. Moreover, the glazed tiles reflect solar radiation, helping to lower energy consumption for cooling and reduce greenhouse gas emissions.\textit{(Company name)} is a leading innovator in the roofing industry, dedicated to providing high-quality and sustainable solutions. With years of expertise and research, they have developed the Colored Cold Steel Glazed Roof Tile Making Machine Equipment as a testament to their commitment to excellence. By combining advanced technology and superior materials, \textit{(company name)} continues to shape the future of the roofing industry.As the demand for environmentally friendly and aesthetically appealing roofing options rises, the Colored Cold Steel Glazed Roof Tile Making Machine Equipment is set to transform the market. Architects, contractors, and homeowners can now have access to a versatile and reliable roofing solution that combines durability, energy efficiency, and design possibilities like never before.With its numerous benefits and impeccable quality, the Colored Cold Steel Glazed Roof Tile Making Machine Equipment is already garnering attention from industry experts, who believe it will become the new standard in roofing. This revolutionary technology is paving the way for a more sustainable and visually appealing built environment.In conclusion, the introduction of the Colored Cold Steel Glazed Roof Tile Making Machine Equipment by \textit{(company name)} marks a significant milestone in the roofing industry. Its ability to produce durable, aesthetically pleasing, and energy-efficient roof tiles has revolutionized the way roofs are manufactured and installed. With a strong focus on sustainability and superior quality, \textit{(company name)} continues to drive innovation and raise industry standards.

Innovative Roll Making Machine for Improved Production Efficiency

Roll making machine is an important piece of equipment in the manufacturing industry. It is used to produce various types of rolls that are essential in the production of a wide range of products, including paper, plastic, textiles, and metal sheets.One company that has been leading the way in the development and production of roll making machines is {}. With over 20 years of experience in the industry, they have become a trusted name in the market and have earned a reputation for delivering high-quality, reliable, and efficient machines.The roll making machines produced by {} are known for their advanced technology, precision engineering, and durable construction. They are designed to meet the specific needs of each customer and are customizable to ensure that they can handle a wide range of roll making applications.One of the key features of {}'s roll making machines is their versatility. They are capable of producing different types of rolls, including embossed, perforated, and laminated rolls, and can accommodate various materials, such as paper, plastic, and metal. This versatility makes them ideal for manufacturers who need a single machine to handle multiple roll making processes.Another important aspect of {}'s roll making machines is their efficiency. They are designed to optimize the production process, with features such as quick changeover capabilities, automatic tension control, and advanced monitoring systems. This ensures that the machines can produce high-quality rolls with minimal downtime, helping manufacturers to increase their productivity and reduce their operating costs.In addition to their advanced technology and efficiency, {}'s roll making machines are also known for their reliability. They are built to withstand the demands of continuous operation and are equipped with robust components and high-quality materials to ensure long-term performance and durability.Furthermore, {} offers comprehensive customer support and after-sales service for their roll making machines. Their team of experienced engineers and technicians is available to provide installation, training, maintenance, and troubleshooting services, ensuring that their customers can get the most out of their machines and minimize any potential downtime.With a commitment to continuous innovation and improvement, {} is constantly developing new technologies and refining their roll making machines to meet the evolving needs of the industry. Their dedication to excellence has earned them a loyal customer base and has positioned them as a leader in the roll making machine market.As the demand for high-quality rolls continues to grow across various industries, the roll making machines produced by {} are poised to play a crucial role in helping manufacturers meet this demand. With their advanced technology, efficiency, reliability, and comprehensive support, {}'s roll making machines are a valuable asset for any company looking to enhance their roll production capabilities.In conclusion, the roll making machines produced by {} are a testament to the company's commitment to innovation, quality, and customer satisfaction. With their advanced technology, efficiency, and reliability, these machines are a valuable asset for manufacturers in various industries and are helping to drive the production of high-quality rolls around the world.

Understanding the Significance and Benefits of C Purlins in Modern Construction

Title: Innovative C Purlins Revolutionize Construction Industry: A Game-Changing Solution by [Company Name]Introduction:[Company Name] has made a significant breakthrough in the construction industry with their revolutionary C Purlins. By combining cutting-edge technology and expertise, [Company Name] is transforming the way builders construct roofs, walls, and other infrastructure support systems. These innovative C Purlins have garnered substantial attention due to their superior strength, durability, and versatility, making them an invaluable addition to modern architectural projects. [Company Name]'s C Purlins - A Testament to Innovation: With a profound dedication to innovation, [Company Name] has engineered C Purlins that offer unmatched structural integrity while also adhering to stringent quality standards. These purlins are manufactured using high-quality galvanized steel, ensuring maximum durability and resistance against corrosion and other environmental factors.Strength and Stability:The C Purlins by [Company Name] have been optimized for strength and stability, making them ideal for modern construction practices. These purlins are designed to withstand heavy loads, making them suitable for a wide range of applications, such as industrial buildings, shopping centers, warehouses, and residential properties. Builders can trust these purlins to provide reliable structural support, ensuring long-lasting and safe infrastructure.Versatility and Flexibility:One of the distinctive features of [Company Name]'s C Purlins is their exceptional versatility and flexibility. Designed to accommodate diverse architectural requirements, these purlins can be easily customized to fit specific project needs. Whether it's adapting to unique geometries or incorporating multi-level support systems, [Company Name]'s C Purlins offer freedom of design, enabling architects and engineers to bring their visions to life.Ease of Installation:[Company Name] understands the importance of time efficiency in the construction industry. To cater to this need, they have simplified the installation process, making it easier for contractors and builders to work with their C Purlins. Their lightweight design and pre-punched holes facilitate quick and hassle-free installation, ensuring reduced labor costs and accelerated project timelines.Sustainable Solution:Recognizing the environmental impact of construction materials, [Company Name] has taken a significant step towards creating a sustainable future. Their C Purlins are made from recyclable materials, reducing the carbon footprint associated with infrastructure development. By adopting these environmentally-friendly purlins, builders can contribute to the preservation of our planet while also meeting their construction needs.Commitment to Quality:[Company Name] values impeccable quality, and this ethos is reflected in their C Purlins. The manufacturing process adheres to rigorous quality control measures, ensuring each purlin meets or exceeds industry standards. Builders and contractors can trust in the reliability, durability, and longevity of [Company Name]'s C Purlins, ensuring projects are built to last.Future Prospects:With their game-changing C Purlins, [Company Name] is set to disrupt the construction industry. As architects and engineers increasingly recognize the benefits of these purlins, the demand is expected to skyrocket. The company's relentless pursuit of innovation and commitment to customer satisfaction positions [Company Name] as a key player in the industry, driving growth and advancements in construction methodologies.Conclusion:[Company Name]'s C Purlins have taken the construction industry by storm, redefining structural support systems and setting new standards for strength, durability, and versatility. These purlins offer architects and builders a sustainable and efficient solution that meets their diverse project requirements. With their cutting-edge technology and unwavering commitment to quality, [Company Name] has firmly established itself as a leading provider of innovative construction products. The future of the construction industry has arrived with [Company Name]'s groundbreaking C Purlins.

Discover the Latest Innovation in Glazed Steel Roofing Tile Roll Former!

Glazed Steel Roofing Tile Roll Former Takes the Market with Impressive FeaturesThe roofing industry is always in need of new technologies to improve the performance and longevity of roofing materials. The glazed steel roofing tile roll former machine seems to be the answer to this demand. The equipment has impressed many clients with its features and the quality of the final roofing tiles it produces.The machine is designed to roll-form steel or aluminum coils into glazed roofing tiles of various colors and profiles. It uses a patented technology for crafting the tiles, which involves a series of steps such as steel decoiling, feeding, molding, pressing, cutting, and shearing. The result is perfectly shaped roofing tiles, ready for installation on site.One of the advantages of the glazed steel roofing tile roll former is its speed. The equipment can produce up to 20 meters of roofing tiles per minute, which means the production line can output over 1,000 square meters of roofing tiles per hour. This speed is a significant improvement over traditional roofing tile production methods, which rely on manual labor.Another feature that differentiates this machine from other roll-formers is its precision. The glazed steel roofing tile roll former uses advanced servo systems and automatic controls to ensure the accuracy and consistency of the roofing tiles. The machine is also equipped with a touch screen interface that allows operators to monitor the production process and make adjustments as needed.The glazed steel roofing tile roll former is also versatile. It can produce an array of roofing tile profiles that cater to different architectural styles and preferences. The machine can manufacture tiles that replicate the look of natural materials such as slate, tile, or wood without compromising their durability and resistance to weathering.Moreover, this equipment is easy to operate and maintain. The machine has a quick-change system that enables operators to switch between different tile profiles and colors easily. It also has a self-lubrication system that reduces the need for manual lubrication. Additionally, the machine's structure is made of high-quality materials that ensure its longevity and durability.The success story of the glazed steel roofing tile roll former would not be complete without mentioning the company behind it. The manufacturer, a Chinese enterprise with over a decade of experience in the production of roll-forming equipment, has invested in research and development to create innovative solutions for the roofing industry.The company, which stands out for its commitment to quality and customer service, has a team of experts that oversees the entire production process and ensures the final product meets the required standards. It also provides after-sales service to its clients to ensure their satisfaction and the optimal performance of the machine.In conclusion, the glazed steel roofing tile roll former is a modern and efficient solution for the roofing industry's needs. Its features, such as speed, precision, versatility, ease of use, and durability, make it a valuable investment for anyone in the business of producing roofing tiles. Combined with the manufacturer's expertise and commitment to quality, this machine's success in the market is not by chance.

Rent a Wood Deck Sanding Machine for Your Next Project

Wood Deck Sanding Machine Rental Available for Homeowners and ContractorsFor homeowners and contractors looking to restore the beauty of their wooden decks, {Company Name} is now offering wood deck sanding machine rentals. With these rentals, individuals can easily sand and refinish their decks, saving time and money compared to hiring professional services.{Company Name} is a leading provider of rental equipment for construction, industrial, and residential projects. With a wide range of equipment available, {Company Name} aims to make it convenient for individuals to access the tools they need for their projects without having to make a significant investment in purchasing new equipment.The wood deck sanding machine rental is a valuable addition to {Company Name}'s rental offerings, as it allows homeowners and contractors to tackle deck refinishing projects with ease. Whether it's removing old paint, sanding down rough surfaces, or preparing the deck for a fresh coat of stain or sealant, the rental machine provides the power and efficiency needed to achieve professional results."We understand the challenges that homeowners and contractors face when it comes to maintaining and restoring wooden decks. Our goal is to provide access to high-quality equipment that can make these tasks more manageable and cost-effective," said [Spokesperson], [Title] at {Company Name}. "Our wood deck sanding machine rental is designed to help individuals achieve the results they desire without having to invest in expensive equipment or hire professional services."The wood deck sanding machine available for rent is a [Brand Name] model, known for its reliability and performance in sanding and refinishing applications. The machine features a powerful motor and a durable sanding drum that can effectively smooth out uneven surfaces, remove old coatings, and prepare the wood for refinishing. Additionally, the machine is designed for ease of use, with adjustable settings that allow users to customize the sanding process to their specific needs.In addition to providing the rental machine, {Company Name} also offers guidance and support to individuals who may be new to deck refinishing. The team is available to provide instructions on operating the machine, as well as tips for achieving the best results. This added support ensures that renters can approach their deck refinishing projects with confidence, knowing that they have access to the resources they need to succeed."Renting equipment from {Company Name} is more than just getting access to the tools. It's about gaining the knowledge and support to use the equipment effectively. We want our customers to feel empowered to take on their projects and achieve professional-quality results," [Spokesperson] added.With the availability of the wood deck sanding machine rental, homeowners can take on DIY refinishing projects at their own pace, avoiding the costs and potential scheduling constraints of hiring professional services. Contractors, on the other hand, can expand their range of services by offering deck refinishing without having to invest in additional equipment.The convenience of having access to a reliable wood deck sanding machine rental has already attracted attention from both individual homeowners and contractors in the area. Many have taken advantage of the rental option to achieve the results they desire for their wooden decks, while appreciating the cost savings and flexibility that come with renting equipment.As the demand for DIY home improvement projects continues to grow, {Company Name} remains committed to providing a wide range of rental equipment that can support the needs of homeowners and contractors alike. With the addition of the wood deck sanding machine rental, individuals can now confidently take on deck refinishing projects, knowing that they have the backing of a reputable rental company.For those interested in renting the wood deck sanding machine or exploring other rental options, {Company Name} encourages individuals to contact their nearest location or visit their website for more information. With a straightforward rental process and a commitment to customer satisfaction, {Company Name} is poised to help individuals achieve their project goals effectively and affordably.

High-Quality Cable Tray Roll Forming Machine from Leading Manufacturers & Suppliers in China

Title: Cable Tray Roll Forming Machines: Supporting Efficient Cable Management SolutionsIntroduction:In the field of cable management solutions, Cable Tray Roll Forming Machines have emerged as a vital component for industries across the globe. Catering to the growing demand for reliable cable tray systems, manufacturers in China are producing high-quality Cable Tray Roll Forming Machines. This blog will delve into the significance, benefits, and features of these machines while highlighting the wide range of choices available for businesses.Cable Tray Roll Forming Machines: Essential Equipment for Efficient Cable ManagementEfficient cable management plays a crucial role in ensuring uninterrupted power supply, reducing downtime, and enhancing safety in industrial settings. Cable trays have become an indispensable solution, providing ample support for organizing and protecting various cables within factories, commercial buildings, and other infrastructure projects. To meet the escalating demand for cable trays, Cable Tray Roll Forming Machines have become essential tools for manufacturers.Why Opt for Cable Tray Roll Forming Machines?1. High-Quality Production: Cable Tray Roll Forming Machines manufactured in China guarantee high-quality results due to their advanced technology and manufacturing processes. These machines are designed to produce cable trays of consistent dimensions, sturdiness, and durability, ensuring reliable cable management solutions.2. Wide Range of Choices: The Chinese Cable Tray Roll Forming Machine market offers a diverse range of options to suit different construction and cable management requirements. From small-scale units to large-scale production lines, manufacturers cater to the varying needs of different industries.3. Automation and Efficiency: Cable Tray Roll Forming Machines incorporate advanced features, such as automated operations, precise control systems, and high-speed production capabilities. The automation not only enhances efficiency but also reduces manual labor, leading to cost savings and improved productivity.4. Customization Possibilities: Businesses can avail themselves of customizable options while selecting a suitable Cable Tray Roll Forming Machine. Manufacturers in China offer flexibility in terms of tray size, material thickness, and design, enabling companies to meet specific project or industry requirements.5. Quality Assurance: Chinese manufacturers adhere to international quality standards and certifications to ensure the reliability and durability of Cable Tray Roll Forming Machines. This dedication to quality helps businesses instill confidence in their investments and delivers consistent, high-performing machines.Key Features of Cable Tray Roll Forming Machines:1. Material Flexibility: Cable Tray Roll Forming Machines can manufacture trays from a variety of materials, including mild steel, galvanized steel, and stainless steel. The ability to work with different materials provides businesses with versatility to cater to varied project specifications and budgets.2. Speed and Accuracy: With the use of advanced technology and precision engineering, Cable Tray Roll Forming Machines can produce trays at high speeds with exceptional accuracy. The consistent dimensions, hole punching, and edge profiling are achieved swiftly and efficiently, meeting production targets effectively.3. Ease of Operation: These machines are designed for ease of use, offering user-friendly interfaces and controls. Operators require minimal training to operate, program, and maintain the Cable Tray Roll Forming Machines, ensuring maximum uptime and productivity.Conclusion:China-based manufacturers have solidified their position as reliable and quality-conscious suppliers of Cable Tray Roll Forming Machines. These machines not only enable businesses to produce cable trays efficiently but also cater to diverse project needs through customization possibilities. The use of advanced technology, automation, and adherence to stringent quality standards ensures these machines will continue to play a crucial role in meeting global cable management requirements.Keywords: Cable Tray Forming Machine, Cable Tray Roll Forming Machine, Cable Tray Roll Forming Machine China, Cable Tray Roll Forming Machine Manufacturer, Cable Tray Roll Forming Machine Suppliers, Cable Tray Roll Forming Machine Factory, Cable Tray Roll Forming Machine Exporters, efficient cable management, high-quality production, wide range of choices, automation, customization possibilities, material flexibility, speed and accuracy, ease of operation.