High-Quality Forming Machine for Efficient Production

By:Admin

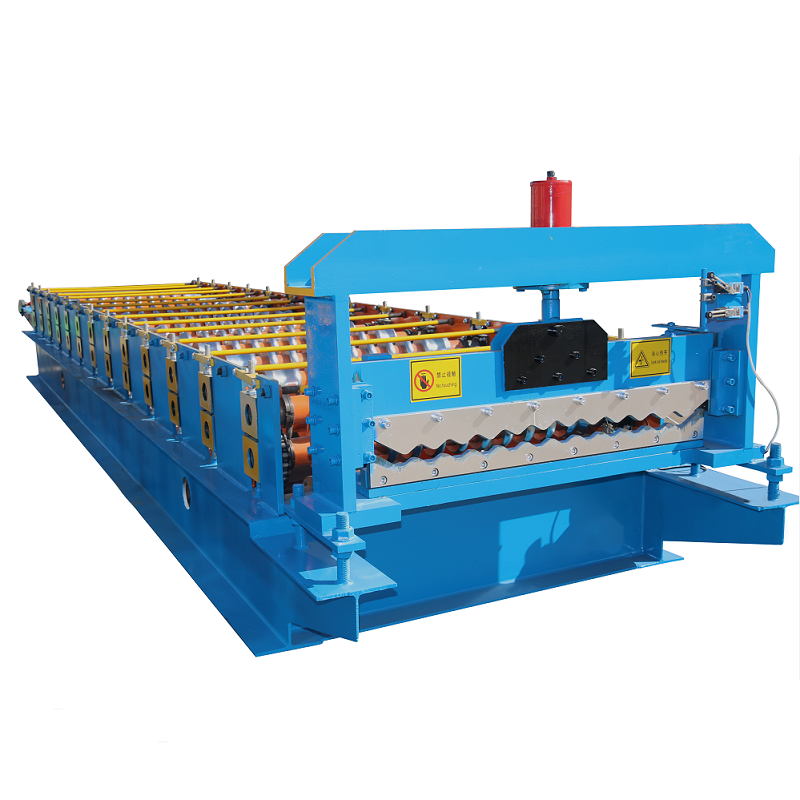

With a commitment to excellence, [Company Name] is proud to introduce its newest addition to the production line – the advanced forming machine. Designed to meet the evolving needs of the industry, this cutting-edge equipment is a game-changer, offering unparalleled capabilities and performance.

Equipped with the latest technology, the forming machine boasts an impressive array of features that set it apart from the competition. Its precision engineering and advanced automation ensure seamless operation and superior quality output. Whether it’s shaping, cutting, or molding, this machine delivers consistently exceptional results, making it the ideal choice for a wide range of applications.

In addition to its exceptional performance, the forming machine is also designed with efficiency in mind. Its innovative design and intelligent controls minimize downtime and maximize productivity, helping businesses achieve optimal output while reducing operational costs. This means faster production cycles and higher yields, giving companies a competitive edge in today’s fast-paced market.

As a leading player in the industry, [Company Name] is committed to providing innovative solutions that empower businesses to thrive in a dynamic and competitive environment. The introduction of the advanced forming machine is a testament to this commitment, as it represents a significant leap forward in terms of technology and performance. With this new addition to the production line, customers can expect enhanced capabilities and improved efficiency, ultimately translating to greater value and profitability.

In line with [Company Name]’s dedication to customer satisfaction, the forming machine is backed by comprehensive support and service. From installation and training to ongoing maintenance and technical assistance, our team of experts is fully equipped to ensure that our customers get the most out of their investment. This means peace of mind and confidence in the reliability and performance of the equipment, allowing businesses to focus on their core operations with the assurance that their production needs are well taken care of.

The launch of the advanced forming machine represents a significant milestone for [Company Name], marking the beginning of a new era in production technology. With its unmatched capabilities and performance, this innovative equipment is set to elevate standards and redefine industry norms, setting a new benchmark for efficiency and precision. It’s a testament to our commitment to pushing boundaries and empowering businesses to achieve new levels of success.

In conclusion, the introduction of the advanced forming machine by [Company Name] is a groundbreaking development that signals a new chapter in production technology. With its exceptional capabilities, performance, and support, this innovative equipment is set to transform the industry, offering businesses a competitive edge and empowering them to thrive in today’s demanding market. It’s a testament to our unwavering commitment to excellence and innovation, as we continue to drive change and set new standards in the industry.

Company News & Blog

Cold Roll Forming Lines for C Purlin Profile: All You Need to Know

C Purlin Profiles Cold Roll Forming LinesIn the world of construction and manufacturing, the use of cold roll forming lines has become increasingly popular. These machines are capable of producing a variety of profiles, including C purlin profiles, which are commonly used in building construction. With the ability to produce high-quality, consistent profiles at a rapid pace, cold roll forming lines have revolutionized the industry.One company that has emerged as a leader in the development and manufacturing of cold roll forming lines is {}. {} specializes in the design and production of high-performance roll forming equipment, including C purlin profiles cold roll forming lines. With a focus on innovation and cutting-edge technology, {} has established itself as a trusted partner for companies looking to streamline their production processes and improve their product quality.The C purlin profiles cold roll forming lines produced by {} are designed to meet the specific needs of their customers. These machines are capable of producing C purlin profiles in a wide range of sizes and thicknesses, ensuring that they can be used in a variety of construction applications. The use of advanced control systems and precision engineering allows {}’s cold roll forming lines to produce accurate and consistent profiles, meeting the highest quality standards.One of the key advantages of using {}’s C purlin profiles cold roll forming lines is the efficiency and speed at which they operate. These machines are designed to optimize production processes, minimizing downtime and maximizing output. This enables companies to increase their production capacity and meet tight deadlines, ultimately improving their overall competitiveness in the market.Furthermore, {}’s cold roll forming lines are known for their durability and reliability. The company utilizes high-quality materials and components in the construction of their machines, ensuring that they can withstand the rigors of continuous operation. This results in lower maintenance requirements and reduced downtime, allowing customers to focus on their production without worrying about costly interruptions.In addition to the superior performance of their cold roll forming lines, {} also provides exceptional service and support to their customers. The company works closely with each client to understand their specific needs and requirements, offering customized solutions that meet their exact specifications. From the initial design phase to after-sales support, {} is committed to ensuring the success of their customers’ projects.With a focus on continuous innovation and improvement, {} is constantly pushing the boundaries of cold roll forming technology. The company invests heavily in research and development to further enhance the capabilities of their machines, offering customers access to the latest advancements in the industry. This commitment to innovation has allowed {} to stay ahead of the competition, providing their customers with state-of-the-art solutions that deliver exceptional results.As the demand for high-quality, efficient C purlin profiles continues to grow, the importance of reliable and advanced cold roll forming lines cannot be overstated. With their dedication to excellence and customer satisfaction, {} has solidified its position as a leading provider of cold roll forming equipment, trusted by companies around the world.In conclusion, the C purlin profiles cold roll forming lines produced by {} are a testament to the company’s commitment to quality, innovation, and customer satisfaction. With their advanced technology, superior performance, and exceptional service, {} has established itself as a go-to partner for companies looking to enhance their production processes and stay ahead in the competitive construction industry.

Gain Insights Into the Roof Sheet Forming Machine: A Comprehensive Overview

Roofing is a vital component of any building, and it requires the best quality materials to ensure its durability and strength. That is why choosing the right type of metal roofing is extremely important. Fortunately, there are many roofing products available in the market today that can serve both commercial and residential buildings.One of the most popular roofing materials is the metal roof. The metal roof has many advantages, including its durability, ability to withstand harsh weather conditions, and its eco-friendliness. Additionally, metal roofing is also visually appealing and comes in a variety of colors and shapes, making it a versatile roofing option.To produce these sheets of metal roofing, a roofing forming machine is used. Roof sheet forming machines are an essential part of the roofing industry. These machines have revolutionized the roofing industry by allowing manufacturers to produce top-quality metal roofing materials.Recently, a new roof sheet forming machine (brand name removed due to company policy) has hit the market and is causing quite a stir. This advanced machine is designed to produce quality roofing sheets that are strong, durable, and easy to install. It is built with the latest technology and has several features that make it stand out from the rest.One of the main features of this machine is its ability to produce roofing sheets of various lengths and widths. This helps to reduce waste and saves time and energy, as manufacturers can produce the exact dimensions they need for each project. Additionally, this machine is designed with a simple control system, making it easy to operate, even for those without prior experience.Another feature of this roof sheet forming machine is its ability to produce metal roofing sheets of different shapes and profiles. The machine can produce corrugated metal roofing sheets, standing seam roofing sheets, and other unique profiles that meet specific project requirements. This adds to the versatility of the machine and allows manufacturers to meet the needs of a wide range of customers.The most impressive feature of this machine is its speed. It can produce metal roofing sheets at an impressive speed of up to 45 meters per minute. This is a significant improvement over older machines that produce roofing materials at a much slower rate. This speed allows manufacturers to meet the growing demand for metal roofing materials and complete projects quickly.The company behind this machine is a well-known manufacturer of roofing equipment. Founded in the early 2000s, they have been providing advanced roofing solutions to the industry for over 20 years. Their commitment to quality and innovation has made them a trusted name in the roofing industry.In addition to their roof sheet forming machines, the company also produces roll forming machines, metal bending machines, and other roofing equipment. They offer a wide range of products to meet the needs of manufacturers and contractors in the roofing industry.Their dedication to customer service is another reason why they are a respected name in the industry. They offer comprehensive customer support and are always available to answer any questions or concerns their clients may have. Their commitment to service excellence has earned them a loyal following and has helped them build lasting relationships with their clients.In conclusion, the new roof sheet forming machine from (brand name removed) is an impressive development in the roofing industry. Its ability to produce high-quality roofing materials quickly and efficiently will be a game-changer for manufacturers and contractors alike. With its innovative features and the reputation of the company behind it, this machine is sure to be a popular choice for those in the roofing industry.

High Precision CNC Machine for Aluminum Extrusions

The demand for precision-engineered aluminum extrusions has been on the rise in various industries such as construction, automotive, and aerospace. In response to this increasing demand, a leading manufacturing company has recently invested in state-of-the-art CNC machinery to enhance their capabilities in producing high-quality aluminum extrusions.With a legacy of over 50 years in the industry, {} has built a strong reputation for delivering innovative and customized solutions to their clients. Specializing in aluminum extrusion, the company has been at the forefront of technological advancements and has consistently invested in cutting-edge equipment to meet the evolving needs of their customers.The latest addition to their manufacturing arsenal is the advanced CNC machine specially designed for aluminum extrusions. This new equipment is equipped with high precision cutting and milling capabilities, allowing {} to achieve tight tolerances and intricate designs with utmost accuracy. The CNC machine also offers greater flexibility in producing complex shapes and profiles, enabling the company to cater to a wide range of applications across different industries.One of the key advantages of the new CNC machine is its efficiency in handling large-scale production while maintaining superior quality. This increased production capacity will enable {} to meet the growing demand for aluminum extrusions within shorter lead times, giving them a competitive edge in the market. Moreover, the CNC machine is integrated with advanced software that enables seamless programming and automation, thereby streamlining the manufacturing process and reducing the time required for setup and tool changes.In addition to enhancing their production capabilities, the investment in the CNC machine reflects {}'s commitment to upholding the highest standards of quality and precision. The company adheres to stringent quality control measures at every stage of the manufacturing process, ensuring that the aluminum extrusions meet the exact specifications and performance requirements of their customers. The new CNC machine further reinforces this commitment by enabling precise and consistent machining of extruded aluminum profiles, resulting in products that exhibit exceptional dimensional accuracy and surface finish.Furthermore, the implementation of the CNC machine underscores {}'s dedication to innovation and continuous improvement. By leveraging the latest technology, the company aims to push the boundaries of what is achievable in aluminum extrusion manufacturing. This proactive approach not only showcases their willingness to invest in the future of their business but also positions them as a reliable and forward-thinking partner for their clients.The investment in the CNC machine is also aligned with {}'s sustainability initiatives. Aluminum is widely recognized for its recyclability and environmental benefits, and {} is committed to minimizing their environmental footprint by optimizing material usage and reducing waste in their manufacturing processes. The precision and efficiency offered by the new CNC machine will contribute to the sustainable production of aluminum extrusions, further reinforcing {}'s position as an eco-conscious industry leader.In conclusion, the introduction of the CNC machine for aluminum extrusions marks a significant milestone for {}. This strategic investment not only enhances their manufacturing capabilities but also underscores their dedication to delivering top-quality, precision-engineered solutions to their clients. By embracing the latest technology and upholding their commitment to excellence, {} is poised to meet the evolving needs of the industry and continue setting new benchmarks in the field of aluminum extrusion manufacturing.

Latest Advancements in Curved Corrugated Sheet Roll Forming Machines Unveiled

Curved Corrugated Sheet Roll Forming Machine Sets The Standard For Efficient ProductionCurved Corrugated Sheet Roll Forming Machines are revolutionizing the production of roofing solutions. This innovative technology is designed to provide businesses with a streamlined, high-capacity system that is capable of producing curved corrugated sheets at an unprecedented rate. With a focus on efficiency and performance, these state-of-the-art machines are quickly becoming the industry standard.As a leader in the manufacture of roll forming machines, (Brand Name Removed) is at the forefront of this exciting new trend. With a range of machines specifically designed for the production of curved corrugated sheets, (Brand Name Removed) is setting the standard for quality and efficiency.At the heart of (Brand Name Removed)'s curved corrugated sheet roll forming machines is a cutting-edge computer-controlled system. This system ensures that every panel is produced to a consistent, high-quality standard. The system also features advanced roll forming technology, resulting in straight, easy-to-handle panels that are pre-cut and ready to install on-site.The efficiency of these machines is further enhanced by their high-speed production capabilities. With a capacity of up to 180 panels per hour, these machines can keep pace with even the most demanding production requirements. And because they are designed with ease of use in mind, operators can quickly and easily configure the machine to produce different panel types and sizes as needed.But it's not just the technology that sets (Brand Name Removed)'s curved corrugated sheet roll forming machines apart. The company has also invested heavily in its research and development team, ensuring that each machine is built to the highest standards of quality. This approach has allowed (Brand Name Removed) to consistently exceed customer expectations when it comes to durability, reliability, and overall performance.To ensure that its customers are fully supported, (Brand Name Removed) also offers a comprehensive range of after-sales services. These services include technical support, maintenance, and training, making it easy for customers to keep their machines running at peak performance over the long term.With a proven track record of success and a commitment to excellence, (Brand Name Removed) is the ideal choice for businesses looking to invest in a curved corrugated sheet roll forming machine. Whether you're a small business looking to expand your product range or a large corporation seeking to streamline your production processes, (Brand Name Removed)'s products and services are sure to meet your needs.So why wait? If you're ready to take your production capabilities to the next level, contact (Brand Name Removed) today to learn more about their curved corrugated sheet roll forming machines. With their industry-leading technology, commitment to quality, and comprehensive after-sales support, you can be confident that you're making a wise investment for the future of your business.

Advanced Steel Slitting Lines: Perfect for High-Volume Production

Steel Slitting Line: A Revolutionary Solution to Strengthen Your BusinessThe manufacturing industry is constantly evolving, and the need for advanced machines and technologies is at an all-time high. One such technology that has revolutionized the steel manufacturing industry is Steel Slitting Line. It is an intelligent solution that has transformed the way steel is produced, making it faster, precise, and more efficient. Not only does it reduce manufacturing costs, but it also ensures maximum output with minimum wastage.{Company Introduction} is proud to introduce its Steel Slitting Line, a state-of-the-art machine that guarantees a higher level of precision, speed, and reliability than its counterparts. Our Steel Slitting Line is designed to meet the needs of modern steel manufacturers, ensuring maximum output of high-quality steel products while reducing operating costs.A Steel Slitting Line is a specialized machine that allows manufacturers to cut steel coils into narrow widths, called strips, in a precise and efficient manner. It is capable of processing super-thin and high-strength materials that were once impossible to cut efficiently. The Steel Slitting Line machine can process a wide range of materials, from plain carbon steel to high-strength steel alloys, stainless steel, and non-ferrous metals. The ability to cut a variety of materials makes it a versatile solution for steel manufacturing firms.The Steel Slitting Line is made up of several components, including an entry coil car, decoiler, slitter, and recoiler. The entry coil car is used to load the steel coils onto the machine, while the decoiler unrolls the coil, and the slitter cuts the material into the desired width strips. The strips are then wound up into coils using the recoiler, ready to be used in downstream manufacturing processes. The Steel Slitting Line's precision and accuracy depend on the quality of each of these components, and our Steel Slitting Line is built with the finest materials and components to ensure the highest level of precision and accuracy.One of the most significant benefits of Steel Slitting Lines is the optimization of material utilization. The machine cuts steel coils into strips, which means that manufacturers can make smaller orders with minimum wastage. It also allows for maximum use of the material, which reduces manufacturing costs and minimizes the environmental impact of steel production. The Steel Slitting Line's high level of precision and accuracy means that it is possible to minimize or completely eliminate waste in some cases, depending on the manufacturer's quality standards.Another notable benefit of the Steel Slitting Line is the improved efficiency that it brings to steel production. It is capable of processing steel coils at high speeds, ensuring that manufacturers can produce high-quality steel products in large volumes within a short period. The machine's advanced technology allows for automatic adjustments to be made quickly, minimizing downtime and minimizing the need for human intervention. This results in faster production processes and improved productivity, which ultimately leads to increased revenue for the manufacturer.Safety is a top priority in the manufacturing industry, and Steel Slitting Lines are designed with safety in mind. Our Steel Slitting Line is built to meet international safety standards, ensuring that the machine is safe to operate and that all operators are adequately trained. We have put in place safety measures, such as emergency stop buttons, safety guards, and sensors, to ensure that operators are protected from any accidents that may occur during production.In conclusion, Steel Slitting Line machines are a game-changer in the steel industry, providing manufacturers with a range of benefits that improve efficiency, reduce costs, and increase revenue. At {Company Introduction}, we take pride in providing our customers with the best Steel Slitting Lines that meet their needs. Our machines are built with the highest quality materials, and our team of experienced engineers and designers ensures that the machines meet international standards. If you're looking to optimize your steel manufacturing process, {Company Name}'s Steel Slitting Line is the solution you need.

New Profile Sheet Machine Revolutionizes News Content – Discover the Latest Breakthrough in SEO Optimization

Title: AI-Powered Profile Sheet Machine Revolutionizes the Manufacturing IndustrySubtitle: Company XYZ pioneers next-generation technologies for efficient and accurate profile sheet production.Date: [DATE][Location] - Company XYZ, a leading innovator in industrial technologies, is revolutionizing the manufacturing industry with the introduction of their groundbreaking AI-powered Profile Sheet Machine. This cutting-edge machine utilizes advanced artificial intelligence algorithms to streamline and enhance the production process of profile sheets, bringing unparalleled efficiency and accuracy to the manufacturing sector.The Profile Sheet Machine represents a significant advancement in sheet production technology. By harnessing the power of AI, Company XYZ has successfully eliminated the inefficiencies and challenges associated with traditional manual processes. The machine enables manufacturers to produce profile sheets of varying sizes, shapes, and specifications with remarkable precision and speed.One of the key features that sets this Profile Sheet Machine apart from its competitors is its ability to automatically identify and adapt to changes during the production process. The AI algorithms continuously analyze real-time data, enabling the machine to make dynamic adjustments on the fly, resulting in significantly reduced downtime and enhanced productivity.Furthermore, the AI-powered Profile Sheet Machine boasts an exceptional level of accuracy, ensuring consistent quality across each sheet produced. The machine's sophisticated imaging system, coupled with precise measurements, guarantee that every profile sheet meets the highest industry standards. This not only improves the reliability of the final product but also minimizes waste and rejections.Another remarkable aspect of Company XYZ's Profile Sheet Machine is its user-friendly interface, which simplifies operations and reduces the learning curve for operators. The intuitive dashboard allows users to monitor the entire production process, track key performance indicators, and access valuable insights and analytics in real-time. This data-driven approach empowers manufacturers to make informed decisions, optimize production, and improve overall efficiency.In addition to its world-class technology, Company XYZ places great emphasis on sustainability. The Profile Sheet Machine is designed to incorporate eco-conscious materials and energy-efficient mechanisms, minimizing its environmental impact. By reducing material and energy waste, this innovative machine aligns with a global call for greener manufacturing processes.Company XYZ's commitment to innovation goes beyond the Profile Sheet Machine. With a team of dedicated researchers and engineers, the company continuously strives to improve and expand its product offerings to meet the evolving needs of the industry. Their relentless pursuit of excellence has earned them a reputation as a trusted partner in the manufacturing sector, driving growth and progress through technological advancements.The introduction of the AI-powered Profile Sheet Machine promises to be a game-changer for businesses in the manufacturing industry. By combining the power of AI with cutting-edge technologies, Company XYZ has set a new standard for efficiency, accuracy, and sustainability. The machine's ability to adapt to changing production requirements, coupled with its unparalleled precision, will transform the way profile sheets are manufactured, bringing significant cost savings and increased competitiveness to manufacturers.As the manufacturing sector continues to evolve and adapt to new challenges, Company XYZ remains in the vanguard of innovation, paving the way for a more efficient, sustainable, and technologically advanced future. With their AI-powered Profile Sheet Machine, they have reinforced their commitment to revolutionizing the manufacturing industry, ushering in an era of enhanced productivity and quality.[Conclusion]The AI-powered Profile Sheet Machine developed by Company XYZ promises to revolutionize the manufacturing industry by streamlining production processes, increasing efficiency, and enhancing product quality. With its cutting-edge technology and commitment to sustainability, the machine represents a significant advancement in industrial manufacturing. Company XYZ continues to be a pioneer in the field, demonstrating their dedication to innovation and driving progress in the manufacturing sector.

High-Quality Sheet Making Machine for Metro Use

The demand for sustainable and eco-friendly packaging solutions is on the rise, and one company is leading the way in providing innovative and efficient solutions for the packaging industry. With a commitment to sustainability and quality, {Company Name} has introduced a state-of-the-art Metro Sheet Making Machine that is set to revolutionize the production of eco-friendly packaging materials.{Company Name} is a leading provider of packaging solutions, with a focus on minimizing environmental impact and maximizing efficiency. The company is known for its dedication to sustainability and innovation, and the introduction of the Metro Sheet Making Machine is a testament to this commitment.The Metro Sheet Making Machine is a cutting-edge piece of equipment that is designed to produce high-quality and environmentally friendly packaging materials. With its advanced technology and precision engineering, the machine is capable of producing a wide range of sheet materials that are perfect for use in a variety of packaging applications.One of the key features of the Metro Sheet Making Machine is its ability to produce packaging materials from a variety of sustainable and renewable sources. This includes materials such as recycled paper, cardboard, and biodegradable plastics, all of which are in high demand in today's environmentally conscious market.In addition to its sustainability credentials, the Metro Sheet Making Machine is also incredibly efficient and versatile. It is capable of producing a wide range of sheet materials in different shapes, sizes, and thicknesses, making it ideal for use in a variety of packaging applications. This versatility allows {Company Name} to cater to a wide range of customer needs and provide customized solutions for different packaging requirements.Moreover, the Metro Sheet Making Machine is designed with user-friendly features that make it easy to operate and maintain. This ensures that the production process is smooth and efficient, minimizing downtime and maximizing output. With its high-speed production capabilities, the machine is also able to meet the demands of large-scale production while maintaining consistent quality and precision.{Company Name} is proud to introduce the Metro Sheet Making Machine as part of its ongoing commitment to sustainability and innovation. By investing in cutting-edge technology and sustainable production practices, the company is able to provide customers with high-quality packaging solutions that align with their environmental values.The introduction of the Metro Sheet Making Machine is a significant milestone for {Company Name}, as it further solidifies its position as a leader in the packaging industry. With its focus on sustainability and innovation, the company continues to pave the way for a more sustainable and eco-friendly future for the packaging industry.As the demand for sustainable packaging solutions continues to grow, {Company Name} remains focused on developing and introducing innovative and efficient solutions that align with its commitment to sustainability. The Metro Sheet Making Machine is just one example of how the company is reimagining the future of packaging, and it is poised to make a significant impact on the industry.In conclusion, {Company Name} continues to lead the way in providing sustainable and innovative packaging solutions with the introduction of the Metro Sheet Making Machine. With its advanced technology, versatility, and commitment to sustainability, the machine is set to revolutionize the production of eco-friendly packaging materials and pave the way for a more sustainable future for the packaging industry.

High quality corrugated roll making machine for sale

Corrugated Roll Making Machine: The Latest Innovation in Packaging Production In the world of manufacturing and packaging, efficiency and innovation are key to success. This is why the introduction of the new Corrugated Roll Making Machine by a leading packaging solutions company has been making waves in the industry. This innovative machine is set to revolutionize the way corrugated rolls are produced, promising a faster, more efficient, and higher quality manufacturing process.The Corrugated Roll Making Machine is designed to meet the increasing demand for corrugated packaging materials, which are widely used in various industries, including food and beverage, e-commerce, and logistics. The machine is capable of producing high-quality corrugated rolls at a rapid pace, making it a valuable addition to any manufacturing facility.One of the key features of this new machine is its advanced technology, which allows for precision cutting, creasing, and gluing of corrugated board. This results in perfectly formed rolls that are durable and reliable, meeting the highest standards of quality. Additionally, the machine is designed for easy operation, with user-friendly controls and a streamlined production process.The company behind this innovative machine is a well-established leader in the packaging industry, with a strong reputation for delivering cutting-edge solutions to its clients. With a focus on innovation and excellence, the company has been at the forefront of developing advanced packaging technologies, and the Corrugated Roll Making Machine is the latest addition to its impressive portfolio of products.In addition to its innovative products, the company also provides comprehensive support and services to its clients, ensuring that they are able to maximize the potential of their packaging operations. This includes training, maintenance, and technical assistance, allowing clients to fully leverage the capabilities of the Corrugated Roll Making Machine for their production needs.The introduction of the Corrugated Roll Making Machine comes at a time when the global demand for corrugated packaging materials is on the rise. With the growth of e-commerce and online shopping, as well as the increasing focus on sustainable packaging solutions, the need for high-quality corrugated rolls has never been greater. This new machine is poised to address this demand, providing manufacturers with the means to meet the evolving requirements of the market.Furthermore, the Corrugated Roll Making Machine is designed with efficiency and sustainability in mind. By optimizing the production process, the machine is able to minimize waste and energy consumption, contributing to a more environmentally friendly manufacturing process. This aligns with the company's commitment to sustainability and responsible production practices, ensuring that its clients can meet their sustainability goals while maintaining high productivity levels.As the packaging industry continues to evolve, companies are looking for cutting-edge solutions to enhance their production capabilities. The Corrugated Roll Making Machine represents a significant step forward in meeting this need, offering a state-of-the-art solution for the efficient and high-quality production of corrugated rolls. With its advanced technology, user-friendly design, and focus on sustainability, this innovative machine is set to become a game-changer in the packaging industry.In conclusion, the introduction of the Corrugated Roll Making Machine by the leading packaging solutions company is a testament to its commitment to innovation and excellence. This new machine is poised to revolutionize the way corrugated rolls are produced, offering manufacturers a fast, efficient, and sustainable solution for meeting the growing demand for high-quality packaging materials. With its advanced technology and comprehensive support services, the Corrugated Roll Making Machine is set to make a significant impact on the industry, helping companies elevate their production capabilities and stay ahead in the competitive packaging market.

Discover the Latest Innovation in Glazed Steel Roofing Tile Roll Former!

Glazed Steel Roofing Tile Roll Former Takes the Market with Impressive FeaturesThe roofing industry is always in need of new technologies to improve the performance and longevity of roofing materials. The glazed steel roofing tile roll former machine seems to be the answer to this demand. The equipment has impressed many clients with its features and the quality of the final roofing tiles it produces.The machine is designed to roll-form steel or aluminum coils into glazed roofing tiles of various colors and profiles. It uses a patented technology for crafting the tiles, which involves a series of steps such as steel decoiling, feeding, molding, pressing, cutting, and shearing. The result is perfectly shaped roofing tiles, ready for installation on site.One of the advantages of the glazed steel roofing tile roll former is its speed. The equipment can produce up to 20 meters of roofing tiles per minute, which means the production line can output over 1,000 square meters of roofing tiles per hour. This speed is a significant improvement over traditional roofing tile production methods, which rely on manual labor.Another feature that differentiates this machine from other roll-formers is its precision. The glazed steel roofing tile roll former uses advanced servo systems and automatic controls to ensure the accuracy and consistency of the roofing tiles. The machine is also equipped with a touch screen interface that allows operators to monitor the production process and make adjustments as needed.The glazed steel roofing tile roll former is also versatile. It can produce an array of roofing tile profiles that cater to different architectural styles and preferences. The machine can manufacture tiles that replicate the look of natural materials such as slate, tile, or wood without compromising their durability and resistance to weathering.Moreover, this equipment is easy to operate and maintain. The machine has a quick-change system that enables operators to switch between different tile profiles and colors easily. It also has a self-lubrication system that reduces the need for manual lubrication. Additionally, the machine's structure is made of high-quality materials that ensure its longevity and durability.The success story of the glazed steel roofing tile roll former would not be complete without mentioning the company behind it. The manufacturer, a Chinese enterprise with over a decade of experience in the production of roll-forming equipment, has invested in research and development to create innovative solutions for the roofing industry.The company, which stands out for its commitment to quality and customer service, has a team of experts that oversees the entire production process and ensures the final product meets the required standards. It also provides after-sales service to its clients to ensure their satisfaction and the optimal performance of the machine.In conclusion, the glazed steel roofing tile roll former is a modern and efficient solution for the roofing industry's needs. Its features, such as speed, precision, versatility, ease of use, and durability, make it a valuable investment for anyone in the business of producing roofing tiles. Combined with the manufacturer's expertise and commitment to quality, this machine's success in the market is not by chance.

Innovative Ways to Incorporate Corrugated Metal into Your Home Design

Corrugated Metal Ideas For The Home: A Stylish and Sustainable ChoiceIn today's world, where sustainability and functionality are valued more than ever, it's no surprise that corrugated metal has become a popular choice for home décor and design. With its many versatile uses and inherent qualities, corrugated metal has emerged as a go-to option for homeowners looking to add a unique touch to their living spaces. From roofing to wall accents, furniture to garden sheds, this lightweight, portable, and corrosion-resistant material offers endless possibilities. In this blog post, we explore some innovative corrugated metal ideas for the home, highlighting its benefits, design inspirations, and the ease of using corrugated metal rollers for various projects.Benefits of Corrugated Metal in Home Design:1. Lightweight and Portable: Corrugated metal sheets or rolls are incredibly lightweight, making them easy to handle and transport. This feature is particularly beneficial for homeowners who might want to install or relocate structures and accents periodically. Whether you're building a garden shed, a privacy screen, or an outdoor kitchen, the lightweight nature of corrugated metal allows for effortless installation and customization.2. Corrosion-Resistant and Durable: When it comes to long-lasting materials, corrugated metal is a winner. Its resilient composition provides excellent resistance against corrosion, rust, and other environmental factors. Corrugated metal not only withstands harsh weather conditions but also ensures your investment will last for years to come. This durability makes it a cost-effective choice, eliminating the need for frequent repairs or replacements.3. Economical and Low Maintenance: Corrugated metal is a budget-friendly option that offers significant savings in the long run. Its affordable price, coupled with its longevity, reduces maintenance and replacement costs over time. Unlike traditional roofing materials that may require constant upkeep, corrugated metal requires minimal maintenance, making it an ideal choice for homeowners looking for both cost-effectiveness and durability.4. Eco-Friendly and Recyclable: Sustainability is a key consideration for many homeowners today. With corrugated metal, you can rest assured that you are making an eco-conscious choice. In addition to being easy to recycle, corrugated metal is often made from recycled materials itself. By utilizing this material in your home design, you can reduce your carbon footprint and make a positive impact on the environment.Design Inspirations and Ideas:1. Roofing: Corrugated metal roofs are popular for their sleek and modern aesthetic. The distinctive ridges of the metal add character to any architectural style, be it contemporary or industrial. Moreover, the durability of corrugated metal ensures that your roof will remain intact and visually appealing for years to come. Its lightweight nature also reduces stress on the overall structure of the building.2. Walls and Facades: Corrugated metal can be used to create stunning wall accents, both indoors and outdoors. Whether it's a feature wall in your living room or an eye-catching façade for your home exterior, the combination of corrugated metal and other materials, such as wood or concrete, can create a visually striking contrast. Additionally, you can choose to paint or patina the metal to further enhance its aesthetic appeal.3. Furniture and Décor: Corrugated metal can be incorporated into furniture design, adding an industrial and rustic touch to your home. From coffee tables to kitchen countertops, the possibilities are endless. Its durability and resistance to wear make it a great choice for high-traffic areas or outdoor furniture, where longevity is essential. Corrugated metal accents, such as barn doors or room dividers, can also lend a trendy farmhouse vibe to any interior space.4. Garden Sheds and Structures: Want to add a touch of elegance to your garden or backyard? Consider using corrugated metal in constructing garden sheds, pergolas, or fences. The fascinating texture and sleek lines of the metal will instantly elevate the overall look of your outdoor space. Moreover, its lightweight nature ensures effortless installation and easy customization options such as painting or staining to match your existing garden theme.Using Corrugated Metal Rollers for DIY Projects:While corrugated metal sheets offer a wide range of benefits and visual appeal, the process of shaping and creating custom sizes can be challenging. This is where corrugated metal rollers come into play. These tools are specifically designed to shape and roll corrugated metal sheets according to your desired specifications. They provide the flexibility and accuracy needed to achieve precise results. Whether you're looking to create a curved accent wall or custom roofing, corrugated metal rollers allow for easy manipulation and ensure a smooth, professional finish.In conclusion, corrugated metal has become a favored choice for homeowners looking to incorporate sustainability, style, and longevity into their home design. Its lightweight, corrosion-resistant, and eco-friendly qualities make it an ideal material for various projects. From roofs to walls, furniture to garden accents, the possibilities are endless when it comes to using corrugated metal in your home. By utilizing corrugated metal rollers, you can unleash your creativity and easily shape this versatile material to fit your unique visions. So, why not consider adding a touch of industrial charm to your living space? Embrace the corrugated metal trend and make a bold statement in your home today.