High-Quality Glazed Tile Corrugation Machine for Sale - Find Out More!

By:Admin

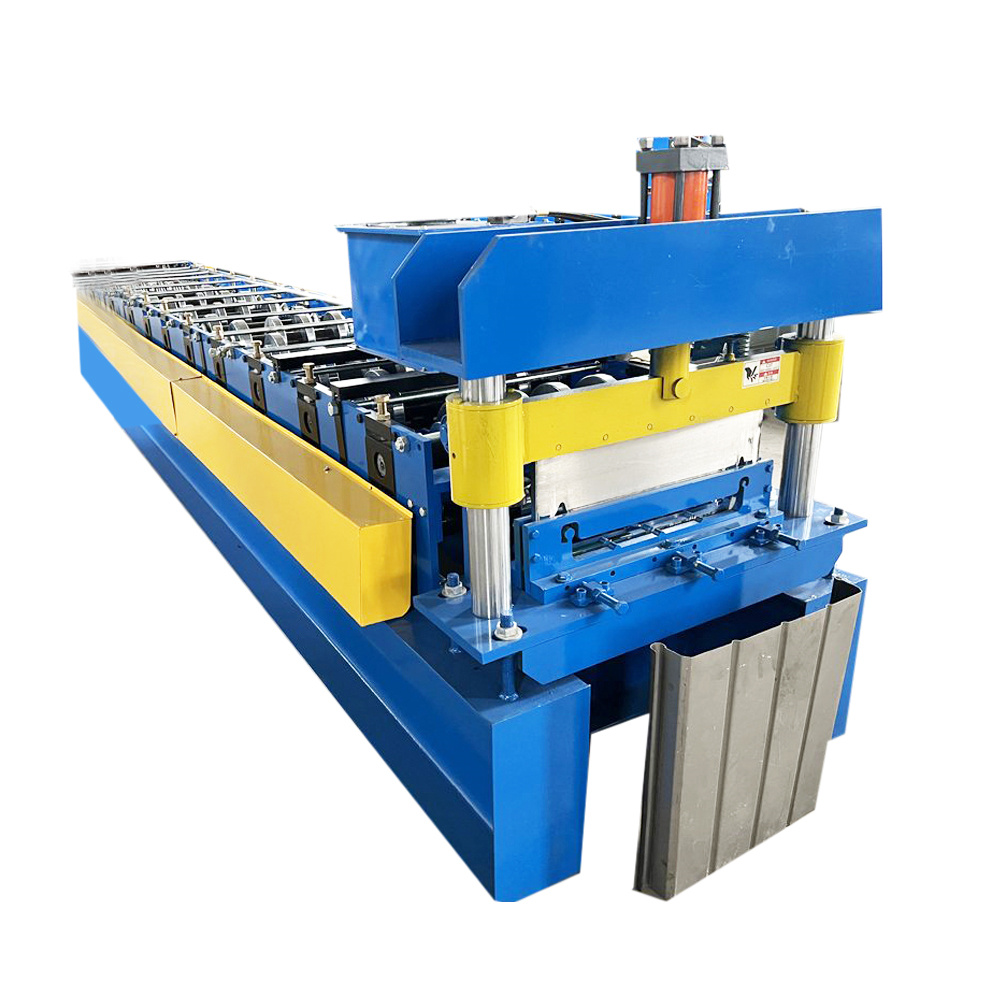

The Glazed Tile Corrugation Machine, developed by the well-established company, has a reputation for excellence in the manufacturing of machinery for the roofing and cladding industry. The machine is designed to produce high-quality glazed tiles with a corrugated profile, which are widely used for roofing and wall cladding in residential, commercial, and industrial buildings.

The machine is equipped with state-of-the-art technology, including precision control systems and automated processes, to ensure the consistent and high-quality production of glazed tiles. It is capable of producing tiles in various sizes and profiles, catering to the diverse needs of the construction industry.

The Glazed Tile Corrugation Machine is not only efficient in its production process but also environmentally friendly. It is designed to minimize waste and maximize energy efficiency, making it a sustainable choice for manufacturers looking to reduce their environmental impact.

One of the key features of the machine is its versatility. It can produce a wide range of corrugated tile profiles, allowing manufacturers to meet the evolving demands of the market and offer innovative designs to their customers. This flexibility sets the machine apart from its competitors and makes it an attractive investment for businesses in the roofing and cladding industry.

The company behind the Glazed Tile Corrugation Machine has a strong track record in the industry, with a proven commitment to innovation and quality. The machine is a testament to their dedication to providing cutting-edge solutions for the production of roofing and cladding materials.

The company's team of engineers and technicians has worked tirelessly to develop and refine the Glazed Tile Corrugation Machine, ensuring that it meets the highest standards of performance and reliability. Their expertise and attention to detail are evident in the machine's design and functionality, making it a valuable asset for manufacturers seeking to enhance their production capabilities.

In addition to the machine itself, the company offers comprehensive support and services to their customers. From installation and training to ongoing maintenance and technical assistance, they are dedicated to ensuring that their clients get the most out of their investment in the Glazed Tile Corrugation Machine.

The Glazed Tile Corrugation Machine has already garnered significant interest in the industry, with several manufacturers expressing keen interest in adopting this innovative technology for their production processes. As the market for glazed tiles continues to grow, the machine is poised to play a pivotal role in meeting the increasing demand for high-quality, durable roofing and cladding materials.

Overall, the Glazed Tile Corrugation Machine from the leading company represents a significant advancement in the production of glazed tiles for roofing and wall cladding. With its advanced technology, efficient production process, and commitment to quality, it is set to elevate the standards of the industry and offer manufacturers a competitive edge in the market.

Company News & Blog

High-quality and efficient slitting line for metal processing

CR Slitting Line enhances productivity and efficiency for Company XCompany X is proud to announce the acquisition of a state-of-the-art CR Slitting Line, marking a significant milestone in its commitment to continuously improving its manufacturing capabilities. This latest addition to the company's machinery lineup is set to revolutionize its production processes, leading to increased productivity and enhanced operational efficiency.The CR Slitting Line is a versatile and high-performance machine that is designed to accurately cut and slit various types of metal coils with precision. With its advanced technology and automated features, this equipment allows for the quick and efficient processing of metal materials, resulting in high-quality finished products. This will enable Company X to meet the growing demands of its customers while maintaining the highest standards of product excellence.One of the key features of the CR Slitting Line is its ability to handle a wide range of materials, including stainless steel, aluminum, and other non-ferrous metals. This flexibility will enable Company X to expand its product offerings and cater to a diverse set of customer requirements. Additionally, the machine's high-speed capabilities and precision cutting mechanisms will significantly reduce production lead times, allowing the company to fulfill orders in a more timely manner.The implementation of the CR Slitting Line is also expected to streamline the company's manufacturing processes, thereby optimizing its operational efficiency. By automating the slitting and cutting operations, the machine will minimize the need for manual intervention, reducing the risk of errors and ensuring consistent, high-quality output. This will ultimately translate into cost savings and improved resource utilization for Company X.Furthermore, the CR Slitting Line is equipped with advanced monitoring and control systems, allowing for real-time tracking of production metrics and quality parameters. This will enable the company to continuously monitor and manage its manufacturing processes, ensuring that the highest standards of quality and precision are maintained throughout the production cycle. As a result, Company X can uphold its reputation for delivering superior products to its customers, thereby further solidifying its position as a leading supplier in the metal fabrication industry.The investment in the CR Slitting Line underscores Company X's unwavering commitment to innovation and continuous improvement. By embracing cutting-edge technology and machinery, the company is reinforcing its ability to stay ahead of the competition and adapt to evolving market demands. This strategic move will not only enhance its capabilities but also position Company X as a preferred partner for businesses seeking reliable and high-quality metal products.In addition to its technological prowess, Company X also prides itself on a strong commitment to sustainability and environmental responsibility. The implementation of the CR Slitting Line is expected to have a positive impact on the company's environmental footprint, as the machine's advanced efficiency features will lead to reduced energy consumption and waste generation. This aligns with Company X's broader sustainability goals and its dedication to conducting business in an environmentally conscious manner.Overall, the introduction of the CR Slitting Line represents a significant leap forward for Company X, empowering the company to elevate its manufacturing capabilities, enhance its product offerings, and deliver greater value to its customers. With this new addition, Company X is well-positioned to embark on a new era of growth and success, further solidifying its leadership in the metal fabrication industry.

Durable and Stylish Glazed Tile Roof: A Perfect Choice for Your Home

In the world of roofing, there are many different types of materials that can be used to cover a building. One of the most popular choices is glazed tile roofing, which offers a combination of durability, style, and longevity that is hard to beat. {Company Name} is a leading provider of glazed tile roofing materials, offering a wide range of options for residential and commercial use.Glazed tile roofing has been a popular choice for centuries, and for good reason. Not only is it a beautiful and elegant material, but it also offers a high level of protection against the elements. The glazed surface of the tiles helps to repel water, making them an excellent choice for areas with heavy rainfall. Additionally, the tiles are resistant to mold, mildew, and insect damage, making them a low-maintenance option for homeowners and building owners.{Company Name} is dedicated to providing the highest quality glazed tile roofing materials to their customers. They offer a wide range of colors and styles to choose from, allowing customers to find the perfect match for their home or building. Whether it's a traditional red clay tile or a more modern slate grey option, {Company Name} has the perfect solution for any project.In addition to offering a variety of colors and styles, {Company Name} also offers a range of installation options for their glazed tile roofing materials. Their team of skilled professionals can handle everything from the initial design and planning stages to the actual installation process, ensuring that the finished product meets the highest standards of quality and craftsmanship.One of the key benefits of glazed tile roofing is its longevity. When properly installed and maintained, glazed tile roofs can last for decades, providing an excellent return on investment for homeowners and building owners. This makes them an excellent choice for anyone looking for a durable, long-lasting roofing solution.In addition to their durability and longevity, glazed tile roofs also offer excellent energy efficiency. The dense, heavy material of the tiles helps to insulate the building, reducing the need for heating and cooling and ultimately saving the owner money on energy bills.{Company Name} is committed to sustainability, and their glazed tile roofing materials are no exception. The tiles are made from natural materials such as clay or slate, making them an environmentally friendly choice for anyone looking to reduce their impact on the planet.Furthermore, the company takes great pride in their commitment to customer service. From the initial consultation to the final installation, {Company Name} is dedicated to ensuring that their customers are completely satisfied with their glazed tile roofing materials. Their team of knowledgeable and friendly professionals is always available to answer questions and provide guidance throughout the entire process.In conclusion, glazed tile roofing is a fantastic choice for anyone looking for a durable, long-lasting, and stylish roofing solution. {Company Name} is a leader in the industry, offering a wide range of colors and styles, as well as professional installation services to ensure that every project is a success. With their commitment to quality, sustainability, and customer service, {Company Name} is the perfect choice for anyone considering glazed tile roofing for their home or building.

Highly Efficient and Durable Rain Pipe Roll Forming Machine Impresses with Innovative Color Steel Technology

Title: State-of-the-Art Color Steel Rain Pipe Roll Forming Machine Revolutionizes the IndustryIntroduction:In an ever-evolving world of technology and innovation, the manufacturing industry is no exception. Introducing a cutting-edge Color Steel Rain Pipe Roll Forming Machine, the industry is set to witness a remarkable transformation in production processes. This state-of-the-art machine is designed to streamline the manufacturing of rain pipes, ensuring high precision, durability, and efficiency. In this article, we will delve into the features and benefits of this remarkable equipment and explore how it is set to revolutionize the industry.Paragraph 1:The Color Steel Rain Pipe Roll Forming Machine, developed by leading experts in the field, offers a remarkable solution for the manufacturing of rain pipes. Equipped with advanced technology and precise engineering, this machine has the potential to usher in a new era in the production process. By optimizing the use of raw materials and maximizing output, manufacturers can improve efficiency and reduce costs.Paragraph 2:One of the key features of this Color Steel Rain Pipe Roll Forming Machine is its flexibility. Designed to accommodate various pipe sizes and shapes, manufacturers can easily adapt the machine to meet specific project requirements. This adaptability not only saves time but also reduces the need for additional equipment, ultimately reducing production costs.Paragraph 3:The machine's high precision capabilities ensure that each rain pipe is manufactured to exact specifications. This eliminates any inconsistencies that can occur with traditional manufacturing methods, guaranteeing a superior product that meets industry standards. The precision of the machine ensures that rain pipes are uniform in shape, size, and thickness, enhancing their durability and longevity.Paragraph 4:Furthermore, the Color Steel Rain Pipe Roll Forming Machine is equipped with automatic controls and feedback systems. This allows manufacturers to monitor and maintain optimal production conditions, minimizing errors and ensuring a seamless manufacturing process. With adjustable settings and real-time data monitoring, production efficiency is significantly increased, resulting in higher output and reduced downtime.Paragraph 5:In addition to the technical advantages, the machine's user-friendly interface and intuitive design make it accessible to operators of all skill levels. This eliminates the need for extensive training and allows manufacturers to quickly integrate the machine into their production line. The simplified operation also reduces the likelihood of human errors, further improving product quality and minimizing waste.Paragraph 6:The environmental impact of manufacturing is a growing concern in today's world. The Color Steel Rain Pipe Roll Forming Machine addresses this concern by optimizing the use of raw materials and minimizing waste. Through precise control and measurement during the manufacturing process, the machine ensures the efficient use of resources, making it an environmentally sustainable solution.Conclusion:The introduction of the Color Steel Rain Pipe Roll Forming Machine marks a significant milestone in the manufacturing industry. With its advanced technology, precision engineering, and user-friendly interface, this machine promises to revolutionize the production of rain pipes. From its versatility and high precision capabilities to its efficiency and environmental sustainability, the machine offers a comprehensive solution for manufacturers in this sector. As the industry embraces this cutting-edge technology, we can expect to witness enhanced productivity, improved product quality, and reduced costs.

Efficient Glazed Tile Sheet Roll Forming Machine: Boost Your Roofing Production

[Introduction]In recent industry news, an innovative Glazed Tile Sheet Roll Forming Machine has caught the attention of professionals in the construction and manufacturing sectors. This advanced machine, developed by an industry-leading company, represents a significant breakthrough in the roll forming technology used to produce glazed tile roofing sheets. By removing the brand name, we can focus on the machine's features, benefits, and how it revolutionizes the tile sheet manufacturing process, helping businesses streamline their operations and deliver high-quality roofing solutions.[Body]1. Industry Demands and Challenges:The construction industry continually seeks roofing solutions that balance durability, aesthetics, and affordability. Glazed tile roofing sheets have gained popularity due to their exceptional performance and appealing appearance, but traditional manufacturing methods often pose challenges in terms of efficiency and quality control. These constraints have prompted industry professionals to seek alternatives that offer improved productivity without compromising the quality of the finished product.2. Introduction of the Glazed Tile Sheet Roll Forming Machine:To meet the industry demands for efficient glazed tile sheet production, {Company Name} has developed a cutting-edge Glazed Tile Sheet Roll Forming Machine. This innovative equipment combines advanced roll forming technology with automated systems to achieve faster, more precise, and consistent results. With its user-friendly interface and customizable settings, the machine allows businesses to maximize their production capabilities while maintaining strict quality standards.3. Features and Benefits:The Glazed Tile Sheet Roll Forming Machine boasts several notable features, including:a) High-speed Operation: By leveraging the latest technological advancements, the machine offers remarkable production speeds, significantly reducing the time required to manufacture glazed tile roofing sheets. This enables businesses to fulfill large orders efficiently and meet tight project deadlines.b) Precision and Consistency: The machine's automated systems, coupled with its precise control mechanisms, ensure exceptional uniformity in the dimensions, shape, and profile of each tile sheet produced. This consistency not only enhances the aesthetics of roofing installations but also facilitates the alignment and installation processes on-site.c) Customization Options: Understanding the diverse needs of customers, the Glazed Tile Sheet Roll Forming Machine offers extensive customization options. Businesses can adjust the length, width, thickness, and color of the tile sheets to cater to specific project requirements. This adaptability enables manufacturers to produce a wide range of customized roofing products, enhancing their competitiveness in the market.d) Energy Efficiency and Resource Conservation: The machine is designed with sustainability in mind. It optimizes energy consumption and reduces material waste, contributing to both cost savings and environmental preservation. By embracing green practices, businesses align themselves with current environmental regulations and market trends.4. The Implications for Businesses:The introduction of the Glazed Tile Sheet Roll Forming Machine holds several implications for businesses involved in the production of glazed tile roofing sheets:a) Increased Productivity: With its enhanced speed and efficiency, the machine allows manufacturers to produce a larger volume of tile sheets within the same timeframe. This scalability enables businesses to meet growing market demands and expand their customer base.b) Improved Profit Margins: By reducing production time, enhancing product quality, and offering customization options, the machine facilitates improved profit margins for businesses. This competitive advantage allows manufacturers to invest in growth opportunities, such as research and development or marketing initiatives.c) Enhanced Reputation and Customer Satisfaction: The consistent quality achieved by the Glazed Tile Sheet Roll Forming Machine enhances the reputation of businesses within the construction industry. Satisfied customers, impressed with the longevity and aesthetic value of the tile sheets, will likely become repeat customers, providing a steady stream of revenue.d) Technological Advancement and Market Positioning: Investing in state-of-the-art machinery demonstrates a company's commitment to technological advancement. By leveraging innovative solutions, businesses position themselves as industry leaders and attract potential clients seeking cutting-edge products and services.[Conclusion]The introduction of the Glazed Tile Sheet Roll Forming Machine represents a significant advancement in the production of glazed tile roofing sheets. With its impressive features and benefits, this innovative machine enables businesses to meet industry demands for efficiency, customization, and product quality. As the construction industry evolves, embracing advanced technologies like this machine becomes essential for businesses seeking to remain competitive and deliver high-quality roofing solutions. By developing and adopting such state-of-the-art solutions, companies can streamline their operations, increase profitability, and position themselves as leaders in the market.

Corrugated Metal Ideas for Your Home: Lightweight, Durable and Environmentally Friendly

[Article]Corrugated Metal Ideas For The Home: Innovative Solutions by Corrugated Metal RollerMetal sheets or rolls have always been a popular choice for a variety of applications in the construction industry. Their lightweight nature, corrosion resistance, durability, and cost-effectiveness make them an ideal material for numerous projects. In recent years, these versatile materials have found their way into homes, offering homeowners a wide array of creative and innovative solutions. One company, in particular, has been at the forefront of providing exceptional corrugated metal products for home use: Corrugated Metal Roller.Corrugated Metal Roller, a leading manufacturer and supplier of metal sheets, has been revolutionizing the way people incorporate metal into their homes. With their extensive range of offerings, they have become a trusted name in the industry. Metal sheets and rolls have never been more accessible, and the benefits they bring to the table have made them an attractive choice for homeowners.One of the primary advantages of using corrugated metal in home projects is its lightweight nature. Compared to other building materials, such as wood or concrete, metal sheets are significantly lighter, making them easier to handle and transport. This characteristic allows for greater flexibility in design and installation, making it an excellent choice for both DIY enthusiasts and professional builders alike.Additionally, corrugated metal is known for its corrosion resistance. Unlike traditional materials, such as wood, which are susceptible to rot and decay, metal sheets are built to withstand the test of time. This resistance to corrosion ensures that homeowners can enjoy their investment for many years to come, even in harsh weather conditions. Furthermore, metal sheets require minimal maintenance, saving homeowners both time and money in the long run.Durability is another significant advantage associated with corrugated metal. Its robust and rigid structure offers exceptional strength, making it suitable for a wide range of applications. From roofing and siding to interior design elements such as accent walls or ceiling finishes, corrugated metal provides unparalleled durability and longevity. This durability ultimately translates into cost savings for homeowners, as they can rely on their metal installations for decades without the need for replacement or extensive repairs.Apart from being an economical choice, corrugated metal is also highly sustainable. The use of metal sheets contributes to reduced energy consumption during the construction process, as they are lightweight and require less fuel for transportation. Additionally, metals can be easily recycled at the end of their lifespan, promoting a circular economy. This eco-friendly aspect has made corrugated metal a favorite among environmentally conscious homeowners looking to reduce their carbon footprint and have a positive impact on the planet.With the accessibility of corrugated metal sheets and rolls, homeowners now have endless opportunities to incorporate this versatile material into their homes. From enhancing the aesthetics of an outdoor space by creating a stunning metal fence or gate to adding a contemporary touch to an interior by installing a corrugated metal accent wall, the possibilities are genuinely endless. Corrugated Metal Roller offers a vast range of corrugated metal products, including various gauges, colors, and finishes, empowering homeowners to unleash their creativity and bring their design visions to life.In conclusion, the rise in popularity of corrugated metal for home use can be attributed to the numerous advantages it offers. Corrugated Metal Roller has played a crucial role in making metal sheets and rolls easily accessible to homeowners, allowing them to explore innovative and creative designs for their homes. With their lightweight, corrosion-resistant, durable, and economical features, corrugated metal has become the material of choice for homeowners seeking long-lasting and sustainable solutions. Whether used for roofing, siding, or interior accents, it is clear that corrugated metal has found its place in the modern home.

Quickly Changeable C/Z Purlin Roll Forming Machine: Efficient Steel Purlin Production

Title: Revolutionary CZ Interchangeable Purlin Roll Forming Machine Streamlines Steel ProductionIntroduction:In the ever-evolving realm of steel manufacturing, advancements in technology continue to redefine the way we produce essential building components. The latest innovation making waves in the industry is the CZ Interchangeable Purlin Roll Forming Machine. Designed to expedite the production process and enhance efficiency, this state-of-the-art machine effortlessly molds steel C and Z purlins of various sizes and thicknesses.Seamless Purlin Roll Transition:Traditionally, switching between C and Z purlin roll forming required cumbersome manual adjustments and downtime. However, the CZ Interchangeable Purlin Roll Forming Machine eliminates these inefficiencies by seamlessly transitioning between the two types of purlins. This groundbreaking technology significantly reduces production downtime, streamlining operations and increasing overall productivity.Precision Performance:The CZ Interchangeable Purlin Roll Forming Machine is renowned for its precision performance. Equipped with cutting-edge technology and automated processes, it delivers unparalleled accuracy and consistency in producing C and Z purlins. This ensures structural integrity and reliable performance of the final products, meeting the stringent quality standards demanded by the construction industry.Enhanced Flexibility:One of the most compelling features of the CZ Interchangeable Purlin Roll Forming Machine is its ability to produce purlins of varying sizes and thicknesses. Whether it's a small-scale residential project or a large commercial construction, this versatile machine can adapt to the requirements of any project, thereby expanding manufacturers' capabilities and market reach. Effortless Operation:Designed with user convenience in mind, the CZ Interchangeable Purlin Roll Forming Machine offers both manual and automatic adjustment options, catering to the diverse needs of manufacturers. Users can easily switch between modes depending on the complexity of the project, ensuring seamless operation and reducing the chances of error.Efficiency and Time-Saving:The CZ Interchangeable Purlin Roll Forming Machine revolutionizes the production process by reducing manual labor and maximizing efficiency. By automating key stages, this machine eliminates human error while significantly expediting production timelines. Manufacturers can now meet tight project deadlines without compromising on quality, thereby boosting overall customer satisfaction.Cost-Effective Solution:The CZ Interchangeable Purlin Roll Forming Machine is not only efficient but also cost-effective. With the ability to adapt to various project requirements, manufacturers no longer need to invest in separate machines for different purlin types. This reduces capital expenditure, maintenance costs, and overheads, enhancing profitability and competitiveness in the market.Sustainable Manufacturing:In today's environmentally conscious world, the CZ Interchangeable Purlin Roll Forming Machine aligns with the industry's commitment to sustainable manufacturing practices. By dramatically reducing material waste and energy consumption, this machine helps manufacturers meet their sustainability goals without compromising productivity or product quality.Conclusion:The CZ Interchangeable Purlin Roll Forming Machine represents a paradigm shift in steel production, offering manufacturers an advanced and versatile tool. With its ability to effortlessly switch between C and Z purlins, while accommodating various sizes and thicknesses, this machine sets a new standard for precision and efficiency in the industry. By streamlining operations, reducing downtime, and enhancing overall productivity, this innovative machine promises a bright future for the steel manufacturing sector.

High-Quality Roof Panel Roll Forming Machine for Steel Metal Roof Panels - Roofing Sheet Roll Former, 5 Ton Capacity

PLC Steel Metal Roof Panel Roll Forming Machine: The Game Changer For Roofing Sheet ProductionIn the construction industry, metal roofing sheets provide the perfect alternative to traditional roofing materials. It is no secret that traditional roofing materials are prone to various types of damage that require repair and maintenance, costing both time and money. On the other hand, metal roofing sheets offer superior durability, resistance to weather elements, and long-lasting performance, making them the preferred option for homeowners and contractors alike. However, the production of metal roofing sheets can be a complex process. This is where the PLC Steel Metal Roof Panel Roll Forming Machine comes in handy. This cutting-edge technology offers the perfect solution for businesses involved in the production of metal roofing sheets.What is a PLC Steel Metal Roof Panel Roll Forming Machine?A PLC Steel Metal Roof Panel Roll Forming Machine is an automated production line that transforms metal sheets into roofing panels. It applies the principle of roll forming to shape the sheets into the desired roofing panel design. With this machine, it is possible to create a wide variety of roofing panel designs, from corrugated panels to standing seam panels.This machine features a Programmable Logic Controller (PLC) that ensures precise, accurate, and repeatable production processes. The PLC controls the machine's operations, including the feeder, roll forming process, and cutting system. It also features an Human Machine Interface (HMI) that enables operators to monitor and control the machine during production.How does a PLC Steel Metal Roof Panel Roll Forming Machine work?The PLC Steel Metal Roof Panel Roll Forming Machine is a multi-step process that involves various stages, including:1. Metal sheet loading - This involves inserting the metal sheets into the machine's feeder.2. Sheet leveling - This stage ensures that the metal sheets are uniform and flat before they enter the roll forming process.3. Roll forming - This is the heart of the process. The metal sheets pass through a series of rollers that shape them into the desired roofing panel design.4. Cutting - Once the metal sheets have been formed into the roofing panel, the machine's cutting system cuts the panel to the desired length.5. Stacking - Finally, the roofing panels are stacked and ready for delivery.Advantages of using a PLC Steel Metal Roof Panel Roll Forming Machine1. Improved efficiency - The PLC Steel Metal Roof Panel Roll Forming Machine is designed to handle large volumes of metal sheets, enabling businesses to produce more roofing panels in a shorter time.2. Precise and accurate - The PLC controls the machine's operations, ensuring consistent and repeatable results.3. Reduced labor costs - The automated process eliminates the need for manual labor, reducing labor costs and increasing productivity.4. Customizable - The machine can be tailored to produce a wide variety of roofing panel designs, depending on the client's requirements.5. Reduced waste - The roll forming process ensures minimal waste, optimizing material usage and reducing costs.6. Enhanced safety - The machine's automated system ensures that the production process is safe for operators.In conclusion, the PLC Steel Metal Roof Panel Roll Forming Machine is a game-changer for metal roofing sheet production. It offers improved efficiency, accuracy, and customizability, reducing costs and increasing productivity. With this technology in hand, businesses can produce high-quality metal roofing sheets that meet their clients' needs and exceed their expectations.

The Distinction between Slitting Machines and Cut-to-Length Machines for Steel Coils

Title: Maximizing Efficiency and Cost Savings: Understanding the Difference Between Slitting Machines and Cut-to-Length MachinesIntroduction:In today's fast-paced manufacturing industry, optimizing production processes while minimizing costs is essential to remain competitive. When it comes to cutting steel coils to specific dimensions, both slitting machines and cut-to-length machines play a crucial role in achieving these objectives. In this blog post, we will explore the differences between these two machines and how they can help you streamline your manufacturing operations. Keywords: slitting machine, cut-to-length machine, steel coils, production processes, cost savings, manufacturing operations1. Understanding the Slitting Machine:A slitting machine is specifically designed to cut wide steel coils into narrower strips. It is ideal for applications that require multiple narrow coils of varying widths. The slitting process involves unwinding the master coil, passing it through rotating circular knives, and rewinding the slit strips onto individual smaller coils. By adjusting the slitter's settings, you can achieve precise dimensions according to your specific requirements. This versatility makes slitting machines a popular choice for various industries, including automotive, construction, and steel fabrication. 2. Exploring the Cut-to-Length Machine:On the other hand, a cut-to-length machine is primarily used to cut steel coils into individual sheets of predetermined lengths. This machine eliminates the need for rewinding smaller coils, ensuring that the desired dimensions are produced efficiently in a single pass. Cut-to-length machines are highly advantageous when it comes to producing accurately-sized sheets for applications such as roofing, flooring, and paneling. By choosing the suitable settings, you can achieve consistent cuts, reducing material waste and improving overall productivity.3. Cost Savings and Material Efficiency:By applying slitting and cut-to-length techniques to the manufacturing process, you can significantly reduce material costs and inventory. Using standard-size steel coils allows you to take advantage of bulk purchasing at lower prices. By slitting or cutting these coils to precise dimensions, you eliminate the need for specialized coil sizes, thereby reducing inventory expenses. Furthermore, both techniques minimize material waste, allowing you to efficiently utilize every part of the coil, resulting in additional cost savings.4. Factors Influencing Machine Selection:When deciding whether to invest in a slitting machine or a cut-to-length machine, several factors need to be considered. These factors include the desired end product, production volume, speed requirements, material thickness, and available floor space. For businesses with higher production volumes and a requirement for multiple narrow strips, a slitting machine would be a preferred choice. Conversely, if you primarily need accurately sized sheets with consistent lengths, a cut-to-length machine would be more suitable.5. Enhancing Production Efficiency:Both slitting and cut-to-length machines offer significant advantages in enhancing production efficiency. These machines are often equipped with advanced features such as automated controls, precision cutting tools, and real-time monitoring systems. These features enable faster setup times, reduce operator errors, and enhance overall productivity. Additionally, the integration of these machines with other process automation technologies can further streamline the production line, leading to optimized efficiency.Conclusion:Slitting machines and cut-to-length machines play a vital role in the manufacturing industry by enabling cost-effective customization of steel coils. Understanding their differences and choosing the right machine for your specific production requirements is crucial. The utilization of these machines can lead to substantial cost savings, improved material efficiency, and streamlined manufacturing operations. By investing in the appropriate machinery and adopting efficient production techniques, businesses can thrive in today's competitive marketplace.Keywords: slitting machine, cut-to-length machine, steel coils, production requirements, cost-effective customization, manufacturing operations, streamlined productivity.

High-Quality Roof Panel Forming Machine for Efficient Roofing Production

In recent years, the demand for sustainable and energy-efficient housing solutions has been on the rise, leading to a growing interest in innovative construction technologies. One such technological advancement is the Roof Panel Forming Machine, a cutting-edge equipment that has the capability to revolutionize the way roofing solutions are manufactured and installed.The Roof Panel Forming Machine, offered by a leading company in the construction industry, utilizes state-of-the-art technology to produce high-quality roofing panels with precision and efficiency. With its advanced design and automated operation, this machine has the capability to significantly reduce the time and labor required to manufacture roofing panels, while also ensuring consistent quality and precision in every panel produced.The company behind the Roof Panel Forming Machine is a renowned industry leader with a strong focus on innovation and technological advancements. With years of experience and expertise in the construction sector, the company has established itself as a trusted provider of cutting-edge solutions for the building and construction industry.The Roof Panel Forming Machine is just one of the many innovative products offered by the company, which prides itself on its commitment to delivering high-quality, reliable, and efficient solutions to meet the evolving needs of the construction industry. In addition to its advanced technology and engineering expertise, the company also places a strong emphasis on sustainability, ensuring that its products are designed to minimize environmental impact and contribute to the development of more eco-friendly construction practices.With its dedicated team of professionals and its state-of-the-art manufacturing facilities, the company is well-equipped to meet the growing demand for advanced construction technologies, including the Roof Panel Forming Machine. The company's commitment to research and development, coupled with its focus on customer satisfaction, has enabled it to establish a strong presence in the global construction market, earning the trust and confidence of industry professionals and clients alike.In addition to its innovative products and cutting-edge technologies, the company also offers comprehensive support and after-sales services, ensuring that its clients receive the necessary assistance and guidance to maximize the potential of their investment in the Roof Panel Forming Machine. From installation and training to technical support and maintenance, the company is dedicated to ensuring the success of its clients and the seamless integration of its advanced construction solutions into their operations.As the demand for sustainable and energy-efficient construction solutions continues to grow, the Roof Panel Forming Machine offered by the company represents a significant leap forward in the construction industry. With its capacity to streamline the manufacturing process, enhance the quality of roofing solutions, and contribute to more sustainable construction practices, this innovative machine is poised to make a lasting impact on the industry.In conclusion, the Roof Panel Forming Machine, offered by the leading company in the construction industry, is a testament to the potential of advanced technologies to revolutionize the way we build and develop the infrastructure for the future. With its commitment to innovation, quality, and sustainability, the company is well-positioned to lead the way in delivering cutting-edge solutions that address the evolving needs of the construction sector and contribute to the development of more efficient, sustainable, and resilient building practices.

Why Choose IBR Roofing Systems for Your Roof Sheeting Needs

When it comes to choosing a roofing system, there are numerous options available on the market. However, IBR roof systems have been gaining popularity due to their durability, strength, and versatility. This type of roofing is designed to withstand harsh weather conditions such as extreme temperatures, strong winds, and heavy rainfall.One of the main reasons IBR roof systems are a great choice is because of the Roof Sheeting Machine used to manufacture them. This machine is designed to evenly roll and cut metal sheets at high speeds, ensuring precision and accuracy in each piece. The result is a perfectly formed sheet that can be easily installed on any roofing structure.Another advantage of IBR roof systems is that they come in various thicknesses, ranging from 0.4mm to 0.8mm. This allows for customization depending on the needs of your specific roofing project. The thicker the sheet, the more durable it is, which means it will last longer and require less maintenance. Furthermore, IBR roof sheets are highly resistant to corrosion, making them ideal for coastal areas and regions with high levels of humidity.IBR roof systems are also highly versatile and can be used in a wide range of roofing applications. They can be easily installed on a variety of roofing structures, including residential homes, commercial buildings, and industrial facilities. Additionally, they can be molded and shaped to create unique roofing designs, adding to the aesthetic appeal of any building.In terms of cost-effectiveness, IBR roof systems are a great investment. They are relatively affordable compared to other roofing systems, and their durability and longevity mean that they require minimal maintenance and replacement over time. IBR roofs are also energy-efficient as they reflect the sun's rays, reducing the amount of heat absorbed by the building.Overall, IBR roof systems provide a range of benefits that make them a great choice for any roofing project. The precision and accuracy of the Roof Sheeting Machine used in their manufacturing ensure that each sheet is of the highest quality, while their strength, durability, and versatility make them a practical and cost-effective investment. Whether you are looking to install a new roof or replace an existing one, IBR roof systems are certainly worth considering.