High-Quality Glazed Tile Sheet Corrugation Equipment for Sale

By:Admin

In recent news, the latest innovation in the field of corrugation equipment has been introduced by a leading company in the industry. The new Glazed Tile Sheet Corrugation Equipment is set to revolutionize the way corrugated sheets are manufactured, offering improved efficiency, durability, and quality.

This new equipment has been designed and developed by a company that has been a pioneer in the field of corrugation machinery. With a history of over 20 years in the industry, the company has gained a solid reputation for delivering high-quality and reliable equipment for the production of corrugated sheets.

The Glazed Tile Sheet Corrugation Equipment is the result of years of research and development, aiming to address the growing demand for advanced machinery in the corrugated sheet manufacturing industry. The equipment is designed to produce high-quality glazed tile sheets with a smooth and attractive finish, making it ideal for a wide range of applications, including roofing, cladding, and interior design.

One of the key features of the Glazed Tile Sheet Corrugation Equipment is its advanced technology that ensures precise and consistent corrugation of the sheets. This technology allows for greater control over the manufacturing process, resulting in sheets that meet the highest standards of quality and durability.

Furthermore, the equipment is equipped with state-of-the-art automation and control systems, allowing for seamless operation and easy adjustment of settings. This not only improves the efficiency of the manufacturing process but also reduces the need for manual intervention, minimizing the risk of errors and ensuring a high level of consistency in the finished products.

Aside from its advanced technology, the Glazed Tile Sheet Corrugation Equipment is also designed with durability and reliability in mind. The equipment is built using high-quality materials and components, ensuring its long-term performance and minimal maintenance requirements.

Moreover, the company behind this innovative equipment is committed to providing comprehensive support for its customers. This includes technical assistance, training, and after-sales service, ensuring that clients can maximize the potential of the equipment and achieve the best results in their sheet manufacturing operations.

With the introduction of the Glazed Tile Sheet Corrugation Equipment, the company aims to set new standards in the industry and provide its customers with cutting-edge solutions for their corrugated sheet manufacturing needs. This innovative equipment is expected to have a significant impact on the market, offering a competitive edge to businesses that adopt it.

The company's dedication to research, development, and customer satisfaction has positioned it as a leader in the field of corrugation machinery. The introduction of the Glazed Tile Sheet Corrugation Equipment is a testament to the company's commitment to innovation and its ability to anticipate and address the evolving needs of the industry.

In conclusion, the Glazed Tile Sheet Corrugation Equipment represents a significant advancement in the field of corrugation machinery. With its advanced technology, durability, and comprehensive support, it is set to redefine the standards of quality and efficiency in the manufacturing of glazed tile sheets. This innovative equipment is a testament to the company's leadership in the industry and its dedication to providing cutting-edge solutions for its customers' manufacturing needs.

Company News & Blog

High-quality roll forming machine for efficient production

Manufacturing process is an essential aspect of various industries. From construction to automotive, the need for efficient and precise manufacturing equipment is always in demand. In this regard, the introduction of the Upright Roll Forming Machine by a leading company has revolutionized the industry, offering innovative solutions for a wide range of manufacturing requirements.The Upright Roll Forming Machine is a versatile piece of equipment that is designed to efficiently produce a wide variety of metal parts and components. It is used in various industries such as automotive, construction, aerospace, and many others. The machine incorporates advanced technology and features, making it a valuable asset for manufacturers seeking to enhance their production capabilities.The Upright Roll Forming Machine is renowned for its high precision, speed, and efficiency. It can create parts with complex shapes and designs, ensuring that the final product meets the required specifications. This level of accuracy is crucial for industries where precision is of utmost importance, such as the automotive and aerospace sectors.The machine is also known for its flexibility, allowing manufacturers to produce a wide range of components using different types of materials. This versatility is invaluable for businesses that need to adapt to changing market demands and explore new opportunities in various industries.One of the most significant advantages of the Upright Roll Forming Machine is its ability to streamline the manufacturing process, reducing both time and cost. This is achieved through its high-speed production capabilities, minimizing downtime and maximizing output. As a result, businesses can benefit from increased efficiency and productivity, ultimately leading to improved profitability.In addition to its impressive performance, the Upright Roll Forming Machine also prioritizes safety and ease of use. The machine is equipped with advanced safety features to ensure a secure working environment for operators. Furthermore, it is designed with user-friendly controls and interfaces, making it accessible for a wide range of operators, including those with minimal experience.The company behind the Upright Roll Forming Machine has a proven track record of delivering high-quality manufacturing equipment. With years of experience and expertise in the industry, they have established themselves as a reliable and innovative provider of machinery solutions. Their commitment to excellence and continuous improvement is reflected in the design and performance of the Upright Roll Forming Machine.The company's dedication to customer satisfaction is evident through their comprehensive support services. They offer tailored solutions to meet the specific needs of each client, ensuring that they can maximize the benefits of the Upright Roll Forming Machine. From installation and training to maintenance and technical support, the company provides a complete package to ensure that their customers can seamlessly integrate the machine into their operations.Overall, the introduction of the Upright Roll Forming Machine by {company name} represents a significant advancement in the manufacturing industry. Its innovative design, advanced features, and proven performance make it a game-changer for businesses seeking to enhance their manufacturing capabilities. With its ability to deliver high precision, efficiency, and flexibility, the machine is set to empower manufacturers across various industries, driving productivity and competitiveness.

Understanding the Benefits of C purlins in Construction Projects

Cz Purlin, a leading manufacturer of steel construction products, has recently announced the introduction of their new range of advanced purlin systems. The company has been a pioneer in the steel construction industry for over three decades and has continually strived to innovate and improve their products to meet the evolving needs of the market.The new range of Cz Purlin products is designed to provide enhanced structural support and flexibility for a wide range of construction projects. The purlins are made from high-quality steel and are available in a variety of sizes and specifications to suit different building requirements. With their advanced design and superior strength, these purlins are set to revolutionize the way steel construction is done.The key features of the new Cz Purlin range include improved load-bearing capacity, greater resistance to corrosion, and easier installation. These features make the purlins ideal for a wide range of applications, from industrial warehouses and commercial buildings to residential construction projects. The company's commitment to quality and innovation is evident in the extensive research and development that has gone into creating these new products.In addition to the technical advancements, Cz Purlin has also focused on ensuring that their new range of products meets the highest standards of sustainability and environmental responsibility. The company has implemented eco-friendly manufacturing processes and sourced materials from sustainable suppliers, in line with their commitment to reducing their carbon footprint and promoting a greener construction industry."We are thrilled to introduce our new range of advanced purlin systems to the market," said a spokesperson for Cz Purlin. "Our team has worked tirelessly to develop these products, and we are confident that they will set a new standard for steel construction. The improved performance, durability, and sustainability of these purlins make them a game-changer for the industry."The company's dedication to providing top-quality products and excellent customer service has earned them a strong reputation in the construction industry. With their state-of-the-art manufacturing facilities and a team of experienced engineers and designers, Cz Purlin is well-equipped to meet the growing demand for high-quality steel construction products.As the construction industry continues to evolve and demand for sustainable and durable building materials grows, Cz Purlin is committed to remaining at the forefront of innovation. The company's new range of advanced purlin systems is a testament to their ongoing commitment to excellence and their ability to adapt to the changing needs of the market.With their new range of products, Cz Purlin is set to continue its legacy of providing top-quality steel construction materials that meet the highest standards of performance, sustainability, and reliability. Whether it's for large-scale industrial projects or smaller residential builds, customers can trust Cz Purlin to deliver products that are not only cutting-edge but also environmentally conscious and built to last.In conclusion, the launch of Cz Purlin's new range of advanced purlin systems represents a significant milestone for the company and the steel construction industry as a whole. With their focus on innovation, sustainability, and customer satisfaction, Cz Purlin is well-positioned to maintain its leadership in the market and continue to provide top-quality products for a wide range of construction projects.

Standing Seam Roll Forming Machine: Advanced Technology for Efficient Metal Panel Manufacturing

Standing Seam Roll Forming Machine Empowers Companies to Enhance Their OperationsStanding seam roofs have been in demand for their sleek and modern appearance, as well as robust durability. These quintessential roofs require efficient machinery that will produce panels with impeccable precision, swiftly and consistently. With the advancement of technology, several reliable machines have been built, including the Standing Seam Roll Forming Machine, which offers top-notch performance and versatility.This high-quality equipment is designed by an industry-leading company focused on manufacturing roll forming machines with optimal technical support. The company has been in operation for years, and with their vast experience, they have created automated systems that meet their clients' unique needs. This Standing Seam Roll Forming Machine uses excellent technology to whip up roofing panels that are top-performing and visually appealing, which makes it a go-to solution for roofing companies.The Standing Seam Roll Forming Machine is electronically controlled and adjustable, making it efficient for creating panels of various sizes and shapes. It is also highly customizable and can be made to fit specific needs instantly without interfering with the machine's quality performance. It is engineered to handle a range of materials, as well as a vast variety of thicknesses, including aluminum, steel, and copper. Additionally, with the consistency in panel production, companies can save money by reducing waste and increasing productivity.The machine is powered using an electric motor, which makes it less cost-prohibitive due to the low cost of electricity. Further, it requires little in terms of maintenance, and its unique design allows for optimum power consumption by utilizing minimal electricity. With very few moving parts, the machine is straightforward to assemble and use. Also, it is built with high-quality materials, which ensures that it remains durable and lasts an extended period, even with minimal maintenance.The Standing Seam Roll Forming Machine comes with efficient technical support from the manufacturer. The engineers are available to offer technical expertise that assists clients in improving their operations. Moreover, clients receive continuous support in matters related to the machines' maintenance and repairs, and spare parts are readily available.Overall, the Standing Seam Roll Forming Machine is an indispensable asset for any roofing company. It is a smart investment that enhances operations, reduces production costs, and boosts profitability. It is reliable, efficient, and cost-friendly, and it ensures that companies remain competitive in their respective markets. Moreover, it is environmentally friendly due to its low power usage, as well as the ability to reduce waste and increase productivity.In conclusion, companies looking to improve their roofing operations ought to consider investing in the Standing Seam Roll Forming Machine. With a high quality, durable design, and customizable features, this machine provides the kind of precision and speed that will satisfy customers and boost productivity. Thanks to its robust engineering and excellent technical support, it is precisely the equipment that roofing companies need to stay on top of their game in the competitive roofing industry.

Innovative Ways to Incorporate Corrugated Metal into Your Home Design

Corrugated Metal Ideas For The Home: A Stylish and Sustainable ChoiceIn today's world, where sustainability and functionality are valued more than ever, it's no surprise that corrugated metal has become a popular choice for home décor and design. With its many versatile uses and inherent qualities, corrugated metal has emerged as a go-to option for homeowners looking to add a unique touch to their living spaces. From roofing to wall accents, furniture to garden sheds, this lightweight, portable, and corrosion-resistant material offers endless possibilities. In this blog post, we explore some innovative corrugated metal ideas for the home, highlighting its benefits, design inspirations, and the ease of using corrugated metal rollers for various projects.Benefits of Corrugated Metal in Home Design:1. Lightweight and Portable: Corrugated metal sheets or rolls are incredibly lightweight, making them easy to handle and transport. This feature is particularly beneficial for homeowners who might want to install or relocate structures and accents periodically. Whether you're building a garden shed, a privacy screen, or an outdoor kitchen, the lightweight nature of corrugated metal allows for effortless installation and customization.2. Corrosion-Resistant and Durable: When it comes to long-lasting materials, corrugated metal is a winner. Its resilient composition provides excellent resistance against corrosion, rust, and other environmental factors. Corrugated metal not only withstands harsh weather conditions but also ensures your investment will last for years to come. This durability makes it a cost-effective choice, eliminating the need for frequent repairs or replacements.3. Economical and Low Maintenance: Corrugated metal is a budget-friendly option that offers significant savings in the long run. Its affordable price, coupled with its longevity, reduces maintenance and replacement costs over time. Unlike traditional roofing materials that may require constant upkeep, corrugated metal requires minimal maintenance, making it an ideal choice for homeowners looking for both cost-effectiveness and durability.4. Eco-Friendly and Recyclable: Sustainability is a key consideration for many homeowners today. With corrugated metal, you can rest assured that you are making an eco-conscious choice. In addition to being easy to recycle, corrugated metal is often made from recycled materials itself. By utilizing this material in your home design, you can reduce your carbon footprint and make a positive impact on the environment.Design Inspirations and Ideas:1. Roofing: Corrugated metal roofs are popular for their sleek and modern aesthetic. The distinctive ridges of the metal add character to any architectural style, be it contemporary or industrial. Moreover, the durability of corrugated metal ensures that your roof will remain intact and visually appealing for years to come. Its lightweight nature also reduces stress on the overall structure of the building.2. Walls and Facades: Corrugated metal can be used to create stunning wall accents, both indoors and outdoors. Whether it's a feature wall in your living room or an eye-catching façade for your home exterior, the combination of corrugated metal and other materials, such as wood or concrete, can create a visually striking contrast. Additionally, you can choose to paint or patina the metal to further enhance its aesthetic appeal.3. Furniture and Décor: Corrugated metal can be incorporated into furniture design, adding an industrial and rustic touch to your home. From coffee tables to kitchen countertops, the possibilities are endless. Its durability and resistance to wear make it a great choice for high-traffic areas or outdoor furniture, where longevity is essential. Corrugated metal accents, such as barn doors or room dividers, can also lend a trendy farmhouse vibe to any interior space.4. Garden Sheds and Structures: Want to add a touch of elegance to your garden or backyard? Consider using corrugated metal in constructing garden sheds, pergolas, or fences. The fascinating texture and sleek lines of the metal will instantly elevate the overall look of your outdoor space. Moreover, its lightweight nature ensures effortless installation and easy customization options such as painting or staining to match your existing garden theme.Using Corrugated Metal Rollers for DIY Projects:While corrugated metal sheets offer a wide range of benefits and visual appeal, the process of shaping and creating custom sizes can be challenging. This is where corrugated metal rollers come into play. These tools are specifically designed to shape and roll corrugated metal sheets according to your desired specifications. They provide the flexibility and accuracy needed to achieve precise results. Whether you're looking to create a curved accent wall or custom roofing, corrugated metal rollers allow for easy manipulation and ensure a smooth, professional finish.In conclusion, corrugated metal has become a favored choice for homeowners looking to incorporate sustainability, style, and longevity into their home design. Its lightweight, corrosion-resistant, and eco-friendly qualities make it an ideal material for various projects. From roofs to walls, furniture to garden accents, the possibilities are endless when it comes to using corrugated metal in your home. By utilizing corrugated metal rollers, you can unleash your creativity and easily shape this versatile material to fit your unique visions. So, why not consider adding a touch of industrial charm to your living space? Embrace the corrugated metal trend and make a bold statement in your home today.

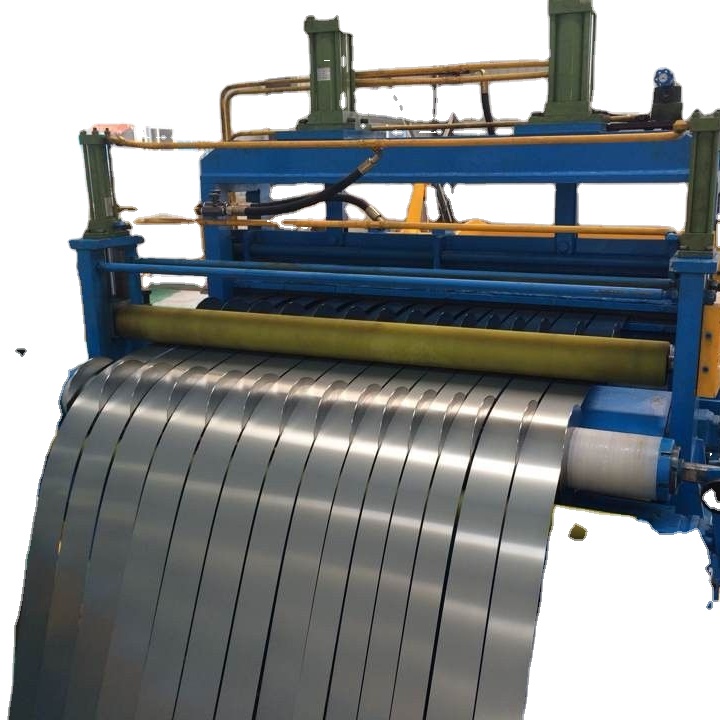

Steel Coil Slitter: The Ultimate Guide

Steel Coil Slitter: Enhancing Efficiency and Precision in Metal ProcessingIn the world of metal processing, precision and efficiency are essential components to ensuring high-quality products and optimal production capabilities. One company that has been at the forefront of innovation in this field is {}. With a strong commitment to excellence and a dedication to meeting the evolving needs of the industry, {} has recently introduced its latest innovation – the Steel Coil Slitter.The Steel Coil Slitter is a cutting-edge machine that has been designed to enhance efficiency and precision in the process of slitting steel coils. This state-of-the-art equipment is capable of processing large steel coils into narrower coils of various widths with exceptional accuracy and speed. By utilizing advanced technology and innovative engineering, the Steel Coil Slitter has set a new standard for performance and productivity in the metal processing industry.One of the key features of the Steel Coil Slitter is its ability to accommodate a wide range of coil widths and thicknesses, making it highly versatile and suitable for a variety of applications. This flexibility allows metal processing companies to streamline their operations and achieve greater levels of efficiency in their production processes. Additionally, the Steel Coil Slitter is equipped with precision cutting blades and advanced control systems that ensure consistent and accurate results, minimizing material waste and maximizing the yield of high-quality slit coils.Furthermore, the Steel Coil Slitter is designed with user-friendly interfaces and intuitive controls, facilitating ease of operation and reducing the need for extensive training. This user-centric approach reflects {}'s commitment to delivering innovative solutions that not only optimize performance but also simplify workflow and improve overall productivity.In addition to its impressive performance capabilities, the Steel Coil Slitter is also built with a strong emphasis on durability and reliability. {} has integrated robust construction and high-quality components into the design of the machine, ensuring that it can withstand the demands of heavy-duty industrial applications and deliver consistent results over an extended lifespan. This emphasis on long-term value and reliability underscores {}'s dedication to providing equipment that not only meets current needs but also anticipates future requirements.As a leader in the metal processing equipment industry, {} has a long-standing reputation for delivering cutting-edge solutions that empower metal fabricators, service centers, and other related businesses to achieve their production goals with precision and efficiency. The introduction of the Steel Coil Slitter further solidifies {}'s position as an innovative force in the industry, offering a solution that addresses the complexities and demands of modern metal processing operations.With a focus on continuous improvement and a deep understanding of the evolving needs of the industry, {} has remained dedicated to staying ahead of the curve through research, development, and the integration of the latest technological advancements. The Steel Coil Slitter is a testament to this ongoing commitment, providing metal processing companies with a powerful tool to enhance their capabilities and drive their success in an increasingly competitive market.In conclusion, the Steel Coil Slitter represents a significant advancement in the field of metal processing equipment, offering a compelling combination of precision, efficiency, and versatility. As {} continues to push the boundaries of innovation, it is poised to redefine the standards of excellence in the industry and empower its customers to achieve new levels of productivity and success. With the introduction of the Steel Coil Slitter, {} has once again demonstrated its dedication to delivering state-of-the-art solutions that meet the complex needs of modern metal processing operations.

PM Modi to participate in UN's Yoga Day, announces big preparations in India

Prime Minister Narendra Modi has announced that he will be participating in the upcoming United Nations' Yoga Day celebrations. According to the Prime Minister, plans for Yoga Day are well underway in the country, with preparations being made for a successful event.The upcoming Yoga Day celebration is not to be taken lightly. The United Nations first declared June 21st as International Yoga Day on December 11, 2014. The declaration was a result of a proposal made by Prime Minister Modi during his address to the United Nations General Assembly. Since then, every year on June 21st, people around the world come together to celebrate Yoga, which has become an integral part of Indian culture.According to the Prime Minister, the benefits of Yoga are well-known and he encourages all people to practice it regularly. With the ongoing pandemic, he also highlighted the importance of Yoga in boosting one's immunity and overall health. He thanked the nation for its enthusiastic participation in past Yoga Day celebrations and urged people to continue taking part in commemorating the day.In light of the pandemic, this year's Yoga Day celebrations may look different than previous years. The government has mandated strict guidelines to ensure the safety of individuals who will be participating in-person. However, participants are welcome to participate in the Yoga Day celebrations from their homes, which is a viable option given that technology has made it possible to partake in activities remotely.Furthermore, the Prime Minister emphasized that Yoga was not just an exercise practice but a way of life. He said that by practicing Yoga, people are not only taking care of their physical health but also enriching their spiritual and mental well-being. He also mentioned that Yoga is an excellent tool for managing stress and anxiety, which have become increasingly prevalent during the pandemic.The Prime Minister's participation in the Yoga Day celebration is likely to boost the morale of individuals who will be taking part in the event. His leadership has been instrumental in raising the profile of Yoga on the global stage. The government has also taken several measures to promote Yoga, such as initiating programs like the International Yoga Festival in Rishikesh, India, and creating the Ministry of AYUSH (Ayurveda, Yoga, and Naturopathy, Unani, Siddha, and Homeopathy) to promote traditional Indian medicine.In addition to the Prime Minister's announcement, the company {Profile Sheet Banane Ki Machine} has expressed their support for the event. They believe that Yoga is a universally beneficial practice that promotes a healthy lifestyle and mental well-being. They encourage individuals to take part in the Yoga Day celebration, whether in-person or remotely.In conclusion, the Prime Minister's announcement of his participation in the United Nations' Yoga Day celebrations is a significant development. It serves as an inspiration and encouragement for individuals to participate in commemorating an event that promotes physical, mental, and spiritual well-being. With preparations in full swing, the government and companies like {Profile Sheet Banane Ki Machine} are leading the way in making the event a success.

Master the Art of Making Authentic Pasta at Home with a Manual Pasta Machine

Title: Master the Art of Homemade Pasta with a Manual Pasta Machine Introduction (approximately 100 words):Fresh, homemade pasta is a culinary delight that can be easily made in the comfort of your own kitchen. With a few simple ingredients, you can create a variety of pasta dishes that will impress your family and friends. If you're new to the world of pasta making or looking to elevate your skills, investing in a manual pasta machine can make the process much easier and enjoyable. In this blog, we will explore the benefits of using a manual pasta machine and provide an in-depth guide on how to make authentic pasta at home. Body:1. The Advantages of Using a Manual Pasta Machine (approximately 200 words):A manual pasta machine offers numerous advantages when it comes to making homemade pasta. Here are some key benefits:a) Efficiency: A manual pasta machine helps streamline the process of rolling and shaping pasta dough, saving you time and effort compared to manual techniques.b) Consistency: With a pasta machine, you can achieve consistent thickness and shape throughout your pasta, ensuring even cooking and a professional result every time.c) Versatility: Manual pasta machines often come with a variety of attachments, allowing you to create different types of pasta, including spaghetti, fettuccine, and lasagna sheets.d) Authenticity: By using a manual pasta machine, you can replicate the traditional techniques used by Italian nonnas for generations, resulting in truly authentic pasta.2. Getting Started with a Manual Pasta Machine (approximately 200 words):Before diving into the pasta-making process, it's important to familiarize yourself with your manual pasta machine. While models may vary slightly, the general steps and techniques remain the same. Follow these guidelines to get started:a) Preparation: Begin by gathering your ingredients – typically flour, eggs, and salt – and combine them to form a dough. Allow the dough to rest for 30 minutes, as this will make it easier to work with.b) Setting up the Machine: Attach the appropriate cutting attachment to the machine, depending on the type of pasta you want to make. Most manual pasta machines have adjustable thickness settings, so start with the widest setting and gradually work your way down to achieve your desired thickness.c) Rolling the Dough: Divide the dough into manageable portions and flatten each one with your hands. Feed the dough through the machine, starting at the widest setting. Fold the dough in half after each pass and repeat this process until the desired thickness is achieved.d) Shaping the Pasta: Once the pasta sheet reaches the desired thickness, switch to the cutting attachment for your chosen pasta shape. Pass the pasta sheet through the machine, and voila! You have freshly cut pasta ready for cooking.3. Cleaning and Maintenance Tips for Your Manual Pasta Machine (approximately 200 words):To ensure your manual pasta machine remains in optimal condition and longevity, it's essential to follow proper cleaning and maintenance procedures. Here are some useful tips:a) Basic Cleaning: After use, wipe away any excess flour or dough from the machine using a dry cloth or brush. Avoid using water to clean the machine, as this can cause rusting or damage.b) Thorough Cleaning: Periodically, disassemble the machine as per the manufacturer's instructions and clean each component thoroughly. Use warm, soapy water and a soft brush to remove any stubborn residue.c) Drying and Storage: After cleaning, ensure that all parts of the machine are completely dry before reassembling and storing it in a dry place. Avoid exposure to humidity or extreme temperatures, as this can affect its performance.Conclusion (approximately 100 words):Investing in a manual pasta machine can transform your pasta-making experience, allowing you to effortlessly create authentic and delicious homemade pasta. Whether you're a culinary enthusiast or a novice in the kitchen, using a manual pasta machine will streamline the process, offering you consistent results and a variety of pasta types. With the right techniques and maintenance, you'll be able to enjoy countless pasta dishes that will rival those from your favorite Italian restaurant. So, why wait? Start your pasta-making journey today and unlock a world of culinary possibilities!Keywords: manual pasta machine, homemade pasta, authentic pasta, pasta-making, Italian nonnas, manual techniques, pasta dough, cutting attachment, cleaning and maintenance, pasta types.

Purlin Profiles Cold Roll Forming Lines: Everything You Need to Know

A leading steel manufacturing company has recently announced the launch of their new Purlin Profiles Cold Roll Forming Lines. These state-of-the-art production lines are capable of manufacturing high-quality CZ purlin profiles, which are essential components in the construction of steel buildings and structures.The new roll forming lines have been designed with precision and efficiency in mind, utilizing the latest technology and manufacturing processes to ensure the highest level of quality and accuracy in the production of CZ purlin profiles. The company has invested heavily in research and development to create these advanced production lines, which are expected to set a new standard in the industry.The CZ purlin profiles produced by these new roll forming lines are known for their superior strength and durability. They are widely used in the construction industry for framing and supporting roof panels, wall panels, and other structural elements. The profiles are designed to provide exceptional load-bearing capacity, making them a preferred choice for engineers and builders.In addition to their exceptional strength, these CZ purlin profiles are also highly versatile. They can be easily customized to meet specific project requirements, with the ability to be tailored to various lengths, thicknesses, and shapes. This level of flexibility makes them an ideal solution for a wide range of construction applications.The launch of these new Purlin Profiles Cold Roll Forming Lines represents a significant milestone for the company, further solidifying their position as a leading manufacturer in the steel industry. With a strong commitment to innovation and quality, the company has continuously invested in the latest technologies and manufacturing processes to meet the evolving needs of their customers.The company's dedication to excellence is evident in their production facilities, which are equipped with state-of-the-art machinery and equipment. This allows them to consistently deliver products of the highest quality, meeting the stringent industry standards and specifications.Additionally, the company's team of skilled engineers and technicians plays a crucial role in the success of these new roll forming lines. Their expertise and knowledge ensure that the production processes run smoothly and efficiently, resulting in the consistent and reliable manufacturing of CZ purlin profiles.The introduction of these new Purlin Profiles Cold Roll Forming Lines is a testament to the company's commitment to innovation and progress. By continually investing in new technologies and processes, they are able to stay at the forefront of the industry and provide their customers with cutting-edge solutions.As the demand for high-quality steel products continues to grow, the company is well-positioned to meet the needs of a wide range of customers, including builders, contractors, and construction companies. The launch of these new roll forming lines will further strengthen their position in the market and solidify their reputation as a trusted and reliable supplier of CZ purlin profiles.In conclusion, the new Purlin Profiles Cold Roll Forming Lines introduced by the company represent a significant advancement in the production of CZ purlin profiles. With their focus on quality, innovation, and customer satisfaction, the company is well-equipped to meet the needs of the construction industry and continue to set new standards for steel manufacturing.

Revolutionary 3D Printer Utilizing Aluminium Extrusion Technology

Aluminium Extrusion 3D Printer Revolutionizing Manufacturing ProcessesIn recent years, the field of additive manufacturing has been rapidly evolving, with numerous advancements being made to enhance the capabilities and efficiency of 3D printers. One groundbreaking innovation that has garnered significant attention is the Aluminium Extrusion 3D Printer developed by a pioneering company that focuses on revolutionizing the manufacturing industry.Introducing lightweight and versatile materials into 3D printing has always been a challenge. However, this newly developed Aluminium Extrusion 3D Printer eliminates the boundaries faced by traditional printing methods by allowing for the creation of complex and intricate designs using aluminium as the primary printing material. This breakthrough technology brings forth a multitude of possibilities for various industries, ranging from aerospace and automotive to construction and consumer products.The construction of this cutting-edge printer involves utilizing high-quality components and state-of-the-art engineering techniques. The company behind this remarkable innovation has ensured that their printer is equipped with the latest advancements in the field of 3D printing technology. This includes a robust frame made from durable materials, precise extrusion systems, and advanced software for seamless operation.One significant advantage of the Aluminium Extrusion 3D Printer is its ability to fabricate large-scale prototypes and parts with exceptional precision. The printer's large build volume allows for the creation of objects up to 2 meters in length, eliminating the need for assembly or welding of multiple parts. This capability greatly reduces manufacturing time and costs, making it an attractive choice for industries looking to streamline their production processes.Moreover, the aluminium material used in the printing process offers several advantages over traditional printing materials. Aluminium has superior strength-to-weight ratio, excellent thermal conductivity, and high corrosion resistance. These properties make it an ideal choice for industries where lightweight structures and high-performance components are crucial. With the Aluminium Extrusion 3D Printer, manufacturers can now easily incorporate aluminium into their designs without compromising the structural integrity or performance of the final product.Furthermore, the Aluminium Extrusion 3D Printer is equipped with an advanced slicing software that ensures precise layer-by-layer deposition of aluminium. This software incorporates complex algorithms to optimize support structures and minimize material waste, resulting in cost-effective and sustainable manufacturing processes. Additionally, it allows for intricate geometries and intricate designs to be printed with minimal post-processing requirements, saving both time and resources.The impact of this Aluminium Extrusion 3D Printer on various industries cannot be overstated. In the aerospace industry, where weight reduction is critical, the ability to 3D print lightweight aluminium components opens up a realm of possibilities for optimizing fuel efficiency. Automotive manufacturers can leverage this technology to fabricate stronger and lighter parts, improving overall performance and reducing emissions. In the construction industry, the Aluminium Extrusion 3D Printer enables the rapid production of customized building components with unparalleled precision, revolutionizing the way structures are built.As the Aluminium Extrusion 3D Printer revolutionizes the manufacturing industry, this pioneering company continues to push the boundaries of 3D printing technology. Their commitment to innovation and dedication to quality ensures that manufacturers across various industries will benefit from this revolutionary printer. With its unparalleled capabilities and immense potential, the Aluminium Extrusion 3D Printer is set to reshape the manufacturing landscape and open up a new era of possibilities.

High Efficiency Horizontal Roof Panel Forming Machine for Faster Production

Introducing the Advanced Horizontal Roof Panel Forming MachineThe roofing industry is constantly evolving with technological advancements and innovative solutions. One such solution is the Horizontal Roof Panel Forming Machine, developed by a leading manufacturer in the industry.The company, with over 20 years of experience in the production of advanced roofing equipment, has recently unveiled their latest offering - the Horizontal Roof Panel Forming Machine. This state-of-the-art machine is designed to revolutionize the way roof panels are manufactured, offering increased efficiency, precision, and customization options.The Horizontal Roof Panel Forming Machine is equipped with advanced features that set it apart from traditional panel forming machines. It is capable of forming large roof panels with precision and speed, reducing production time and costs for manufacturers. The machine also allows for seamless customization, enabling the production of panels in various shapes, sizes, and patterns to meet the specific requirements of different roofing projects.In addition to its impressive functionality, the Horizontal Roof Panel Forming Machine is also built with user-friendly features, making it easy to operate and maintain. This facilitates a smooth and hassle-free manufacturing process for users, ensuring maximum productivity and minimal downtime.The company's commitment to innovation and quality is evident in the design and production of the Horizontal Roof Panel Forming Machine. Through extensive research and development, they have created a machine that meets the highest industry standards and exceeds the expectations of roofing professionals.The launch of the Horizontal Roof Panel Forming Machine represents a significant milestone for the company, further establishing their position as a leading provider of cutting-edge roofing equipment. With a strong focus on customer satisfaction and continuous improvement, the company continues to invest in research and development to bring innovative solutions to the market.To complement the Horizontal Roof Panel Forming Machine, the company also offers comprehensive training and support services to ensure that customers can maximize the benefits of this advanced technology. This includes training programs, technical assistance, and ongoing maintenance services to keep the machine operating at peak performance.As the roofing industry continues to evolve, the demand for efficient and versatile manufacturing solutions is on the rise. The Horizontal Roof Panel Forming Machine is well-positioned to meet this demand, offering a reliable and cost-effective solution for manufacturers looking to enhance their production capabilities.In conclusion, the introduction of the Horizontal Roof Panel Forming Machine by the company represents a significant advancement in the roofing industry. With its advanced features, user-friendly design, and commitment to quality, this machine is set to revolutionize the way roof panels are manufactured. As the industry continues to evolve, the company remains at the forefront of innovation, delivering cutting-edge solutions to meet the changing needs of roofing professionals.