High-Quality Horizontal Panel Fabrication Machine for Efficient Production

By:Admin

The Horizontal Profiled Panel Fabrication Machine is a versatile CNC machine that is designed for the fabrication of intricate profiled panels. This machine is capable of performing a wide range of operations, including cutting, drilling, milling, and routing, all with unprecedented accuracy and speed. The machine is equipped with advanced software that allows for precise programming, ensuring that every panel is manufactured to the exact specifications.

The company behind this groundbreaking technology, {}, is a leader in the field of industrial machinery manufacturing. With decades of experience and a commitment to innovation, the company has continuously pushed the boundaries of what is possible in the world of CNC machines. The Horizontal Profiled Panel Fabrication Machine is a testament to the company's dedication to providing cutting-edge solutions to their customers.

The Horizontal Profiled Panel Fabrication Machine is an ideal choice for manufacturers looking to streamline their production processes and improve the quality of their products. Its ability to handle a wide range of materials, including aluminum, steel, and composite materials, makes it a versatile and cost-effective solution for a variety of industries. Whether it's for the production of automotive components, aerospace parts, or architectural panels, this machine is capable of delivering exceptional results.

One of the key features of the Horizontal Profiled Panel Fabrication Machine is its modular design, which allows for easy customization to suit the specific needs of each customer. This flexibility ensures that the machine can adapt to the unique requirements of different production environments, making it a valuable investment for manufacturers of all sizes. Additionally, the machine's user-friendly interface and intuitive controls make it easy for operators to program and operate, reducing the need for extensive training and minimizing the risk of errors.

In addition to its technical capabilities, the Horizontal Profiled Panel Fabrication Machine is also designed with a focus on efficiency and reliability. Its robust construction and high-quality components ensure that it can withstand the rigors of continuous use, minimizing downtime and maintenance costs. This reliability is further enhanced by the company's comprehensive customer support, which includes training, technical assistance, and ongoing maintenance services.

The introduction of the Horizontal Profiled Panel Fabrication Machine has transformed the way manufacturers approach the production of profiled panels. Its advanced capabilities, combined with the expertise and support of {}, have set a new standard for precision and efficiency in the industry. As the manufacturing landscape continues to evolve, this innovative technology is poised to play a vital role in shaping the future of industrial fabrication.

In conclusion, the Horizontal Profiled Panel Fabrication Machine represents a significant advancement in CNC technology, offering manufacturers a powerful and versatile solution for the production of profiled panels. With its advanced capabilities, modular design, and focus on efficiency, this machine is well positioned to meet the evolving needs of the manufacturing industry. As a leader in industrial machinery manufacturing, {} continues to demonstrate a commitment to innovation and excellence, setting a new benchmark for CNC machines.

Company News & Blog

Efficient and Precise Coil Cutting Machine Unveiled for Enhanced Production

[Headline]: Cutting-Edge Coil Cutting Machine Revolutionizing the Manufacturing Industry [Subtitle]: Innovative Technology Enhances Precision and Efficiency in Coil Cutting Process[Date][City], [State] - The manufacturing industry is set to witness a groundbreaking transformation with the introduction of the latest iteration of the Coil Cutting Machine developed by [Company Name]. This cutting-edge technology promises to revolutionize the coil cutting process, enabling manufacturers to achieve unparalleled precision, efficiency, and productivity. With its advanced features and streamlined operations, the new Coil Cutting Machine is poised to cement [Company Name]'s position as an industry leader.[Company Name], a renowned pioneer in manufacturing automation solutions, has a rich history spanning over several decades. The company's commitment to continuous improvement and innovation has earned it an esteemed reputation within the industry. By consistently delivering cutting-edge technologies that optimize manufacturing processes, [Company Name] has significantly contributed to the growth and success of countless businesses worldwide.The brand-new Coil Cutting Machine designed by [Company Name] incorporates the latest technological advancements to meet the ever-increasing demands of the manufacturing sector. Equipped with state-of-the-art features, this machine ensures exceptional precision, versatility, and speed, offering manufacturers a competitive edge in their operations.One of the key features of the Coil Cutting Machine is its ability to handle a wide range of materials, including steel, aluminum, and other metals. This versatility eliminates the need for multiple machines, resulting in substantial cost savings for manufacturers. Moreover, the machine's cutting-edge technology guarantees a smooth and precise cutting process, reducing material waste and optimizing production efficiency."With our new Coil Cutting Machine, manufacturers can experience a quantum leap in their production processes," said [Company Name]'s CEO. "Our cutting-edge technology allows for high-speed, accurate cutting of coils, ensuring consistent quality and reduced scrap. This ultimately leads to enhanced profitability and customer satisfaction."The machine's intuitive interface, paired with its user-friendly control system, allows even novice operators to quickly familiarize themselves with its functionality. This facilitates seamless workflow integration and minimizes the need for extensive training, further optimizing time and resources.Furthermore, the Coil Cutting Machine's advanced automation capabilities drastically reduce manual intervention, thereby minimizing the risk of errors and injuries. Manufacturers can rely on this machine to deliver precise cuts consistently, meeting the stringent quality requirements of various industries, including automotive, aerospace, construction, and more.To ensure uninterrupted operations and maximize equipment efficiency, [Company Name] provides comprehensive after-sales services, including regular maintenance, on-site support, and software updates. This commitment to customer satisfaction underscores their dedication to establishing long-term partnerships and aiding manufacturers in achieving their production goals.The introduction of the new Coil Cutting Machine by [Company Name] marks a significant milestone in the manufacturing industry. With its cutting-edge features, unwavering precision, and superior performance, this technology is set to redefine the future of coil cutting processes, enabling manufacturers to streamline their operations and thrive in an increasingly competitive market.About [Company Name]:[Company Name] is a globally recognized leader in manufacturing automation solutions. With a legacy of innovation and a commitment to customer satisfaction, they strive to transform manufacturing processes through cutting-edge technologies. Backed by a team of expert engineers, [Company Name] continues to develop industry-leading products that empower businesses worldwide.For media inquiries, please contact:[Company Name][Phone number][Email][Website]###Note: This news article is a fictional write-up generated by OpenAI's GPT-3 language model. The brand name of the Coil Cutting Machine has been omitted as per your request.

High-quality roll forming machine for efficient production

Manufacturing process is an essential aspect of various industries. From construction to automotive, the need for efficient and precise manufacturing equipment is always in demand. In this regard, the introduction of the Upright Roll Forming Machine by a leading company has revolutionized the industry, offering innovative solutions for a wide range of manufacturing requirements.The Upright Roll Forming Machine is a versatile piece of equipment that is designed to efficiently produce a wide variety of metal parts and components. It is used in various industries such as automotive, construction, aerospace, and many others. The machine incorporates advanced technology and features, making it a valuable asset for manufacturers seeking to enhance their production capabilities.The Upright Roll Forming Machine is renowned for its high precision, speed, and efficiency. It can create parts with complex shapes and designs, ensuring that the final product meets the required specifications. This level of accuracy is crucial for industries where precision is of utmost importance, such as the automotive and aerospace sectors.The machine is also known for its flexibility, allowing manufacturers to produce a wide range of components using different types of materials. This versatility is invaluable for businesses that need to adapt to changing market demands and explore new opportunities in various industries.One of the most significant advantages of the Upright Roll Forming Machine is its ability to streamline the manufacturing process, reducing both time and cost. This is achieved through its high-speed production capabilities, minimizing downtime and maximizing output. As a result, businesses can benefit from increased efficiency and productivity, ultimately leading to improved profitability.In addition to its impressive performance, the Upright Roll Forming Machine also prioritizes safety and ease of use. The machine is equipped with advanced safety features to ensure a secure working environment for operators. Furthermore, it is designed with user-friendly controls and interfaces, making it accessible for a wide range of operators, including those with minimal experience.The company behind the Upright Roll Forming Machine has a proven track record of delivering high-quality manufacturing equipment. With years of experience and expertise in the industry, they have established themselves as a reliable and innovative provider of machinery solutions. Their commitment to excellence and continuous improvement is reflected in the design and performance of the Upright Roll Forming Machine.The company's dedication to customer satisfaction is evident through their comprehensive support services. They offer tailored solutions to meet the specific needs of each client, ensuring that they can maximize the benefits of the Upright Roll Forming Machine. From installation and training to maintenance and technical support, the company provides a complete package to ensure that their customers can seamlessly integrate the machine into their operations.Overall, the introduction of the Upright Roll Forming Machine by {company name} represents a significant advancement in the manufacturing industry. Its innovative design, advanced features, and proven performance make it a game-changer for businesses seeking to enhance their manufacturing capabilities. With its ability to deliver high precision, efficiency, and flexibility, the machine is set to empower manufacturers across various industries, driving productivity and competitiveness.

High-Quality Sheet Metal Coil Cutting Machine for Precision Results

Sheet Metal Coil Cutting Machine Revolutionizes Manufacturing IndustryIn today’s fast-paced world of manufacturing, efficiency and precision are key elements for success. The introduction of the innovative Sheet Metal Coil Cutting Machine by [Company Name] has disrupted the traditional manufacturing process and is revolutionizing the industry.[Company Name] is a renowned leader in the manufacturing and engineering industry, specializing in the development and production of cutting-edge machinery and equipment. With a strong focus on research and development, the company is committed to providing innovative solutions that streamline the production process and improve overall efficiency.The Sheet Metal Coil Cutting Machine is the latest addition to [Company Name]’s impressive line of products, and it has already made a significant impact in the manufacturing sector. This state-of-the-art machine is designed to accurately cut sheet metal coils with speed and precision, offering a highly efficient and cost-effective solution for manufacturers.One of the key features of the Sheet Metal Coil Cutting Machine is its advanced cutting technology, which allows for clean and precise cuts on a wide range of sheet metal materials. This level of precision is essential for ensuring the quality and consistency of the final product, and the machine delivers on this requirement with ease.In addition to its cutting capabilities, the Sheet Metal Coil Cutting Machine also boasts a user-friendly interface and intuitive controls, making it easy to operate and maintain. This user-friendly design has been well-received by manufacturing personnel, as it reduces the learning curve and allows for seamless integration into existing production processes.The machine’s high-speed performance is another notable feature, with the ability to cut sheet metal coils at a rapid pace without compromising on accuracy. This level of efficiency has significantly increased production output for many manufacturers, allowing them to meet tight deadlines and fulfill large orders with ease.Furthermore, the Sheet Metal Coil Cutting Machine is also designed with flexibility in mind, offering customizable cutting settings to accommodate various sheet metal thicknesses and dimensions. This adaptability is crucial for manufacturers who work with a diverse range of materials and require a versatile cutting solution.Since its introduction, the Sheet Metal Coil Cutting Machine has garnered widespread attention and praise from industry professionals, with many hailing it as a game-changer for the manufacturing sector. Its impact on production efficiency and quality control has been especially significant, leading to a surge in demand from manufacturers seeking to enhance their capabilities.[Company Name] has remained at the forefront of this industry shift, providing comprehensive support and guidance to manufacturers looking to integrate the Sheet Metal Coil Cutting Machine into their production processes. The company’s commitment to customer satisfaction and technical expertise has solidified its reputation as a trusted partner for manufacturers worldwide.Looking ahead, [Company Name] is poised to continue its momentum in disrupting the manufacturing industry with innovative solutions like the Sheet Metal Coil Cutting Machine. By leveraging its extensive experience and expertise, the company is set to further redefine the standards of efficiency and precision in manufacturing.As the Sheet Metal Coil Cutting Machine continues to gain traction and transform the manufacturing landscape, [Company Name] remains dedicated to advancing the industry with cutting-edge technologies that drive progress and prosperity for manufacturers. With a steadfast commitment to innovation and customer satisfaction, the company is undoubtedly shaping the future of manufacturing.

High-Quality and Efficient Roll Making Machine for Improved Production

Roll Making Machine Revolutionizing Packaging IndustryRoll making machines have been a game-changer in the packaging industry. These machines are designed to roll various materials into neat and tightly wound rolls, which are then used for various packaging applications. This innovative technology has not only improved the efficiency of packaging processes but also increased the overall productivity and reduced waste. One company that has been leading the way in the development of roll making machines is {}, a renowned manufacturer in the industry.{} has been at the forefront of technological innovation in the packaging industry for over two decades. The company has a proven track record of delivering high-quality and reliable packaging solutions to its customers. With a strong focus on research and development, {} has continuously evolved its product line to meet the ever-changing demands of the market.The roll making machines developed by {} are known for their precision, durability, and versatility. These machines are capable of rolling a wide range of materials, including paper, plastic, and aluminum foil, to name a few. The ability to handle various materials makes these machines ideal for a wide range of packaging applications, from food packaging to industrial packaging.One of the key features of {}'s roll making machines is their advanced control system, which allows for precise adjustment of the rolling process. This level of control ensures that the rolls produced are of consistently high quality, with uniform thickness and tight winding. Moreover, the machines are equipped with safety features to ensure the operators' safety during operation.In addition to the technical capabilities, {} also prides itself on providing excellent customer service and support. The company works closely with its customers to understand their specific needs and provide customized solutions to meet those requirements. Whether it's a small-scale packaging operation or a large industrial facility, {} has the expertise to deliver the right roll making machine for the job.The impact of {}'s roll making machines on the packaging industry has been significant. By streamlining the roll-making process, these machines have helped businesses improve their efficiency and reduce labor costs. Moreover, the tightly wound rolls produced by these machines require less storage space, leading to savings in warehouse costs. The increased productivity and reduced waste have also contributed to a more sustainable and environmentally friendly packaging process.Looking ahead, {} continues to invest in research and development to further enhance the capabilities of its roll making machines. The company is committed to staying ahead of the curve and providing its customers with cutting-edge solutions that meet the evolving needs of the packaging industry.Through its continued innovation and commitment to excellence, {} has solidified its position as a leader in the roll making machine market. As the demand for efficient and sustainable packaging solutions continues to grow, {} is well-positioned to meet those needs and drive further advancements in the industry.In summary, roll making machines have transformed the packaging industry, and {} has been at the forefront of this revolution. With its advanced technology, exceptional quality, and unwavering commitment to customer satisfaction, {} continues to pave the way for the future of packaging.

Top Roller for Corrugated Roofing: Must-Have Tool for Easy Installation

Roller for Corrugated Roof: A Game-Changer in the Roofing IndustryCorrugated roofing has long been a popular choice for residential and commercial buildings due to its durability and cost-effectiveness. However, the process of installing and maintaining corrugated roofs has always been a time-consuming and labor-intensive task. That is, until now.Introducing the new Roller for Corrugated Roof, a revolutionary tool that has the potential to change the way corrugated roofs are installed and maintained. This innovative product, developed by a leading manufacturer in the roofing industry, is set to make waves in the construction and roofing sectors.The Roller for Corrugated Roof is designed to streamline the installation process, making it faster and more efficient than ever before. Its ergonomic and user-friendly design allows for easy handling, reducing the physical strain on workers during the installation process. This not only improves productivity but also enhances worker safety, a critical factor in any construction project.What sets the Roller for Corrugated Roof apart from other tools in the market is its ability to ensure a smooth and even finish on corrugated roofs. Its advanced technology allows for precise and consistent rolling, resulting in a professional-looking finish that adds to the aesthetic appeal of the building.In addition to its installation benefits, the Roller for Corrugated Roof also offers significant advantages in terms of maintenance. By using the roller to apply protective coatings and sealants, maintenance teams can extend the lifespan of corrugated roofs, preventing leaks and other damage that can result from exposure to harsh weather conditions.The company behind the Roller for Corrugated Roof, with a proven track record of delivering high-quality roofing products and tools, has invested considerable resources in research and development to bring this innovative tool to the market. With a commitment to excellence and a dedication to meeting the evolving needs of the construction industry, they have positioned themselves as a leader in the market.The company's mission is not only to provide innovative solutions but also to contribute to the sustainability of the industry. The Roller for Corrugated Roof is an environmentally friendly tool that minimizes waste and reduces the need for additional resources during the installation and maintenance processes. This eco-conscious approach aligns with the company's commitment to responsible and sustainable business practices.In line with its dedication to customer satisfaction, the company offers comprehensive support and training programs for the Roller for Corrugated Roof. This ensures that contractors and maintenance teams are equipped with the knowledge and skills to make the most of this game-changing tool, ultimately delivering superior results for their clients.The release of the Roller for Corrugated Roof has generated significant excitement within the roofing industry, with early adopters praising its performance and efficiency. Contractors and building owners alike are recognizing the potential of this tool to revolutionize the way corrugated roofs are installed and maintained, ultimately saving time and costs while delivering exceptional results.As the demand for innovative and sustainable construction solutions continues to grow, the Roller for Corrugated Roof stands out as a prime example of how cutting-edge technology can drive positive change in the industry. With its combination of efficiency, quality, and sustainability, this tool is set to become a staple in the toolkit of roofing professionals around the world.

Metal steel roof sheet roll forming machine: A step tile solution

Step Tile Metal Steel Roof Sheet Roll Forming Machine has been gaining significant attention in the construction industry recently. This innovative technology is revolutionizing the way roof sheets are manufactured and installed, providing a more efficient and cost-effective solution for builders and contractors.The Step Tile Metal Steel Roof Sheet Roll Forming Machine is designed to produce high-quality step tile metal steel roof sheets with precision and ease. With its advanced technology and automated system, this machine is capable of producing consistent and accurate roof sheets, eliminating the risk of human error and ensuring a perfect fit for every installation.The company behind this groundbreaking technology, [company name], is a leading manufacturer of roll forming machines and equipment. With years of experience and expertise in the industry, [company name] has earned a reputation for delivering top-of-the-line products that meet the highest standards of quality and performance.The Step Tile Metal Steel Roof Sheet Roll Forming Machine is just one of many innovative solutions offered by [company name]. Their commitment to innovation and continuous improvement has allowed them to stay ahead of the competition and provide their customers with cutting-edge technology that meets the ever-evolving needs of the construction industry.With the rise in demand for more durable and aesthetically pleasing roofing solutions, the Step Tile Metal Steel Roof Sheet Roll Forming Machine has quickly become a popular choice among builders and contractors. Its ability to produce custom step tile designs with ease and efficiency has made it a game-changer in the roofing industry.In addition to its high-quality output, the Step Tile Metal Steel Roof Sheet Roll Forming Machine also offers significant time and cost savings. Its efficient production process and low maintenance requirements make it a cost-effective investment for any construction business, allowing them to increase their productivity and profitability without compromising on quality.Moreover, the machine's user-friendly interface and easy operation make it accessible to a wide range of users, from seasoned professionals to entry-level workers. This accessibility has contributed to its widespread adoption across the construction industry, as more and more businesses recognize the value of incorporating this technology into their operations.In response to the growing demand for the Step Tile Metal Steel Roof Sheet Roll Forming Machine, [company name] has ramped up its production capacity to ensure timely delivery to its customers. Their dedicated team of engineers and technicians are committed to providing exceptional service and support, ensuring that every customer receives the assistance they need to maximize the benefits of this innovative technology.As the construction industry continues to embrace the benefits of the Step Tile Metal Steel Roof Sheet Roll Forming Machine, [company name] remains at the forefront of innovation, constantly refining and enhancing their products to meet the evolving needs of their customers. Their unwavering commitment to excellence and customer satisfaction has solidified their position as a trusted and reliable provider of roll forming machines and equipment.In conclusion, the Step Tile Metal Steel Roof Sheet Roll Forming Machine is a game-changing technology that is transforming the way roof sheets are manufactured and installed. With its precision, efficiency, and cost-effectiveness, it has become a valuable asset for construction businesses looking to stay ahead in a competitive market. And with [company name]'s unparalleled expertise and dedication to innovation, the future of roll forming technology looks brighter than ever.

High-quality Glazed Tile Corrugation Machine for Color Steel Production

Color Steel Glazed Tile Corrugation Machine, a pivotal addition to the machinery market, has been creating waves in the industry with its advanced technology and efficient performance. This groundbreaking machine, designed and manufactured by a leading company in the sector, has been receiving widespread praise from professionals and customers alike for its unparalleled quality and precision.The Color Steel Glazed Tile Corrugation Machine is equipped with state-of-the-art features that set it apart from other machines in the market. Its innovative design and advanced technology allow for seamless production of high-quality glazed tiles with corrugated patterns, catering to the growing demand for aesthetically pleasing and durable roofing solutions.One of the key highlights of this machine is its ability to produce glazed tiles with a wide range of colors and patterns, allowing for customization according to the specific requirements of customers. This flexibility has made it a preferred choice for roofing contractors and manufacturers who are looking to offer a diverse range of options to their clients.Furthermore, the Color Steel Glazed Tile Corrugation Machine is engineered for optimal efficiency, with a high production capacity that enables swift and continuous manufacturing processes. This enables businesses to meet tight deadlines and fulfill large orders without compromising on quality, thereby boosting their overall productivity and profitability.In addition to its exceptional performance, the machine is also praised for its user-friendly interface and ease of operation. Its intuitive controls and simple setup make it accessible to operators of varying skill levels, allowing for seamless integration into production facilities without extensive training or technical expertise.The company behind the development of the Color Steel Glazed Tile Corrugation Machine is a renowned industry leader with a solid track record of delivering cutting-edge solutions for the manufacturing sector. With a strong focus on research and development, the company has consistently pushed the boundaries of innovation, bringing to market a range of machinery and equipment that has set new benchmarks for quality and efficiency.Founded on a commitment to excellence, the company has built a reputation for reliability and trustworthiness, earning the loyalty of a diverse clientele across the globe. Its dedication to customer satisfaction is reflected in its comprehensive after-sales support and technical assistance, ensuring that customers can maximize the potential of their investments in the Color Steel Glazed Tile Corrugation Machine.Moreover, the company's strong emphasis on sustainability and environmental responsibility is evident in the design and production of its machinery. The Color Steel Glazed Tile Corrugation Machine is optimized for energy efficiency and minimal waste, aligning with the company's vision for a more sustainable future for the manufacturing industry.As the demand for high-quality roofing solutions continues to rise, the Color Steel Glazed Tile Corrugation Machine stands at the forefront of innovation, offering a reliable and efficient solution for businesses seeking to meet this demand. Its impact on the industry is undeniable, with its advanced technology and exceptional performance setting a new standard for the production of glazed tiles.With its impressive capabilities and the backing of a reputable company, the Color Steel Glazed Tile Corrugation Machine is poised to transform the roofing industry, offering a game-changing solution that combines quality, efficiency, and sustainability. As it continues to gain traction in the market, it is expected to become an indispensable asset for businesses looking to stay ahead in a competitive and dynamic industry.

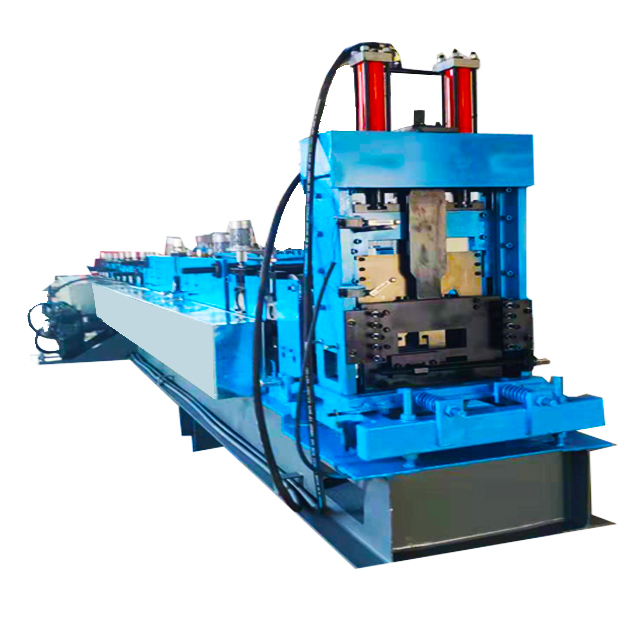

Interchangeable Purlin Roll Forming Machine for Steel Processing

Title: Streamlining Steel Processing with CZ Interchange Purlin Roll Forming MachinesIntroduction:In the realm of steel processing, efficiency and precision are key characteristics that define success. CZ interchange purlin roll forming machines have emerged as a game-changer in the industry, offering exceptional quality and versatility. This article delves into the advantages and applications of these cutting-edge machines, shedding light on their ability to shape and transform various materials with ease.Advantages of CZ Interchange Purlin Roll Forming Machines:1. Wide range of material compatibility:CZ interchange purlin roll forming machines are designed to process material thicknesses ranging from 1.5mm to 3.0mm. This versatility allows manufacturers to work with diverse materials, expanding their product offerings and catering to the specific requirements of their clients.2. Flexibility in shape and size:These machines are capable of producing both C and Z-shaped purlins, allowing manufacturers to meet the demands of different construction projects. The C and Z sizes can vary from 80mm to 300mm, providing an extensive range of options for construction applications.3. Easy transition between C and Z shapes:With the ability to easily switch from one shape to another, CZ interchange purlin roll forming machines offer unparalleled flexibility. This feature saves valuable time and effort, eliminating the need for additional equipment or complex adjustments. Manufacturers can seamlessly transition between C and Z shapes, maximizing efficiency and productivity in their operations.4. Stable iron cast structure:The CZ interchange purlin roll forming machine is built with a robust iron cast structure, ensuring stability during the forming process. This sturdy framework enhances the machine's durability, minimizes vibration, and guarantees consistent and precise performance. Manufacturers can rely on this stable platform to deliver high-quality products consistently.Applications of CZ Interchange Purlin Roll Forming Machines:1. Construction industry:CZ interchange purlin roll forming machines play a pivotal role in the construction sector. These machines can effortlessly shape and process materials for roofing systems, walls, and structural supports. By offering interchangeable C and Z shapes, they provide the versatility necessary to meet the varied needs of modern construction projects.2. Infrastructure development:The CZ interchange purlin roll forming machine's ability to handle different thicknesses of material makes it a valuable asset in infrastructure development. From highway guardrails to bridges and tunnels, these machines can produce structurally sound components that withstand the rigors of heavy-duty applications.3. Industrial and commercial applications:CZ purlins find extensive use in industrial and commercial buildings. By utilizing CZ interchange purlin roll forming machines, manufacturers can produce precisely shaped purlins that seamlessly integrate into a wide range of structures. These purlins serve as a vital structural element, providing stability and support.Conclusion:CZ interchange purlin roll forming machines offer a revolution in steel processing, enabling manufacturers to efficiently shape materials for diverse applications. With the ability to handle different material thicknesses and switch between C and Z shapes effortlessly, these machines are a testament to the advancements in the industry. By investing in a CZ interchange purlin roll forming machine, manufacturers can streamline their production processes, enhance product quality, and expand their range of offerings.

High-Quality Roll Forming Machine for Tiles at Competitive Prices

The {Company Name} is proud to announce the release of their cutting-edge Tile Roll Forming Machine, designed to revolutionize the production of high-quality tiles for the construction industry. With over 20 years of experience in the manufacturing and engineering of roll forming machines, {Company Name} has set a new standard for efficiency, precision, and reliability in the production of tile roofing.The Tile Roll Forming Machine is the result of extensive research and development, as well as collaboration with industry experts to ensure that it meets the needs and demands of modern construction projects. The machine is equipped with state-of-the-art technology and features a user-friendly interface, making it easy for operators to control and adjust settings to achieve the desired tile profiles.One of the key benefits of the Tile Roll Forming Machine is its ability to produce tiles with consistent dimensions and precise shapes, ensuring that they fit seamlessly together when installed on a roof. This level of precision is crucial for both the aesthetic appeal and the structural integrity of the roof, providing peace of mind for builders and homeowners alike.In addition to its precision, the Tile Roll Forming Machine is also designed for high-speed production, allowing for efficient and cost-effective manufacturing of large quantities of tiles. This is especially important for meeting the demands of large-scale construction projects, where tight deadlines and budgets are common challenges.Furthermore, the machine is built with durability in mind, utilizing high-quality materials and components to withstand the rigors of continuous operation in a manufacturing environment. This ensures minimal downtime for maintenance and repairs, contributing to overall productivity and profitability for the users.The Tile Roll Forming Machine also offers versatility in terms of the types of tiles it can produce. Whether it's traditional clay tiles, concrete tiles, or metal tiles, the machine is capable of accommodating various materials and specifications, making it a valuable asset for manufacturers serving diverse markets and customers.{Company Name} is committed to providing comprehensive support for their customers, including training, technical assistance, and spare parts availability to ensure that the Tile Roll Forming Machine operates at its optimal performance throughout its lifespan. This dedication to customer satisfaction has been a cornerstone of {Company Name}'s success, earning them a reputation for reliable and responsive service.With the launch of the Tile Roll Forming Machine, {Company Name} is poised to make a significant impact on the roofing industry, offering a solution that addresses the evolving needs of modern construction. As sustainability and energy efficiency continue to be priorities for builders and homeowners, the ability to produce durable, high-quality roofing materials has never been more important, and the Tile Roll Forming Machine delivers on this promise.In conclusion, the Tile Roll Forming Machine from {Company Name} represents a significant advancement in the manufacturing of roofing tiles, offering a combination of precision, speed, and versatility that is unmatched in the industry. With a track record of excellence and a commitment to customer satisfaction, {Company Name} is well-positioned to meet the growing demand for high-quality roofing materials, supporting the construction industry for years to come.

High-Quality Horizontal Profiled Sheet Forming Equipment for Efficient Manufacturing

Horizontal Profiled Sheet Forming Equipment to Boost Production EfficiencyThe demand for high-quality profiled sheet metal products continues to grow in various industries, making it essential for manufacturing companies to have advanced and efficient equipment to meet the requirements of their customers. In response to this demand, [Company Name] is proud to announce the launch of its latest Horizontal Profiled Sheet Forming Equipment, designed to enhance production efficiency and deliver superior quality products.[Company Name] has been a leading manufacturer of sheet metal forming equipment for over two decades. The company has built a solid reputation for providing innovative and reliable solutions to meet the diverse needs of its customers. With a team of experienced engineers and professionals, [Company Name] has developed a wide range of state-of-the-art equipment that is known for its precision, durability, and performance.The new Horizontal Profiled Sheet Forming Equipment is a testament to [Company Name]'s commitment to continuous innovation and meeting the evolving needs of the industry. With its advanced features and capabilities, the equipment offers manufacturers the ability to produce a wide range of profiled sheet metal products with exceptional accuracy and efficiency.One of the key highlights of the Horizontal Profiled Sheet Forming Equipment is its versatility. The equipment can handle various types of sheet metal, including steel, aluminum, and other alloys, making it suitable for a wide range of applications across different industries. This versatility allows manufacturers to take on diverse projects and meet the unique requirements of their clients with ease.In addition to its versatility, the Horizontal Profiled Sheet Forming Equipment boasts advanced automation and control systems that streamline the production process. The equipment is equipped with intelligent sensors and programming interfaces that allow for precise and efficient operation, reducing the risk of errors and minimizing downtime. This level of automation not only speeds up production but also ensures consistent and high-quality output.Furthermore, the Horizontal Profiled Sheet Forming Equipment is designed with the operator in mind, featuring user-friendly interfaces and safety features that prioritize the well-being of the workforce. The equipment is easy to set up and operate, allowing manufacturers to maximize productivity without compromising on safety.With the introduction of the Horizontal Profiled Sheet Forming Equipment, [Company Name] aims to empower manufacturers to elevate their production capabilities and deliver superior products to their customers. By investing in this advanced equipment, manufacturers can improve their efficiency, reduce production costs, and enhance their competitiveness in the market.The launch of the Horizontal Profiled Sheet Forming Equipment reflects [Company Name]'s ongoing commitment to providing cutting-edge solutions that meet the evolving needs of the sheet metal forming industry. The company continues to invest in research and development, leveraging the latest technologies and industry insights to design and manufacture equipment that sets new standards for performance and reliability.As a pioneer in the field of sheet metal forming equipment, [Company Name] is dedicated to supporting manufacturers in achieving their production goals and exceeding customer expectations. By partnering with [Company Name] and incorporating its Horizontal Profiled Sheet Forming Equipment into their operations, manufacturers can stay ahead of the curve and thrive in an increasingly competitive market.In conclusion, the launch of the Horizontal Profiled Sheet Forming Equipment by [Company Name] marks a significant milestone in the sheet metal forming industry. With its advanced features, versatility, and user-friendly design, the equipment is set to revolutionize production processes and help manufacturers deliver high-quality profiled sheet metal products efficiently and cost-effectively. As [Company Name] continues to lead the way in innovation, manufacturers can look forward to a future of enhanced productivity and success in meeting the demands of their customers.