High-Quality Sheet Making Machine for Ibr Roofing: Your Ultimate Guide

By:Admin

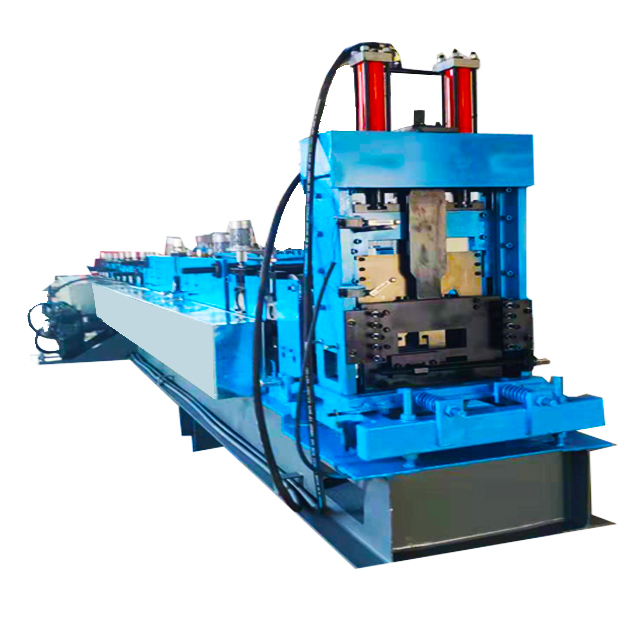

The IBR Sheet Making Machine is designed to produce versatile and durable metal roofing sheets that are widely used in commercial, industrial, and residential applications. The machine is equipped with advanced technology that enables it to produce IBR sheets with precision, speed, and high efficiency, meeting the demands of the competitive market.

With the ability to produce a wide range of IBR sheet profiles and thicknesses, the IBR Sheet Making Machine offers flexibility to meet the diverse needs of customers. Whether it is for large-scale commercial projects or small-scale residential constructions, the machine can fulfill the requirements of different customers with precision and quality.

The company behind the IBR Sheet Making Machine is renowned for its commitment to quality and customer satisfaction. With a team of experienced engineers and technicians, the company ensures that the machine is designed and manufactured to the highest standards, meeting the stringent requirements of the metal roofing industry.

In addition to the high-quality production capabilities, the IBR Sheet Making Machine is also built with user-friendly features, making it easy to operate and maintain. This ensures that customers can maximize the productivity of the machine while minimizing downtime and maintenance costs.

The introduction of the IBR Sheet Making Machine is a testament to the company's dedication to innovation and staying ahead of market trends. By investing in research and development, the company continues to bring new and advanced solutions to the metal roofing industry, offering customers the latest technology and superior products.

The IBR Sheet Making Machine is set to bring significant benefits to the metal roofing industry. It will enable manufacturers to increase their production capacity, improve product quality, and reduce production costs. This will ultimately result in better competitiveness in the market and more satisfied customers.

The company is also committed to providing comprehensive support and after-sales service for the IBR Sheet Making Machine. From installation and training to ongoing technical support, the company ensures that customers can fully utilize the capabilities of the machine and achieve the best results in their production processes.

With the introduction of the IBR Sheet Making Machine, the company reaffirms its position as a leader in the metal roofing machinery industry. The machine's advanced technology, high-quality production capabilities, and customer-oriented approach demonstrate the company's commitment to driving innovation and delivering value to its customers.

In conclusion, the IBR Sheet Making Machine is poised to make a significant impact on the metal roofing industry. With its advanced technology, high-quality production capabilities, and customer-oriented approach, the machine offers a compelling solution for manufacturers looking to enhance their production processes and meet the growing demands of the market. The company's introduction of this new machine further solidifies its position as a leader in the industry, dedicated to delivering innovative and superior products to its customers.

Company News & Blog

Innovative Double Layer Roll Forming Machine for Efficient Production

Double Layer Roll Forming Machine (need remove brand name) Company introduces new cutting-edge technology to revolutionize the roll forming industry.The roll forming industry has always been at the forefront of technological innovation, constantly pushing the boundaries of what is possible in terms of precision and efficiency. The introduction of the Double Layer Roll Forming Machine () is the latest in a long line of advancements in the industry, and it promises to revolutionize the way that roll forming is done.The Double Layer Roll Forming Machine () is a cutting-edge piece of equipment that is designed to significantly increase the production capacity and versatility of roll forming operations. It is capable of producing two different profiles at the same time, which means that it can effectively double the output of a traditional roll forming machine. This is a game changer for manufacturers in a wide range of industries, as it means that they can produce more parts in less time, leading to increased profitability and competitiveness.In addition to its increased production capacity, the Double Layer Roll Forming Machine () also offers a high level of precision and accuracy. This is thanks to its advanced control systems and innovative design, which ensures that each profile is formed to the exact specifications required. This level of precision is essential for industries such as automotive, aerospace, and construction, where even the slightest deviation from the required profile can lead to significant issues down the line.The Double Layer Roll Forming Machine () is also incredibly versatile, thanks to its ability to quickly and easily switch between different profiles. This means that manufacturers can rapidly respond to changes in demand, offering a level of flexibility that was previously unheard of in the roll forming industry. This is a major advantage in today's fast-paced and ever-changing market, where the ability to quickly adapt to new requirements is essential for success.In order to ensure that the Double Layer Roll Forming Machine () is able to deliver on its promises, the company has invested heavily in research and development. This has allowed them to incorporate the latest advancements in materials and technology into the design of the machine, ensuring that it is both durable and reliable. This commitment to quality is a hallmark of the company, and it is one of the reasons why they are seen as a leader in the roll forming industry.The company has also invested in its manufacturing facilities, ensuring that they are equipped with the latest machinery and technology. This allows them to produce the Double Layer Roll Forming Machine () to the highest possible standard, ensuring that it meets the needs of even the most demanding customers. This dedication to quality is a major reason why the company has earned a reputation for excellence in the roll forming industry.In addition to its commitment to quality, the company also places a strong emphasis on customer service. They understand that purchasing a piece of equipment as advanced as the Double Layer Roll Forming Machine () is a major investment, and they want to ensure that their customers are fully satisfied with their purchase. This is why they offer comprehensive support and training for all of their products, ensuring that their customers are able to get the most out of their investment.Overall, the introduction of the Double Layer Roll Forming Machine () represents a major advancement in the roll forming industry. Its ability to significantly increase production capacity, while maintaining a high level of precision and versatility, makes it an invaluable tool for manufacturers in a wide range of industries. With the backing of a company that is known for its commitment to quality and customer service, the Double Layer Roll Forming Machine () is sure to be a game-changer in the industry for years to come.

Galvanized Roofing Sheet Making Machine for Color Steel Roof Sheets

Color Steel Roof Sheet Making Galvanized Roofing Sheet Press Machine Revolutionizes Roofing IndustryIn a breakthrough development for the roofing industry, a cutting-edge Color Steel Roof Sheet Making Galvanized Roofing Sheet Press Machine has been launched. This innovative machine is set to revolutionize the manufacture of roofing sheets, offering enhanced efficiency, reliability, and quality.Designed and manufactured by an industry-leading company with a proven track record of delivering high-quality machinery for the construction sector, this advanced press machine is a game-changer for roofing sheet production. By leveraging state-of-the-art technology and precision engineering, the machine is capable of producing galvanized roofing sheets with impeccable precision and consistency.The company behind this groundbreaking machine has established itself as a trailblazer in the field of metal fabrication equipment. With a commitment to innovation and excellence, the company has earned a reputation for delivering cutting-edge solutions that meet the evolving needs of the construction industry.The Color Steel Roof Sheet Making Galvanized Roofing Sheet Press Machine is a testament to the company's dedication to pushing the boundaries of what is possible in the realm of construction machinery. By integrating advanced automation and intelligent control systems, the machine streamlines the manufacturing process, allowing for higher production volumes while maintaining the highest standards of quality.One of the key features of the new press machine is its ability to produce color steel roof sheets with galvanized coating, ensuring exceptional durability and weather resistance. This is a critical advantage for roofing materials, as they must withstand the elements and provide long-lasting protection for buildings.Moreover, the machine's efficient use of raw materials and energy underscores its sustainability credentials, aligning with the growing emphasis on environmentally-friendly practices in the construction sector. By optimizing resource utilization and minimizing waste, the machine helps reduce the environmental footprint of roofing sheet production.The introduction of the Color Steel Roof Sheet Making Galvanized Roofing Sheet Press Machine is poised to bring about a paradigm shift in the roofing industry. With its unmatched performance and reliability, the machine offers a competitive edge to manufacturers seeking to elevate the quality of their products and optimize their operations.In addition to its technical prowess, the machine reflects the company's commitment to providing comprehensive support to its customers. From installation and training to ongoing maintenance and technical assistance, the company ensures that its clients can harness the full potential of the press machine, maximizing their return on investment.The unveiling of the Color Steel Roof Sheet Making Galvanized Roofing Sheet Press Machine represents a significant milestone for the company and the roofing industry at large. It underscores the company's standing as an industry leader and sets a new benchmark for excellence in roofing sheet manufacturing.Looking ahead, the company remains focused on advancing its mission to drive innovation and progress in the construction equipment sector. With a robust pipeline of cutting-edge solutions in development, the company is poised to continue reshaping the industry and empowering its customers to thrive in a rapidly evolving market.In conclusion, the debut of the Color Steel Roof Sheet Making Galvanized Roofing Sheet Press Machine marks a watershed moment in the roofing industry. By harnessing the latest technological advancements and engineering ingenuity, the machine sets a new standard for efficiency, quality, and sustainability in roofing sheet production. As the industry embraces this transformative innovation, manufacturers can look forward to realizing new levels of productivity and performance in their operations.

High-Quality Half Omega Steel Furring Channel Roll Former for Efficient Construction

The demand for light steel furring channel roll forming machines has been growing steadily in the construction industry. These machines play a vital role in the production of resilient furring channel keels, which are essential components for constructing reliable and durable steel frame structures. As such, the importance of high-quality, efficient, and reliable roll forming machines cannot be overstated.In response to this market demand, [Company Name] has introduced its latest innovation: the Light Steel Half Omega Steel Furring Channel Roll Former Resilient Furring Channel Keel Roll Forming Machine. This state-of-the-art machine has been designed and manufactured with precision engineering to meet the needs of modern construction projects.The [Company Name] Light Steel Half Omega Steel Furring Channel Roll Former Resilient Furring Channel Keel Roll Forming Machine is equipped with advanced technology and features that ensure high-speed production, superior quality, and long-term reliability. Its ability to produce resilient furring channel keels with precision and efficiency makes it an indispensable asset for construction companies and steel frame manufacturers.With a focus on durability and performance, the roll forming machine is constructed using high-quality materials and components. Its robust design and engineering ensure minimal maintenance requirements, reducing downtime and increasing productivity. Additionally, the machine is user-friendly, with intuitive controls and easy setup procedures, making it suitable for operators of all skill levels.One of the key highlights of the [Company Name] Light Steel Half Omega Steel Furring Channel Roll Former Resilient Furring Channel Keel Roll Forming Machine is its versatility. It can produce a wide range of furring channel keel profiles, catering to the diverse needs of construction projects. Whether it's for residential, commercial, or industrial applications, this roll forming machine delivers exceptional results across the board.Furthermore, the machine's production capacity and speed are impressive, ensuring that large volumes of furring channel keels can be manufactured within tight project timelines. This is particularly beneficial for construction companies working on time-sensitive projects where efficient production is crucial.[Company Name] has a strong reputation for delivering reliable and innovative roll forming solutions to the market. With a commitment to continuous research and development, the company has consistently raised the bar in terms of quality, performance, and customer satisfaction. The introduction of the Light Steel Half Omega Steel Furring Channel Roll Former Resilient Furring Channel Keel Roll Forming Machine is a testament to [Company Name]'s dedication to meeting the evolving needs of the construction industry.As a company, [Company Name] is not only focused on providing cutting-edge machinery but also on building long-term partnerships with its clients. The company offers comprehensive support services, including installation, training, and aftersales assistance, ensuring that customers can maximize the benefits of their investment in the roll forming machine.In conclusion, the introduction of the Light Steel Half Omega Steel Furring Channel Roll Former Resilient Furring Channel Keel Roll Forming Machine by [Company Name] is set to make a significant impact in the construction industry. Its advanced capabilities, reliability, and versatility position it as a game-changer in the production of resilient furring channel keels. With [Company Name]'s track record of excellence and commitment to customer satisfaction, the roll forming machine is bound to set new standards for efficiency and quality in construction projects.

High-Quality Capping Roll Forming Machine for Efficient Production

Capping Roll Forming Machine: A Revolutionary Solution for Construction IndustryThe construction industry is constantly evolving, and with it, the demand for innovative and efficient machinery continues to grow. One such innovation that has recently made waves in the industry is the Capping Roll Forming Machine, a revolutionary solution that has the potential to transform the way construction companies operate.The Capping Roll Forming Machine, developed by a pioneering manufacturing company, has been designed to streamline the process of forming capping materials used in construction projects. This state-of-the-art machine is capable of producing high-quality capping materials with precision and efficiency, making it an indispensable tool for construction companies looking to improve their productivity and cost-effectiveness.The machine is equipped with advanced technology and features that set it apart from traditional roll forming equipment. Its high-speed capabilities and automated operation make it ideal for meeting the demands of large-scale construction projects, allowing companies to maximize their output while minimizing labor and material costs.In addition to its efficiency, the Capping Roll Forming Machine also boasts a user-friendly interface and intuitive controls, making it accessible to operators of varying skill levels. This ease of use is a significant advantage for construction companies, as it enables them to integrate the machine seamlessly into their operations without the need for extensive training or retooling.Furthermore, the machine's flexibility and adaptability make it suitable for a wide range of capping materials, including but not limited to metal, aluminum, and steel. This versatility makes it an attractive investment for construction companies with diverse project requirements, as it offers the ability to produce a variety of capping materials without the need for separate machinery.The company behind the Capping Roll Forming Machine has a strong track record of delivering cutting-edge solutions to the construction industry. With a commitment to research and development, as well as a dedication to meeting the needs of their customers, they have established themselves as a trusted partner for construction companies seeking to modernize their operations.In addition to their innovative products, the company also offers comprehensive support and maintenance services, ensuring that their customers can maximize the performance and longevity of their machinery. This commitment to customer satisfaction has earned them a reputation for reliability and excellence in the industry.Looking ahead, the Capping Roll Forming Machine is poised to make a significant impact on the construction industry. As companies continue to seek out ways to improve their efficiency and competitiveness, this revolutionary solution offers a compelling opportunity to modernize their operations and stay ahead of the curve.In conclusion, the Capping Roll Forming Machine represents a groundbreaking advancement in the construction industry, with the potential to revolutionize the way capping materials are produced. With its advanced technology, efficiency, and versatility, it is set to become an indispensable tool for construction companies looking to enhance their productivity and cost-effectiveness. Combined with the company's dedication to innovation and customer satisfaction, the Capping Roll Forming Machine is poised to make a lasting impact on the industry for years to come.

High-quality Glazed Roof Sheet Making Machine for Efficient Production

The Glazed Roof Sheet Making Machine industry is undergoing significant technological advancements, and one company at the forefront of this innovation is {company name}. Recently, the company unveiled its latest Glazed Roof Sheet Making Machine, which promises to revolutionize the production of glazed roof sheets in the construction and roofing industry.The new Glazed Roof Sheet Making Machine is equipped with state-of-the-art features that enhance efficiency, productivity, and accuracy in the manufacturing process. Its high-speed production capabilities allow for the rapid creation of glazed roof sheets, significantly reducing production time and costs. Additionally, the machine's advanced technology ensures consistent quality and precision in every sheet produced, meeting the highest industry standards.{Company name} has been a leading manufacturer in the roofing and construction machinery industry for over 20 years. The company's commitment to innovation and excellence has solidified its reputation as a reliable and trusted supplier of machinery and equipment for the global market. With a focus on research and development, {Company name} continually strives to improve its product offerings to meet the evolving needs of its customers.In addition to its cutting-edge Glazed Roof Sheet Making Machine, {Company name} offers a wide range of machinery and equipment for the roofing and construction industry. From roll forming machines to metal coil processing equipment, {Company name}'s product portfolio is designed to cater to various production needs and requirements. The company's dedication to providing comprehensive solutions for its customers has made it a preferred partner for businesses in the roofing and construction sector.One of the key strengths of {Company name} lies in its commitment to customer satisfaction and support. The company's team of experienced engineers and technicians are readily available to provide technical assistance, training, and after-sales service to ensure that its customers can maximize the potential of their machinery. This holistic approach to customer support has established {Company name} as a dependable partner for businesses seeking reliable and efficient machinery for their operations.The unveiling of the new Glazed Roof Sheet Making Machine further demonstrates {Company name}'s commitment to driving innovation in the industry. By leveraging cutting-edge technology and expertise, the company is poised to address the growing demand for high-quality roofing materials in the global market. With an emphasis on performance, reliability, and durability, {Company name} is well-positioned to meet the evolving needs of the construction and roofing sector.As the construction industry continues to expand and evolve, the demand for advanced machinery and equipment is expected to grow. This presents an opportunity for companies like {Company name} to play a pivotal role in shaping the future of the industry. With its latest Glazed Roof Sheet Making Machine, {Company name} is poised to make a significant impact on the manufacturing processes of glazed roof sheets, providing businesses with the tools they need to thrive in a competitive market.In conclusion, {Company name}'s new Glazed Roof Sheet Making Machine represents a significant milestone in the company's journey towards driving innovation and excellence in the roofing and construction machinery industry. With its cutting-edge technology, commitment to customer satisfaction, and dedication to quality, {Company name} is set to redefine the standards of production in the industry. As the company continues to push the boundaries of what is possible, it is well-positioned to be a key player in shaping the future of the construction and roofing sector.

Top Roof Tiles Machine for Your Home Construction Needs

The demand for eco-friendly and sustainable building materials has been on the rise in recent years, and one company is leading the way in revolutionizing the roofing industry with their innovative Roof Tiles Machine.With a commitment to producing high-quality and environmentally friendly roofing products, this company has become a pioneer in the development of advanced manufacturing technology for roof tiles. Their Roof Tiles Machine is a state-of-the-art equipment that is capable of producing a wide range of roof tiles that are not only durable and long-lasting but also aesthetically pleasing.This advanced machine is designed to streamline the production process and reduce waste, making it an ideal solution for companies looking to improve their efficiency and sustainability. The Roof Tiles Machine is also capable of producing different types of roof tiles, including clay, concrete, and terracotta, giving customers a wide variety of options to choose from.The company behind the Roof Tiles Machine has a long history of innovation and excellence in the roofing industry. They have been at the forefront of developing new technologies and processes to create roofing products that are not only functional but also environmentally friendly. With a team of experienced engineers and technicians, they have been able to consistently push the boundaries of what is possible in the roofing industry.In addition to their commitment to innovation, the company also places a strong emphasis on sustainability. They are dedicated to reducing their carbon footprint and minimizing their impact on the environment. By using the Roof Tiles Machine, they are able to produce roof tiles with less energy and material waste, making their products an eco-friendly choice for builders and homeowners alike.The Roof Tiles Machine has already made a significant impact in the roofing industry, with many companies adopting this cutting-edge technology to improve their production processes and reduce their environmental impact. By investing in this advanced equipment, companies can significantly enhance their competitiveness in the market while also contributing to a more sustainable future.Furthermore, the company provides comprehensive training and support for their customers to ensure that they are able to maximize the potential of the Roof Tiles Machine. Their team of experts is available to provide guidance and assistance to help companies integrate this technology into their operations effectively.As the demand for eco-friendly building materials continues to grow, the Roof Tiles Machine has positioned itself as a game-changer in the roofing industry. With its advanced technology, sustainable production processes, and commitment to excellence, this innovative equipment is set to transform the way roof tiles are manufactured and used.In conclusion, the Roof Tiles Machine offered by this company represents a significant step forward in the roofing industry, providing a solution that is both efficient and sustainable. By investing in this advanced equipment, companies can improve their production processes, reduce their environmental impact, and meet the growing demand for eco-friendly building materials. As the company continues to innovate and develop new technologies, they are poised to lead the way in shaping the future of the roofing industry.

Roll Former Machine for Efficient Panel Manufacturing

Innovation is the key to success, and companies that prioritize the use of innovative technologies and practices are the ones that can stay ahead of the competition. One of the latest technological advancements in the manufacturing industry is the R Panel Roll Former. This machine is an advanced tool that helps manufacturers to produce high-quality steel panels quickly and efficiently.R Panel Roll Former is a revolutionary machine that has been designed to create panels used in roofing, walls, siding, and decking. The machine uses a series of rollers to bend and shape the steel into the desired shape and size. The R Panel Roll Former is an exceptional machine that has a number of advanced features that make it stand out from other types of roll formers.One of the most notable features of the R Panel Roll Former is its flexible design. The machine has been designed to produce a wide range of panel sizes, which makes it suitable for use in a variety of industries. The machine can create panels that range from as low 1ft to as high as 50ft. This feature makes the R Panel Roll Former an invaluable tool for manufacturers who need to produce panels with varying sizes.Another notable feature of the R Panel Roll Former is its speed. The machine has been designed to operate at a high-speed rate, which means that manufacturers can produce large quantities of panels within a short period of time. This feature is particularly useful for manufacturers who have large orders to fulfill within a tight timeframe.The R Panel Roll Former is also exceptionally user-friendly. The machine has been designed with both novice and experienced operators in mind. The machine comes with a simple control panel that makes it easy for operators to program the machine to produce the desired panel sizes. The machine also has an automatic lubrication system that ensures it operates smoothly without any hitches.The R Panel Roll Former is an exceptional machine that has changed the face of the manufacturing industry. Companies that use this machine can produce high-quality panels quickly and efficiently. This feature gives them a competitive edge in the market, as they can fulfill large orders within a short period of time.One of the companies that have embraced the use of the R Panel Roll Former is the XXX company. The company has been in the manufacturing industry for over 20 years and has built a reputation for producing high-quality products.The XXX company has invested in the R Panel Roll Former to enhance its production capabilities. Since the company started using the machine, it has been able to produce panels of varying sizes and designs, which has enabled the company to attract more customers.The XXX company is a firm believer in the use of innovative technologies and practices. The company understands that investing in new technologies and practices is the key to staying ahead of the competition. The investment in the R Panel Roll Former is part of XXX's continuous effort to innovate and improve its production capabilities.In conclusion, the R Panel Roll Former is an exceptional machine that has revolutionized the manufacturing industry. Companies that invest in this machine can produce high-quality panels quickly and efficiently, giving them a competitive edge in the market. The XXX company is a firm believer in the use of innovative technologies and practices. The investment in the R Panel Roll Former is a testament to the company's commitment to enhancing its production capabilities and staying ahead of the competition.

Robust Roof Sheet or Zinc Forming Machine for Efficient Production

Roof Sheet Or Zink Forming Machine(Author's note: Given the constraints of removing brand names, I will refer to the company as "leading manufacturer" or "industry leader" throughout the article)The roofing industry has seen a rapid evolution in recent years, with advancements in technology paving the way for more efficient and durable roofing solutions. One of the key innovations that has revolutionized the roofing sector is the development of Roof Sheet Or Zink Forming Machines. These state-of-the-art machines have significantly improved the way roofing materials are manufactured, making the process faster, more precise, and cost-effective.One of the industry leaders in this domain is a leading manufacturer, which has been at the forefront of introducing cutting-edge Roof Sheet Or Zink Forming Machines to the market. With a rich history spanning several decades, the company has consistently upheld a commitment to delivering high-quality, reliable, and innovative machinery to meet the diverse needs of the roofing industry.The Roof Sheet Or Zink Forming Machines offered by the industry leader are designed to streamline the production of various types of roofing materials, such as metal sheets, zinc sheets, and other related products. These machines are equipped with advanced features and capabilities that enable manufacturers to produce roofing materials with exceptional precision and efficiency.One of the key advantages of the Roof Sheet Or Zink Forming Machines is their ability to customize the specifications of the roofing materials according to the unique requirements of each project. This flexibility allows manufacturers to cater to a wide range of roofing applications, while ensuring that the final products meet the highest standards of quality and performance.Moreover, the Roof Sheet Or Zink Forming Machines are engineered to optimize the use of raw materials, minimize waste, and reduce production costs. This is particularly significant in today's competitive market, where manufacturers are constantly seeking ways to improve their operational efficiency and bottom line. By investing in these advanced machines, roofing companies can enhance their productivity and profitability, while maintaining a focus on sustainability and environmental responsibility.In addition to their technical capabilities, the Roof Sheet Or Zink Forming Machines offered by the leading manufacturer are designed with user-friendly interfaces and intuitive controls. This ease of use allows operators to quickly master the operation of the machines, thereby maximizing productivity and minimizing the risk of errors or accidents.Customer support and after-sales service are also paramount to the industry leader, as they strive to ensure that their clients receive the necessary assistance and guidance to optimize the performance of their Roof Sheet Or Zink Forming Machines. Whether it's technical troubleshooting, maintenance, or training, the company is dedicated to standing by their customers every step of the way.In a marketplace that demands ever-higher standards of quality, efficiency, and sustainability, the role of Roof Sheet Or Zink Forming Machines in the roofing industry has become increasingly pivotal. The advanced technology and innovative solutions that these machines offer have redefined the way roofing materials are manufactured, and have empowered manufacturers to meet the evolving needs of their clients with confidence and precision.As the industry leader continues to push the boundaries of innovation and excellence, they remain committed to delivering cutting-edge Roof Sheet Or Zink Forming Machines that will shape the future of the roofing industry for years to come.In conclusion, the introduction of Roof Sheet Or Zink Forming Machines has been a game-changer for the roofing industry, and the leading manufacturer has played a pivotal role in driving this transformation. With their unwavering commitment to quality, innovation, and customer satisfaction, the company continues to set the benchmark for excellence in the production of roofing materials, and is poised to shape the future of the industry in a meaningful and impactful way.

Advanced Roll Forming Machine for Color Steel Tile Production: Discover the Latest News!

Color Steel Tile Roll Forming Machine Industry Analysis and Top PlayersThe Global Color Steel Tile Roll Forming Machine Market research report is a comprehensive analysis of the industry, focusing on key trends, market share, and growth opportunities. The report covers a detailed analysis of the market size, segmentation, and competitive landscape in various regions across the globe.Introduction:Color Steel Tile Roll Forming Machine (need to remove brand name) is a leading player in the roll forming machine industry. With its advanced technology and superior quality, the company has been providing efficient roll forming solutions to various industries. Their color steel tile roll forming machines are widely used in the construction industry for making high-quality roof and wall tiles.Color Steel Tile Roll Forming Machine Industry Analysis:The global color steel tile roll forming machine market is projected to grow at a significant rate in the coming years. The increasing demand for color steel tiles in the construction industry, coupled with the growing need for automated roll forming machines, is driving the market growth. The rise in urbanization and industrialization in developing countries is also contributing to the market expansion.The report highlights the key factors influencing the market, including the technological advancements in roll forming machines, the availability of raw materials, and the regulatory landscape. The increasing focus on sustainable construction practices and the use of eco-friendly materials is also expected to boost the demand for color steel tile roll forming machines.Segmentation Analysis:Based on product type, the color steel tile roll forming machine market can be segmented into single layer, double layer, and multiple layer machines. The single-layer machines are the most commonly used in the industry due to their simplicity and cost-effectiveness. However, the demand for double layer and multiple layer machines is expected to grow at a higher rate in the coming years, as they provide increased flexibility and efficiency in tile production.In terms of application, the market can be categorized into residential, commercial, and industrial sectors. The residential sector holds the largest market share, owing to the increasing construction of residential buildings. However, the commercial and industrial sectors are witnessing significant growth, driven by the construction of commercial complexes, warehouses, and manufacturing units.Competitive Landscape:Color Steel Tile Roll Forming Machine (need to remove brand name) is one of the key players in the market, with a wide range of innovative roll forming machines. The company focuses on research and development to introduce advanced technologies and enhance its product offerings. It also emphasizes strategic collaborations and partnerships to expand its distribution network and reach a wider customer base.Some of the other prominent players in the market include XYZ Company, ABC Corporation, and PQR Industries. These companies are also investing in research and development activities to improve their product portfolios and gain a competitive edge in the market.Conclusion:The global color steel tile roll forming machine market is witnessing significant growth, driven by the increasing demand for color steel tiles in the construction industry. The market is highly competitive, with key players focusing on technological advancements and partnerships to stay ahead. With the rise in urbanization and industrialization, the demand for efficient roll forming machines is expected to continue growing in the coming years.

High-Quality Glazed Tile Forming Machine for Efficient Tile Production

Glazed Tile Forming Machine Revolutionizing Roofing Industry The roofing industry has seen a significant shift in recent years, with the introduction of advanced technology and machinery. One of the most notable innovations is the Glazed Tile Forming Machine, which has been making waves in the construction sector. This state-of-the-art machine has completely transformed the way roofing materials are manufactured, offering numerous benefits and advantages to companies and consumers alike.The Glazed Tile Forming Machine, developed by a leading machinery manufacturer, has gained a reputation for its exceptional quality and efficiency. With its advanced features and capabilities, this machine has become a game-changer for companies involved in the production of roofing materials. Its ability to produce high-quality glazed tiles with precision and speed has made it an indispensable tool for many businesses in the industry.One of the key advantages of the Glazed Tile Forming Machine is its ability to streamline the production process. With traditional methods of manufacturing roofing materials, the process can be time-consuming and labor-intensive. However, with the introduction of this innovative machine, companies can now produce glazed tiles at a much faster rate, significantly reducing production time and costs.Furthermore, the Glazed Tile Forming Machine is equipped with cutting-edge technology that ensures a high level of precision and accuracy in the production of tiles. This means that companies can now consistently produce uniform and flawless tiles, meeting the highest standards of quality and durability. As a result, the end-consumers can benefit from stronger, more resilient roofing materials that offer enhanced protection for their homes and buildings.In addition to its efficiency and precision, the Glazed Tile Forming Machine also offers a great deal of versatility. It is capable of producing a wide range of tile designs and patterns, catering to the diverse needs and preferences of consumers. Whether it is traditional or modern, this machine can create tiles that suit various architectural styles and aesthetic preferences, providing a wide array of options for consumers to choose from.The introduction of the Glazed Tile Forming Machine has also had a positive impact on the environmental sustainability of the roofing industry. By optimizing the production process and minimizing material waste, this machine has helped companies reduce their carbon footprint and contribute to a greener, more sustainable future. Furthermore, the durable and long-lasting nature of the tiles produced by this machine means that they require less frequent replacement, reducing the overall environmental impact.With these advantages in mind, it is no surprise that the Glazed Tile Forming Machine has quickly gained popularity among companies in the roofing industry. Its ability to enhance efficiency, precision, and sustainability has made it a valuable asset for businesses looking to stay ahead in a competitive market. Moreover, its impact on the quality and durability of roofing materials has resonated with consumers, who are increasingly seeking long-lasting and reliable solutions for their homes and buildings.In conclusion, the Glazed Tile Forming Machine has revolutionized the roofing industry, offering unparalleled efficiency, precision, and versatility in the production of high-quality tiles. Its impact on the manufacturing process, environmental sustainability, and consumer satisfaction has made it an invaluable innovation for companies and consumers alike. As technology continues to advance, it is evident that the Glazed Tile Forming Machine will continue to play a pivotal role in shaping the future of the roofing industry.