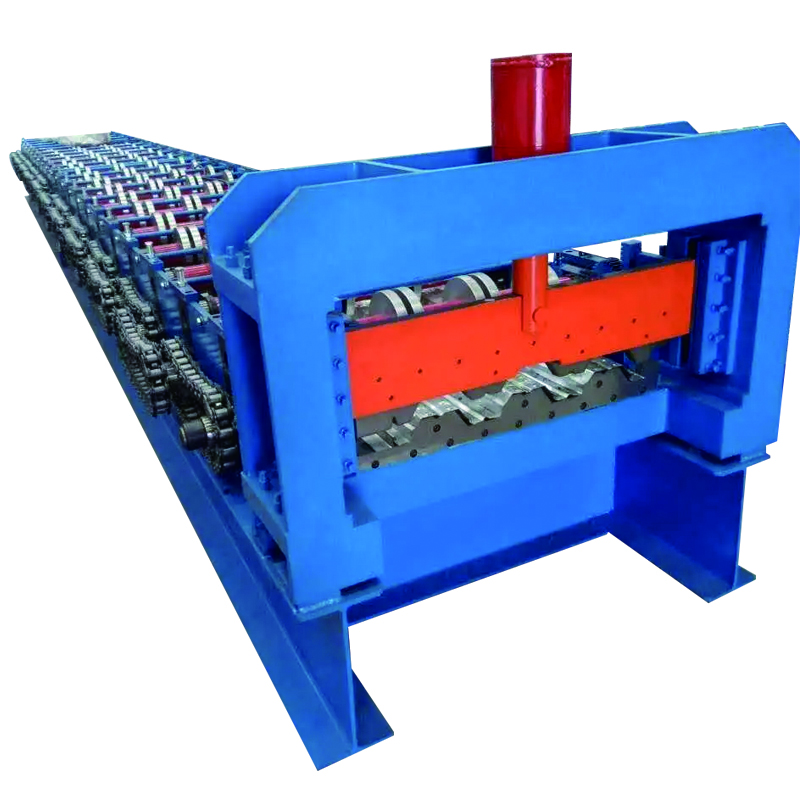

Highly Efficient Horizontal Profiled Panel Forming Machine for Metal Fabrication

By:Admin

{Company Name} has a long-standing reputation for delivering innovative and reliable manufacturing solutions. With a focus on research and development, the company has continuously pushed the boundaries of technology to provide its customers with state-of-the-art equipment. The Horizontal Profiled Panel Forming Machine is a testament to {Company Name}'s commitment to excellence and its dedication to meeting the evolving needs of the manufacturing industry.

The Horizontal Profiled Panel Forming Machine is equipped with advanced features that ensure precision and efficiency in the panel forming process. Its horizontal configuration allows for seamless operation and optimal use of space, making it an ideal choice for manufacturers looking to maximize their production capacity. Additionally, the machine is designed to handle a wide range of panel profiles, giving manufacturers the flexibility to meet diverse customer requirements.

One of the standout features of the Horizontal Profiled Panel Forming Machine is its user-friendly interface. {Company Name} has integrated intuitive controls and automation technology into the machine, allowing operators to easily program and monitor the panel forming process. This not only improves the overall efficiency of production but also reduces the potential for errors, ensuring consistent and high-quality panel output.

In addition to its advanced technology, the Horizontal Profiled Panel Forming Machine is built with durability and reliability in mind. {Company Name} has utilized high-quality materials and precision engineering to create a machine that can withstand the rigors of continuous operation. This durability, coupled with {Company Name}'s commitment to customer support and maintenance, ensures that the Horizontal Profiled Panel Forming Machine delivers long-term value to its users.

The introduction of the Horizontal Profiled Panel Forming Machine is a testament to {Company Name}'s understanding of the evolving needs of the manufacturing industry. By combining innovative technology with a customer-centric approach, the company has once again demonstrated its leadership in the manufacturing equipment market. As manufacturers continue to seek efficient and reliable solutions to streamline their operations, {Company Name} remains a trusted partner in meeting these needs.

The Horizontal Profiled Panel Forming Machine is already generating excitement among manufacturers who are looking to enhance their panel forming capabilities. With its advanced features, user-friendly interface, and robust construction, the machine is poised to set a new standard for panel forming equipment. {Company Name} is confident that this latest innovation will not only meet the current demands of the industry but also pave the way for future advancements in panel forming technology.

As the manufacturing industry continues to evolve, {Company Name} remains committed to driving innovation and delivering cutting-edge solutions to its customers. The Horizontal Profiled Panel Forming Machine is a testament to the company's dedication to meeting the dynamic needs of manufacturers and supporting their growth and success. With its latest innovation, {Company Name} is once again proving why it is a leader in the manufacturing equipment market.

Company News & Blog

Efficient Quick Interchangeable Purlin Roll Forming Machine for C/Z Shapes

If you are in the market for a high-quality roll forming machine that can produce both C and Z shape purlins without the need for changing rollers, then the Quick Interchangeable C/Z Purlin Roll Forming Machine is the ideal solution for you. Designed with efficiency and ease of operation in mind, this machine has quickly become a popular choice for many industries.One of the key features of this machine is its quick interchangeable capability. This means that you can easily switch between producing C and Z shaped purlins without the need for any additional tooling or equipment. This feature not only saves time but also makes it more convenient for operators to use.The roll forming process is an important aspect of this machine. The materials are fed into the machine and then go through a series of rollers that gradually shape and form them into the desired C or Z purlin profile. What makes this machine unique is that it offers a high level of accuracy and precision, ensuring that each purlin produced is consistent in shape and size.Additionally, this machine can also punch holes into the purlins as they are being formed. This feature is especially useful in industries such as construction, where holes are required for fixing the purlins to the building structure.The Quick Interchangeable C/Z Purlin Roll Forming Machine is also built to meet strict European standards. It is made from high-quality materials that are sturdy and highly durable, allowing it to withstand heavy usage and long-term wear and tear.In terms of its operation, this machine is easy to use and requires minimal maintenance. It also has a high production capacity, making it suitable for a range of applications and industries.In conclusion, the Quick Interchangeable C/Z Purlin Roll Forming Machine is a versatile, efficient, and highly reliable machine that is ideal for producing both C and Z shaped purlins. Its quick interchangeable feature, high production capacity, and ability to punch holes make it a popular choice in industries such as construction and manufacturing. It is built to meet European standards and is easy to use, making it a great investment for businesses looking to improve their production capabilities.

High quality corrugated roll making machine for sale

Corrugated Roll Making Machine: The Latest Innovation in Packaging Production In the world of manufacturing and packaging, efficiency and innovation are key to success. This is why the introduction of the new Corrugated Roll Making Machine by a leading packaging solutions company has been making waves in the industry. This innovative machine is set to revolutionize the way corrugated rolls are produced, promising a faster, more efficient, and higher quality manufacturing process.The Corrugated Roll Making Machine is designed to meet the increasing demand for corrugated packaging materials, which are widely used in various industries, including food and beverage, e-commerce, and logistics. The machine is capable of producing high-quality corrugated rolls at a rapid pace, making it a valuable addition to any manufacturing facility.One of the key features of this new machine is its advanced technology, which allows for precision cutting, creasing, and gluing of corrugated board. This results in perfectly formed rolls that are durable and reliable, meeting the highest standards of quality. Additionally, the machine is designed for easy operation, with user-friendly controls and a streamlined production process.The company behind this innovative machine is a well-established leader in the packaging industry, with a strong reputation for delivering cutting-edge solutions to its clients. With a focus on innovation and excellence, the company has been at the forefront of developing advanced packaging technologies, and the Corrugated Roll Making Machine is the latest addition to its impressive portfolio of products.In addition to its innovative products, the company also provides comprehensive support and services to its clients, ensuring that they are able to maximize the potential of their packaging operations. This includes training, maintenance, and technical assistance, allowing clients to fully leverage the capabilities of the Corrugated Roll Making Machine for their production needs.The introduction of the Corrugated Roll Making Machine comes at a time when the global demand for corrugated packaging materials is on the rise. With the growth of e-commerce and online shopping, as well as the increasing focus on sustainable packaging solutions, the need for high-quality corrugated rolls has never been greater. This new machine is poised to address this demand, providing manufacturers with the means to meet the evolving requirements of the market.Furthermore, the Corrugated Roll Making Machine is designed with efficiency and sustainability in mind. By optimizing the production process, the machine is able to minimize waste and energy consumption, contributing to a more environmentally friendly manufacturing process. This aligns with the company's commitment to sustainability and responsible production practices, ensuring that its clients can meet their sustainability goals while maintaining high productivity levels.As the packaging industry continues to evolve, companies are looking for cutting-edge solutions to enhance their production capabilities. The Corrugated Roll Making Machine represents a significant step forward in meeting this need, offering a state-of-the-art solution for the efficient and high-quality production of corrugated rolls. With its advanced technology, user-friendly design, and focus on sustainability, this innovative machine is set to become a game-changer in the packaging industry.In conclusion, the introduction of the Corrugated Roll Making Machine by the leading packaging solutions company is a testament to its commitment to innovation and excellence. This new machine is poised to revolutionize the way corrugated rolls are produced, offering manufacturers a fast, efficient, and sustainable solution for meeting the growing demand for high-quality packaging materials. With its advanced technology and comprehensive support services, the Corrugated Roll Making Machine is set to make a significant impact on the industry, helping companies elevate their production capabilities and stay ahead in the competitive packaging market.

High-Quality Corrugated Sheet Making Machine for Efficient Production

Corrugated Sheet Making Machine Brings Innovation to Packaging IndustryThe packaging industry is constantly evolving, with new technologies and machinery transforming the way products are packaged and shipped. One such innovation is the Corrugated Sheet Making Machine, which has revolutionized the production of corrugated sheets for packaging purposes. This machine, developed by a leading machinery manufacturer, has made it easier and more efficient to produce high-quality corrugated sheets, meeting the growing demand for sustainable packaging solutions.The Corrugated Sheet Making Machine is a sophisticated piece of equipment that is capable of producing corrugated sheets in various sizes and styles. It is designed to handle a wide range of materials, including paper, cardboard, and other sustainable packaging materials, making it a versatile solution for packaging manufacturers. The machine's advanced technology allows for fast and precise production, ensuring that the corrugated sheets meet industry standards for strength and durability.One of the key benefits of the Corrugated Sheet Making Machine is its ability to produce custom-designed corrugated sheets, giving packaging manufacturers the flexibility to meet the unique requirements of their clients. This allows for the creation of innovative and eye-catching packaging solutions that can help products stand out on store shelves and attract consumer attention. In addition, the machine's high production capacity means that large orders can be fulfilled quickly and efficiently, making it a valuable asset for packaging companies with high-volume production needs.In addition to its advanced production capabilities, the Corrugated Sheet Making Machine is also designed with sustainability in mind. It is equipped with energy-saving features that reduce electricity consumption and minimize waste, making it an environmentally friendly solution for packaging manufacturers. This aligns with the company's commitment to sustainability and responsible manufacturing practices, ensuring that their machinery not only meets industry standards but also contributes to a more sustainable future for the packaging industry.The company behind the Corrugated Sheet Making Machine is a renowned manufacturer of packaging machinery, known for its innovative solutions and commitment to quality. With decades of experience in the industry, the company has earned a reputation for excellence and reliability, delivering machinery that meets the evolving needs of packaging manufacturers around the world. Their dedication to innovation and customer satisfaction has made them a trusted partner for businesses seeking cutting-edge solutions for their packaging production needs.The introduction of the Corrugated Sheet Making Machine represents a significant milestone for the company, demonstrating their continued investment in research and development to bring new and improved machinery to the market. This latest innovation is a testament to their ongoing commitment to driving progress in the packaging industry and providing packaging manufacturers with the tools they need to succeed in an increasingly competitive market.As the demand for sustainable packaging solutions continues to grow, the Corrugated Sheet Making Machine is set to play a pivotal role in meeting this demand and empowering packaging manufacturers to create innovative, eco-friendly packaging solutions. With its advanced technology, customizable production capabilities, and commitment to sustainability, this machine is poised to reshape the future of packaging production, setting new standards for efficiency, quality, and environmental responsibility.In conclusion, the Corrugated Sheet Making Machine represents a game-changing innovation for the packaging industry, offering packaging manufacturers a state-of-the-art solution for producing high-quality corrugated sheets. With its advanced technology, customizable production capabilities, and sustainability features, this machine is set to drive progress in the packaging industry and meet the growing demand for eco-friendly packaging solutions. The company's dedication to innovation and customer satisfaction has once again set a new standard for excellence in the packaging machinery market, demonstrating their commitment to empowering businesses with the tools they need to succeed.

Discover High-Quality Standing Seam Metal Roof Suppliers for Resilient, Weather-Tight, and Fire-Resistant Home Roofs

When it comes to roofing options for your home, there are a lot of choices out there. However, few can match the durability and versatility of standing seam metal roofs. That's why many homeowners are turning to standing seam metal roof suppliers (without brand names) to get the best products for their homes.One of the key benefits of a standing seam metal roof is its weather resistance. Whether you're dealing with heavy rain, high winds, or snow and ice storms, a standing seam metal roof can stand up to the elements. Unlike other roofing materials, such as asphalt shingle or wood shake roofs, standing seam metal roofs are designed to shed water quickly and resist damage from wind, hail, and other types of weather-related events.Another major advantage of standing seam metal roofs is their fire resistance. Unlike other roofing materials that can catch fire easily, such as wood shingles or asphalt shingles, metal roofs are much more fire-resistant. This is because metal is an inherently non-flammable material, which means that a standing seam metal roof can help protect your home in case of a fire.But perhaps one of the most appealing aspects of a standing seam metal roof is its aesthetic appeal. With its clean, modern lines and sleek design, a standing seam metal roof can be a striking addition to any home. And because standing seam metal roofs come in a variety of colors and finishes, you can easily customize your roof to match your home's style and color scheme.So where can you find the best standing seam metal roof suppliers (without brand names) for your home? Look for companies that specialize in manufacturing high-quality metal roofing products, such as standing seam roll formers. These machines are designed to create high-quality metal roofing panels that are perfect for standing seam roofs, ensuring that your roof is weather-tight, durable, and attractive for years to come.In conclusion, if you're looking for an affordable, durable, and attractive roofing option for your home, consider a standing seam metal roof. And be sure to work with reputable standing seam metal roof suppliers (without brand names) to get the best products and service for your needs. By choosing the right roofing materials and working with the right professionals, you can enjoy a beautiful, long-lasting roof for your home.

Quickly Changeable C/Z Purlin Roll Forming Machine: Efficient Steel Purlin Production

Title: Revolutionary CZ Interchangeable Purlin Roll Forming Machine Streamlines Steel ProductionIntroduction:In the ever-evolving realm of steel manufacturing, advancements in technology continue to redefine the way we produce essential building components. The latest innovation making waves in the industry is the CZ Interchangeable Purlin Roll Forming Machine. Designed to expedite the production process and enhance efficiency, this state-of-the-art machine effortlessly molds steel C and Z purlins of various sizes and thicknesses.Seamless Purlin Roll Transition:Traditionally, switching between C and Z purlin roll forming required cumbersome manual adjustments and downtime. However, the CZ Interchangeable Purlin Roll Forming Machine eliminates these inefficiencies by seamlessly transitioning between the two types of purlins. This groundbreaking technology significantly reduces production downtime, streamlining operations and increasing overall productivity.Precision Performance:The CZ Interchangeable Purlin Roll Forming Machine is renowned for its precision performance. Equipped with cutting-edge technology and automated processes, it delivers unparalleled accuracy and consistency in producing C and Z purlins. This ensures structural integrity and reliable performance of the final products, meeting the stringent quality standards demanded by the construction industry.Enhanced Flexibility:One of the most compelling features of the CZ Interchangeable Purlin Roll Forming Machine is its ability to produce purlins of varying sizes and thicknesses. Whether it's a small-scale residential project or a large commercial construction, this versatile machine can adapt to the requirements of any project, thereby expanding manufacturers' capabilities and market reach. Effortless Operation:Designed with user convenience in mind, the CZ Interchangeable Purlin Roll Forming Machine offers both manual and automatic adjustment options, catering to the diverse needs of manufacturers. Users can easily switch between modes depending on the complexity of the project, ensuring seamless operation and reducing the chances of error.Efficiency and Time-Saving:The CZ Interchangeable Purlin Roll Forming Machine revolutionizes the production process by reducing manual labor and maximizing efficiency. By automating key stages, this machine eliminates human error while significantly expediting production timelines. Manufacturers can now meet tight project deadlines without compromising on quality, thereby boosting overall customer satisfaction.Cost-Effective Solution:The CZ Interchangeable Purlin Roll Forming Machine is not only efficient but also cost-effective. With the ability to adapt to various project requirements, manufacturers no longer need to invest in separate machines for different purlin types. This reduces capital expenditure, maintenance costs, and overheads, enhancing profitability and competitiveness in the market.Sustainable Manufacturing:In today's environmentally conscious world, the CZ Interchangeable Purlin Roll Forming Machine aligns with the industry's commitment to sustainable manufacturing practices. By dramatically reducing material waste and energy consumption, this machine helps manufacturers meet their sustainability goals without compromising productivity or product quality.Conclusion:The CZ Interchangeable Purlin Roll Forming Machine represents a paradigm shift in steel production, offering manufacturers an advanced and versatile tool. With its ability to effortlessly switch between C and Z purlins, while accommodating various sizes and thicknesses, this machine sets a new standard for precision and efficiency in the industry. By streamlining operations, reducing downtime, and enhancing overall productivity, this innovative machine promises a bright future for the steel manufacturing sector.

Metal Deck Roll Forming Machine for Efficient Decking Production in 2019

Floor Deck Roll Forming Machine | Decking Machine 2019: A Revolution in Metal Deck ProductionIn today's rapidly evolving construction industry, the demand for innovative and efficient machinery is at an all-time high. Companies are constantly on the lookout for advanced equipment that can help streamline their production processes and enhance the quality of their products. In line with these requirements, lotos design has introduced an exceptional Floor Deck Roll Forming Machine in 2019 that is set to revolutionize metal deck production.The Floor Deck Roll Forming Machine is a state-of-the-art piece of equipment that provides unparalleled precision and efficiency in manufacturing a variety of metal decks. With its computer-optimized design, this machine is capable of producing various types of metal decks catering to the specific needs of the construction industry. This cutting-edge technology takes the production process to a whole new level, ensuring superior quality and durability in each deck manufactured.One of the key features of the Floor Deck Roll Forming Machine is its computer optimization. This ensures that the machine operates at its peak performance, enabling the production of consistent and accurate metal decks. By removing any potential human error from the equation, lotos design has created a machine that guarantees exceptional quality with every deck produced. This not only increases the efficiency of the production process but also reduces material waste, thus making it an environmentally friendly solution.The lotos design Floor Deck Roll Forming Machine is a result of extensive research and development carried out by their team of experts. With years of experience in the industry, the company has gained invaluable knowledge about the requirements and challenges faced by construction companies when it comes to metal deck production. By incorporating this knowledge into the design of the machine, lotos design has created a solution that addresses these challenges, making metal deck production a breeze for their customers.Moreover, the company's dedication to customer satisfaction is evident in the quality of their product. They have gone above and beyond to ensure that their machine not only meets but exceeds industry standards. With a focus on durability and performance, lotos design has tested the Floor Deck Roll Forming Machine rigorously to ensure its reliability in demanding production environments. This dedication to quality has earned them a reputation as a trusted name in the industry.The Floor Deck Roll Forming Machine is not just another piece of equipment to lotos design. It is a testament to their commitment to innovation and providing their customers with the best possible solutions. With this machine, construction companies can significantly enhance their productivity and efficiency, thereby giving them a competitive edge in the market.As the construction industry continues to evolve, lotos design remains at the forefront of innovation. They continuously strive to develop groundbreaking machinery that revolutionizes the way metal decks are produced. The introduction of the Floor Deck Roll Forming Machine in 2019 is a testament to their dedication to excellence.In conclusion, the lotos design Floor Deck Roll Forming Machine is a game-changer in the construction industry. With its computer optimization and advanced features, it offers unparalleled precision and efficiency in metal deck production. By addressing the specific needs and challenges faced by construction companies, lotos design has created a solution that sets a new benchmark for the industry. As the demand for superior quality and efficient machinery continues to rise, the Floor Deck Roll Forming Machine proves to be a true game-changer.

Durable Standing Seam Roof Machine for Efficient Roofing

Standing Seam Roof Machine Revolutionizes Roofing IndustryThe roofing industry has seen a revolution with the introduction of the state-of-the-art Standing Seam Roof Machine by a leading manufacturer in the field. This innovative machine has been designed with precision and advanced technology to meet the growing demands of the roofing industry.The Standing Seam Roof Machine is a game-changer for roofing professionals as it offers efficiency, durability, and unmatched precision in producing standing seam roofs. The machine features a cutting-edge design that allows for seamless and fast production of standing seam roofs, meeting the high standards of quality and performance.This revolutionary machine is the result of years of research and development by a dedicated team of engineers and experts. With an unwavering commitment to excellence, the company has set a new benchmark in the industry with its Standing Seam Roof Machine. The machine is built with high-quality materials and components, ensuring durability and long-term performance.One of the key features of the Standing Seam Roof Machine is its versatility. It is capable of producing standing seam roofs of various widths and profiles, catering to the diverse needs of roofing projects. This flexibility makes it an ideal choice for roofing contractors and professionals who require a reliable and efficient solution for their projects.In addition to its versatility, the machine is also equipped with advanced automation and control systems, allowing for precise and accurate production of standing seam roofs. This not only enhances the efficiency of the production process but also ensures the consistency of the final product.The company behind the Standing Seam Roof Machine has a long-standing reputation for delivering high-quality and innovative solutions to the roofing industry. Their commitment to excellence and customer satisfaction has earned them a trusted position in the market. With the introduction of the Standing Seam Roof Machine, they have once again solidified their leadership in the industry.The company takes pride in its customer-centric approach, offering comprehensive technical support and training to ensure that roofing professionals can fully harness the capabilities of the Standing Seam Roof Machine. Their team of technical experts is readily available to provide assistance and guidance, guaranteeing a seamless integration of the machine into the customers' operations.Furthermore, the company's dedication to sustainability is reflected in the design and production of the Standing Seam Roof Machine. It has been engineered to minimize waste, energy consumption, and environmental impact, aligning with the growing demand for eco-friendly solutions in the roofing industry.The introduction of the Standing Seam Roof Machine has garnered widespread attention in the roofing industry, with professionals recognizing its potential to streamline operations and elevate the quality of standing seam roofs. Its impact is not only limited to production efficiency but also extends to the overall performance and longevity of standing seam roofs, offering a compelling value proposition to roofing professionals.In conclusion, the Standing Seam Roof Machine is a testament to the relentless pursuit of innovation and excellence by the company. With its cutting-edge design, advanced technology, and commitment to customer satisfaction, the machine has set a new standard in the roofing industry. It represents a significant advancement that is poised to reshape the production of standing seam roofs, empowering roofing professionals to deliver exceptional results.

High-Quality Aluminum Profile Polishing Machine for Metal Finishing

Aluminum Profile Polishing Machine Helps Company Achieve High-Quality ProductsIn the fast-paced world of manufacturing, companies are constantly striving to enhance the quality of their products while also increasing efficiency. One crucial aspect of achieving this goal is the use of advanced machinery that can streamline production processes and improve the overall quality of final products. One company that has successfully incorporated cutting-edge technology into its operations is {Company Name}, a leading manufacturer of aluminum profiles.{Company Name} has recently implemented a state-of-the-art Aluminum Profile Polishing Machine, which has significantly improved the company's ability to produce high-quality aluminum profiles for a variety of applications. The machine, which has been carefully integrated into the company's production line, is capable of polishing aluminum profiles to a mirror-like finish, ensuring that the final products meet the highest standards of quality.The decision to invest in the Aluminum Profile Polishing Machine was driven by {Company Name}'s commitment to delivering exceptional products to its customers. By incorporating this advanced technology into its operations, the company has been able to elevate the quality of its aluminum profiles, setting it apart from its competitors in the industry.The Aluminum Profile Polishing Machine is equipped with advanced polishing techniques and precision controls, allowing {Company Name} to achieve a level of consistency and excellence that was previously unattainable. This has not only resulted in a significant improvement in the overall appearance of the aluminum profiles but has also enhanced their durability and resistance to corrosion, making them suitable for a wide range of applications in various industries.Furthermore, the integration of the Aluminum Profile Polishing Machine has had a notable impact on {Company Name}'s production efficiency. The machine's automated processes and efficient operation have helped to streamline the polishing process, reducing production lead times and increasing the company's overall output capacity. As a result, {Company Name} has been able to meet the growing demand for its high-quality aluminum profiles, without compromising on quality or consistency.The introduction of the Aluminum Profile Polishing Machine has also had a positive effect on the company's workforce. By automating certain aspects of the polishing process, {Company Name} has been able to redeploy its skilled workers to other areas of the production line, where their expertise and experience can create additional value. This has not only improved overall operational efficiency but has also enhanced employee satisfaction and morale within the organization.{Company Name} is proud to be at the forefront of technological innovation within the industry, and the successful incorporation of the Aluminum Profile Polishing Machine is a testament to the company's commitment to continuous improvement. By embracing advanced machinery and processes, {Company Name} is positioning itself as a leader in the manufacturing of high-quality aluminum profiles, meeting the ever-evolving needs of its customers and setting new standards for excellence in the industry.Moving forward, {Company Name} remains dedicated to investing in cutting-edge technology and equipment that will further enhance its production capabilities and product offerings. By staying ahead of the curve and embracing innovation, {Company Name} is poised to maintain its position as a trusted provider of premium aluminum profiles, delivering exceptional value to its customers and driving continued growth and success in the industry.

Z Purlin Roll Forming Machine: A Comprehensive Guide to Roll Forming Z Purlins for Structural Support

NEW PURLIN ROLL FORMING MACHINE PROMISES EFFICIENCY AND PRECISION[City], [Date] - The development of technology has revolutionized various industries, and the manufacturing sector is no exception. One of the latest innovations in the field of manufacturing machinery is the new Z Purlin Roll Forming Machine, designed to provide enhanced efficiency, accuracy, and reliability in the production of Z-shaped purlins. This advanced machine is set to transform the purlin manufacturing industry, meeting the increasing demand for high-quality construction materials.A leader in manufacturing equipment, [Company Name] has introduced its latest addition to the industry - the Z Purlin Roll Forming Machine. With its state-of-the-art features and cutting-edge technology, this machine promises to streamline the process of creating Z-shaped purlins, reducing manual labor and increasing productivity.The Z Purlin Roll Forming Machine is designed to withstand heavy-duty industrial usage, ensuring durability and longevity. It boasts an ergonomic design that allows for easy operation, making it accessible even to less experienced operators. Equipped with a user-friendly interface, the machine offers a seamless experience, and its automated functions contribute to the overall efficiency of production.Precision and accuracy are crucial in the manufacturing of Z-shaped purlins, and this is where the Z Purlin Roll Forming Machine truly excels. With its advanced roll-forming technology, it enables the production of perfectly shaped purlins with consistent dimensions. The machine optimizes material usage, minimizing waste and reducing costs for manufacturers. Additionally, its high-speed production capabilities enable rapid turnaround times, meeting the time-sensitive demands of the construction industry.Incorporating safety features is of paramount importance in any industrial machinery, and the Z Purlin Roll Forming Machine lives up to this expectation. Enhanced safety measures have been integrated into its design, safeguarding operators and preventing potential accidents. The machine complies with international safety regulations, ensuring a secure environment for workers.While the Z Purlin Roll Forming Machine offers numerous benefits for manufacturers, it also delivers advantages to the end-users. By utilizing this advanced technology, construction companies can obtain consistently high-quality Z-shaped purlins for their projects. The superior strength and structural integrity of these purlins enhance the overall stability and durability of buildings, guaranteeing a longer lifespan.Moreover, the versatility of the Z Purlin Roll Forming Machine allows for the production of purlins of various sizes and shapes. This flexibility caters to the diverse requirements of different construction projects, providing a custom solution to architects, engineers, and contractors alike.The implementation of this cutting-edge technology by the manufacturing industry marks a significant step towards improvement and progress. By investing in modern machinery such as the Z Purlin Roll Forming Machine, manufacturers can stay competitive in the market and meet the rising demands of customers.As [Company Name] continues to redefine manufacturing equipment, its commitment to innovation and customer satisfaction remains unwavering. With the introduction of the Z Purlin Roll Forming Machine, the company aims to revolutionize the manufacturing process and set new industry standards.In conclusion, the new Z Purlin Roll Forming Machine brings efficiency, precision, and reliability to the purlin manufacturing industry. This advanced machinery promises to streamline production, improve product quality, and cater to the diverse needs of different construction projects. As technology continues to evolve, manufacturers can rely on [Company Name] to deliver cutting-edge solutions that optimize their operations and drive industry growth.

BenQ's LK970 Blue Core Laser 4K Projector Installed by Bag&Baggage Productions for Theater and Venue in Oregon

Bag&Baggage Productions (B&B), a theater company based in Hillsboro, Oregon, recently completed the installation of the BenQ LK970 Blue Core 4K projector in their new theater and multipurpose venue, The Vault. This state-of-the-art projector enables B&B to project realistic set backgrounds, reducing the need for manual set designs and creating opportunities for digital content creators in the area.The theater industry is constantly evolving, and B&B recognized the potential of incorporating projection technology into their performances. By utilizing the BenQ LK970 Blue Core 4K projector, B&B is able to enhance their productions by projecting realistic set backgrounds. This eliminates the need for manual set designs, reducing both the scale and expense of traditional set construction, and saving on labor costs. In the past, theater companies relied heavily on physical sets to create the desired atmosphere for their performances. The process of constructing and changing sets during shows could be time-consuming and costly. However, with the introduction of projection technology like the BenQ LK970, theater companies can now project lifelike set backgrounds onto screens, eliminating the need for physical set changes.This transition to projection technology provides several benefits to B&B. Firstly, it allows for greater flexibility in terms of designing and modifying sets. Virtual set backgrounds can be easily changed with a few clicks, accommodating different scenes and settings seamlessly. The time and effort required for physical set changes is significantly reduced, allowing for smoother, more efficient productions.Moreover, projection technology offers cost savings to theater companies. Manual set designs can be expensive, requiring materials, labor, and storage space. By using a projector to create set backgrounds, B&B can reduce these costs and allocate resources to other aspects of their productions, such as costumes or lighting. Additionally, the labor required for set changes is minimized, freeing up staff to focus on other tasks.Beyond the benefits for theater productions, B&B is also utilizing the BenQ LK970 projector to create a state-of-the-art digital projection laboratory and film festival. The Vault serves as a hub for digital content creators in the area, providing a platform for them to showcase their work and interact with the local community. The high-quality projection capabilities of the BenQ LK970 allow for stunning visual displays, enhancing the viewing experience for both filmmakers and audiences.Overall, the installation of the BenQ LK970 Blue Core 4K projector at The Vault marks a pivotal moment for B&B. By embracing projection technology, the theater company is able to enhance their productions, reduce costs, and create opportunities for digital content creators in their community. This innovative approach showcases B&B's commitment to pushing the boundaries of traditional theater and embracing new technologies to enhance the overall theater-going experience. With the BenQ LK970, B&B is bringing a new level of realism and creativity to their performances while supporting the growth of the local digital content industry.