Highly efficient metal wall panel machine for producing precision panels

By:Admin

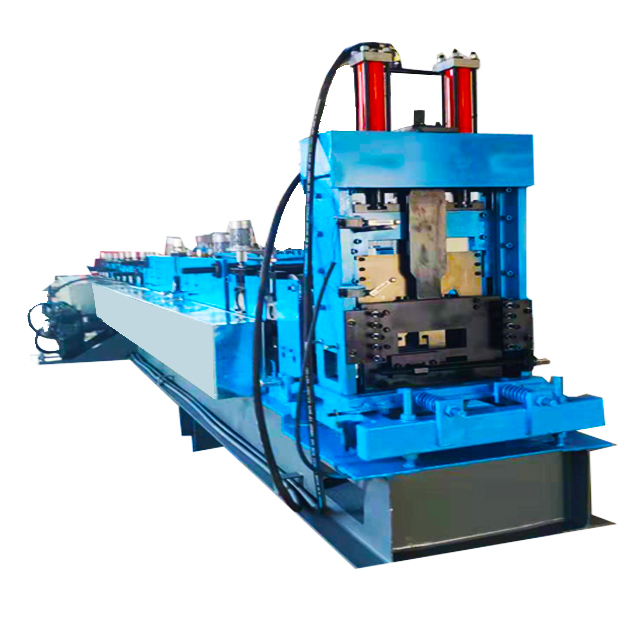

{Company Name}, a leading manufacturer of metal forming machinery, has recently unveiled its latest innovation in the field of metal wall panel production - the new {Machine Model}.

With years of experience in the industry, {Company Name} has been at the forefront of developing high-quality, advanced machinery for the metal forming industry. The {Machine Model} is the latest addition to their wide range of metal forming equipment, and it promises to revolutionize the production of metal wall panels.

The {Machine Model} is equipped with state-of-the-art technology that allows for precision forming and shaping of metal panels. Its advanced features include a high-speed servo drive system, which ensures precise and smooth operation, resulting in consistently high-quality panels. The machine is also designed to accommodate a wide range of panel sizes and shapes, making it suitable for a variety of applications in the construction and architectural industries.

One of the key advantages of the {Machine Model} is its versatility. It is capable of producing a variety of panel profiles, including flat, ribbed, and corrugated panels, as well as custom designs to meet the specific requirements of customers. This flexibility makes the {Machine Model} an ideal choice for manufacturers looking to diversify their product offerings and cater to a wider range of market demands.

Moreover, the {Machine Model} is designed with efficiency in mind. It features a user-friendly interface and intuitive controls, making it easy to operate and requiring minimal training for operators. Additionally, the machine's quick changeover capabilities and automated tooling adjustments contribute to increased productivity and reduced downtime, leading to cost savings for manufacturers.

In terms of durability and reliability, the {Machine Model} is built to last. Its robust construction and high-quality components ensure long-term performance and minimal maintenance requirements, allowing manufacturers to focus on their production processes without worrying about frequent equipment breakdowns or repairs.

The introduction of the {Machine Model} has set a new standard in the metal forming industry. It represents a significant leap forward in technology, offering manufacturers the opportunity to enhance their production capabilities and deliver superior quality products to their customers.

{Company Name} has a long-standing reputation for delivering innovative solutions and best-in-class machinery to the metal forming industry, and the {Machine Model} is a testament to their commitment to excellence. With its cutting-edge technology and advanced features, the {Machine Model} is poised to lead the industry and set new benchmarks for metal wall panel production.

As the global demand for high-quality, custom metal wall panels continues to grow, the {Machine Model} is set to play a pivotal role in meeting these needs and supporting manufacturers in their quest for innovation and competitiveness. Its ability to streamline production processes, increase efficiency, and deliver outstanding results will undoubtedly make it a sought-after choice for metal forming companies around the world.

In conclusion, the {Machine Model} from {Company Name} is a game-changer in the metal forming industry. Its groundbreaking technology, unmatched versatility, and superior performance make it a must-have for manufacturers looking to stay ahead in a competitive market. As the industry evolves, {Company Name} remains at the forefront, driving innovation and empowering manufacturers to excel in their metal forming endeavors.

Company News & Blog

High-Quality Floor Tile Making Machine for Efficient and Cost-Effective Production

Floor Tile Making Machine Revolutionizes the Tile industryInnovations in technology continue to revolutionize the way industries operate, and the tile manufacturing sector is no exception. The introduction of the latest Floor Tile Making Machine by [Company Name] has brought significant advancements to the industry, offering improved efficiency and quality in tile production. With its state-of-the-art features and dedication to innovation, this new machine is expected to set a new standard in tile manufacturing.The Floor Tile Making Machine, developed by [Company Name], is a result of extensive research and development aimed at addressing the challenges faced by tile manufacturers. The machine boasts a high level of automation, allowing for seamless production processes and eliminating the need for manual intervention. This not only improves efficiency but also reduces the margin of error, resulting in consistently high-quality tiles. Additionally, the machine is capable of producing a wide range of tile designs and sizes, providing manufacturers with greater flexibility to meet diverse market demands.[Company Name] has been a leading player in the manufacturing industry for several years, known for its commitment to excellence and innovation. The company’s extensive experience and expertise in engineering and manufacturing have been instrumental in the development of the Floor Tile Making Machine. With a keen understanding of the challenges faced by tile manufacturers, [Company Name] has designed a machine that addresses these pain points and sets new benchmarks for quality and efficiency in tile production.The Floor Tile Making Machine incorporates advanced technology to optimize the production process. Its precise cutting and shaping capabilities ensure that each tile is manufactured with utmost accuracy, resulting in a uniform and flawless finish. Moreover, the machine’s automated systems minimize the risk of defects, thereby enhancing the overall quality of the tiles produced. This level of precision and consistency is a game-changer for the industry, as it allows manufacturers to deliver superior products to their customers.One of the key advantages of the Floor Tile Making Machine is its versatility. The machine is equipped to handle various types of raw materials, including ceramic, porcelain, and stone, enabling manufacturers to produce diverse range of tiles to cater to different customer preferences. This flexibility is invaluable in today’s market, where consumers seek unique and customizable tile solutions for their spaces. By offering the capability to produce a wide array of tile designs, the machine empowers manufacturers to stay ahead of the curve and meet ever-evolving market trends.In addition to its technical prowess, the Floor Tile Making Machine is also designed with user convenience in mind. The machine’s intuitive interface and user-friendly controls make it easy to operate, minimizing the need for extensive training and specialized skills. This not only enhances the efficiency of production but also reduces the operational costs associated with training and skill development. As a result, manufacturers can streamline their operations and allocate resources more effectively, leading to improved profitability.[Company Name] is dedicated to providing comprehensive support to its customers, and the introduction of the Floor Tile Making Machine is no exception. The company offers extensive training and technical assistance to ensure that manufacturers can fully leverage the capabilities of the machine. Furthermore, [Company Name]’s commitment to ongoing research and development means that the machine will continue to evolve, incorporating new features and capabilities to further enhance its performance.The release of the Floor Tile Making Machine marks a significant milestone in the tile manufacturing industry. With its cutting-edge technology and focus on quality and efficiency, the machine is poised to transform the way tiles are produced. By setting new standards for precision, versatility, and user-friendliness, the machine is not only a game-changer for manufacturers but also a boon for consumers who seek high-quality, customizable tile solutions for their spaces. As [Company Name] continues to lead the charge in innovation, the future of the tile industry looks brighter than ever.

Learn About the Horizontal Profiled Panel Roll Forming Process

The roll forming process has long been recognized as a highly efficient and cost-effective method for producing continuous lengths of metal profiles with a consistent cross-section. This process involves feeding a metal strip through a series of roll stations, where each station performs a specific bending or forming operation to gradually shape the metal into the desired profile. One of the most commonly used roll forming processes is the Horizontal Profiled Panel Roll Forming Process, which is known for its versatility and ability to produce a wide range of complex profiles.{Company} is a leading manufacturer and supplier of roll forming equipment, known for its innovative and high-quality solutions for the metal forming industry. With over [X] years of experience, {Company} has built a solid reputation for delivering state-of-the-art roll forming machines and providing exceptional customer service to clients worldwide.The Horizontal Profiled Panel Roll Forming Process offered by {Company} is a highly efficient and automated solution for producing a variety of horizontal profiles with precision and consistency. This process involves feeding a metal strip into the roll forming machine, where a series of roll stations work together to gradually bend and form the metal into the desired profile. The flexibility and versatility of this process allow for the production of a wide range of panel profiles, including roofing panels, wall panels, and other structural components used in the construction and manufacturing industries.One of the key benefits of the Horizontal Profiled Panel Roll Forming Process is its ability to produce profiles with a high level of accuracy and repeatability. This ensures that each panel produced is uniform and meets the required specifications, leading to fewer rejects and higher overall production efficiency. Additionally, the automated nature of the process reduces the need for manual labor, leading to savings in labor costs and increased productivity.{Company} has further enhanced the Horizontal Profiled Panel Roll Forming Process with advanced technologies and features to improve its performance and reliability. The integration of computerized controls, precision tooling, and in-line inspection systems ensures that the production process is closely monitored and adjustments can be made in real time to maintain the quality of the profiles being produced. This results in a more streamlined and efficient production process, ultimately leading to higher customer satisfaction and a competitive edge in the market.In addition to its technical capabilities, {Company} also prides itself on its commitment to customer satisfaction and service. The company offers comprehensive support to its clients, including initial consultation and design, installation and training, as well as ongoing maintenance and technical assistance. This personalized approach has allowed {Company} to build long-lasting relationships with its clients and establish itself as a trusted partner in the roll forming industry.The Horizontal Profiled Panel Roll Forming Process offered by {Company} has been widely adopted by manufacturers in various industries, including construction, automotive, and aerospace, due to its versatility, efficiency, and high-quality output. As the demand for custom metal profiles continues to grow, {Company} remains at the forefront of innovation, continuously improving its roll forming solutions to meet the evolving needs of its clients.As the global market for roll formed products continues to expand, {Company} is well-positioned to capitalize on the growing demand for its Horizontal Profiled Panel Roll Forming Process. With its dedication to innovation, quality, and customer satisfaction, {Company} is poised to continue leading the way in the roll forming industry for years to come.

How to Use a Metal Roof Sheet Roll Forming Machine for Efficient Roofing

Metal Roof Sheet Roll Forming Machine Designed to Meet Growing Demand In response to the growing demand for high-quality metal roof sheet roll forming machines in the construction industry, a leading manufacturer of construction machinery {} has introduced a new and innovative machine that is designed to meet the specific needs of the market.The metal roof sheet roll forming machine is widely used in the production of metal roofing sheets for residential, commercial, and industrial buildings. With the increasing popularity of metal roofing due to its durability, energy efficiency, and aesthetic appeal, there has been a surge in demand for advanced roll forming machines that can produce high-quality metal roofing sheets with precision and efficiency.The new metal roof sheet roll forming machine from {} is equipped with state-of-the-art technology and advanced features that make it capable of producing metal roofing sheets of various sizes and designs. It is designed to deliver high levels of accuracy, speed, and reliability, ensuring that each sheet produced meets the highest standards of quality.One of the key features of the new machine is its ability to handle a wide range of metal materials, including steel, aluminum, and copper, allowing for greater flexibility in production. This versatility enables manufacturers to cater to the diverse needs of their customers and offer a wider range of metal roofing options.In addition to its advanced technological capabilities, the metal roof sheet roll forming machine is also designed with user-friendly features that make it easy to operate and maintain. The intuitive control system and automated processes minimize the need for manual intervention, reducing the risk of errors and increasing productivity.Furthermore, the machine is built with a robust and durable structure to withstand the rigors of continuous operation in a demanding production environment. This ensures long-term reliability and minimal downtime, contributing to higher efficiency and lower operating costs for manufacturers.With the introduction of this new metal roof sheet roll forming machine, {} continues to demonstrate its commitment to innovation and excellence in the construction machinery industry. The company has a long-standing reputation for delivering cutting-edge solutions that empower manufacturers to meet the evolving demands of the market.{} has invested heavily in research and development to bring this new machine to market, drawing on its expertise in metal forming technology and its understanding of the unique requirements of the construction industry. The result is a machine that not only meets but exceeds the expectations of manufacturers, enabling them to elevate their production capabilities and differentiate themselves in the market.The introduction of the new metal roof sheet roll forming machine comes at a time when the construction industry is experiencing a strong demand for metal roofing solutions. As more builders, contractors, and homeowners recognize the benefits of metal roofing, the need for advanced roll forming machines that can deliver superior quality and performance has never been greater.In light of this demand, {} is poised to make a significant impact with its new machine, offering manufacturers a competitive edge in meeting the growing needs of the market. By providing a reliable and efficient solution for producing high-quality metal roofing sheets, the company is empowering manufacturers to capitalize on the opportunities presented by the booming metal roofing industry.As the construction industry continues to evolve and embrace the benefits of metal roofing, the demand for advanced roll forming machines like the one introduced by {} is expected to remain strong. With its innovative design, cutting-edge technology, and proven track record of excellence, the new metal roof sheet roll forming machine is set to become a game-changer for manufacturers seeking to thrive in the competitive landscape of the construction industry.

Wide Coil Slitter Operator Jobs in Oldbury - Experience in Metals Environment Required

Title: Wide Coil Slitter Operator Jobs Available in Oldbury's Metal IndustryIntroduction:Oldbury, a key industrial area known for its metal manufacturing, is currently seeking experienced wide coil slitters to join its thriving workforce. This exciting opportunity offers rotating shifts and the chance to work within a dynamic metals environment. Interested applicants are encouraged to apply and become a part of Oldbury's esteemed metal coil slitting industry.Oldbury's Thriving Metal Industry:Oldbury has long been renowned for its robust metal manufacturing industry. The demand for high-quality metal products, particularly in the automotive and construction sectors, has contributed to the growth and success of the region. As a result, the need for skilled workers, such as wide coil slitters, has become paramount.The Role of a Wide Coil Slitter Operator:A wide coil slitter operator plays a crucial role in the metal manufacturing process. Working within a metals environment, their primary responsibility is to operate machinery that cuts wide metal coils into narrower strips of desired sizes. This process involves precise measurements, attention to detail, and adherence to safety protocols. The slitter operator ensures that the metal coils are prepared and cut according to specific requirements, meeting the industry's high standards.Job Requirements and Shift Pattern:To be considered for this role, prospective candidates must possess experience working within a metals environment. This experience should ideally include previous work as a wide coil slitter operator. The ability to work effectively and efficiently within a team is essential, as operators often collaborate with colleagues to ensure seamless production.The job itself requires undertaking rotating shifts, with two sets of shifts available: 6-2 and 2-10. This flexibility allows for optimal workflow and accommodates personal schedules.Benefits of the Role:Working as a wide coil slitter operator in Oldbury offers numerous advantages. The position provides an opportunity to work within a dynamic and constantly evolving industry, contributing to the production of essential components used in various sectors. Moreover, the rotating shift pattern allows for a healthy work-life balance, as individuals can adjust their schedules accordingly.Oldbury's metal industry boasts a supportive and inclusive work environment. Employees can expect consistent training, career development opportunities, and competitive remuneration packages. Those seeking job security and professional growth will find this industry and role particularly appealing.How to Apply:To apply for this exciting opportunity, interested individuals should submit their applications through the Jobcentre Plus Universal Jobmatch platform. The application process will include providing relevant professional experiences, skills, and contact information. Candidates are encouraged to apply promptly, as these positions often fill quickly due to the strong demand within the metal manufacturing industry.Conclusion:Oldbury's metal industry is actively seeking experienced wide coil slitter operators to join its esteemed workforce. The demand for high-quality metal products continues to grow, making this an excellent opportunity for individuals with experience in metals environments. The rotating shift pattern and inclusive work environment further enhance the appeal of this position. Interested applicants should take advantage of this opportunity and apply promptly to secure their place within this thriving industry.

Glazed Tile Sheet Forming And Corrugating Machine for Color Steel: Latest News

Color Steel Glazed Tile Sheet Forming And Corrugating Machine (Need Remove Brand Name) Brings Innovation to the Construction IndustryInnovation in the construction industry has always been a driving force for companies looking to stay ahead of the competition and meet the changing demands of the market. One such innovation is the Color Steel Glazed Tile Sheet Forming And Corrugating Machine, which has been making waves in the industry for its ability to produce high-quality glazed tile sheets that are both durable and aesthetically pleasing.The Color Steel Glazed Tile Sheet Forming And Corrugating Machine, which is manufactured by a leading company in the industry, represents a significant leap forward in the production of glazed tile sheets. With its advanced technology and precise engineering, this machine is capable of producing sheets with a high level of precision and uniformity, ensuring that every sheet meets the highest quality standards.The process of forming and corrugating the steel sheets is carried out with great efficiency and speed, thanks to the innovative design of the machine. This not only increases the productivity of the manufacturing process but also reduces the overall production costs, making it a cost-effective solution for companies looking to expand their production capacity.The company behind the Color Steel Glazed Tile Sheet Forming And Corrugating Machine has a long-standing reputation for delivering high-quality products and innovative solutions to the construction industry. With a strong focus on research and development, they have been able to stay at the forefront of technological advancements and continue to push the boundaries of what is possible in this field.Their commitment to quality and innovation is reflected in the design of the Color Steel Glazed Tile Sheet Forming And Corrugating Machine, which has been meticulously engineered to deliver superior performance and reliability. This dedication to excellence has earned them the trust and respect of their customers, who rely on their products to meet the demands of their projects.The Color Steel Glazed Tile Sheet Forming And Corrugating Machine is not only a testament to the company's commitment to innovation but also a reflection of their dedication to sustainability. By using advanced technology and efficient manufacturing processes, they have been able to minimize waste and reduce their environmental impact, making their products a more sustainable choice for construction projects.Furthermore, the glazed tile sheets produced by this machine are highly versatile and can be used in a wide range of applications, from residential roofing to commercial building facades. Their durability and resistance to weathering make them an ideal choice for projects in diverse environments, ensuring that they can withstand the test of time and maintain their aesthetic appeal.As the construction industry continues to evolve, the demand for high-quality and innovative materials is only expected to grow. The Color Steel Glazed Tile Sheet Forming And Corrugating Machine is well-positioned to meet this demand, offering a solution that is both technologically advanced and environmentally friendly.In conclusion, the Color Steel Glazed Tile Sheet Forming And Corrugating Machine represents a significant step forward in the production of glazed tile sheets, offering a solution that is both innovative and sustainable. With its advanced technology, precise engineering, and commitment to quality, it is poised to make a lasting impact on the construction industry and continue to be a preferred choice for companies looking to elevate their projects to the next level.

Durable and Stylish Horizontal Corrugated Roof Tile for Your Home

Horizontal Corrugated Roof Tile is a new innovative product that has been launched by a well-known company in the construction industry. This product is designed to provide a durable and stylish roofing solution for residential and commercial buildings. With its unique design and advanced technology, Horizontal Corrugated Roof Tile is set to revolutionize the roofing industry and provide customers with a high-quality, long-lasting solution for their roofing needs.The company producing Horizontal Corrugated Roof Tile has been a leader in the construction industry for many years. They are known for their commitment to quality and innovation, and this new product is a testament to their dedication to providing customers with the best possible solutions for their building needs. With a strong focus on research and development, the company has been able to create a product that meets the highest standards of quality and performance.Horizontal Corrugated Roof Tile is designed to withstand the elements and provide superior protection for buildings. The unique corrugated design of the tiles allows for maximum strength and durability, while also creating a sleek and modern look for any building. The tiles are made from high-quality materials that are designed to last for many years, making them an excellent investment for any property owner.In addition to its durability, Horizontal Corrugated Roof Tile is also designed to be easy to install and maintain. The tiles are lightweight and easy to handle, making the installation process quick and efficient. Once installed, the tiles require minimal maintenance, saving customers time and money in the long run. This is a key selling point for customers who want a low-maintenance roofing solution that will last for many years.Another key feature of Horizontal Corrugated Roof Tile is its versatility. The tiles are available in a wide range of colors and finishes, allowing customers to choose the perfect option to complement their building design. Whether it's a residential home or a commercial building, the tiles can be customized to fit the unique style and aesthetic of any property. This versatility makes Horizontal Corrugated Roof Tile a popular choice for architects, builders, and property owners alike.The launch of Horizontal Corrugated Roof Tile has generated a lot of excitement in the construction industry. Customers are eager to take advantage of this innovative new product, and the company is already seeing a high demand for the tiles. With its combination of durability, style, and ease of installation, Horizontal Corrugated Roof Tile is poised to become a top choice for roofing solutions in the market.To meet the growing demand for Horizontal Corrugated Roof Tile, the company has ramped up production and distribution of the product. They have expanded their manufacturing facilities and have partnered with distributors and retailers to make the tiles readily available to customers. This proactive approach demonstrates the company's commitment to meeting customer needs and ensuring that Horizontal Corrugated Roof Tile is accessible to anyone looking for a reliable and attractive roofing solution.Overall, Horizontal Corrugated Roof Tile is a game-changer in the roofing industry. With its advanced technology, durability, and versatility, the tiles are set to make a lasting impact on the market and provide customers with a superior roofing solution. The company behind the product is dedicated to delivering high-quality solutions for their customers, and Horizontal Corrugated Roof Tile is a shining example of their commitment to excellence. As the product continues to gain traction in the market, it is clear that it will become a staple in the construction industry for years to come.

Metal Roof Panel Roll Forming Machine for Corrugated Panels: Ultimate Guide

The demand for high-quality, reliable metal roofing solutions is on the rise, and one company is stepping up to meet this demand with their state-of-the-art Corrugated Metal Roof Panel Roll Forming Machine. With a reputation for superior products and exceptional customer service, {Company Name} is proud to introduce their latest innovation to the market.The Corrugated Metal Roof Panel Roll Forming Machine is designed to produce top-notch metal roofing panels with precision and efficiency. Using advanced technology and high-quality materials, this machine is capable of creating corrugated metal panels that are not only durable and long-lasting but also aesthetically pleasing. The machine operates at high speeds, enabling {Company Name} to meet the growing demand for metal roofing products in a timely manner.One of the key features of the Corrugated Metal Roof Panel Roll Forming Machine is its versatility. It is capable of producing a wide range of panel sizes and shapes, allowing {Company Name} to cater to the diverse needs of their customers. Whether it's for residential, commercial, or industrial applications, this machine can produce customized metal roof panels to meet specific requirements.In addition to its exceptional performance, the Corrugated Metal Roof Panel Roll Forming Machine is also designed with safety and efficiency in mind. It incorporates advanced safety features to ensure the well-being of the operators, while also minimizing downtime and optimizing production output. This commitment to safety and efficiency aligns with {Company Name}'s dedication to delivering top-quality products and services.{Company Name} is a leading manufacturer in the metal roofing industry with a strong track record of delivering innovative solutions. With a focus on continuous improvement and investment in cutting-edge technologies, they have established themselves as a trusted partner for customers seeking reliable metal roofing products. The introduction of the Corrugated Metal Roof Panel Roll Forming Machine is a testament to their commitment to meeting the evolving needs of the market.As a customer-centric company, {Company Name} places great emphasis on establishing strong relationships with their clients. They understand that every project is unique and are dedicated to providing personalized solutions that exceed expectations. The Corrugated Metal Roof Panel Roll Forming Machine is a reflection of their dedication to delivering excellence and customer satisfaction.The unveiling of the Corrugated Metal Roof Panel Roll Forming Machine is a significant milestone for {Company Name} as it reinforces their position as an industry leader. This latest addition to their range of products is set to further elevate their competitiveness in the market and solidify their reputation for quality and reliability.With the demand for metal roofing solutions continuing to grow, {Company Name} is well-positioned to capitalize on this trend with their state-of-the-art Corrugated Metal Roof Panel Roll Forming Machine. This new innovation not only demonstrates their commitment to excellence but also signifies their readiness to meet the evolving needs of the market.In conclusion, the introduction of the Corrugated Metal Roof Panel Roll Forming Machine by {Company Name} represents a significant advancement in the metal roofing industry. With its cutting-edge technology, versatility, and commitment to safety and efficiency, this machine is set to redefine the standard for metal roof panel production. {Company Name} continues to be at the forefront of innovation, delivering top-quality products and services to their valued customers.

High-Quality Roof Panel Forming Machine for Efficient Roofing Production

In recent years, the demand for sustainable and energy-efficient housing solutions has been on the rise, leading to a growing interest in innovative construction technologies. One such technological advancement is the Roof Panel Forming Machine, a cutting-edge equipment that has the capability to revolutionize the way roofing solutions are manufactured and installed.The Roof Panel Forming Machine, offered by a leading company in the construction industry, utilizes state-of-the-art technology to produce high-quality roofing panels with precision and efficiency. With its advanced design and automated operation, this machine has the capability to significantly reduce the time and labor required to manufacture roofing panels, while also ensuring consistent quality and precision in every panel produced.The company behind the Roof Panel Forming Machine is a renowned industry leader with a strong focus on innovation and technological advancements. With years of experience and expertise in the construction sector, the company has established itself as a trusted provider of cutting-edge solutions for the building and construction industry.The Roof Panel Forming Machine is just one of the many innovative products offered by the company, which prides itself on its commitment to delivering high-quality, reliable, and efficient solutions to meet the evolving needs of the construction industry. In addition to its advanced technology and engineering expertise, the company also places a strong emphasis on sustainability, ensuring that its products are designed to minimize environmental impact and contribute to the development of more eco-friendly construction practices.With its dedicated team of professionals and its state-of-the-art manufacturing facilities, the company is well-equipped to meet the growing demand for advanced construction technologies, including the Roof Panel Forming Machine. The company's commitment to research and development, coupled with its focus on customer satisfaction, has enabled it to establish a strong presence in the global construction market, earning the trust and confidence of industry professionals and clients alike.In addition to its innovative products and cutting-edge technologies, the company also offers comprehensive support and after-sales services, ensuring that its clients receive the necessary assistance and guidance to maximize the potential of their investment in the Roof Panel Forming Machine. From installation and training to technical support and maintenance, the company is dedicated to ensuring the success of its clients and the seamless integration of its advanced construction solutions into their operations.As the demand for sustainable and energy-efficient construction solutions continues to grow, the Roof Panel Forming Machine offered by the company represents a significant leap forward in the construction industry. With its capacity to streamline the manufacturing process, enhance the quality of roofing solutions, and contribute to more sustainable construction practices, this innovative machine is poised to make a lasting impact on the industry.In conclusion, the Roof Panel Forming Machine, offered by the leading company in the construction industry, is a testament to the potential of advanced technologies to revolutionize the way we build and develop the infrastructure for the future. With its commitment to innovation, quality, and sustainability, the company is well-positioned to lead the way in delivering cutting-edge solutions that address the evolving needs of the construction sector and contribute to the development of more efficient, sustainable, and resilient building practices.

How to Make Roof Tiles: A Comprehensive Guide for Machine Users

Title: Revolutionary Roof Tile Making Machine Makes Waves in the Construction IndustryIntroduction:In a groundbreaking development, an innovative and state-of-the-art roof tile making machine has emerged as a game-changer in the construction industry. This groundbreaking technology, developed by a leading company in the field, has revolutionized the way roof tiles are manufactured, offering a sustainable, efficient, and cost-effective solution for construction projects worldwide.Transforming Roofing Processes:Traditional methods of manufacturing roof tiles have long been associated with labor-intensive practices that consume vast amounts of resources and contribute to environmental degradation. However, this new roof tile making machine has effectively transformed the roofing processes, ensuring minimal environmental impact while keeping up with the ever-increasing demands of the construction industry.Key Features and Technology:This cutting-edge roof tile making machine incorporates a range of features and utilizes advanced technology to streamline the production process. It offers precision molding, allowing for the creation of consistent and high-quality roof tiles. With its automated system and minimal manual labor requirements, this machine enhances operational efficiency, reducing labor costs and minimizing the risk of human error.Sustainable Materials and Practices:One of the main selling points of this roof tile making machine is its commitment to sustainability. It employs environmentally-friendly materials and practices, ensuring minimal waste generation and energy consumption. By utilizing recycled materials or eco-friendly alternatives, this machine significantly reduces the environmental footprint associated with traditional manufacturing methods.Cost-Effectiveness and Versatility:The use of this innovative roof tile making machine not only benefits the environment but also proves economically advantageous for construction companies. Its highly efficient production process, coupled with low energy consumption, enables significant cost savings. Additionally, the machine supports the creation of various roof tile designs, catering to the diverse aesthetic preferences of builders and homeowners alike.Enhanced Durability and Longevity:Roof tiles manufactured by this state-of-the-art machine are highly durable and weather-resistant, making them ideal for diverse climatic conditions. Through meticulous design and quality control measures, these tiles withstand harsh environmental factors, such as heavy rain, extreme temperatures, and strong winds. With increased longevity, these tiles offer long-term value to builders and homeowners alike.Streamlined Maintenance and Repair:An added advantage of this advanced roof tile making machine is its focus on easy maintenance and repair of the tiles it produces. With a standardized design and precise molding, any necessary repairs or replacements can be accomplished swiftly and conveniently, minimizing disruption to the building and the occupants.Global Impact and Industry Acceptance:The introduction of this innovative roof tile making machine has generated considerable interest within the construction industry globally. With its ability to transform traditional methods, this technology has disrupted the market and paved the way for a more sustainable and efficient future. Companies worldwide are recognizing its potential and adopting this technology to revolutionize their roofing processes.Conclusion:The emergence of this futuristic roof tile making machine is set to reshape the construction industry by providing a sustainable, cost-effective, and efficient solution for manufacturing high-quality roof tiles. With its focus on environmental responsibility and the incorporation of advanced technology, this machine epitomizes a new era of innovation and progress in the field. As construction companies increasingly embrace this technology, we can expect to witness a significant shift towards sustainable building practices, benefiting not only the industry but also our planet as a whole.

High-Quality Cable Tray Roll Forming Machine from Leading Manufacturers & Suppliers in China

Title: Cable Tray Roll Forming Machines: Supporting Efficient Cable Management SolutionsIntroduction:In the field of cable management solutions, Cable Tray Roll Forming Machines have emerged as a vital component for industries across the globe. Catering to the growing demand for reliable cable tray systems, manufacturers in China are producing high-quality Cable Tray Roll Forming Machines. This blog will delve into the significance, benefits, and features of these machines while highlighting the wide range of choices available for businesses.Cable Tray Roll Forming Machines: Essential Equipment for Efficient Cable ManagementEfficient cable management plays a crucial role in ensuring uninterrupted power supply, reducing downtime, and enhancing safety in industrial settings. Cable trays have become an indispensable solution, providing ample support for organizing and protecting various cables within factories, commercial buildings, and other infrastructure projects. To meet the escalating demand for cable trays, Cable Tray Roll Forming Machines have become essential tools for manufacturers.Why Opt for Cable Tray Roll Forming Machines?1. High-Quality Production: Cable Tray Roll Forming Machines manufactured in China guarantee high-quality results due to their advanced technology and manufacturing processes. These machines are designed to produce cable trays of consistent dimensions, sturdiness, and durability, ensuring reliable cable management solutions.2. Wide Range of Choices: The Chinese Cable Tray Roll Forming Machine market offers a diverse range of options to suit different construction and cable management requirements. From small-scale units to large-scale production lines, manufacturers cater to the varying needs of different industries.3. Automation and Efficiency: Cable Tray Roll Forming Machines incorporate advanced features, such as automated operations, precise control systems, and high-speed production capabilities. The automation not only enhances efficiency but also reduces manual labor, leading to cost savings and improved productivity.4. Customization Possibilities: Businesses can avail themselves of customizable options while selecting a suitable Cable Tray Roll Forming Machine. Manufacturers in China offer flexibility in terms of tray size, material thickness, and design, enabling companies to meet specific project or industry requirements.5. Quality Assurance: Chinese manufacturers adhere to international quality standards and certifications to ensure the reliability and durability of Cable Tray Roll Forming Machines. This dedication to quality helps businesses instill confidence in their investments and delivers consistent, high-performing machines.Key Features of Cable Tray Roll Forming Machines:1. Material Flexibility: Cable Tray Roll Forming Machines can manufacture trays from a variety of materials, including mild steel, galvanized steel, and stainless steel. The ability to work with different materials provides businesses with versatility to cater to varied project specifications and budgets.2. Speed and Accuracy: With the use of advanced technology and precision engineering, Cable Tray Roll Forming Machines can produce trays at high speeds with exceptional accuracy. The consistent dimensions, hole punching, and edge profiling are achieved swiftly and efficiently, meeting production targets effectively.3. Ease of Operation: These machines are designed for ease of use, offering user-friendly interfaces and controls. Operators require minimal training to operate, program, and maintain the Cable Tray Roll Forming Machines, ensuring maximum uptime and productivity.Conclusion:China-based manufacturers have solidified their position as reliable and quality-conscious suppliers of Cable Tray Roll Forming Machines. These machines not only enable businesses to produce cable trays efficiently but also cater to diverse project needs through customization possibilities. The use of advanced technology, automation, and adherence to stringent quality standards ensures these machines will continue to play a crucial role in meeting global cable management requirements.Keywords: Cable Tray Forming Machine, Cable Tray Roll Forming Machine, Cable Tray Roll Forming Machine China, Cable Tray Roll Forming Machine Manufacturer, Cable Tray Roll Forming Machine Suppliers, Cable Tray Roll Forming Machine Factory, Cable Tray Roll Forming Machine Exporters, efficient cable management, high-quality production, wide range of choices, automation, customization possibilities, material flexibility, speed and accuracy, ease of operation.