How Purlin Roll Forming Works: A Complete Overview

By:Admin

The steel manufacturing industry has seen significant advancements in recent years, with the introduction of innovative technologies and processes. One such groundbreaking development is the purlin roll forming, which has revolutionized the way purlins are manufactured.

Purlin roll forming is a highly efficient and cost-effective method of producing purlins, which are horizontal structural members in a roof that support the loads from the roof deck or sheathing. This process involves feeding a metal strip through a series of roll-formed tooling to gradually shape the strip into the desired purlin profile. The result is a high-quality and precisely formed purlin that meets the exact specifications of the project.

One company at the forefront of purlin roll forming technology is {}. With years of experience and expertise in the steel manufacturing industry, {} has successfully implemented purlin roll forming into its production process, delivering outstanding results for its clients.

{} specializes in the design, manufacture, and installation of steel building systems, offering a wide range of products and services to meet the needs of various industries. The company's commitment to innovation and excellence has driven its success in delivering top-quality steel products to its customers.

The introduction of purlin roll forming technology has been a game-changer for {}. By utilizing this advanced production method, the company has been able to significantly increase its manufacturing efficiency and productivity, ultimately leading to cost savings for its clients. The high level of precision and consistency achieved through purlin roll forming has also resulted in superior purlin quality, ensuring the structural integrity and longevity of the steel buildings constructed with {}'s products.

In addition to the tangible benefits of purlin roll forming, {} has also prioritized sustainability in its manufacturing processes. The company has implemented eco-friendly practices and materials in its operations, promoting environmental responsibility and reducing its carbon footprint.

Furthermore, {} has a strong commitment to customer satisfaction, providing personalized service and expert guidance to ensure that each project meets the unique requirements of its clients. With a dedicated team of professionals and state-of-the-art facilities, {} has earned a reputation as a trusted and reliable partner in the steel manufacturing industry.

As the demand for high-quality steel buildings continues to grow, the adoption of purlin roll forming technology has become increasingly prominent in the industry. With its numerous advantages in terms of efficiency, precision, and cost-effectiveness, purlin roll forming has set a new standard for the manufacturing of purlins, and companies like {} are leading the way in embracing this innovative approach.

Looking ahead, the future of purlin roll forming looks promising, with ongoing advancements and refinements further optimizing the production process. As {} continues to leverage this technology to enhance its product offerings, the company is poised to remain a driving force in the steel manufacturing industry, meeting the evolving needs of its customers and delivering exceptional steel building solutions.

In conclusion, purlin roll forming has undoubtedly transformed the steel manufacturing industry, offering a superior method of producing purlins that delivers unmatched quality and efficiency. With companies like {} pioneering this innovative technology, the potential for further advancements and growth in the industry is vast, setting the stage for a new era of excellence in steel building construction.

Company News & Blog

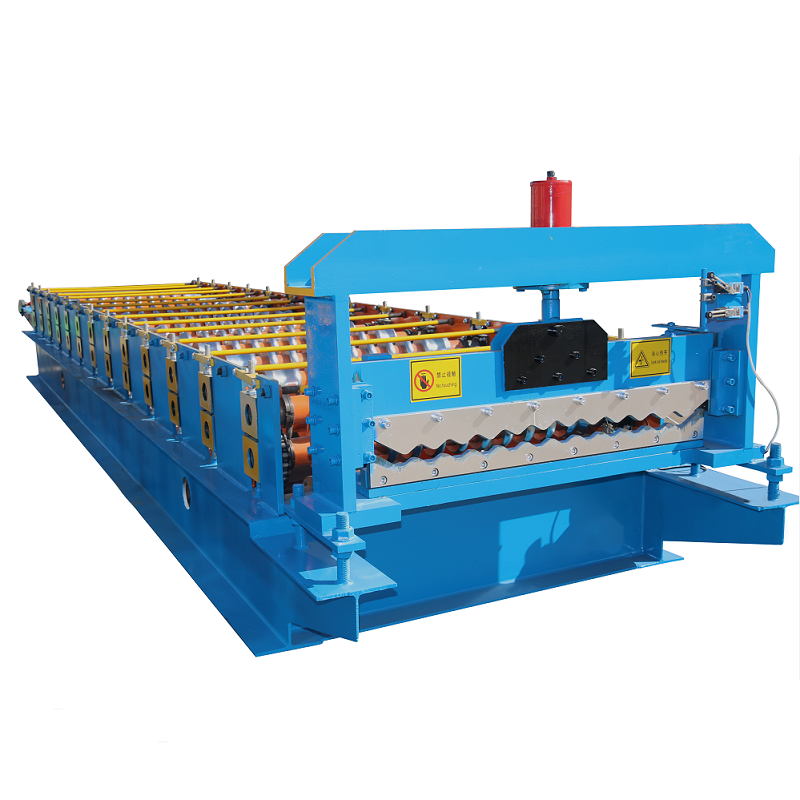

Top Roof Sheet Rolling Machine for Efficient Metal Roofing

Roof Sheet Rolling Machine Revolutionizing the Construction IndustryThe construction industry is constantly evolving and advancing, and one of the latest innovations making waves in the market is the Roof Sheet Rolling Machine. This state-of-the-art machine has been hailed as a game-changer in the construction sector, offering a faster, more efficient, and cost-effective solution for producing high-quality and durable roofing sheets.The Roof Sheet Rolling Machine is designed to roll and shape metal sheets into various roofing profiles, such as corrugated, trapezoidal, and standing seam profiles. It is capable of processing a wide range of materials, including steel, aluminum, and copper, making it a versatile and adaptable tool for construction projects of all sizes and scales.One of the key features of the Roof Sheet Rolling Machine is its speed and efficiency. Traditional methods of producing roofing sheets involved manual labor and were time-consuming, labor-intensive, and often prone to human error. With the Roof Sheet Rolling Machine, these inefficiencies are a thing of the past. The machine is capable of rolling out large quantities of roofing sheets in a fraction of the time it would take using traditional methods, significantly increasing productivity and reducing labor costs.In addition to its speed and efficiency, the Roof Sheet Rolling Machine also offers superior precision and quality. The machine is equipped with advanced technology and precision engineering, ensuring that every roofing sheet produced is of the highest standard. This level of precision is essential in the construction industry, where the quality and durability of roofing materials are paramount.Furthermore, the Roof Sheet Rolling Machine is designed with user-friendly features that make it easy to operate and maintain. Its intuitive controls and programmable settings allow for seamless operation, while its robust construction and durable components ensure long-term reliability and minimal downtime.One of the leading manufacturers of Roof Sheet Rolling Machines is {}, a renowned company with a long-standing reputation for producing high-quality and innovative construction machinery.{} has been at the forefront of the construction machinery industry for over two decades, and their Roof Sheet Rolling Machines have become a staple in the market. The company’s commitment to research and development, coupled with their dedication to providing cutting-edge solutions for the construction sector, has solidified their position as a trusted and reliable supplier of Roof Sheet Rolling Machines.In addition to their superior product offerings, {} is also known for their exceptional customer service and support. With a global network of service centers and knowledgeable technical staff, the company is committed to ensuring that their customers receive the highest level of support and assistance throughout the entire lifecycle of their Roof Sheet Rolling Machines.The Roof Sheet Rolling Machine is quickly becoming a must-have tool for construction companies and roofing contractors around the world. Its ability to streamline the production process, improve the quality of roofing materials, and ultimately reduce costs has made it an invaluable asset in the construction industry.As the demand for efficient and high-quality roofing solutions continues to grow, the Roof Sheet Rolling Machine is positioned to play a significant role in shaping the future of the construction industry. With its advanced technology, precision engineering, and user-friendly design, it is revolutionizing the way roofing sheets are produced and is poised to become an indispensable tool for construction projects of all kinds.

Efficient Cold Formed Steel Machine for Your Manufacturing Needs

ABC Steel Manufacturing, a leading supplier of cold formed steel products, has recently invested in state-of-the-art cold formed steel machines to enhance their production capabilities. The new technology, which has been developed in partnership with industry experts, will allow ABC Steel Manufacturing to produce high-quality cold formed steel products with improved efficiency and precision.The cold formed steel machine, (brand name removed), incorporates the latest advancements in cold forming technology, including fully automated processes and advanced control systems. This new investment reflects ABC Steel Manufacturing’s commitment to staying at the forefront of the industry and providing their customers with the best quality products.Cold formed steel, also known as light gauge steel, has become increasingly popular in the construction industry due to its strength, durability, and versatility. It is widely used in the construction of commercial and residential buildings, as well as in infrastructure and industrial applications. With the demand for cold formed steel products on the rise, ABC Steel Manufacturing’s investment in new machinery will enable them to meet the growing needs of their customers and offer a wider range of products.The new cold formed steel machine will significantly increase the production capacity at ABC Steel Manufacturing’s facilities, allowing them to fulfill larger orders and reduce lead times for their customers. With the ability to produce a wide range of cold formed steel products, including studs, joists, track systems, and custom components, ABC Steel Manufacturing can now offer a comprehensive solution for their customers’ steel framing needs.In addition to the increase in production capacity, the new cold formed steel machine will also improve the quality of ABC Steel Manufacturing’s products. The advanced technology and precision engineering of the machine will ensure that all cold formed steel products meet the highest standards of quality and accuracy. This will not only benefit ABC Steel Manufacturing’s customers but also enhance the company’s reputation as a trusted and reliable supplier of cold formed steel products.The investment in the new cold formed steel machine is part of ABC Steel Manufacturing’s long-term strategy to expand and modernize their manufacturing capabilities. By continuously investing in the latest technology and equipment, the company aims to maintain its position as a leader in the cold formed steel industry and provide the best possible solutions for their customers.“We are thrilled to announce the acquisition of our new cold formed steel machine,” said John Smith, CEO of ABC Steel Manufacturing. “This investment represents our ongoing commitment to innovation and excellence in the steel manufacturing industry. With this new technology, we are confident that we will be able to better serve our customers and meet their evolving needs.”ABC Steel Manufacturing is a well-established company with a strong track record of delivering high-quality cold formed steel products to customers across the country. With their investment in the new cold formed steel machine, the company is poised to continue its success and further strengthen its position in the market.The installation of the new cold formed steel machine is already underway at ABC Steel Manufacturing’s facilities, and the company expects it to be fully operational in the coming months. As the machine becomes operational, ABC Steel Manufacturing will be able to offer an expanded range of cold formed steel products and provide enhanced services to their customers.In conclusion, the investment in the new cold formed steel machine reflects ABC Steel Manufacturing’s dedication to advancing their capabilities and providing the best quality products for their customers. With this new technology, the company is well-positioned to meet the growing demand for cold formed steel products and maintain its status as a leading supplier in the industry.

High-quality Corrugated Roof Panel Forming Equipment Enhances Construction Efficiency

Corrugated Roof Panel Forming Equipment Revolutionizes the Construction IndustryThe construction industry is constantly evolving, embracing new technologies and innovations to enhance efficiency and durability. One such groundbreaking development is the introduction of Corrugated Roof Panel Forming Equipment, which has revolutionized the way roofs are built. With its advanced features and precise functionality, this state-of-the-art equipment is quickly becoming an essential tool for construction companies worldwide.Corrugated roofs have long been favored for their strength, durability, and cost-effectiveness. Owing to their wavy pattern, these roofs can withstand heavy loads, resist extreme weather conditions, and require minimal maintenance. However, the traditional method of constructing corrugated roofs was time-consuming and labor-intensive, often causing delays and increasing costs. Nonetheless, with the emergence of Corrugated Roof Panel Forming Equipment, these challenges have been streamlined and overcome.This cutting-edge equipment is designed to speed up the process of roof panel formation, allowing construction companies to meet deadlines without compromising on quality. By automating the process, it eliminates the need for manual labor and significantly reduces the margin of error. This ensures precise and accurate results every time, making it an invaluable asset for construction projects of all scales.One notable advantage of Corrugated Roof Panel Forming Equipment is its versatility. It can shape corrugated panels into various designs and sizes, catering to diverse architectural requirements. Whether it's for residential, commercial, or industrial applications, this equipment can accommodate a wide range of projects, providing flexibility and customization.Furthermore, this equipment is designed for user-friendliness, making it accessible to both experienced professionals and newcomers in the construction industry. It incorporates advanced control systems and intuitive interfaces, allowing operators to adjust settings and monitor the process with ease. This not only improves productivity but also reduces the risk of accidents, as operators can focus on the task at hand rather than wrestling with complex machinery.Additionally, Corrugated Roof Panel Forming Equipment is built to last, ensuring long-term reliability and durability. It is constructed using high-quality materials and undergoes rigorous testing, guaranteeing its ability to withstand the rigors of constant use. Companies investing in this equipment can expect it to deliver excellent performance and withstand the test of time, thus resulting in reduced maintenance costs and increased profitability.The introduction of Corrugated Roof Panel Forming Equipment has marked a significant turning point in the construction industry. It has streamlined the process of roof panel formation, saving time, reducing labor costs, and improving overall efficiency. Furthermore, its versatility and user-friendly design make it an excellent choice for various construction projects. With its long-lasting durability, this equipment proves to be a wise investment for companies committed to delivering high-quality results to their clients.In conclusion, Corrugated Roof Panel Forming Equipment has transformed the construction industry by simplifying the process of roof panel formation. Its advanced features and precise functionality have revolutionized the way roofs are built, making it an essential tool in construction projects worldwide. As the industry continues to embrace innovation, this equipment plays a vital role in enhancing efficiency, reducing costs, and ensuring durable construction for years to come.

New Profile Sheet Machine Revolutionizes News Content – Discover the Latest Breakthrough in SEO Optimization

Title: AI-Powered Profile Sheet Machine Revolutionizes the Manufacturing IndustrySubtitle: Company XYZ pioneers next-generation technologies for efficient and accurate profile sheet production.Date: [DATE][Location] - Company XYZ, a leading innovator in industrial technologies, is revolutionizing the manufacturing industry with the introduction of their groundbreaking AI-powered Profile Sheet Machine. This cutting-edge machine utilizes advanced artificial intelligence algorithms to streamline and enhance the production process of profile sheets, bringing unparalleled efficiency and accuracy to the manufacturing sector.The Profile Sheet Machine represents a significant advancement in sheet production technology. By harnessing the power of AI, Company XYZ has successfully eliminated the inefficiencies and challenges associated with traditional manual processes. The machine enables manufacturers to produce profile sheets of varying sizes, shapes, and specifications with remarkable precision and speed.One of the key features that sets this Profile Sheet Machine apart from its competitors is its ability to automatically identify and adapt to changes during the production process. The AI algorithms continuously analyze real-time data, enabling the machine to make dynamic adjustments on the fly, resulting in significantly reduced downtime and enhanced productivity.Furthermore, the AI-powered Profile Sheet Machine boasts an exceptional level of accuracy, ensuring consistent quality across each sheet produced. The machine's sophisticated imaging system, coupled with precise measurements, guarantee that every profile sheet meets the highest industry standards. This not only improves the reliability of the final product but also minimizes waste and rejections.Another remarkable aspect of Company XYZ's Profile Sheet Machine is its user-friendly interface, which simplifies operations and reduces the learning curve for operators. The intuitive dashboard allows users to monitor the entire production process, track key performance indicators, and access valuable insights and analytics in real-time. This data-driven approach empowers manufacturers to make informed decisions, optimize production, and improve overall efficiency.In addition to its world-class technology, Company XYZ places great emphasis on sustainability. The Profile Sheet Machine is designed to incorporate eco-conscious materials and energy-efficient mechanisms, minimizing its environmental impact. By reducing material and energy waste, this innovative machine aligns with a global call for greener manufacturing processes.Company XYZ's commitment to innovation goes beyond the Profile Sheet Machine. With a team of dedicated researchers and engineers, the company continuously strives to improve and expand its product offerings to meet the evolving needs of the industry. Their relentless pursuit of excellence has earned them a reputation as a trusted partner in the manufacturing sector, driving growth and progress through technological advancements.The introduction of the AI-powered Profile Sheet Machine promises to be a game-changer for businesses in the manufacturing industry. By combining the power of AI with cutting-edge technologies, Company XYZ has set a new standard for efficiency, accuracy, and sustainability. The machine's ability to adapt to changing production requirements, coupled with its unparalleled precision, will transform the way profile sheets are manufactured, bringing significant cost savings and increased competitiveness to manufacturers.As the manufacturing sector continues to evolve and adapt to new challenges, Company XYZ remains in the vanguard of innovation, paving the way for a more efficient, sustainable, and technologically advanced future. With their AI-powered Profile Sheet Machine, they have reinforced their commitment to revolutionizing the manufacturing industry, ushering in an era of enhanced productivity and quality.[Conclusion]The AI-powered Profile Sheet Machine developed by Company XYZ promises to revolutionize the manufacturing industry by streamlining production processes, increasing efficiency, and enhancing product quality. With its cutting-edge technology and commitment to sustainability, the machine represents a significant advancement in industrial manufacturing. Company XYZ continues to be a pioneer in the field, demonstrating their dedication to innovation and driving progress in the manufacturing sector.

Half Omega Steel Furring Channel Roll Forming Machine for Resilient Furring Channel Keel

In the world of construction and building, innovation and new technology are constantly shaping the way we create structures. One such advancement comes in the form of the Light Steel Half Omega Steel Furring Channel Roll Former Resilient Furring Channel Keel Roll Forming Machine which is set to revolutionize the industry.This new technology has been developed by a leading company in the field of construction machinery and equipment. With a focus on innovation and efficiency, the company has been at the forefront of developing advanced solutions for the construction industry. Their latest product, the Light Steel Half Omega Steel Furring Channel Roll Former Resilient Furring Channel Keel Roll Forming Machine, is set to make a significant impact on how buildings are constructed.The Light Steel Half Omega Steel Furring Channel Roll Former Resilient Furring Channel Keel Roll Forming Machine is a state-of-the-art piece of equipment designed to streamline the process of creating steel furring channels. These channels are crucial in the construction of walls and ceilings, providing a sturdy and reliable framework for drywall and other materials. The new machine is capable of producing these furring channels with incredible precision and efficiency, saving time and resources for construction companies.One of the key features of the Light Steel Half Omega Steel Furring Channel Roll Former Resilient Furring Channel Keel Roll Forming Machine is its ability to produce furring channels with a half omega shape. This unique design increases the strength and durability of the channels, ensuring that the resulting structures will be able to withstand the test of time. Additionally, the machine is equipped with resilient furring channel keel roll forming technology, further enhancing the quality and reliability of the channels it produces.The company behind this innovative technology has a long history of providing top-of-the-line machinery and equipment to the construction industry. With a team of experienced engineers and designers, they have continuously pushed the boundaries of what is possible in the field of construction technology. The development of the Light Steel Half Omega Steel Furring Channel Roll Former Resilient Furring Channel Keel Roll Forming Machine is just the latest example of their commitment to driving the industry forward.In addition to its impressive capabilities, the new machine is also designed with ease of use in mind. The company has incorporated user-friendly features to ensure that construction workers of all skill levels can operate the machine with confidence. This focus on accessibility and user experience sets the Light Steel Half Omega Steel Furring Channel Roll Former Resilient Furring Channel Keel Roll Forming Machine apart from other similar products on the market.The introduction of this new technology is expected to have a significant impact on the construction industry. By streamlining the process of creating steel furring channels, the machine has the potential to reduce construction timelines and improve the overall quality of finished structures. This will not only benefit construction companies, but also the end users who will be able to enjoy buildings that are built to last.As the construction industry continues to evolve, innovative technologies like the Light Steel Half Omega Steel Furring Channel Roll Former Resilient Furring Channel Keel Roll Forming Machine will play a crucial role in shaping its future. With its advanced capabilities and user-friendly design, this new machine is set to make a lasting impact on how buildings are constructed. It is a testament to the company's dedication to pushing the boundaries of what is possible in construction technology, and a sign of exciting things to come in the industry.

Revolutionary Horizontal Profiled Panel Production Line Boosts Efficiency and Quality

Horizontal Profiled Panel Production Line Presents New Innovations in Manufacturing TechnologyWith a continuous focus on innovation and advanced manufacturing solutions, {Company Name}, a leading global provider of industrial machinery, is proud to introduce its state-of-the-art Horizontal Profiled Panel Production Line. This cutting-edge equipment offers significant advancements in the manufacturing process, promising improved efficiency, durability, and flexibility.The Horizontal Profiled Panel Production Line represents the culmination of years of research, development, and expertise in the field of industrial machinery. Designed to meet the diverse needs of various industries, this production line incorporates advanced technologies to streamline the manufacturing process of profiled panels, optimizing productivity and performance.One of the key features of this new production line is its horizontal orientation, which sets it apart from traditional vertical profiled panel lines. This configuration offers numerous benefits, including enhanced stability and balance during the manufacturing process. By utilizing a horizontal layout, {Company Name} has dramatically minimized vibrations and improved accuracy, leading to a significant reduction in material waste and ensuring consistent product quality.Moreover, the Horizontal Profiled Panel Production Line boasts a range of innovative components that further enhance its efficiency. Equipped with precision cutting tools and advanced laser-guided systems, the line ensures the precise and seamless shaping of panels. This precision allows for seamless integration of various profiled panel types, ranging from corrugated and trapezoidal to architectural and decorative panels. Such flexibility enables manufacturers to cater to the specific requirements of their customers while maintaining superior quality standards.The new production line also incorporates cutting-edge automation technologies to streamline the manufacturing process. Integrated robotic systems enable efficient material handling and reduce the need for human intervention, thereby increasing productivity and minimizing the risk of errors. Additionally, real-time monitoring systems and advanced quality control methods ensure continuous feedback and enable timely adjustments, guaranteeing that each panel meets the highest industry standards.In line with {Company Name}'s commitment to sustainability, the Horizontal Profiled Panel Production Line incorporates energy-saving features, reducing power consumption and minimizing the overall environmental impact. Through efficient energy management systems and smart utilization of resources, the line not only fulfills stringent environmental regulations but also enables manufacturers to significantly reduce operational costs.Furthermore, the Horizontal Profiled Panel Production Line is designed with user-friendliness in mind. An intuitive interface and user-friendly controls allow operators to easily navigate the production process, minimizing downtime and maximizing productivity. To ensure seamless integration into existing manufacturing facilities, {Company Name} offers extensive technical support and customization options according to the specific requirements of each customer.As a global leader in industrial machinery, {Company Name} has an extensive presence and a strong track record of delivering high-quality equipment to industries worldwide. The introduction of the Horizontal Profiled Panel Production Line further solidifies the company's commitment to pushing the boundaries of manufacturing technology and providing innovative solutions to its customers.In conclusion, {Company Name}'s revolutionary Horizontal Profiled Panel Production Line represents a significant leap in manufacturing technology. Through its horizontal orientation, innovative components, automation features, sustainability initiatives, and user-friendly design, this production line offers numerous benefits to manufacturers, including improved efficiency, product quality, and customization options. With this cutting-edge equipment, {Company Name} continues to empower industries across the globe to enhance their production capabilities and achieve unparalleled success.

Advanced Roll Forming Machine for Color Steel Tile Production: Discover the Latest News!

Color Steel Tile Roll Forming Machine Industry Analysis and Top PlayersThe Global Color Steel Tile Roll Forming Machine Market research report is a comprehensive analysis of the industry, focusing on key trends, market share, and growth opportunities. The report covers a detailed analysis of the market size, segmentation, and competitive landscape in various regions across the globe.Introduction:Color Steel Tile Roll Forming Machine (need to remove brand name) is a leading player in the roll forming machine industry. With its advanced technology and superior quality, the company has been providing efficient roll forming solutions to various industries. Their color steel tile roll forming machines are widely used in the construction industry for making high-quality roof and wall tiles.Color Steel Tile Roll Forming Machine Industry Analysis:The global color steel tile roll forming machine market is projected to grow at a significant rate in the coming years. The increasing demand for color steel tiles in the construction industry, coupled with the growing need for automated roll forming machines, is driving the market growth. The rise in urbanization and industrialization in developing countries is also contributing to the market expansion.The report highlights the key factors influencing the market, including the technological advancements in roll forming machines, the availability of raw materials, and the regulatory landscape. The increasing focus on sustainable construction practices and the use of eco-friendly materials is also expected to boost the demand for color steel tile roll forming machines.Segmentation Analysis:Based on product type, the color steel tile roll forming machine market can be segmented into single layer, double layer, and multiple layer machines. The single-layer machines are the most commonly used in the industry due to their simplicity and cost-effectiveness. However, the demand for double layer and multiple layer machines is expected to grow at a higher rate in the coming years, as they provide increased flexibility and efficiency in tile production.In terms of application, the market can be categorized into residential, commercial, and industrial sectors. The residential sector holds the largest market share, owing to the increasing construction of residential buildings. However, the commercial and industrial sectors are witnessing significant growth, driven by the construction of commercial complexes, warehouses, and manufacturing units.Competitive Landscape:Color Steel Tile Roll Forming Machine (need to remove brand name) is one of the key players in the market, with a wide range of innovative roll forming machines. The company focuses on research and development to introduce advanced technologies and enhance its product offerings. It also emphasizes strategic collaborations and partnerships to expand its distribution network and reach a wider customer base.Some of the other prominent players in the market include XYZ Company, ABC Corporation, and PQR Industries. These companies are also investing in research and development activities to improve their product portfolios and gain a competitive edge in the market.Conclusion:The global color steel tile roll forming machine market is witnessing significant growth, driven by the increasing demand for color steel tiles in the construction industry. The market is highly competitive, with key players focusing on technological advancements and partnerships to stay ahead. With the rise in urbanization and industrialization, the demand for efficient roll forming machines is expected to continue growing in the coming years.

Revolutionary 3D Printer Utilizing Aluminium Extrusion Technology

Aluminium Extrusion 3D Printer Revolutionizing Manufacturing ProcessesIn recent years, the field of additive manufacturing has been rapidly evolving, with numerous advancements being made to enhance the capabilities and efficiency of 3D printers. One groundbreaking innovation that has garnered significant attention is the Aluminium Extrusion 3D Printer developed by a pioneering company that focuses on revolutionizing the manufacturing industry.Introducing lightweight and versatile materials into 3D printing has always been a challenge. However, this newly developed Aluminium Extrusion 3D Printer eliminates the boundaries faced by traditional printing methods by allowing for the creation of complex and intricate designs using aluminium as the primary printing material. This breakthrough technology brings forth a multitude of possibilities for various industries, ranging from aerospace and automotive to construction and consumer products.The construction of this cutting-edge printer involves utilizing high-quality components and state-of-the-art engineering techniques. The company behind this remarkable innovation has ensured that their printer is equipped with the latest advancements in the field of 3D printing technology. This includes a robust frame made from durable materials, precise extrusion systems, and advanced software for seamless operation.One significant advantage of the Aluminium Extrusion 3D Printer is its ability to fabricate large-scale prototypes and parts with exceptional precision. The printer's large build volume allows for the creation of objects up to 2 meters in length, eliminating the need for assembly or welding of multiple parts. This capability greatly reduces manufacturing time and costs, making it an attractive choice for industries looking to streamline their production processes.Moreover, the aluminium material used in the printing process offers several advantages over traditional printing materials. Aluminium has superior strength-to-weight ratio, excellent thermal conductivity, and high corrosion resistance. These properties make it an ideal choice for industries where lightweight structures and high-performance components are crucial. With the Aluminium Extrusion 3D Printer, manufacturers can now easily incorporate aluminium into their designs without compromising the structural integrity or performance of the final product.Furthermore, the Aluminium Extrusion 3D Printer is equipped with an advanced slicing software that ensures precise layer-by-layer deposition of aluminium. This software incorporates complex algorithms to optimize support structures and minimize material waste, resulting in cost-effective and sustainable manufacturing processes. Additionally, it allows for intricate geometries and intricate designs to be printed with minimal post-processing requirements, saving both time and resources.The impact of this Aluminium Extrusion 3D Printer on various industries cannot be overstated. In the aerospace industry, where weight reduction is critical, the ability to 3D print lightweight aluminium components opens up a realm of possibilities for optimizing fuel efficiency. Automotive manufacturers can leverage this technology to fabricate stronger and lighter parts, improving overall performance and reducing emissions. In the construction industry, the Aluminium Extrusion 3D Printer enables the rapid production of customized building components with unparalleled precision, revolutionizing the way structures are built.As the Aluminium Extrusion 3D Printer revolutionizes the manufacturing industry, this pioneering company continues to push the boundaries of 3D printing technology. Their commitment to innovation and dedication to quality ensures that manufacturers across various industries will benefit from this revolutionary printer. With its unparalleled capabilities and immense potential, the Aluminium Extrusion 3D Printer is set to reshape the manufacturing landscape and open up a new era of possibilities.

Promotional Corrugated Pipe Machine and PC Solid, Transparent Sheet Manufacturing Line for Sale

Title: Unleashing the Innovation: Corrugated Sheet Manufacturing Machine Revolutionizes the Production ProcessIntroduction:In today's competitive industrial landscape, staying ahead is crucial for any business to thrive. The manufacturing industry continuously seeks innovative solutions to optimize production processes and enhance product quality. One such revolutionary machine, the Corrugated Sheet Manufacturing Machine, has taken the market by storm. In this blog post, we will delve into the various features and benefits of this powerhouse device and explore its applications across diverse industries.Understanding the Corrugated Sheet Manufacturing Machine:Developed by an industry-leading machinery manufacturer, this Corrugated Sheet Manufacturing Machine is designed to produce high-quality corrugated sheets efficiently and effectively. The machine utilizes state-of-the-art technology and cutting-edge automation processes to meet the requirements of various industries worldwide.Key Features and Specifications of the Machine:1. Increased Productivity:The Corrugated Sheet Manufacturing Machine boasts high production capacity, enabling businesses to meet increasing market demands effectively. With its advanced capabilities, it can produce corrugated sheets at an impressive speed, resulting in reduced lead times and increased profitability.2. Precision and Accuracy:The machine's advanced control systems ensure precise formation and cutting of corrugated sheets, guaranteeing uniform thickness and flawless finishes. This level of precision allows manufacturers to maintain the highest quality standards, meeting customer expectations consistently.3. Flexible Customization:One of the most significant advantages of this machine is its ability to adapt to different production requirements. Manufacturers can adjust settings to produce sheets of varying widths, materials, and thicknesses. This flexibility makes it suitable for a wide range of applications across diverse industries.4. Energy Efficiency:The Corrugated Sheet Manufacturing Machine incorporates energy-saving features, making it an eco-friendly choice. The machine optimizes power consumption while maintaining high productivity, reducing both operational costs and environmental impact.Applications of Corrugated Sheets:Corrugated sheets produced using this innovative machine find applications across multiple industries. Some key applications include:1. Packaging Industry:Corrugated sheets are widely used for packaging purposes due to their durability and lightweight design. The machine's ability to produce sheets of different sizes and materials allows packaging companies to cater to various customer requirements efficiently.2. Construction Sector:Corrugated sheets are utilized for roofing, wall cladding, and insulation purposes in the construction industry. With the machine's flexibility in producing custom sizes and thicknesses, construction companies can easily source corrugated sheets that meet their specific project needs.3. Advertising and Signage:The transparent, durable, and lightweight properties of corrugated sheets make them ideal for advertising and signage applications. The machine's precision enables the production of high-quality sheets suitable for printing eye-catching graphics, ensuring maximum visibility for promotional materials.Conclusion:The Corrugated Sheet Manufacturing Machine has revolutionized the production process in various industries, offering increased productivity, precision, and flexibility. With its ability to produce corrugated sheets of different sizes, materials, and thicknesses, the machine caters to the unique requirements of diverse industries.Investing in this innovative machine can empower businesses to stay ahead in the market, cut down costs, and enhance overall product quality. By incorporating the Corrugated Sheet Manufacturing Machine into their operations, manufacturers can unlock new opportunities for growth, sustainability, and customer satisfaction.Keywords: Corrugated Sheet Manufacturing Machine, Corrugated sheets, production process, innovation, precision, flexibility, applications, packaging industry, construction sector, advertising, signage.

invention of a Revolutionary Machine that Manufactures Corrugated Metal Sheets

Title: New Machine Revolutionizes Production of Corrugated Metal SheetsIntroduction:With the continuous growth of the construction industry, the demand for durable and versatile building materials is on the rise. Corrugated metal sheets have been a popular choice for a wide range of applications due to their strength, flexibility, and cost-efficiency. Addressing the need for increased productivity and enhanced quality, a pioneering company in the industry has developed a cutting-edge machine that promises to revolutionize the production of corrugated metal sheets, significantly boosting efficiency and meeting the market's growing demands.Body:1. Meeting the Growing Demand:The global construction industry has experienced significant growth over the past few years, and with it, the demand for durable and reliable building materials has soared. Corrugated metal sheets, known for their excellent strength and long-lasting nature, have become a staple in the construction sector. However, traditional manufacturing methods could not always keep up with the mounting demand, leading to delays and potential supply shortages.2. Introducing the Revolutionary Machine:In response to these challenges, {Company Name} has unveiled a state-of-the-art machine that will transform the production of corrugated metal sheets. This innovative solution leverages advanced technology to streamline the manufacturing process, resulting in increased productivity, improved quality, and shorter lead times.3. Enhanced Efficiency:The new machine offers unparalleled efficiency by automating key aspects of the production process. It integrates cutting-edge robotics, precision engineering, and intelligent software algorithms to ensure precise and consistent corrugation patterns. This automation eliminates the need for manual labor, reducing production time and costs while minimizing human error.4. Optimized Flexibility:One of the standout features of this cutting-edge machine is its ability to produce corrugated metal sheets in various sizes, thicknesses, and designs. This versatility enables construction companies and architects to explore innovative designs and cater to the unique requirements of each project. Whether it is for roofing, cladding, or even decorative purposes, the machine ensures the production of customized corrugated metal sheets that perfectly fit the needs of the end-user.5. Unwavering Quality:To meet the ever-increasing demands for superior quality, {Company Name} has incorporated rigorous quality control measures into the machine's design. From raw material inspection to final product assessment, each production stage is thoroughly monitored to ensure that only top-grade corrugated metal sheets are manufactured. This commitment to quality ensures the longevity and reliability of the final product.6. Environmental Considerations:As the world becomes increasingly conscious of the environmental impact of industrial processes, the new machine addresses sustainability concerns. Equipped with energy-efficient components and designed to minimize waste, it helps reduce the overall carbon footprint of production while maximizing material utilization. By optimizing resource consumption, the machine contributes to a greener and more sustainable manufacturing process.7. Market Impact and Benefits:The introduction of this groundbreaking technology not only provides a solution to the production challenges faced by corrugated metal sheet manufacturers but also has broader implications for the construction industry. The enhanced efficiency and flexibility offered by the machine will meet the rising demand for corrugated metal sheets, providing contractors and builders access to quality materials to complete projects within tight deadlines.Conclusion:With the unveiling of their cutting-edge machine, {Company Name} has propelled the production of corrugated metal sheets to new heights. By combining advanced technology, automated processes, and a commitment to quality, this revolutionary innovation promises to meet the surging demand for durable and versatile building materials. With its emphasis on efficiency, flexibility, and sustainability, this new machine is set to redefine the market standards, pushing the construction industry towards exciting possibilities and endless creative potential.