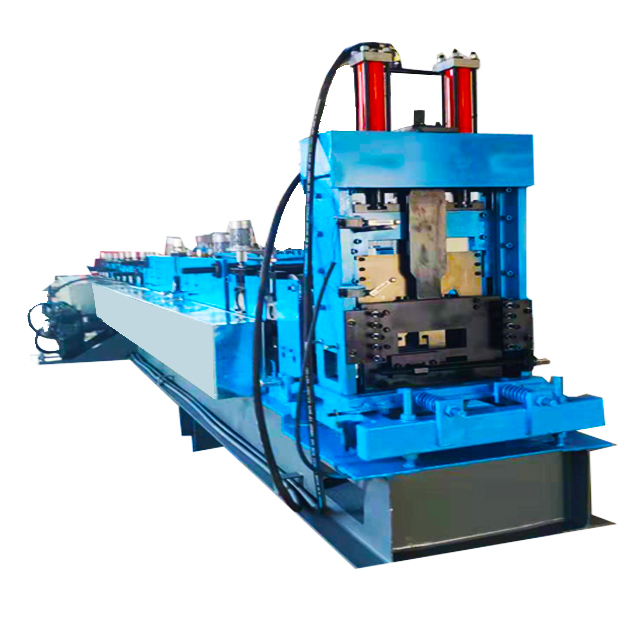

Light Gauge Steel Frame Roll Forming Machine for CZ Purlin Profile

By:Admin

In response to this growing demand, [Company Name] has developed a state-of-the-art CZ Purlin Profile Light Gauge Steel Frame Roll Forming Machine that is capable of producing high-quality purlin profiles with precision and efficiency. This machine is equipped with advanced technology and features that make it suitable for a wide range of construction projects.

[Company Name] is a leading manufacturer and supplier of roll forming machines and has been in the industry for over 20 years. The company is known for its commitment to innovation, quality, and customer satisfaction. With a team of experienced engineers and technicians, [Company Name] has been able to develop cutting-edge solutions that meet the evolving needs of the construction industry.

The CZ Purlin Profile Light Gauge Steel Frame Roll Forming Machine offered by [Company Name] is designed to be user-friendly and efficient. It is capable of producing CZ purlin profiles with a high degree of accuracy and consistency, making it ideal for large-scale construction projects. The machine is also equipped with a range of safety features to ensure the security of the operator and the surrounding environment.

One of the key features of the CZ Purlin Profile Light Gauge Steel Frame Roll Forming Machine is its flexibility. It can be easily programmed to produce purlin profiles of different sizes and specifications, making it suitable for a variety of construction applications. This flexibility allows contractors and builders to utilize the machine for a wide range of projects, resulting in cost savings and improved efficiency.

In addition to its performance, the CZ Purlin Profile Light Gauge Steel Frame Roll Forming Machine is also designed for durability and longevity. The machine is built with high-quality materials and components that are capable of withstanding the rigors of heavy-duty use. This ensures that the machine will provide reliable performance for many years, making it a valuable investment for any construction business.

As part of its commitment to customer satisfaction, [Company Name] offers comprehensive technical support and after-sales service for its CZ Purlin Profile Light Gauge Steel Frame Roll Forming Machine. The company's team of experts is available to provide assistance with installation, training, and maintenance, ensuring that customers are able to make the most of their investment.

Overall, the CZ Purlin Profile Light Gauge Steel Frame Roll Forming Machine offered by [Company Name] represents a significant advancement in the construction industry. Its advanced technology, flexibility, and durability make it an ideal solution for contractors and builders looking to streamline their operations and improve the quality of their construction projects.

With its proven track record of innovation and commitment to excellence, [Company Name] is well-positioned to meet the growing demand for high-quality roll forming machines in the construction industry. As the industry continues to evolve, [Company Name] remains dedicated to developing cutting-edge solutions that enable its customers to succeed in an increasingly competitive market.

Company News & Blog

Half Omega Steel Furring Channel Roll Forming Machine for Resilient Furring Channel Keel

In the world of construction and building, innovation and new technology are constantly shaping the way we create structures. One such advancement comes in the form of the Light Steel Half Omega Steel Furring Channel Roll Former Resilient Furring Channel Keel Roll Forming Machine which is set to revolutionize the industry.This new technology has been developed by a leading company in the field of construction machinery and equipment. With a focus on innovation and efficiency, the company has been at the forefront of developing advanced solutions for the construction industry. Their latest product, the Light Steel Half Omega Steel Furring Channel Roll Former Resilient Furring Channel Keel Roll Forming Machine, is set to make a significant impact on how buildings are constructed.The Light Steel Half Omega Steel Furring Channel Roll Former Resilient Furring Channel Keel Roll Forming Machine is a state-of-the-art piece of equipment designed to streamline the process of creating steel furring channels. These channels are crucial in the construction of walls and ceilings, providing a sturdy and reliable framework for drywall and other materials. The new machine is capable of producing these furring channels with incredible precision and efficiency, saving time and resources for construction companies.One of the key features of the Light Steel Half Omega Steel Furring Channel Roll Former Resilient Furring Channel Keel Roll Forming Machine is its ability to produce furring channels with a half omega shape. This unique design increases the strength and durability of the channels, ensuring that the resulting structures will be able to withstand the test of time. Additionally, the machine is equipped with resilient furring channel keel roll forming technology, further enhancing the quality and reliability of the channels it produces.The company behind this innovative technology has a long history of providing top-of-the-line machinery and equipment to the construction industry. With a team of experienced engineers and designers, they have continuously pushed the boundaries of what is possible in the field of construction technology. The development of the Light Steel Half Omega Steel Furring Channel Roll Former Resilient Furring Channel Keel Roll Forming Machine is just the latest example of their commitment to driving the industry forward.In addition to its impressive capabilities, the new machine is also designed with ease of use in mind. The company has incorporated user-friendly features to ensure that construction workers of all skill levels can operate the machine with confidence. This focus on accessibility and user experience sets the Light Steel Half Omega Steel Furring Channel Roll Former Resilient Furring Channel Keel Roll Forming Machine apart from other similar products on the market.The introduction of this new technology is expected to have a significant impact on the construction industry. By streamlining the process of creating steel furring channels, the machine has the potential to reduce construction timelines and improve the overall quality of finished structures. This will not only benefit construction companies, but also the end users who will be able to enjoy buildings that are built to last.As the construction industry continues to evolve, innovative technologies like the Light Steel Half Omega Steel Furring Channel Roll Former Resilient Furring Channel Keel Roll Forming Machine will play a crucial role in shaping its future. With its advanced capabilities and user-friendly design, this new machine is set to make a lasting impact on how buildings are constructed. It is a testament to the company's dedication to pushing the boundaries of what is possible in construction technology, and a sign of exciting things to come in the industry.

Z Purlin Roll Forming Machine: A Comprehensive Guide to Roll Forming Z Purlins for Structural Support

NEW PURLIN ROLL FORMING MACHINE PROMISES EFFICIENCY AND PRECISION[City], [Date] - The development of technology has revolutionized various industries, and the manufacturing sector is no exception. One of the latest innovations in the field of manufacturing machinery is the new Z Purlin Roll Forming Machine, designed to provide enhanced efficiency, accuracy, and reliability in the production of Z-shaped purlins. This advanced machine is set to transform the purlin manufacturing industry, meeting the increasing demand for high-quality construction materials.A leader in manufacturing equipment, [Company Name] has introduced its latest addition to the industry - the Z Purlin Roll Forming Machine. With its state-of-the-art features and cutting-edge technology, this machine promises to streamline the process of creating Z-shaped purlins, reducing manual labor and increasing productivity.The Z Purlin Roll Forming Machine is designed to withstand heavy-duty industrial usage, ensuring durability and longevity. It boasts an ergonomic design that allows for easy operation, making it accessible even to less experienced operators. Equipped with a user-friendly interface, the machine offers a seamless experience, and its automated functions contribute to the overall efficiency of production.Precision and accuracy are crucial in the manufacturing of Z-shaped purlins, and this is where the Z Purlin Roll Forming Machine truly excels. With its advanced roll-forming technology, it enables the production of perfectly shaped purlins with consistent dimensions. The machine optimizes material usage, minimizing waste and reducing costs for manufacturers. Additionally, its high-speed production capabilities enable rapid turnaround times, meeting the time-sensitive demands of the construction industry.Incorporating safety features is of paramount importance in any industrial machinery, and the Z Purlin Roll Forming Machine lives up to this expectation. Enhanced safety measures have been integrated into its design, safeguarding operators and preventing potential accidents. The machine complies with international safety regulations, ensuring a secure environment for workers.While the Z Purlin Roll Forming Machine offers numerous benefits for manufacturers, it also delivers advantages to the end-users. By utilizing this advanced technology, construction companies can obtain consistently high-quality Z-shaped purlins for their projects. The superior strength and structural integrity of these purlins enhance the overall stability and durability of buildings, guaranteeing a longer lifespan.Moreover, the versatility of the Z Purlin Roll Forming Machine allows for the production of purlins of various sizes and shapes. This flexibility caters to the diverse requirements of different construction projects, providing a custom solution to architects, engineers, and contractors alike.The implementation of this cutting-edge technology by the manufacturing industry marks a significant step towards improvement and progress. By investing in modern machinery such as the Z Purlin Roll Forming Machine, manufacturers can stay competitive in the market and meet the rising demands of customers.As [Company Name] continues to redefine manufacturing equipment, its commitment to innovation and customer satisfaction remains unwavering. With the introduction of the Z Purlin Roll Forming Machine, the company aims to revolutionize the manufacturing process and set new industry standards.In conclusion, the new Z Purlin Roll Forming Machine brings efficiency, precision, and reliability to the purlin manufacturing industry. This advanced machinery promises to streamline production, improve product quality, and cater to the diverse needs of different construction projects. As technology continues to evolve, manufacturers can rely on [Company Name] to deliver cutting-edge solutions that optimize their operations and drive industry growth.

High Precision CNC Machine for Aluminum Extrusions

The demand for precision-engineered aluminum extrusions has been on the rise in various industries such as construction, automotive, and aerospace. In response to this increasing demand, a leading manufacturing company has recently invested in state-of-the-art CNC machinery to enhance their capabilities in producing high-quality aluminum extrusions.With a legacy of over 50 years in the industry, {} has built a strong reputation for delivering innovative and customized solutions to their clients. Specializing in aluminum extrusion, the company has been at the forefront of technological advancements and has consistently invested in cutting-edge equipment to meet the evolving needs of their customers.The latest addition to their manufacturing arsenal is the advanced CNC machine specially designed for aluminum extrusions. This new equipment is equipped with high precision cutting and milling capabilities, allowing {} to achieve tight tolerances and intricate designs with utmost accuracy. The CNC machine also offers greater flexibility in producing complex shapes and profiles, enabling the company to cater to a wide range of applications across different industries.One of the key advantages of the new CNC machine is its efficiency in handling large-scale production while maintaining superior quality. This increased production capacity will enable {} to meet the growing demand for aluminum extrusions within shorter lead times, giving them a competitive edge in the market. Moreover, the CNC machine is integrated with advanced software that enables seamless programming and automation, thereby streamlining the manufacturing process and reducing the time required for setup and tool changes.In addition to enhancing their production capabilities, the investment in the CNC machine reflects {}'s commitment to upholding the highest standards of quality and precision. The company adheres to stringent quality control measures at every stage of the manufacturing process, ensuring that the aluminum extrusions meet the exact specifications and performance requirements of their customers. The new CNC machine further reinforces this commitment by enabling precise and consistent machining of extruded aluminum profiles, resulting in products that exhibit exceptional dimensional accuracy and surface finish.Furthermore, the implementation of the CNC machine underscores {}'s dedication to innovation and continuous improvement. By leveraging the latest technology, the company aims to push the boundaries of what is achievable in aluminum extrusion manufacturing. This proactive approach not only showcases their willingness to invest in the future of their business but also positions them as a reliable and forward-thinking partner for their clients.The investment in the CNC machine is also aligned with {}'s sustainability initiatives. Aluminum is widely recognized for its recyclability and environmental benefits, and {} is committed to minimizing their environmental footprint by optimizing material usage and reducing waste in their manufacturing processes. The precision and efficiency offered by the new CNC machine will contribute to the sustainable production of aluminum extrusions, further reinforcing {}'s position as an eco-conscious industry leader.In conclusion, the introduction of the CNC machine for aluminum extrusions marks a significant milestone for {}. This strategic investment not only enhances their manufacturing capabilities but also underscores their dedication to delivering top-quality, precision-engineered solutions to their clients. By embracing the latest technology and upholding their commitment to excellence, {} is poised to meet the evolving needs of the industry and continue setting new benchmarks in the field of aluminum extrusion manufacturing.

Purlin Machine with Punching Hole Device for Manual Shaping

Manual Shape C Purlin Machine With Punching Hole DeviceIn the world of construction and manufacturing, the importance of high-quality machinery cannot be overstated. One company that has been leading the way in providing top-notch industrial equipment is {}. With a commitment to excellence and innovation, they have recently launched their Manual Shape C Purlin Machine with Punching Hole Device, promising to revolutionize the industry.{"} is a renowned manufacturer of industrial machinery, with a strong focus on producing high-quality equipment that meets the needs of their customers. With years of experience in the industry, they have developed a reputation for delivering cutting-edge solutions that enhance productivity and efficiency in various sectors, including construction and manufacturing.The newly launched Manual Shape C Purlin Machine with Punching Hole Device is the latest addition to their impressive lineup of industrial equipment. This machine is designed to streamline the process of producing C-shaped purlins, which are essential components in the construction of buildings and other structures. By incorporating a punching hole device, it offers the added capability of creating precise holes in the purlins, further enhancing its functionality and versatility.One of the key features of this new machine is its manual operation, which allows for greater control and precision during the manufacturing process. With a user-friendly interface and intuitive controls, operators can easily adjust settings and parameters to meet their specific requirements. This level of customization ensures that the machine can accommodate a wide range of project needs, making it a valuable asset for businesses of all sizes.Furthermore, the Manual Shape C Purlin Machine with Punching Hole Device is constructed with durability and longevity in mind. By utilizing high-quality materials and advanced engineering techniques, it offers robust performance and reliability, even in demanding industrial environments. This ensures that businesses can count on this machine to deliver consistent results, day in and day out.In addition to its impressive performance capabilities, this new machine is also designed with efficiency in mind. With a focus on optimizing the production process, it is capable of producing C-shaped purlins with punching holes at a rapid pace, helping businesses meet tight deadlines and maximize their output. This level of productivity can have a significant impact on overall operational efficiency and profitability.To complement the launch of the Manual Shape C Purlin Machine with Punching Hole Device, {} is also offering comprehensive support and services to their customers. This includes expert guidance on machine selection and installation, as well as ongoing maintenance and technical assistance to ensure optimal performance. By offering a complete package, they are demonstrating their commitment to customer satisfaction and success.In conclusion, the launch of the Manual Shape C Purlin Machine with Punching Hole Device by {} represents a significant advancement in industrial machinery. With its precision, durability, and efficiency, this machine is poised to make a positive impact on the construction and manufacturing sectors. As {} continues to push the boundaries of innovation, it is clear that they are a force to be reckoned with in the industry. Businesses looking to enhance their production capabilities would be wise to consider the Manual Shape C Purlin Machine with Punching Hole Device as a valuable addition to their operations.With a track record of delivering exceptional products and services, there is no doubt that {} will continue to be a leader in the industry for years to come.

Metal Steel Roof Sheet Roll Forming Machine for Step Tile Production

In an effort to meet the growing demand for high-quality roofing materials, {Company Name} has recently announced the launch of their new Step Tile Metal Steel Roof Sheet Roll Forming Machine. The machine, which was developed by a team of experienced engineers and designers, is set to revolutionize the production of metal roofing sheets by offering improved efficiency and precision.The Step Tile Metal Steel Roof Sheet Roll Forming Machine is designed to produce step tile roof sheets, which are known for their durability and aesthetic appeal. With the ability to form metal sheets into precise, uniform shapes, this machine is expected to significantly reduce the time and labor required for manufacturing high-quality roofing materials.One of the key features of this new machine is its advanced automation capabilities. Equipped with state-of-the-art controls and sensors, the machine is able to continuously monitor and adjust the forming process to ensure consistently accurate results. This not only improves the overall quality of the roofing sheets but also minimizes material waste and production costs.In addition to its advanced automation, the Step Tile Metal Steel Roof Sheet Roll Forming Machine is also designed for user-friendly operation. Its intuitive interface and easy-to-use controls make it accessible to operators of varying skill levels, reducing the need for extensive training and supervision."We are thrilled to introduce our new Step Tile Metal Steel Roof Sheet Roll Forming Machine to the market," said {Company CEO}. "With its innovative design and advanced features, we believe that this machine will set a new standard for the production of metal roofing materials. We are confident that it will help our customers streamline their operations and deliver exceptional products to their clients."As a leading manufacturer and supplier of metal roofing materials, {Company Name} is committed to providing innovative solutions that meet the evolving needs of the construction industry. With the introduction of the Step Tile Metal Steel Roof Sheet Roll Forming Machine, the company is reaffirming its dedication to quality, efficiency, and customer satisfaction.The launch of this new machine comes at a time of increased demand for metal roofing materials, driven by the growing focus on sustainable and long-lasting construction solutions. By investing in advanced manufacturing technology, {Company Name} is positioning itself as a reliable partner for contractors, builders, and distributors seeking to source high-quality metal roofing products.In addition to the new Step Tile Metal Steel Roof Sheet Roll Forming Machine, {Company Name} offers a comprehensive range of metal roofing solutions, including various profiles, coatings, and colors to suit diverse architectural styles and project requirements. With a strong commitment to product innovation and customer service, the company has established itself as a trusted provider in the metal roofing industry.Looking ahead, {Company Name} plans to continue investing in research and development to further enhance its product offerings and manufacturing capabilities. By staying at the forefront of technological advancements, the company aims to anticipate market trends and deliver solutions that empower its customers to achieve their project goals efficiently and economically.The introduction of the Step Tile Metal Steel Roof Sheet Roll Forming Machine marks a significant milestone for {Company Name}, signaling its ongoing commitment to excellence and innovation in the metal roofing industry. With its cutting-edge design and performance, this machine is set to elevate the standard for metal roofing production and contribute to the advancement of sustainable and resilient construction practices.

Top Supplier and Manufacturer of Ungrouped Forming Machines in China - Products List Page-9

Global Market Leader in Sheet Roll Forming Introduces State-Of-The-Art Ungrouped Forming Machine(Company Name - No Brand Name) is proud to announce the launch of its latest innovation - the Ungrouped Forming Machine. As a global market leader in sheet roll forming, (Company Name - No Brand Name) has built its reputation on its cutting-edge technology and high-quality products. This new machine is no exception and promises to be a game-changer in the industry.The Ungrouped Forming Machine is a versatile and efficient machine that can produce a wide range of sheet metal products. It is designed to simplify the forming process and provide precision and accuracy every time. The machine is equipped with advanced technology that ensures quick and easy setup, reducing production time and increasing efficiency."Our new Ungrouped Forming Machine is a prime example of our commitment to innovation and excellence," said the company spokesperson. "We understand the need for our clients to remain competitive in the ever-changing market, and this machine is designed to do just that. Its versatility means it can produce a variety of sheet metal products, from roofing to wall cladding, to rain gutters and downspouts. And with its advanced technology, it provides accuracy, efficiency, and reliability every time."The machine's compact design allows it to fit comfortably in any workshop space, making it an ideal choice for small to medium-sized businesses. It is also easy to operate, reducing the need for skilled labor, and its low maintenance requirements keep costs down. Plus, the machine's durability ensures a longer lifespan, providing better value for money.(Undisclosed Name) is a long-standing manufacturer of sheet metal forming equipment, mainly focusing on roof panel forming machines, wall panel forming machines, standing seam roof panel machines, gutter forming machines, and other related equipment. The company's commitment to quality has resulted in (Company Name - No Brand Name) becoming a global leader in sheet metal roll forming equipment. They have a strong reputation for designing and manufacturing high-quality equipment that is built to last. Their machines are used by clients worldwide for a variety of applications, including residential, commercial, and industrial projects.(Undisclosed Name) clients have access to a comprehensive range of services, including design and layout assistance, installation support, and an aftersales service team that provides ongoing support and training. (Company Name - No Brand Name) understands the importance of providing exceptional customer service and support, and this is reflected in its commitment to delivering high-quality equipment that meets the needs of its clients.In conclusion, the launch of the Ungrouped Forming Machine is a significant milestone for (Company Name - No Brand Name). It is the latest addition to the company's extensive range of sheet metal forming equipment, and it promises to deliver exceptional results for clients worldwide. With its advanced technology, versatility, and efficiency, the machine is set to become a game-changer in the industry. (Company Name - No Brand Name) is proud to offer this innovative machine to its clients and is committed to providing exceptional customer service and support.

Metal steel roof sheet roll forming machine: A step tile solution

Step Tile Metal Steel Roof Sheet Roll Forming Machine has been gaining significant attention in the construction industry recently. This innovative technology is revolutionizing the way roof sheets are manufactured and installed, providing a more efficient and cost-effective solution for builders and contractors.The Step Tile Metal Steel Roof Sheet Roll Forming Machine is designed to produce high-quality step tile metal steel roof sheets with precision and ease. With its advanced technology and automated system, this machine is capable of producing consistent and accurate roof sheets, eliminating the risk of human error and ensuring a perfect fit for every installation.The company behind this groundbreaking technology, [company name], is a leading manufacturer of roll forming machines and equipment. With years of experience and expertise in the industry, [company name] has earned a reputation for delivering top-of-the-line products that meet the highest standards of quality and performance.The Step Tile Metal Steel Roof Sheet Roll Forming Machine is just one of many innovative solutions offered by [company name]. Their commitment to innovation and continuous improvement has allowed them to stay ahead of the competition and provide their customers with cutting-edge technology that meets the ever-evolving needs of the construction industry.With the rise in demand for more durable and aesthetically pleasing roofing solutions, the Step Tile Metal Steel Roof Sheet Roll Forming Machine has quickly become a popular choice among builders and contractors. Its ability to produce custom step tile designs with ease and efficiency has made it a game-changer in the roofing industry.In addition to its high-quality output, the Step Tile Metal Steel Roof Sheet Roll Forming Machine also offers significant time and cost savings. Its efficient production process and low maintenance requirements make it a cost-effective investment for any construction business, allowing them to increase their productivity and profitability without compromising on quality.Moreover, the machine's user-friendly interface and easy operation make it accessible to a wide range of users, from seasoned professionals to entry-level workers. This accessibility has contributed to its widespread adoption across the construction industry, as more and more businesses recognize the value of incorporating this technology into their operations.In response to the growing demand for the Step Tile Metal Steel Roof Sheet Roll Forming Machine, [company name] has ramped up its production capacity to ensure timely delivery to its customers. Their dedicated team of engineers and technicians are committed to providing exceptional service and support, ensuring that every customer receives the assistance they need to maximize the benefits of this innovative technology.As the construction industry continues to embrace the benefits of the Step Tile Metal Steel Roof Sheet Roll Forming Machine, [company name] remains at the forefront of innovation, constantly refining and enhancing their products to meet the evolving needs of their customers. Their unwavering commitment to excellence and customer satisfaction has solidified their position as a trusted and reliable provider of roll forming machines and equipment.In conclusion, the Step Tile Metal Steel Roof Sheet Roll Forming Machine is a game-changing technology that is transforming the way roof sheets are manufactured and installed. With its precision, efficiency, and cost-effectiveness, it has become a valuable asset for construction businesses looking to stay ahead in a competitive market. And with [company name]'s unparalleled expertise and dedication to innovation, the future of roll forming technology looks brighter than ever.

Title: Discover the Ultimate Roof Sheet Rolling Machine for Your Roofing ProjectIntroduction:In today's competitive construction industry, it's essential to invest in the right tools and equipment to ensure the success of your projects. One crucial aspect of any roofing project is the roof sheet rolling machine, also known as the roof panel forming machine or roof panel roll forming machine. This advanced machinery plays a vital role in creating high-quality and durable roof sheets that are an integral part of any structure. In this blog, we will explore the significance of a roof sheet rolling machine and why finding the perfect one is essential. Additionally, we will discuss the leading manufacturers in China and their superior roof sheet rolling machine models available in the market.Understanding the Importance of a Roof Sheet Rolling Machine:A roof sheet rolling machine is specifically designed to transform raw metal sheets into precisely shaped and sized roof panels. This process involves a series of intricate stages, including material loading, roll forming, cutting, and product stacking. By using a roof sheet rolling machine, construction professionals can streamline the production process, ensuring accuracy, efficiency, and consistency.Benefits of Using a High-Quality Roof Sheet Rolling Machine:Investing in a high-quality roof sheet rolling machine offers numerous advantages for contractors and construction firms:1. Superior Durability: Top-notch machines are manufactured using premium-grade materials and components, ensuring the longevity and resilience of the equipment.2. Precision and Efficiency: Advanced technology and design features allow for precise panel forming, cutting, and sizing, minimizing material waste and increasing productivity.3. Versatility: Leading roof sheet rolling machines can produce a variety of different panel designs, enabling contractors to cater to diverse customer requirements.4. Easy Operation and Maintenance: Quality machines come with user-friendly interfaces, making them easy to operate. Moreover, maintenance requirements are minimal, reducing downtime during the production process.5. Output Quality: The use of reliable roof sheet rolling machines ensures consistent and uniform panel quality, giving clients peace of mind regarding the structural integrity of their roofs.Leading Manufacturers of Roof Sheet Rolling Machines in China:China has established itself as a global leader in manufacturing top-quality roof sheet rolling machines. Some renowned Chinese manufacturers that provide exceptional machines include:1. [Manufacturer 1]: Known for their commitment to superior design and engineering, this manufacturer offers a range of high-performance roof sheet rolling machines suitable for various roofing applications.2. [Manufacturer 2]: With a reputation built on innovation and precision engineering, this manufacturer produces advanced roof panel forming machines that promise remarkable accuracy, durability, and efficiency.3. [Manufacturer 3]: Known for their wide range of roll forming machinery, this manufacturer delivers top-quality roof panel roll forming machines that cater to the diverse needs of construction professionals.Conclusion:Investing in a roof sheet rolling machine is a game-changer for construction firms looking to enhance their roofing projects' efficiency, accuracy, and overall quality. The significance of finding a reliable and high-quality machine cannot be overstated. Manufacturers in China, such as [Manufacturer 1], [Manufacturer 2], and [Manufacturer 3], offer exceptional options that guarantee superior performance and durability. By choosing the right roof sheet rolling machine, you can elevate your roofing projects to new heights, ensuring customer satisfaction and success in your construction endeavors.Keywords: Roof Sheet Rolling Machine, Roof Panel Forming Machine, Roof Panel Roll Forming Machine

Maximizing Efficiency and Durability: A Comprehensive Guide to Roll Forming Techniques

article discussing the benefits and applications of roll forming in manufacturing.Roll Forming: A Highly Efficient Tool in Modern ManufacturingAs the manufacturing industry continues to evolve, new technologies and innovations are constantly emerging to meet the needs of the market and keep companies competitive. One of the tools that has gained popularity in recent years is roll forming, a process of shaping metal sheets or coils into specific shapes using specialized machinery.At its core, roll forming involves passing a continuous strip of metal through a series of rolls, each of which gradually bends the metal into the desired shape. The end result is a precisely formed product that can be used in a wide range of applications, from construction and automotive to aerospace and electronics.According to industry experts and manufacturers, roll forming offers several benefits over traditional metal forming processes. For one, it is highly efficient and can produce large volumes of parts quickly. Because the process is continuous, manufacturers can create long runs of parts without having to stop and start the machinery between each piece, which can help reduce downtime and increase productivity.Additionally, roll forming allows for greater flexibility in design and customization. With a wide range of roll forming tools and dies available, manufacturers can create complex shapes and profiles that would be difficult or impossible to achieve with other methods. This flexibility can be especially useful in industries with unique or specialized requirements, such as aerospace or medical device manufacturing.Another advantage of roll forming is its high level of precision and consistency. Because the machinery is designed to produce identical parts each time, manufacturers can ensure a high level of quality control and reduce the risk of defects or errors. This can help improve the overall reliability and durability of the final product, making it more appealing to customers and end-users.Roll forming is also a highly cost-effective process in many cases. The tooling required for roll forming can be expensive upfront, but the cost per part is typically much lower than with other metal forming methods due to the efficiencies of the process. Additionally, the ability to create long runs of parts without interruptions can help reduce labor costs and minimize scrap and waste.One company that has embraced roll forming as a core part of its manufacturing capabilities is (Total Roll Forming). The company specializes in creating custom roll formed parts for a wide range of industries, from construction and transportation to petrochemicals and telecommunications.According to (Total Roll Forming)’s website, the company utilizes a combination of state-of-the-art roll forming machinery and experienced technicians to create high-quality, precision parts. Their capabilities include forming a wide range of metals, including steel, aluminum, and copper, and creating parts in a variety of shapes and thicknesses.Some of the products that (Total Roll Forming) produces include metal roofing and siding panels, framing components for construction, and components for HVAC and electrical systems. They also offer custom roll forming services for clients who require specialized parts or unique shapes.Ultimately, roll forming is a powerful tool for modern manufacturers who seek to maximize efficiency, precision, and cost-effectiveness in their operations. Whether it is to create simple parts or complex profiles, this process offers a range of benefits that can help companies stay ahead of the competition and meet the demands of their customers.

High-Quality Corrugated Iron Machine for Sale: Find Your Perfect Solution Here

[Company Name] is proud to announce the launch of their latest innovation in the manufacturing industry - the new Corrugated Iron Machine. This state-of-the-art machine is set to revolutionize the production of corrugated iron sheets, offering increased efficiency, precision, and quality.The Corrugated Iron Machine is the result of years of research and development, drawing on [Company Name]'s expertise and experience in the manufacturing sector. The machine is designed to meet the growing demand for corrugated iron sheets, which are commonly used in construction, roofing, and structural projects.One of the key features of the Corrugated Iron Machine is its advanced technology, which allows for precise and uniform corrugation of iron sheets. This ensures that the finished products are of the highest quality, with consistent dimensions and excellent structural integrity. The machine also offers increased production capacity, allowing for higher output and faster turnaround times.In addition to its advanced technology, the Corrugated Iron Machine is also designed with ease of use and maintenance in mind. With user-friendly controls and a robust construction, the machine is built to withstand the rigors of heavy-duty industrial use, while also being easy to operate and maintain. This makes it a valuable asset for manufacturing facilities of all sizes."We are thrilled to introduce the new Corrugated Iron Machine to the market," said [Company Name] spokesperson. "This machine represents a significant advancement in the manufacturing of corrugated iron sheets, offering unparalleled precision, efficiency, and quality. We believe that it will have a positive impact on the industry and help our customers meet the growing demand for high-quality corrugated iron products."The launch of the Corrugated Iron Machine is the latest in a series of innovative products and solutions from [Company Name]. With a commitment to excellence and a focus on meeting the needs of their customers, the company has established itself as a leader in the manufacturing industry. Their dedication to research and development, as well as investment in cutting-edge technology, have allowed them to stay ahead of the competition and continue to deliver products that exceed industry standards.In addition to the Corrugated Iron Machine, [Company Name] offers a comprehensive range of equipment and machinery for the manufacturing sector. This includes metal forming machines, roll forming machines, and other custom solutions tailored to the specific needs of their customers. With a team of experienced engineers and technicians, they also provide expert support and service to ensure that their customers get the most out of their investments.As the demand for corrugated iron sheets continues to grow, the launch of the Corrugated Iron Machine could not have come at a better time. [Company Name] is confident that this innovative machine will help their customers meet this demand with ease, while also improving their production processes and overall efficiency.The Corrugated Iron Machine is now available for purchase, and [Company Name] is inviting interested parties to get in touch for more information. With its cutting-edge technology, user-friendly design, and focus on quality, this machine is set to make a significant impact on the manufacturing industry and set a new standard for the production of corrugated iron sheets.