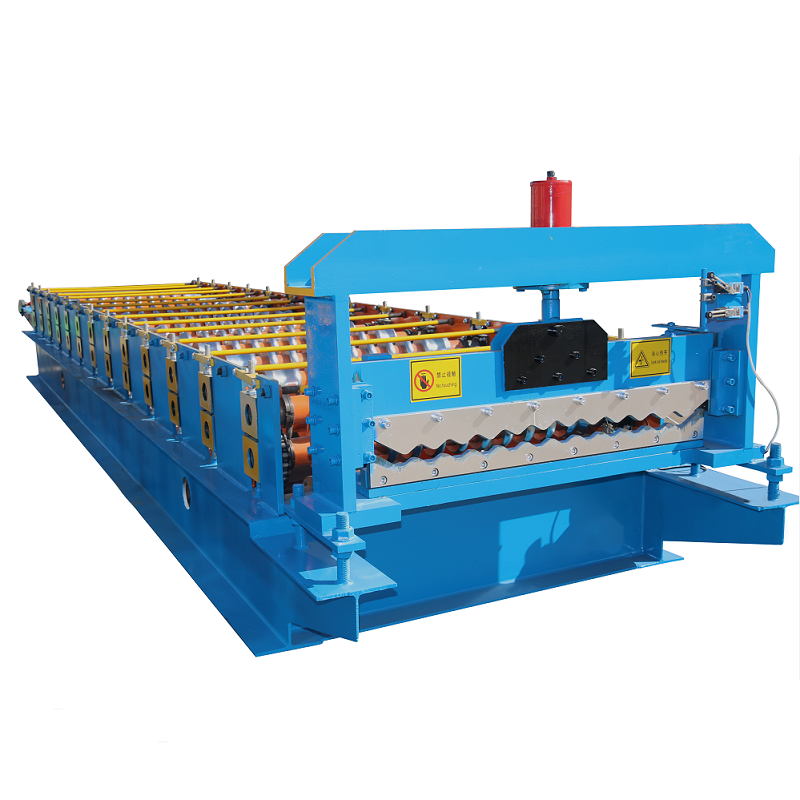

Metal Forming Machine for Roofing: Your Ultimate Guide

By:Admin

The roofing industry is set to be revolutionized with the introduction of the latest technological innovation in metal forming machines. The new machine, developed by [Company Name], is set to change the way roofing materials are produced, making the process faster, more efficient and environmentally friendly.

[Company Name] has been a leader in the manufacturing and production of metal forming machines for over 20 years. The company is renowned for its commitment to innovation and quality, and its latest offering is no exception. The new roofing metal forming machine is set to transform the construction industry by providing a sustainable and cost-effective solution for the production of roofing materials.

The machine is capable of producing a wide range of roofing materials, including corrugated sheets, standing seam panels, and metal tiles, all of which are essential components in the construction of modern buildings. The versatility of the machine means that it can cater to the diverse needs of the construction industry, from residential to commercial projects.

One of the standout features of the new machine is its ability to produce roofing materials at an unprecedented speed. By utilizing advanced technology and precision engineering, the machine is able to significantly reduce production times, allowing for faster completion of construction projects. This not only benefits the construction companies, but also contributes to the overall efficiency and productivity of the industry as a whole.

In addition to its speed, the machine also boasts a high level of accuracy and consistency in the production of roofing materials. This ensures that the final products meet the highest quality standards, providing durability and longevity to the buildings they are used in. This level of precision is crucial in the construction industry, where quality and reliability are paramount.

Furthermore, the machine is designed with sustainability in mind. It utilizes eco-friendly materials and energy-efficient processes to minimize its environmental impact. This aligns with the growing demand for sustainable practices in the construction industry, as more and more companies seek to reduce their carbon footprint and promote environmentally friendly practices.

The introduction of the new roofing metal forming machine by [Company Name] is set to have a significant impact on the construction industry. Its innovative technology, speed, accuracy, and sustainability make it a game-changer in the production of roofing materials. The machine not only meets the current needs of the industry, but also sets a new standard for the future of construction.

With its proven track record of delivering high-quality and reliable products, [Company Name] has once again demonstrated its commitment to driving innovation in the construction industry. The new machine is a testament to the company's dedication to providing cutting-edge solutions that meet the evolving needs of the market.

As the demands for faster, more efficient, and sustainable construction practices continue to grow, the introduction of the roofing metal forming machine by [Company Name] comes at a crucial time. It is set to address these needs while setting a new benchmark for the industry as a whole.

In conclusion, the new roofing metal forming machine by [Company Name] is poised to revolutionize the construction industry. Its innovative technology, combined with the company's commitment to quality and sustainability, makes it a game-changer in the production of roofing materials. This latest offering reaffirms [Company Name]'s position as a leader in the manufacturing and production of metal forming machines, and sets a new standard for the future of construction.

Company News & Blog

C/Z/U Channel Interchangeable Roll Forming Machine - Find Out More on China-Glorious.com Today

Introduction:Roll forming is the process of shaping metals into custom cross-section profiles, and it is widely used in various industries, including construction, automotive, and appliances. The roll forming machines are designed to automate this process, and they come in different types depending on the desired profile and material. In this blog, we will discuss the C channel rolling machine, its features, benefits, and applications.What is a C Channel Rolling Machine?A C channel rolling machine is a roll forming machine that is designed to produce C channel profiles from coils of sheet metal. The machine consists of several roll stations, where each station progressively shapes the metal into the desired C channel profile. The machine's design allows for the interchangeability of the C, Z, and U channels, producing different sizes and shapes according to the customer's needs.Features of the C Channel Rolling Machine:- Interchangeable channel profiles: The C channel rolling machine can produce various channel profiles, including C, Z, and U channels, by interchanging the roller stations.- High precision and efficiency: The rolling machine has a digital control system that ensures high precision and consistency in the production process.- Customizable sizes and shapes: The machine can produce C channel profiles of different sizes and shapes, depending on the customer's requirements.- Easy to operate: The C channel rolling machine is user-friendly and easy to operate, making it suitable for both small and large-scale production.Benefits of using a C Channel Rolling Machine:- Cost-effective: The machine's automated process reduces labor costs and material waste, resulting in cost savings.- High production output: The C channel rolling machine has a high production output, allowing for the efficient and timely completion of large orders.- Customizable profiles: The flexibility of the machine allows for the production of customized C channel profiles, meeting individual customer needs.- High-quality output: The digital control system ensures high precision in the production process, resulting in a high-quality output.Applications of the C Channel Rolling Machine:The C channel rolling machine is widely used in various industries, including:- Construction: C channel profiles are used in the construction industry for building frameworks, supports, and columns.- Automotive: C channel profiles are used in vehicle frames, exhaust systems, and roof rails.- Appliances: C channel profiles are used in the production of refrigerators, air conditioners, and washing machines.Conclusion:The C channel rolling machine is a versatile and cost-effective roll forming machine, suitable for the production of C, Z, and U channel profiles. Its customizable sizes and shapes, high precision, and efficiency make it ideal for various applications in different industries. If you are looking for a reliable machine for your C channel production needs, the C channel rolling machine is a worthy investment.

Metal steel roof sheet roll forming machine: A step tile solution

Step Tile Metal Steel Roof Sheet Roll Forming Machine has been gaining significant attention in the construction industry recently. This innovative technology is revolutionizing the way roof sheets are manufactured and installed, providing a more efficient and cost-effective solution for builders and contractors.The Step Tile Metal Steel Roof Sheet Roll Forming Machine is designed to produce high-quality step tile metal steel roof sheets with precision and ease. With its advanced technology and automated system, this machine is capable of producing consistent and accurate roof sheets, eliminating the risk of human error and ensuring a perfect fit for every installation.The company behind this groundbreaking technology, [company name], is a leading manufacturer of roll forming machines and equipment. With years of experience and expertise in the industry, [company name] has earned a reputation for delivering top-of-the-line products that meet the highest standards of quality and performance.The Step Tile Metal Steel Roof Sheet Roll Forming Machine is just one of many innovative solutions offered by [company name]. Their commitment to innovation and continuous improvement has allowed them to stay ahead of the competition and provide their customers with cutting-edge technology that meets the ever-evolving needs of the construction industry.With the rise in demand for more durable and aesthetically pleasing roofing solutions, the Step Tile Metal Steel Roof Sheet Roll Forming Machine has quickly become a popular choice among builders and contractors. Its ability to produce custom step tile designs with ease and efficiency has made it a game-changer in the roofing industry.In addition to its high-quality output, the Step Tile Metal Steel Roof Sheet Roll Forming Machine also offers significant time and cost savings. Its efficient production process and low maintenance requirements make it a cost-effective investment for any construction business, allowing them to increase their productivity and profitability without compromising on quality.Moreover, the machine's user-friendly interface and easy operation make it accessible to a wide range of users, from seasoned professionals to entry-level workers. This accessibility has contributed to its widespread adoption across the construction industry, as more and more businesses recognize the value of incorporating this technology into their operations.In response to the growing demand for the Step Tile Metal Steel Roof Sheet Roll Forming Machine, [company name] has ramped up its production capacity to ensure timely delivery to its customers. Their dedicated team of engineers and technicians are committed to providing exceptional service and support, ensuring that every customer receives the assistance they need to maximize the benefits of this innovative technology.As the construction industry continues to embrace the benefits of the Step Tile Metal Steel Roof Sheet Roll Forming Machine, [company name] remains at the forefront of innovation, constantly refining and enhancing their products to meet the evolving needs of their customers. Their unwavering commitment to excellence and customer satisfaction has solidified their position as a trusted and reliable provider of roll forming machines and equipment.In conclusion, the Step Tile Metal Steel Roof Sheet Roll Forming Machine is a game-changing technology that is transforming the way roof sheets are manufactured and installed. With its precision, efficiency, and cost-effectiveness, it has become a valuable asset for construction businesses looking to stay ahead in a competitive market. And with [company name]'s unparalleled expertise and dedication to innovation, the future of roll forming technology looks brighter than ever.

Innovative Roll Making Machine for Improved Production Efficiency

Roll making machine is an important piece of equipment in the manufacturing industry. It is used to produce various types of rolls that are essential in the production of a wide range of products, including paper, plastic, textiles, and metal sheets.One company that has been leading the way in the development and production of roll making machines is {}. With over 20 years of experience in the industry, they have become a trusted name in the market and have earned a reputation for delivering high-quality, reliable, and efficient machines.The roll making machines produced by {} are known for their advanced technology, precision engineering, and durable construction. They are designed to meet the specific needs of each customer and are customizable to ensure that they can handle a wide range of roll making applications.One of the key features of {}'s roll making machines is their versatility. They are capable of producing different types of rolls, including embossed, perforated, and laminated rolls, and can accommodate various materials, such as paper, plastic, and metal. This versatility makes them ideal for manufacturers who need a single machine to handle multiple roll making processes.Another important aspect of {}'s roll making machines is their efficiency. They are designed to optimize the production process, with features such as quick changeover capabilities, automatic tension control, and advanced monitoring systems. This ensures that the machines can produce high-quality rolls with minimal downtime, helping manufacturers to increase their productivity and reduce their operating costs.In addition to their advanced technology and efficiency, {}'s roll making machines are also known for their reliability. They are built to withstand the demands of continuous operation and are equipped with robust components and high-quality materials to ensure long-term performance and durability.Furthermore, {} offers comprehensive customer support and after-sales service for their roll making machines. Their team of experienced engineers and technicians is available to provide installation, training, maintenance, and troubleshooting services, ensuring that their customers can get the most out of their machines and minimize any potential downtime.With a commitment to continuous innovation and improvement, {} is constantly developing new technologies and refining their roll making machines to meet the evolving needs of the industry. Their dedication to excellence has earned them a loyal customer base and has positioned them as a leader in the roll making machine market.As the demand for high-quality rolls continues to grow across various industries, the roll making machines produced by {} are poised to play a crucial role in helping manufacturers meet this demand. With their advanced technology, efficiency, reliability, and comprehensive support, {}'s roll making machines are a valuable asset for any company looking to enhance their roll production capabilities.In conclusion, the roll making machines produced by {} are a testament to the company's commitment to innovation, quality, and customer satisfaction. With their advanced technology, efficiency, and reliability, these machines are a valuable asset for manufacturers in various industries and are helping to drive the production of high-quality rolls around the world.

High-Quality C Profile Roll Forming Machine for Efficient Production

C Profile Roll Forming Machine Market: OverviewThe global C Profile Roll Forming Machine market is expected to witness significant growth in the coming years, according to a new research report. The study, conducted by {company name}, indicates that the market is driven by the increasing demand for efficient and cost-effective manufacturing processes in various industries.C Profile Roll Forming Machine is a highly versatile machine used for manufacturing C-shaped metal profiles with high precision and speed. These machines are widely used in industries such as construction, automotive, and aerospace for producing metal components and profiles with various sizes and shapes.The report highlights the key factors driving the growth of the C Profile Roll Forming Machine market, including the increasing demand for lightweight and durable metal components in the automotive and aerospace industries. In addition, the growing trend of automation and digitization in manufacturing processes is expected to fuel the demand for C Profile Roll Forming Machines in the coming years.Furthermore, the research report provides an in-depth analysis of the market trends, growth drivers, challenges, and opportunities that are likely to impact the growth of the C Profile Roll Forming Machine market. The report also includes a comprehensive analysis of the competitive landscape, including the profiles of key players in the market.{Company name} is one of the leading manufacturers of C Profile Roll Forming Machines in the industry, with a strong focus on innovation and product development. The company has a wide range of C Profile Roll Forming Machines that are designed to meet the specific requirements of different industries.With a commitment to quality and customer satisfaction, {company name} has established itself as a trusted name in the C Profile Roll Forming Machine market. The company's state-of-the-art manufacturing facilities and a team of experienced engineers enable it to deliver high-quality machines that meet the highest standards of performance and reliability.{Company name}'s C Profile Roll Forming Machines are known for their superior precision, high speed, and flexibility, making them ideal for a wide range of applications. The company also offers customized solutions to meet the specific needs of its customers, ensuring that they get the best value for their investment.In addition to its strong focus on product quality, {company name} is also committed to providing excellent customer service and support. The company has a dedicated team of professionals who are available to assist customers with installation, training, and ongoing maintenance of their C Profile Roll Forming Machines.As the demand for efficient and cost-effective manufacturing processes continues to grow, {company name} is well positioned to capitalize on the opportunities in the C Profile Roll Forming Machine market. With a strong reputation for quality and reliability, the company is poised to maintain its leadership position in the industry and drive innovation in C Profile Roll Forming technology.The research report predicts that the global C Profile Roll Forming Machine market is expected to grow at a substantial rate in the coming years, driven by the increasing demand for metal components in various industries. With its focus on innovation, quality, and customer service, {company name} is well positioned to capitalize on this growth and continue to be a key player in the market.

Pros and Cons of Corrugated Metal Roofing: Cost, Installation, and Benefits

If you're considering a new roof for your home or business, you might want to take a closer look at corrugated metal roofing. This type of roofing has become increasingly popular in recent years, thanks to its many advantages over traditional roofing materials like asphalt shingles or tile. In this blog post, we'll take a closer look at corrugated metal roofing, its pros and cons, and why you should consider it for your next roofing project.What is Corrugated Metal Roofing?Corrugated metal roofing is made from sheets of galvanized steel or aluminum that have been shaped into corrugated waves or ridges. These ridges are what give the roofing its distinctive look, as well as its strength and durability. The sheets are typically installed over a layer of insulation, which helps to keep your home or business warm in the winter and cool in the summer.Pros of Corrugated Metal RoofingThere are many reasons to choose corrugated metal roofing over other types of roofing materials. Here are just a few of the pros:Durability: Corrugated metal roofing is incredibly strong and durable, which means it can withstand harsh weather conditions like heavy rain, hail, and high winds. It's also resistant to fire, rot, and pests like termites.Longevity: Because of its durability, corrugated metal roofing can last for many years with minimal maintenance. In fact, many manufacturers offer warranties of up to 50 years on their roofing products.Energy Efficiency: Corrugated metal roofing is highly reflective, which means it can help to keep your home or business cool in the summer by reflecting the sun's rays away from your roof. This, in turn, can help to lower your energy bills and reduce your carbon footprint.Low Maintenance: Unlike other types of roofing materials, corrugated metal roofing requires very little maintenance. You don't need to worry about repairing or replacing shingles like you would with an asphalt roof, and you don't need to worry about moss or algae growth like you would with a tile roof.Cons of Corrugated Metal RoofingWhile there are many advantages to corrugated metal roofing, there are also a few disadvantages to consider. Here are some of the cons:Cost: Corrugated metal roofing can be more expensive than traditional roofing materials like asphalt shingles, although the cost has come down in recent years. However, when you consider the durability and longevity of corrugated metal roofing, it can actually save you money in the long run.Sound: Some people find that corrugated metal roofing is louder than other types of roofing materials when it rains or hails. However, this can be mitigated by installing a layer of insulation between the roofing and the building.Appearance: Corrugated metal roofing has a distinctive look that may not be to everyone's taste. However, there are many different styles and colors of corrugated metal roofing available, so you're sure to find something that matches your aesthetic preferences.Why You Should Consider Corrugated Metal RoofingThere are many reasons to consider corrugated metal roofing for your home or business. Here are just a few:Durability: Corrugated metal roofing is incredibly strong and durable, which means it can withstand harsh weather conditions and last for many years with minimal maintenance.Energy Efficiency: Corrugated metal roofing is highly reflective, which can help to lower your energy bills and reduce your carbon footprint.Low Maintenance: Corrugated metal roofing requires very little maintenance compared to other types of roofing materials.Appearance: Corrugated metal roofing has a distinctive look that can add character and visual interest to your home or business.If you're considering a new roof for your home or business, be sure to explore all of your options before making a decision. Corrugated metal roofing offers many advantages over other types of roofing materials, and it just might be the perfect choice for your next roofing project.Corrugated Roofing Sheet Forming MachineTo ensure your corrugated metal roofing is made to the highest quality and specifications, it's important to work with a manufacturer who uses a high-quality corrugated roofing sheet forming machine. This machine is designed to create perfectly shaped corrugations in the metal roofing sheet, which ensures a secure fit and superior durability. At Regan Industrial, we use only the best machinery and materials to create our corrugated metal roofing products, so you can be confident that you're getting the best possible product for your home or business.

High-Quality Replacement Roof Tiles for Your Cambridge Property - PE7 Area

Title: The Ultimate Guide to Roof Tiles: Types, Installation, and MaintenanceIntroduction:When it comes to protecting our homes, a well-maintained roof is essential. The type of roof tiles we choose plays a vital role in enhancing the aesthetics, durability, and overall value of our property. In this comprehensive guide, we will delve into the world of roof tiles, covering various types, the installation process, and essential maintenance tips. Whether you are a homeowner or a roofing professional, this blog post is here to acquaint you with everything you need to know about roof tiles!Types of Roof Tiles:1. Concrete Roof Tiles: These affordable and low-maintenance tiles are known for their durability and ability to withstand harsh weather conditions. Concrete roof tiles come in a variety of colors and styles, offering flexibility in design choices.2. Clay Roof Tiles: Clay roof tiles exude elegance and sophistication, enhancing the curb appeal of any property. Made from natural clay and kiln-fired, these tiles offer superior durability while reflecting heat effectively.3. Slate Roof Tiles: Known for their distinctive appearance, slate roof tiles are strong, fire-resistant, and highly durable. With a lifespan of over a century, these tiles offer exceptional longevity. Slate tiles are available in a range of colors and can be shaped to suit different architectural styles.4. Metal Roof Tiles: With their lightweight composition, metal roof tiles are ideal for various architectural designs. They are resistant to rust, insects, and UV radiation, making them an excellent option for long-lasting roofing solutions.Installation Process:Installing roof tiles requires a systematic approach to ensure proper functionality and longevity. Here are the key steps involved in the installation process:1. Inspection: Before installing any roof tiles, a preliminary inspection is crucial to identify any underlying issues or damage that require repairs.2. Roof Surface Preparation: The roof surface must be clean, free from debris, and properly waterproofed. This step includes installing underlayment to provide additional protection against moisture and improve thermal insulation.3. Tile Layout: Based on the selected tile pattern and design, layout lines are marked to guide the installation process and ensure precision.4. Tile Installation: Each tile is installed carefully, and proper fastening techniques are used to prevent tile shifting or damage during severe weather conditions. Contractor-grade adhesives and sealants are commonly employed for added stability.5. Ridge and Hip Installation: The finishing touches of installing ridge and hip tiles contribute to the overall aesthetic appeal and improve the roof's water shedding ability.Roof Tile Maintenance Tips:Regular maintenance is crucial to prolonging the life of your roof tiles and preventing major repairs. Here are some essential maintenance tips to consider:1. Inspect: Schedule periodic inspections to identify and address any visible or potential issues promptly.2. Clean Gutters: Clearing debris from gutters and downspouts ensures proper water flow and prevents overflowing, which can lead to roof leaks and damage.3. Trim Overhanging Trees: Overhanging branches can scrape and damage roof tiles during strong winds. Regular trimming will minimize this risk.4. Moss and Algae Removal: Moss and algae can compromise roof tiles' integrity and cause discoloration. Safely remove them to maintain the aesthetics and longevity of your roof.5. Professional Maintenance: Engage professional roofing contractors for comprehensive maintenance checks, especially for intricate tasks such as tile realignment and fixing damaged or cracked tiles.Conclusion:Choosing the right roof tiles, understanding the installation process, and implementing regular maintenance practices are key to ensuring a safe, durable, and attractive roof. From concrete and clay to slate and metal, various roof tile options are available to suit different styles and budgets. Whether you reside in Cambridge or the PE7 region, be sure to consult trusted roofing professionals who offer reliable replacement roof tiles for your project. Remember, a well-maintained roof not only protects your home but also adds value and visual appeal for years to come.Keywords: roof tiles, replacement, Cambridge, PE7, installation, maintenance, concrete, clay, slate, metal

Metal Roof Panel Roll Forming Machine for Corrugated Panels: Ultimate Guide

The demand for high-quality, reliable metal roofing solutions is on the rise, and one company is stepping up to meet this demand with their state-of-the-art Corrugated Metal Roof Panel Roll Forming Machine. With a reputation for superior products and exceptional customer service, {Company Name} is proud to introduce their latest innovation to the market.The Corrugated Metal Roof Panel Roll Forming Machine is designed to produce top-notch metal roofing panels with precision and efficiency. Using advanced technology and high-quality materials, this machine is capable of creating corrugated metal panels that are not only durable and long-lasting but also aesthetically pleasing. The machine operates at high speeds, enabling {Company Name} to meet the growing demand for metal roofing products in a timely manner.One of the key features of the Corrugated Metal Roof Panel Roll Forming Machine is its versatility. It is capable of producing a wide range of panel sizes and shapes, allowing {Company Name} to cater to the diverse needs of their customers. Whether it's for residential, commercial, or industrial applications, this machine can produce customized metal roof panels to meet specific requirements.In addition to its exceptional performance, the Corrugated Metal Roof Panel Roll Forming Machine is also designed with safety and efficiency in mind. It incorporates advanced safety features to ensure the well-being of the operators, while also minimizing downtime and optimizing production output. This commitment to safety and efficiency aligns with {Company Name}'s dedication to delivering top-quality products and services.{Company Name} is a leading manufacturer in the metal roofing industry with a strong track record of delivering innovative solutions. With a focus on continuous improvement and investment in cutting-edge technologies, they have established themselves as a trusted partner for customers seeking reliable metal roofing products. The introduction of the Corrugated Metal Roof Panel Roll Forming Machine is a testament to their commitment to meeting the evolving needs of the market.As a customer-centric company, {Company Name} places great emphasis on establishing strong relationships with their clients. They understand that every project is unique and are dedicated to providing personalized solutions that exceed expectations. The Corrugated Metal Roof Panel Roll Forming Machine is a reflection of their dedication to delivering excellence and customer satisfaction.The unveiling of the Corrugated Metal Roof Panel Roll Forming Machine is a significant milestone for {Company Name} as it reinforces their position as an industry leader. This latest addition to their range of products is set to further elevate their competitiveness in the market and solidify their reputation for quality and reliability.With the demand for metal roofing solutions continuing to grow, {Company Name} is well-positioned to capitalize on this trend with their state-of-the-art Corrugated Metal Roof Panel Roll Forming Machine. This new innovation not only demonstrates their commitment to excellence but also signifies their readiness to meet the evolving needs of the market.In conclusion, the introduction of the Corrugated Metal Roof Panel Roll Forming Machine by {Company Name} represents a significant advancement in the metal roofing industry. With its cutting-edge technology, versatility, and commitment to safety and efficiency, this machine is set to redefine the standard for metal roof panel production. {Company Name} continues to be at the forefront of innovation, delivering top-quality products and services to their valued customers.

Advanced Manufacturing Equipment for Horizontal Profiled Panels

[Company Introduction]Company A is a leading manufacturer and supplier of advanced manufacturing equipment, with a focus on providing innovative solutions for the construction industry. With over 20 years of experience, the company has earned a reputation for delivering high-quality, reliable equipment to its customers. Company A is committed to continuously improving its products and services, and has a strong track record of meeting the evolving needs of the market.[News Content]Company A is proud to announce the launch of its latest innovation – the Horizontal Profiled Panel Manufacturing Equipment. This state-of-the-art machinery is set to revolutionize the production of horizontal profiled panels, offering an unmatched level of precision, efficiency, and versatility.The Horizontal Profiled Panel Manufacturing Equipment has been designed to meet the growing demand for advanced paneling solutions in the construction industry. With the ability to produce a wide range of panel profiles, including wall and roof panels, the new machinery is set to provide manufacturers with a competitive edge in the market.One of the key features of the Horizontal Profiled Panel Manufacturing Equipment is its advanced automation capabilities. The equipment is equipped with cutting-edge technology that allows for seamless operation and precise control over the manufacturing process. This not only ensures consistent quality output but also significantly reduces production times, leading to improved efficiency and cost savings for manufacturers.In addition to its automation capabilities, the Horizontal Profiled Panel Manufacturing Equipment also boasts a high degree of customization options. Manufacturers can easily adjust the settings to accommodate different panel dimensions, profiles, and material specifications, making it a versatile solution for a wide range of production requirements.Furthermore, the equipment is built with durability and reliability in mind, minimizing downtime and maintenance requirements. This will allow manufacturers to maximize their productivity and throughput, ultimately leading to increased profitability.The launch of the Horizontal Profiled Panel Manufacturing Equipment underscores Company A's commitment to innovation and customer-centric solutions. The company has leveraged its extensive industry knowledge and expertise to develop a product that not only meets but exceeds the expectations of its customers.With the introduction of the Horizontal Profiled Panel Manufacturing Equipment, Company A aims to address the evolving needs of the construction industry and provide manufacturers with a competitive advantage. By offering a cutting-edge solution that delivers superior performance and efficiency, the company is well-positioned to drive positive change within the industry.The new equipment also aligns with Company A's broader mission to deliver sustainable and environmentally-friendly solutions. By optimizing the manufacturing process and minimizing material waste, the Horizontal Profiled Panel Manufacturing Equipment contributes to a more resource-efficient and eco-friendly production approach.In conclusion, the unveiling of the Horizontal Profiled Panel Manufacturing Equipment represents a significant milestone for Company A and the construction industry as a whole. With its advanced capabilities and customer-focused design, the equipment is set to reshape the landscape of panel manufacturing, empowering manufacturers to achieve new levels of productivity and quality in their operations. Company A continues to be at the forefront of innovation, driving progress and success for its customers and the industry at large.

Rewrite: Industry News: Innovative Cut-To-Length Machine for Fabric Manufacturing

Title: Innovative Cut-To-Length Machine Revolutionizes Fabric IndustryIntroduction:In a bid to meet the growing demand for streamlined fabric production processes, XYZ Company, a pioneer in industrial machinery, has unveiled its highly efficient Cut-To-Length Machine. This groundbreaking technology promises to revolutionize the fabric industry by offering unparalleled precision and speed in cutting fabric rolls to custom lengths, all while maintaining quality and minimizing waste. With its remarkable features and state-of-the-art design, the Cut-To-Length Machine is set to become a game-changer for textile manufacturers worldwide.Paragraph 1:The innovative Cut-To-Length Machine is the result of years of research and development by XYZ Company. With a firm commitment to enhancing efficiency and reducing costs across various industries, XYZ Company has produced an advanced cutting-edge solution specifically tailored to meet the needs of fabric manufacturers. By integrating cutting-edge technology and the latest automation systems, this machine is poised to transform the fabric production landscape.Paragraph 2:The Cut-To-Length Machine boasts an impressive array of features that sets it apart from its competitors. Equipped with a high-precision optical sensor system, it ensures pinpoint accuracy in measuring and cutting fabric rolls of various sizes and materials. The machine's intuitive interface allows operators to easily input custom length requirements, after which the machine executes precise cuts. This not only minimizes production time but also significantly reduces material waste, leading to improved overall operational efficiency.Paragraph 3:One of the biggest advantages of the Cut-To-Length Machine is its ability to accommodate a wide range of fabric materials. Whether it's delicate silk, sturdy denim, or stretchable spandex, this machine can handle it all, ensuring consistent results across different materials. This versatility not only saves time but also eliminates the need for multiple manual interventions, enabling textile manufacturers to increase their output and maintain product quality.Paragraph 4:In addition to its high precision and versatility, the Cut-To-Length Machine incorporates advanced safety features, prioritizing the well-being of operators. Its automated system ensures minimal contact with sharp cutting blades, reducing the risk of accidents and injuries. Moreover, the machine's built-in error detection mechanism promptly alerts operators to any issues, preventing potential damage to the fabric or the machine itself.Paragraph 5:The introduction of the Cut-To-Length Machine is expected to have a significant impact on fabric manufacturing businesses worldwide. By optimizing production processes and reducing waste, textile manufacturers will benefit from significant cost savings and increased efficiency. With this highly advanced technology, XYZ Company aims to empower fabric manufacturers, allowing them to stay competitive in an ever-evolving market.Conclusion:The new Cut-To-Length Machine developed by XYZ Company marks a giant leap forward in the fabric industry. Its innovation and versatility promise to transform fabric production processes by improving accuracy, reducing waste, and increasing overall efficiency. As textile manufacturers across the globe adopt this groundbreaking technology, they will be able to stay ahead of the competition while meeting the increasing demands of the market. XYZ Company's commitment to revolutionizing the fabric industry with the introduction of this innovative machine reinforces their position as an industry leader in cutting-edge industrial machinery.