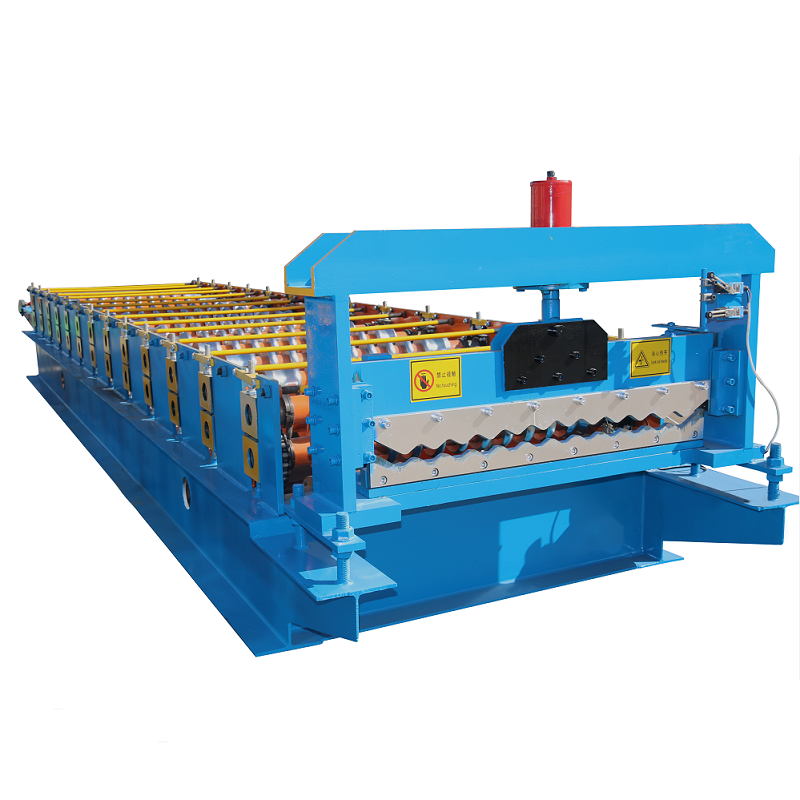

Metal steel roof sheet roll forming machine: A step tile solution

By:Admin

The Step Tile Metal Steel Roof Sheet Roll Forming Machine is designed to produce high-quality step tile metal steel roof sheets with precision and ease. With its advanced technology and automated system, this machine is capable of producing consistent and accurate roof sheets, eliminating the risk of human error and ensuring a perfect fit for every installation.

The company behind this groundbreaking technology, [company name], is a leading manufacturer of roll forming machines and equipment. With years of experience and expertise in the industry, [company name] has earned a reputation for delivering top-of-the-line products that meet the highest standards of quality and performance.

The Step Tile Metal Steel Roof Sheet Roll Forming Machine is just one of many innovative solutions offered by [company name]. Their commitment to innovation and continuous improvement has allowed them to stay ahead of the competition and provide their customers with cutting-edge technology that meets the ever-evolving needs of the construction industry.

With the rise in demand for more durable and aesthetically pleasing roofing solutions, the Step Tile Metal Steel Roof Sheet Roll Forming Machine has quickly become a popular choice among builders and contractors. Its ability to produce custom step tile designs with ease and efficiency has made it a game-changer in the roofing industry.

In addition to its high-quality output, the Step Tile Metal Steel Roof Sheet Roll Forming Machine also offers significant time and cost savings. Its efficient production process and low maintenance requirements make it a cost-effective investment for any construction business, allowing them to increase their productivity and profitability without compromising on quality.

Moreover, the machine's user-friendly interface and easy operation make it accessible to a wide range of users, from seasoned professionals to entry-level workers. This accessibility has contributed to its widespread adoption across the construction industry, as more and more businesses recognize the value of incorporating this technology into their operations.

In response to the growing demand for the Step Tile Metal Steel Roof Sheet Roll Forming Machine, [company name] has ramped up its production capacity to ensure timely delivery to its customers. Their dedicated team of engineers and technicians are committed to providing exceptional service and support, ensuring that every customer receives the assistance they need to maximize the benefits of this innovative technology.

As the construction industry continues to embrace the benefits of the Step Tile Metal Steel Roof Sheet Roll Forming Machine, [company name] remains at the forefront of innovation, constantly refining and enhancing their products to meet the evolving needs of their customers. Their unwavering commitment to excellence and customer satisfaction has solidified their position as a trusted and reliable provider of roll forming machines and equipment.

In conclusion, the Step Tile Metal Steel Roof Sheet Roll Forming Machine is a game-changing technology that is transforming the way roof sheets are manufactured and installed. With its precision, efficiency, and cost-effectiveness, it has become a valuable asset for construction businesses looking to stay ahead in a competitive market. And with [company name]'s unparalleled expertise and dedication to innovation, the future of roll forming technology looks brighter than ever.

Company News & Blog

Roll Forming Machine for Metal Roofing: Everything You Need to Know

Metal Roofing Roll Former Revolutionizes Roofing IndustryThe roofing industry is constantly evolving with new technologies and innovations, and the introduction of Metal Roofing Roll Former from [Company Name] is revolutionizing the way metal roofing is manufactured and installed.[Company Name] is a leading manufacturer of innovative roofing solutions, and their Metal Roofing Roll Former is setting new standards for efficiency, quality, and performance in the industry. This state-of-the-art machine is designed to seamlessly roll form metal roofing panels on-site, providing a faster and more cost-effective option for roofing contractors and builders.The Metal Roofing Roll Former from [Company Name] is capable of producing a wide variety of metal roofing profiles, including standing seam, corrugated, and ribbed panels. This flexibility allows builders and contractors to meet the specific needs of their projects, whether it's a residential, commercial, or industrial application.One of the most significant advantages of the Metal Roofing Roll Former is its ability to produce custom-length panels onsite, eliminating the need for pre-cutting and reducing material waste. This not only saves time and money but also allows for a more precise and accurate installation, resulting in a longer-lasting and more durable roof.In addition to its versatility and efficiency, the Metal Roofing Roll Former also delivers superior quality and performance. The machine is equipped with advanced technology and precision controls, ensuring that each panel is manufactured to the highest standards of durability, weather-resistance, and aesthetic appeal.The Metal Roofing Roll Former is also designed with user-friendly features, making it easy for operators to set up and operate the machine with minimal training. This allows roofing contractors and builders to streamline their production process and complete projects more efficiently, ultimately benefiting both their bottom line and the satisfaction of their customers.Furthermore, the Metal Roofing Roll Former is engineered for durability and reliability, backed by [Company Name]'s commitment to product performance and customer satisfaction. This ensures that the investment in this innovative machine is a long-term solution that will continue to deliver exceptional results for years to come.The introduction of the Metal Roofing Roll Former from [Company Name] is not only changing the way metal roofing is manufactured, but it is also raising the bar for the entire roofing industry. With its unmatched combination of efficiency, quality, and performance, this innovative machine is empowering roofing contractors and builders to take their projects to the next level.To learn more about the Metal Roofing Roll Former and other roofing solutions from [Company Name], visit their website or contact their team of experts to explore how their products can transform the roofing process and deliver superior results for every project.

Master the Art of Making Authentic Pasta at Home with a Manual Pasta Machine

Title: Master the Art of Homemade Pasta with a Manual Pasta Machine Introduction (approximately 100 words):Fresh, homemade pasta is a culinary delight that can be easily made in the comfort of your own kitchen. With a few simple ingredients, you can create a variety of pasta dishes that will impress your family and friends. If you're new to the world of pasta making or looking to elevate your skills, investing in a manual pasta machine can make the process much easier and enjoyable. In this blog, we will explore the benefits of using a manual pasta machine and provide an in-depth guide on how to make authentic pasta at home. Body:1. The Advantages of Using a Manual Pasta Machine (approximately 200 words):A manual pasta machine offers numerous advantages when it comes to making homemade pasta. Here are some key benefits:a) Efficiency: A manual pasta machine helps streamline the process of rolling and shaping pasta dough, saving you time and effort compared to manual techniques.b) Consistency: With a pasta machine, you can achieve consistent thickness and shape throughout your pasta, ensuring even cooking and a professional result every time.c) Versatility: Manual pasta machines often come with a variety of attachments, allowing you to create different types of pasta, including spaghetti, fettuccine, and lasagna sheets.d) Authenticity: By using a manual pasta machine, you can replicate the traditional techniques used by Italian nonnas for generations, resulting in truly authentic pasta.2. Getting Started with a Manual Pasta Machine (approximately 200 words):Before diving into the pasta-making process, it's important to familiarize yourself with your manual pasta machine. While models may vary slightly, the general steps and techniques remain the same. Follow these guidelines to get started:a) Preparation: Begin by gathering your ingredients – typically flour, eggs, and salt – and combine them to form a dough. Allow the dough to rest for 30 minutes, as this will make it easier to work with.b) Setting up the Machine: Attach the appropriate cutting attachment to the machine, depending on the type of pasta you want to make. Most manual pasta machines have adjustable thickness settings, so start with the widest setting and gradually work your way down to achieve your desired thickness.c) Rolling the Dough: Divide the dough into manageable portions and flatten each one with your hands. Feed the dough through the machine, starting at the widest setting. Fold the dough in half after each pass and repeat this process until the desired thickness is achieved.d) Shaping the Pasta: Once the pasta sheet reaches the desired thickness, switch to the cutting attachment for your chosen pasta shape. Pass the pasta sheet through the machine, and voila! You have freshly cut pasta ready for cooking.3. Cleaning and Maintenance Tips for Your Manual Pasta Machine (approximately 200 words):To ensure your manual pasta machine remains in optimal condition and longevity, it's essential to follow proper cleaning and maintenance procedures. Here are some useful tips:a) Basic Cleaning: After use, wipe away any excess flour or dough from the machine using a dry cloth or brush. Avoid using water to clean the machine, as this can cause rusting or damage.b) Thorough Cleaning: Periodically, disassemble the machine as per the manufacturer's instructions and clean each component thoroughly. Use warm, soapy water and a soft brush to remove any stubborn residue.c) Drying and Storage: After cleaning, ensure that all parts of the machine are completely dry before reassembling and storing it in a dry place. Avoid exposure to humidity or extreme temperatures, as this can affect its performance.Conclusion (approximately 100 words):Investing in a manual pasta machine can transform your pasta-making experience, allowing you to effortlessly create authentic and delicious homemade pasta. Whether you're a culinary enthusiast or a novice in the kitchen, using a manual pasta machine will streamline the process, offering you consistent results and a variety of pasta types. With the right techniques and maintenance, you'll be able to enjoy countless pasta dishes that will rival those from your favorite Italian restaurant. So, why wait? Start your pasta-making journey today and unlock a world of culinary possibilities!Keywords: manual pasta machine, homemade pasta, authentic pasta, pasta-making, Italian nonnas, manual techniques, pasta dough, cutting attachment, cleaning and maintenance, pasta types.

Understanding the Benefits of C purlins in Construction Projects

Cz Purlin, a leading manufacturer of steel construction products, has recently announced the introduction of their new range of advanced purlin systems. The company has been a pioneer in the steel construction industry for over three decades and has continually strived to innovate and improve their products to meet the evolving needs of the market.The new range of Cz Purlin products is designed to provide enhanced structural support and flexibility for a wide range of construction projects. The purlins are made from high-quality steel and are available in a variety of sizes and specifications to suit different building requirements. With their advanced design and superior strength, these purlins are set to revolutionize the way steel construction is done.The key features of the new Cz Purlin range include improved load-bearing capacity, greater resistance to corrosion, and easier installation. These features make the purlins ideal for a wide range of applications, from industrial warehouses and commercial buildings to residential construction projects. The company's commitment to quality and innovation is evident in the extensive research and development that has gone into creating these new products.In addition to the technical advancements, Cz Purlin has also focused on ensuring that their new range of products meets the highest standards of sustainability and environmental responsibility. The company has implemented eco-friendly manufacturing processes and sourced materials from sustainable suppliers, in line with their commitment to reducing their carbon footprint and promoting a greener construction industry."We are thrilled to introduce our new range of advanced purlin systems to the market," said a spokesperson for Cz Purlin. "Our team has worked tirelessly to develop these products, and we are confident that they will set a new standard for steel construction. The improved performance, durability, and sustainability of these purlins make them a game-changer for the industry."The company's dedication to providing top-quality products and excellent customer service has earned them a strong reputation in the construction industry. With their state-of-the-art manufacturing facilities and a team of experienced engineers and designers, Cz Purlin is well-equipped to meet the growing demand for high-quality steel construction products.As the construction industry continues to evolve and demand for sustainable and durable building materials grows, Cz Purlin is committed to remaining at the forefront of innovation. The company's new range of advanced purlin systems is a testament to their ongoing commitment to excellence and their ability to adapt to the changing needs of the market.With their new range of products, Cz Purlin is set to continue its legacy of providing top-quality steel construction materials that meet the highest standards of performance, sustainability, and reliability. Whether it's for large-scale industrial projects or smaller residential builds, customers can trust Cz Purlin to deliver products that are not only cutting-edge but also environmentally conscious and built to last.In conclusion, the launch of Cz Purlin's new range of advanced purlin systems represents a significant milestone for the company and the steel construction industry as a whole. With their focus on innovation, sustainability, and customer satisfaction, Cz Purlin is well-positioned to maintain its leadership in the market and continue to provide top-quality products for a wide range of construction projects.

Glazed Tile Sheet Forming And Corrugating Machine for Color Steel: Latest News

Color Steel Glazed Tile Sheet Forming And Corrugating Machine (Need Remove Brand Name) Brings Innovation to the Construction IndustryInnovation in the construction industry has always been a driving force for companies looking to stay ahead of the competition and meet the changing demands of the market. One such innovation is the Color Steel Glazed Tile Sheet Forming And Corrugating Machine, which has been making waves in the industry for its ability to produce high-quality glazed tile sheets that are both durable and aesthetically pleasing.The Color Steel Glazed Tile Sheet Forming And Corrugating Machine, which is manufactured by a leading company in the industry, represents a significant leap forward in the production of glazed tile sheets. With its advanced technology and precise engineering, this machine is capable of producing sheets with a high level of precision and uniformity, ensuring that every sheet meets the highest quality standards.The process of forming and corrugating the steel sheets is carried out with great efficiency and speed, thanks to the innovative design of the machine. This not only increases the productivity of the manufacturing process but also reduces the overall production costs, making it a cost-effective solution for companies looking to expand their production capacity.The company behind the Color Steel Glazed Tile Sheet Forming And Corrugating Machine has a long-standing reputation for delivering high-quality products and innovative solutions to the construction industry. With a strong focus on research and development, they have been able to stay at the forefront of technological advancements and continue to push the boundaries of what is possible in this field.Their commitment to quality and innovation is reflected in the design of the Color Steel Glazed Tile Sheet Forming And Corrugating Machine, which has been meticulously engineered to deliver superior performance and reliability. This dedication to excellence has earned them the trust and respect of their customers, who rely on their products to meet the demands of their projects.The Color Steel Glazed Tile Sheet Forming And Corrugating Machine is not only a testament to the company's commitment to innovation but also a reflection of their dedication to sustainability. By using advanced technology and efficient manufacturing processes, they have been able to minimize waste and reduce their environmental impact, making their products a more sustainable choice for construction projects.Furthermore, the glazed tile sheets produced by this machine are highly versatile and can be used in a wide range of applications, from residential roofing to commercial building facades. Their durability and resistance to weathering make them an ideal choice for projects in diverse environments, ensuring that they can withstand the test of time and maintain their aesthetic appeal.As the construction industry continues to evolve, the demand for high-quality and innovative materials is only expected to grow. The Color Steel Glazed Tile Sheet Forming And Corrugating Machine is well-positioned to meet this demand, offering a solution that is both technologically advanced and environmentally friendly.In conclusion, the Color Steel Glazed Tile Sheet Forming And Corrugating Machine represents a significant step forward in the production of glazed tile sheets, offering a solution that is both innovative and sustainable. With its advanced technology, precise engineering, and commitment to quality, it is poised to make a lasting impact on the construction industry and continue to be a preferred choice for companies looking to elevate their projects to the next level.

Half Omega Steel Furring Channel Roll Forming Machine for Resilient Furring Channel Keel

In the world of construction and building, innovation and new technology are constantly shaping the way we create structures. One such advancement comes in the form of the Light Steel Half Omega Steel Furring Channel Roll Former Resilient Furring Channel Keel Roll Forming Machine which is set to revolutionize the industry.This new technology has been developed by a leading company in the field of construction machinery and equipment. With a focus on innovation and efficiency, the company has been at the forefront of developing advanced solutions for the construction industry. Their latest product, the Light Steel Half Omega Steel Furring Channel Roll Former Resilient Furring Channel Keel Roll Forming Machine, is set to make a significant impact on how buildings are constructed.The Light Steel Half Omega Steel Furring Channel Roll Former Resilient Furring Channel Keel Roll Forming Machine is a state-of-the-art piece of equipment designed to streamline the process of creating steel furring channels. These channels are crucial in the construction of walls and ceilings, providing a sturdy and reliable framework for drywall and other materials. The new machine is capable of producing these furring channels with incredible precision and efficiency, saving time and resources for construction companies.One of the key features of the Light Steel Half Omega Steel Furring Channel Roll Former Resilient Furring Channel Keel Roll Forming Machine is its ability to produce furring channels with a half omega shape. This unique design increases the strength and durability of the channels, ensuring that the resulting structures will be able to withstand the test of time. Additionally, the machine is equipped with resilient furring channel keel roll forming technology, further enhancing the quality and reliability of the channels it produces.The company behind this innovative technology has a long history of providing top-of-the-line machinery and equipment to the construction industry. With a team of experienced engineers and designers, they have continuously pushed the boundaries of what is possible in the field of construction technology. The development of the Light Steel Half Omega Steel Furring Channel Roll Former Resilient Furring Channel Keel Roll Forming Machine is just the latest example of their commitment to driving the industry forward.In addition to its impressive capabilities, the new machine is also designed with ease of use in mind. The company has incorporated user-friendly features to ensure that construction workers of all skill levels can operate the machine with confidence. This focus on accessibility and user experience sets the Light Steel Half Omega Steel Furring Channel Roll Former Resilient Furring Channel Keel Roll Forming Machine apart from other similar products on the market.The introduction of this new technology is expected to have a significant impact on the construction industry. By streamlining the process of creating steel furring channels, the machine has the potential to reduce construction timelines and improve the overall quality of finished structures. This will not only benefit construction companies, but also the end users who will be able to enjoy buildings that are built to last.As the construction industry continues to evolve, innovative technologies like the Light Steel Half Omega Steel Furring Channel Roll Former Resilient Furring Channel Keel Roll Forming Machine will play a crucial role in shaping its future. With its advanced capabilities and user-friendly design, this new machine is set to make a lasting impact on how buildings are constructed. It is a testament to the company's dedication to pushing the boundaries of what is possible in construction technology, and a sign of exciting things to come in the industry.

Understanding the Significance and Benefits of C Purlins in Modern Construction

Title: Innovative C Purlins Revolutionize Construction Industry: A Game-Changing Solution by [Company Name]Introduction:[Company Name] has made a significant breakthrough in the construction industry with their revolutionary C Purlins. By combining cutting-edge technology and expertise, [Company Name] is transforming the way builders construct roofs, walls, and other infrastructure support systems. These innovative C Purlins have garnered substantial attention due to their superior strength, durability, and versatility, making them an invaluable addition to modern architectural projects. [Company Name]'s C Purlins - A Testament to Innovation: With a profound dedication to innovation, [Company Name] has engineered C Purlins that offer unmatched structural integrity while also adhering to stringent quality standards. These purlins are manufactured using high-quality galvanized steel, ensuring maximum durability and resistance against corrosion and other environmental factors.Strength and Stability:The C Purlins by [Company Name] have been optimized for strength and stability, making them ideal for modern construction practices. These purlins are designed to withstand heavy loads, making them suitable for a wide range of applications, such as industrial buildings, shopping centers, warehouses, and residential properties. Builders can trust these purlins to provide reliable structural support, ensuring long-lasting and safe infrastructure.Versatility and Flexibility:One of the distinctive features of [Company Name]'s C Purlins is their exceptional versatility and flexibility. Designed to accommodate diverse architectural requirements, these purlins can be easily customized to fit specific project needs. Whether it's adapting to unique geometries or incorporating multi-level support systems, [Company Name]'s C Purlins offer freedom of design, enabling architects and engineers to bring their visions to life.Ease of Installation:[Company Name] understands the importance of time efficiency in the construction industry. To cater to this need, they have simplified the installation process, making it easier for contractors and builders to work with their C Purlins. Their lightweight design and pre-punched holes facilitate quick and hassle-free installation, ensuring reduced labor costs and accelerated project timelines.Sustainable Solution:Recognizing the environmental impact of construction materials, [Company Name] has taken a significant step towards creating a sustainable future. Their C Purlins are made from recyclable materials, reducing the carbon footprint associated with infrastructure development. By adopting these environmentally-friendly purlins, builders can contribute to the preservation of our planet while also meeting their construction needs.Commitment to Quality:[Company Name] values impeccable quality, and this ethos is reflected in their C Purlins. The manufacturing process adheres to rigorous quality control measures, ensuring each purlin meets or exceeds industry standards. Builders and contractors can trust in the reliability, durability, and longevity of [Company Name]'s C Purlins, ensuring projects are built to last.Future Prospects:With their game-changing C Purlins, [Company Name] is set to disrupt the construction industry. As architects and engineers increasingly recognize the benefits of these purlins, the demand is expected to skyrocket. The company's relentless pursuit of innovation and commitment to customer satisfaction positions [Company Name] as a key player in the industry, driving growth and advancements in construction methodologies.Conclusion:[Company Name]'s C Purlins have taken the construction industry by storm, redefining structural support systems and setting new standards for strength, durability, and versatility. These purlins offer architects and builders a sustainable and efficient solution that meets their diverse project requirements. With their cutting-edge technology and unwavering commitment to quality, [Company Name] has firmly established itself as a leading provider of innovative construction products. The future of the construction industry has arrived with [Company Name]'s groundbreaking C Purlins.

High Precision CNC Machine for Aluminum Extrusions

The demand for precision-engineered aluminum extrusions has been on the rise in various industries such as construction, automotive, and aerospace. In response to this increasing demand, a leading manufacturing company has recently invested in state-of-the-art CNC machinery to enhance their capabilities in producing high-quality aluminum extrusions.With a legacy of over 50 years in the industry, {} has built a strong reputation for delivering innovative and customized solutions to their clients. Specializing in aluminum extrusion, the company has been at the forefront of technological advancements and has consistently invested in cutting-edge equipment to meet the evolving needs of their customers.The latest addition to their manufacturing arsenal is the advanced CNC machine specially designed for aluminum extrusions. This new equipment is equipped with high precision cutting and milling capabilities, allowing {} to achieve tight tolerances and intricate designs with utmost accuracy. The CNC machine also offers greater flexibility in producing complex shapes and profiles, enabling the company to cater to a wide range of applications across different industries.One of the key advantages of the new CNC machine is its efficiency in handling large-scale production while maintaining superior quality. This increased production capacity will enable {} to meet the growing demand for aluminum extrusions within shorter lead times, giving them a competitive edge in the market. Moreover, the CNC machine is integrated with advanced software that enables seamless programming and automation, thereby streamlining the manufacturing process and reducing the time required for setup and tool changes.In addition to enhancing their production capabilities, the investment in the CNC machine reflects {}'s commitment to upholding the highest standards of quality and precision. The company adheres to stringent quality control measures at every stage of the manufacturing process, ensuring that the aluminum extrusions meet the exact specifications and performance requirements of their customers. The new CNC machine further reinforces this commitment by enabling precise and consistent machining of extruded aluminum profiles, resulting in products that exhibit exceptional dimensional accuracy and surface finish.Furthermore, the implementation of the CNC machine underscores {}'s dedication to innovation and continuous improvement. By leveraging the latest technology, the company aims to push the boundaries of what is achievable in aluminum extrusion manufacturing. This proactive approach not only showcases their willingness to invest in the future of their business but also positions them as a reliable and forward-thinking partner for their clients.The investment in the CNC machine is also aligned with {}'s sustainability initiatives. Aluminum is widely recognized for its recyclability and environmental benefits, and {} is committed to minimizing their environmental footprint by optimizing material usage and reducing waste in their manufacturing processes. The precision and efficiency offered by the new CNC machine will contribute to the sustainable production of aluminum extrusions, further reinforcing {}'s position as an eco-conscious industry leader.In conclusion, the introduction of the CNC machine for aluminum extrusions marks a significant milestone for {}. This strategic investment not only enhances their manufacturing capabilities but also underscores their dedication to delivering top-quality, precision-engineered solutions to their clients. By embracing the latest technology and upholding their commitment to excellence, {} is poised to meet the evolving needs of the industry and continue setting new benchmarks in the field of aluminum extrusion manufacturing.

Roll Forming Machines for Metal Roof and Drywall Studs and Track

If you are involved in the construction industry, you probably know how important it is to have the right equipment to get the job done quickly and efficiently. One of the most essential pieces of equipment that you need is a metal stud making machine.There are many different types of metal stud making machines on the market, but the most popular ones are those that are designed to produce high-quality metal studs and tracks used in drywall installation and house making. These machines are known for their precision, accuracy, and speed, making them the perfect tools for any construction project.One of the best things about metal stud making machines is that they are incredibly versatile. They can be used to produce a wide range of metal studs and tracks, including those made from steel, aluminum, and other metals. This means that you can use them for a variety of different projects, from small-scale jobs like installing a new drywall partition to large commercial construction projects.Metal stud making machines come in a range of sizes and configurations to meet the needs of different construction businesses. Some machines are designed to be portable, while others are more stationary. Some machines are designed to produce only metal studs, while others can produce both studs and tracks.To ensure that you are getting the best metal stud making machine for your needs, it is important to do your research and compare different models and brands. Look for a machine that is easy to use, has a high level of automation, and can produce high-quality metal studs quickly and efficiently.One popular brand of metal stud making machines is Alibaba. Their drywall stud roll forming machine is designed to produce high-quality studs and tracks for drywall installation and house framing. This machine is easy to operate and can produce metal studs and tracks in a range of different sizes and configurations.Another popular brand of metal stud making machine is Jobsite Roll Forming Equipment. Their machines are designed to produce metal studs and tracks for a range of different applications, including both residential and commercial construction projects. These machines are known for their precision and speed, making them the perfect choice for any construction business.In conclusion, if you are in the construction industry and looking to invest in a metal stud making machine, there are plenty of options to choose from. Whether you are looking for a portable machine or a more stationary model, there is sure to be a machine that fits your needs. Just be sure to do your research and compare different brands and models to find the best machine for your construction business.

Get the Latest Updates on Trapezoid Profile Machines for Metal Roofing Sheets

Metal Roofing Sheet Trapezoid Profile Machine Revolutionizes Roofing IndustryMetal roofing has long been a popular choice for many homeowners and businesses due to its durability, longevity, and aesthetic appeal. However, the process of installing metal roofing sheets has traditionally been labor-intensive and time-consuming. That is, until the introduction of the revolutionary Metal Roofing Sheet Trapezoid Profile Machine.Developed by an industry-leading company, this state-of-the-art machine has completely transformed the roofing industry, drastically improving efficiency and reducing installation time. With its advanced technology and innovative design, the Metal Roofing Sheet Trapezoid Profile Machine has become a game-changer, offering unmatched benefits to roofing professionals and end-users alike.One of the key features of this machine is its ability to produce trapezoidal-profiled metal roofing sheets with precision and consistency. The trapezoid shape not only enhances the visual appeal of the roof but also increases its strength and resistance against various weather conditions. The machine utilizes top-quality materials, ensuring that each metal roofing sheet is of the highest standard.In addition to its cutting-edge design, the Metal Roofing Sheet Trapezoid Profile Machine boasts exceptional speed, allowing for quick and efficient installation. The machine's advanced automated system enables it to produce a large number of trapezoidal-profiled metal roofing sheets in a fraction of the time compared to traditional methods. This not only saves time but also reduces labor costs, making the machine a cost-effective solution for roofing companies.Moreover, the Metal Roofing Sheet Trapezoid Profile Machine is user-friendly and straightforward to operate. Its intuitive interface and easy-to-understand controls enable even novice users to operate the machine with ease. This eliminates the need for specialized training or extensive experience, opening up opportunities for aspiring roofing professionals to enter the industry.The durability of the metal roofing sheets produced by this machine is unmatched. Made from high-quality materials, these sheets offer exceptional resistance against corrosion, UV rays, and extreme weather conditions. Homeowners and businesses can now enjoy peace of mind, knowing that their metal roofs will not only provide aesthetic appeal but also withstand the test of time.Furthermore, the Metal Roofing Sheet Trapezoid Profile Machine promotes sustainability by offering eco-friendly roofing solutions. Metal roofing is known for its recyclability, reducing the environmental impact of waste materials. By manufacturing high-quality metal roofing sheets, this machine contributes to a greener future by encouraging the use of sustainable building materials.The company behind this groundbreaking invention has been an industry leader for several decades. With a strong commitment to innovation and customer satisfaction, they have continually revolutionized the roofing industry with their cutting-edge technology and exceptional products. Their expertise and dedication to excellence have earned them a stellar reputation among professionals and homeowners alike.In conclusion, the Metal Roofing Sheet Trapezoid Profile Machine represents a significant milestone in the roofing industry. Its advanced technology, efficiency, durability, and sustainability make it an invaluable asset for roofing professionals and consumers. As more and more individuals recognize the benefits of metal roofing, the demand for this revolutionary machine is set to soar. With its unrivaled capabilities, it has undoubtedly reshaped the way roofs are installed, ensuring a brighter and more efficient future for the roofing industry.

Top Purline Machine for Stacking CZ Profiles

In today's fast-paced world of manufacturing and construction, efficiency and precision are key factors in staying ahead of the competition. That's why the latest technology in purlin manufacturing has caught the attention of industry leaders. The Stacker for the CZ Purline Machine, developed by a leading machinery manufacturer, has revolutionized the way purlins are produced, improving both speed and accuracy in the manufacturing process.{Company} is a renowned name in the machinery manufacturing industry, known for their innovative and high-quality products. With a strong focus on research and development, the company has continuously introduced cutting-edge technology to the market, helping businesses across the globe enhance their productivity and streamline their operations.The Stacker for the CZ Purline Machine is the latest addition to {Company}'s extensive product line, and it has already made a significant impact on the industry. Purlins, which are horizontal beams that provide structural support in construction, are widely used in a variety of applications, including the framing of roofs and walls. The traditional method of purlin manufacturing involves multiple steps and manual handling, which can be time-consuming and prone to errors. However, the Stacker for the CZ Purline Machine has completely transformed this process.This innovative machine is equipped with state-of-the-art technology that allows for seamless integration with the CZ purline forming machine. It automatically collects, stacks, and packs the finished purlins, eliminating the need for manual intervention. This not only speeds up the production process but also ensures consistency in the quality of the purlins. The Stacker is designed to handle various sizes and types of purlins, making it a versatile solution for manufacturers with diverse production needs.One of the key advantages of the Stacker for the CZ Purline Machine is its user-friendly interface, which makes it easy to operate and monitor. The machine also features advanced safety mechanisms, providing a secure working environment for operators. In addition, it is built to withstand the rigors of heavy-duty industrial use, ensuring long-term reliability and minimal downtime.The impact of the Stacker for the CZ Purline Machine on manufacturing operations has been remarkable. With increased production efficiency, businesses can fulfill orders in a shorter time frame, leading to improved customer satisfaction and higher output. Moreover, the precision and consistency achieved by the machine contribute to a reduction in material waste and rework, resulting in cost savings for manufacturers.{Company}'s commitment to innovation and customer satisfaction is evident in the development of the Stacker for the CZ Purline Machine. As a company that values continuous improvement, they have also provided comprehensive training and support for their customers, ensuring that they can fully maximize the benefits of this new technology. The machine has already been adopted by leading manufacturers in the industry, earning praise for its performance and reliability.Looking ahead, {Company} is poised to further expand its reach and influence in the machinery manufacturing landscape, with a focus on developing solutions that address the evolving needs of the industry. The Stacker for the CZ Purline Machine is just one example of their dedication to driving progress and innovation in manufacturing. As the demand for efficient and high-quality production solutions continues to grow, {Company} remains at the forefront, delivering cutting-edge technology that empowers businesses to thrive in the competitive market.In conclusion, the Stacker for the CZ Purline Machine is a game-changing innovation that has set a new standard in purlin manufacturing. With its advanced technology and seamless integration capabilities, it has significantly improved the efficiency and precision of production processes for manufacturers. As a leading machinery manufacturer, {Company} has once again demonstrated their ability to deliver impactful solutions that drive progress and success in the industry. With their commitment to innovation and excellence, {Company} is set to make a lasting impact on the future of manufacturing.