New Sheet Machine Revolutionizes Profile Creation for Businesses

By:Admin

Introduction:

XYZ Manufacturing is a leading provider of innovative and high-quality profile sheet machines for the construction and manufacturing industries. With a strong focus on research and development, the company has been at the forefront of technological advancements in the field, consistently delivering cutting-edge solutions to its customers. With a commitment to excellence and customer satisfaction, XYZ Manufacturing has established itself as a trusted partner for businesses looking to enhance their production capabilities.

News Article:

XYZ Manufacturing Introduces Next-Generation Profile Sheet Machine

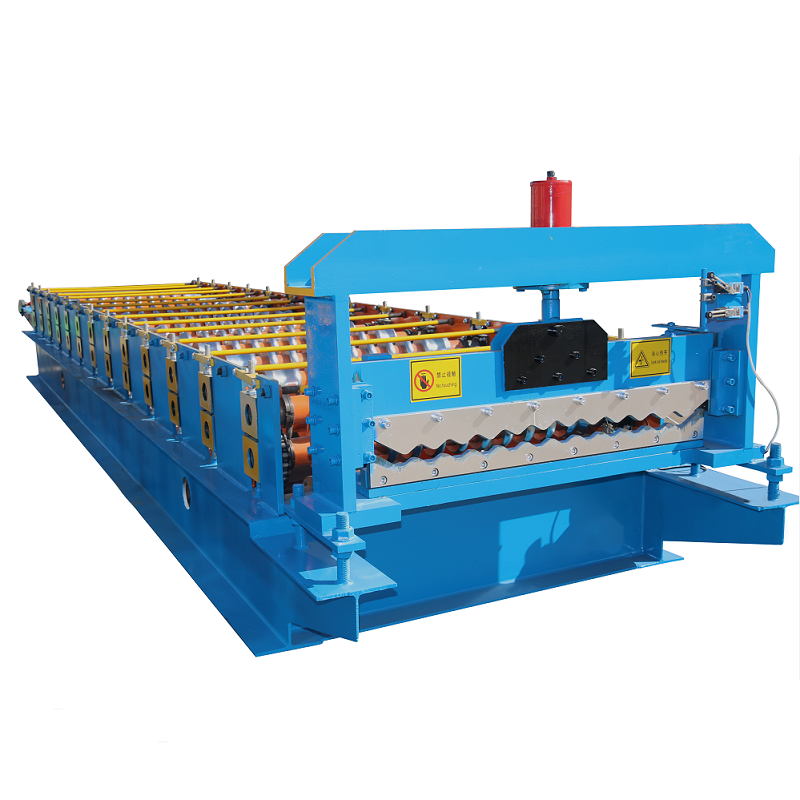

XYZ Manufacturing, a renowned leader in the manufacturing industry, has once again raised the bar with the introduction of its latest profile sheet machine. The new machine, which combines state-of-the-art technology with unparalleled performance, is set to revolutionize the way businesses approach sheet metal fabrication.

Designed to meet the evolving needs of the construction and manufacturing sectors, the new profile sheet machine boasts a range of advanced features that set it apart from the competition. With a focus on precision, efficiency, and versatility, the machine is capable of producing high-quality profile sheets with remarkable speed and accuracy.

One of the key highlights of the new machine is its advanced automation capabilities. Equipped with cutting-edge robotics and control systems, the machine can handle complex fabrication processes with minimal human intervention, significantly improving productivity and reducing operational costs for businesses. This level of automation also ensures consistent quality across all output, meeting the stringent standards of the industry.

In addition to its automation capabilities, the new profile sheet machine from XYZ Manufacturing offers a high degree of flexibility. With the ability to accommodate a wide range of materials and thicknesses, the machine is well-suited for diverse applications, making it an ideal choice for businesses with varying production requirements. This versatility enables companies to streamline their operations and adapt to changing market demands with ease.

Furthermore, the machine incorporates advanced safety features to protect operators and minimize the risk of accidents in the workplace. By prioritizing the well-being of its users, XYZ Manufacturing has demonstrated its commitment to creating a safe and conducive working environment for its customers.

The introduction of the new profile sheet machine represents a significant milestone for XYZ Manufacturing, reaffirming its position as an industry leader in providing cutting-edge solutions for sheet metal fabrication. The company's unwavering dedication to innovation and product excellence has once again set a new standard for the industry, allowing businesses to elevate their production capabilities and stay ahead of the competition.

As part of its commitment to customer satisfaction, XYZ Manufacturing provides comprehensive support and training for the new profile sheet machine, ensuring that businesses can fully leverage its capabilities and maximize their return on investment. With a global network of service centers and technical experts, the company offers timely assistance and maintenance services to keep the machines running at peak performance.

In conclusion, the launch of the new profile sheet machine by XYZ Manufacturing marks a significant advancement in the field of sheet metal fabrication. With its cutting-edge technology, unparalleled performance, and commitment to customer satisfaction, the machine is set to redefine the industry standard and empower businesses to achieve new heights of productivity and efficiency.

Company News & Blog

High-quality Cold Steel Glazed Roof Tile Making Machine Equipment for Colored Tiles

Colored Cold Steel Glazed Roof Tile Making Machine Equipment Revolutionizes Roofing IndustryIn a game-changing move for the roofing industry, an innovative company has introduced advanced technology in the form of the Colored Cold Steel Glazed Roof Tile Making Machine Equipment. This state-of-the-art equipment has the potential to transform the way roof tiles are manufactured, offering numerous benefits in terms of quality, efficiency, and sustainability.The Colored Cold Steel Glazed Roof Tile Making Machine Equipment boasts advanced features that set it apart from traditional tile-making machines. With its cutting-edge design and technology, it is capable of producing high-quality glazed roof tiles in a variety of colors and finishes. The equipment is also highly efficient, with the ability to produce a large volume of tiles in a relatively short amount of time.One of the key advantages of the Colored Cold Steel Glazed Roof Tile Making Machine Equipment is its ability to produce tiles that are not only aesthetically pleasing but also durable and long-lasting. The equipment is designed to use high-quality cold steel, which is known for its strength and resistance to corrosion. This means that the tiles produced by this equipment are capable of withstanding harsh weather conditions, making them a reliable and cost-effective roofing solution for residential and commercial buildings alike.Furthermore, the Colored Cold Steel Glazed Roof Tile Making Machine Equipment is equipped with advanced coating technology, which allows for the application of a high-quality glaze to the tiles. This not only enhances the appearance of the tiles but also provides an additional layer of protection, further increasing their durability and longevity. With a wide range of colors and finishes available, this equipment offers unparalleled flexibility in meeting the diverse aesthetic preferences of customers.In addition to its superior performance and durability, the Colored Cold Steel Glazed Roof Tile Making Machine Equipment is also designed with sustainability in mind. The equipment is engineered to minimize waste and energy consumption, making it an environmentally friendly choice for roofing tile production. By using advanced manufacturing processes and materials, the equipment helps reduce the carbon footprint associated with traditional tile-making methods.The introduction of the Colored Cold Steel Glazed Roof Tile Making Machine Equipment is a testament to the commitment of the company to innovation and excellence in the roofing industry. With years of experience and expertise in the field, the company has established itself as a leading provider of roofing solutions, known for its dedication to quality, reliability, and customer satisfaction.As a company spokesperson explains, "We are thrilled to introduce the Colored Cold Steel Glazed Roof Tile Making Machine Equipment to the market. This equipment represents a significant advancement in roofing technology, offering unmatched quality, efficiency, and sustainability. We believe that it will revolutionize the way roof tiles are manufactured, setting new standards for the industry."With its groundbreaking features and unparalleled performance, the Colored Cold Steel Glazed Roof Tile Making Machine Equipment is poised to make a lasting impact on the roofing industry. As demand for high-quality, durable, and sustainable roofing solutions continues to grow, this innovative equipment is set to play a pivotal role in meeting the needs of customers and advancing the industry as a whole.In conclusion, the introduction of the Colored Cold Steel Glazed Roof Tile Making Machine Equipment marks a major milestone in the roofing industry. With its advanced technology, superior performance, and commitment to sustainability, this equipment is set to redefine the standards for roofing tile production. As the company continues to lead the way in innovation and excellence, customers can expect to benefit from a new era of high-quality, durable, and environmentally friendly roofing solutions.

Top quality machine for light steel keel production

[Company Name] is a leading manufacturer of high-quality light steel keel machines, specializing in the design, development, and production of innovative machinery for the construction industry. With a commitment to providing cutting-edge technology and reliable solutions, [Company Name] has established a strong presence in the global market and has become a trusted partner for construction companies and contractors.Recently, [Company Name] introduced a new light steel keel machine that is set to revolutionize the way steel keels are produced and used in construction projects. This state-of-the-art machine is designed to streamline the manufacturing process, improve efficiency, and ensure consistent quality, making it an essential addition to any construction operation.The light steel keel machine offered by [Company Name] is capable of producing various types of steel keels, including C-channel, U-channel, and L-angle keels, with precision and speed. The machine's advanced technology and automated features allow for quick and easy adjustments, reducing downtime and increasing productivity. Additionally, the machine is equipped with safety measures to ensure a secure working environment for operators.One of the key advantages of the new light steel keel machine is its versatility. It can accommodate different sizes and thicknesses of steel coils, offering flexibility to meet various project requirements. The machine's ability to produce high-quality steel keels with consistent dimensions and strength is crucial for the structural integrity of buildings and other construction applications.In addition to its technical capabilities, the light steel keel machine from [Company Name] is also designed with user convenience in mind. Its intuitive controls and user-friendly interface make it easy for operators to set up and operate the machine with minimal training. This allows for smoother production processes and faster adaptation to changing project demands.[Company Name] takes pride in delivering not only top-of-the-line machinery but also comprehensive support and service to its customers. From installation and training to ongoing maintenance and technical assistance, the company's team of experts is dedicated to ensuring that clients get the most out of their investment in the light steel keel machine. This commitment to customer satisfaction has earned [Company Name] a reputation for reliability and professionalism in the construction industry.The introduction of the new light steel keel machine represents [Company Name]'s dedication to innovation and continuous improvement. By listening to the needs of construction professionals and staying at the forefront of technology, the company continues to develop solutions that facilitate the construction process and contribute to the success of its clients' projects.As the construction industry continues to evolve, the demand for efficient and high-quality machinery is on the rise. [Company Name] is well-positioned to meet this demand with its extensive experience, technical expertise, and commitment to excellence. The new light steel keel machine is a testament to the company's commitment to providing reliable solutions that meet the evolving needs of the construction industry.In conclusion, [Company Name]'s new light steel keel machine is a testament to the company's dedication to innovation, excellence, and customer satisfaction. With its advanced technology, versatility, and user-friendly design, the machine is set to make a significant impact on the construction industry. As [Company Name] continues to push the boundaries of what is possible in construction machinery, it remains a trusted partner for construction professionals seeking reliable and efficient solutions.

Top Supplier and Manufacturer of Ungrouped Forming Machines in China - Products List Page-9

Global Market Leader in Sheet Roll Forming Introduces State-Of-The-Art Ungrouped Forming Machine(Company Name - No Brand Name) is proud to announce the launch of its latest innovation - the Ungrouped Forming Machine. As a global market leader in sheet roll forming, (Company Name - No Brand Name) has built its reputation on its cutting-edge technology and high-quality products. This new machine is no exception and promises to be a game-changer in the industry.The Ungrouped Forming Machine is a versatile and efficient machine that can produce a wide range of sheet metal products. It is designed to simplify the forming process and provide precision and accuracy every time. The machine is equipped with advanced technology that ensures quick and easy setup, reducing production time and increasing efficiency."Our new Ungrouped Forming Machine is a prime example of our commitment to innovation and excellence," said the company spokesperson. "We understand the need for our clients to remain competitive in the ever-changing market, and this machine is designed to do just that. Its versatility means it can produce a variety of sheet metal products, from roofing to wall cladding, to rain gutters and downspouts. And with its advanced technology, it provides accuracy, efficiency, and reliability every time."The machine's compact design allows it to fit comfortably in any workshop space, making it an ideal choice for small to medium-sized businesses. It is also easy to operate, reducing the need for skilled labor, and its low maintenance requirements keep costs down. Plus, the machine's durability ensures a longer lifespan, providing better value for money.(Undisclosed Name) is a long-standing manufacturer of sheet metal forming equipment, mainly focusing on roof panel forming machines, wall panel forming machines, standing seam roof panel machines, gutter forming machines, and other related equipment. The company's commitment to quality has resulted in (Company Name - No Brand Name) becoming a global leader in sheet metal roll forming equipment. They have a strong reputation for designing and manufacturing high-quality equipment that is built to last. Their machines are used by clients worldwide for a variety of applications, including residential, commercial, and industrial projects.(Undisclosed Name) clients have access to a comprehensive range of services, including design and layout assistance, installation support, and an aftersales service team that provides ongoing support and training. (Company Name - No Brand Name) understands the importance of providing exceptional customer service and support, and this is reflected in its commitment to delivering high-quality equipment that meets the needs of its clients.In conclusion, the launch of the Ungrouped Forming Machine is a significant milestone for (Company Name - No Brand Name). It is the latest addition to the company's extensive range of sheet metal forming equipment, and it promises to deliver exceptional results for clients worldwide. With its advanced technology, versatility, and efficiency, the machine is set to become a game-changer in the industry. (Company Name - No Brand Name) is proud to offer this innovative machine to its clients and is committed to providing exceptional customer service and support.

High-quality and efficient slitting line for metal processing

CR Slitting Line enhances productivity and efficiency for Company XCompany X is proud to announce the acquisition of a state-of-the-art CR Slitting Line, marking a significant milestone in its commitment to continuously improving its manufacturing capabilities. This latest addition to the company's machinery lineup is set to revolutionize its production processes, leading to increased productivity and enhanced operational efficiency.The CR Slitting Line is a versatile and high-performance machine that is designed to accurately cut and slit various types of metal coils with precision. With its advanced technology and automated features, this equipment allows for the quick and efficient processing of metal materials, resulting in high-quality finished products. This will enable Company X to meet the growing demands of its customers while maintaining the highest standards of product excellence.One of the key features of the CR Slitting Line is its ability to handle a wide range of materials, including stainless steel, aluminum, and other non-ferrous metals. This flexibility will enable Company X to expand its product offerings and cater to a diverse set of customer requirements. Additionally, the machine's high-speed capabilities and precision cutting mechanisms will significantly reduce production lead times, allowing the company to fulfill orders in a more timely manner.The implementation of the CR Slitting Line is also expected to streamline the company's manufacturing processes, thereby optimizing its operational efficiency. By automating the slitting and cutting operations, the machine will minimize the need for manual intervention, reducing the risk of errors and ensuring consistent, high-quality output. This will ultimately translate into cost savings and improved resource utilization for Company X.Furthermore, the CR Slitting Line is equipped with advanced monitoring and control systems, allowing for real-time tracking of production metrics and quality parameters. This will enable the company to continuously monitor and manage its manufacturing processes, ensuring that the highest standards of quality and precision are maintained throughout the production cycle. As a result, Company X can uphold its reputation for delivering superior products to its customers, thereby further solidifying its position as a leading supplier in the metal fabrication industry.The investment in the CR Slitting Line underscores Company X's unwavering commitment to innovation and continuous improvement. By embracing cutting-edge technology and machinery, the company is reinforcing its ability to stay ahead of the competition and adapt to evolving market demands. This strategic move will not only enhance its capabilities but also position Company X as a preferred partner for businesses seeking reliable and high-quality metal products.In addition to its technological prowess, Company X also prides itself on a strong commitment to sustainability and environmental responsibility. The implementation of the CR Slitting Line is expected to have a positive impact on the company's environmental footprint, as the machine's advanced efficiency features will lead to reduced energy consumption and waste generation. This aligns with Company X's broader sustainability goals and its dedication to conducting business in an environmentally conscious manner.Overall, the introduction of the CR Slitting Line represents a significant leap forward for Company X, empowering the company to elevate its manufacturing capabilities, enhance its product offerings, and deliver greater value to its customers. With this new addition, Company X is well-positioned to embark on a new era of growth and success, further solidifying its leadership in the metal fabrication industry.

How a Roofing Roll Former Can Benefit Your Next Project

Roofing Roll Former, a leading manufacturer in the roofing industry, has announced the launch of its newest product, the TRF-550 Roll Former. This state-of-the-art machine is designed to meet the increasing demand for high-quality roofing materials in the construction industry.With over 20 years of experience in the field, Roofing Roll Former has established itself as a trusted name in the industry. The company is known for its commitment to innovation, quality, and customer satisfaction. By continually investing in research and development, Roofing Roll Former has consistently delivered cutting-edge solutions to meet the evolving needs of the market.The TRF-550 Roll Former is the latest addition to the company's extensive product line. This machine is capable of producing a wide range of roofing materials, including standing seam panels, corrugated panels, and other custom profiles. Its high precision and efficiency make it an ideal choice for both small-scale and large-scale roofing projects.One of the key features of the TRF-550 Roll Former is its versatility. It is designed to accommodate various materials, including steel, aluminum, and copper, making it suitable for a diverse range of roofing applications. Additionally, the machine is equipped with advanced controls that allow for easy customization of panel profiles, ensuring that customers can achieve their desired aesthetic and functional requirements.The TRF-550 Roll Former is also designed with the operator in mind. Its user-friendly interface and automated processes streamline production, reducing the need for manual intervention and minimizing the risk of errors. This not only enhances productivity but also ensures consistent quality in every finished product.Furthermore, Roofing Roll Former's commitment to customer support sets it apart in the industry. The company provides comprehensive training and technical assistance to ensure that customers can maximize the potential of their investment in the TRF-550 Roll Former. This includes on-site support, remote troubleshooting, and access to a dedicated team of experts who are readily available to address any queries or concerns.In addition to its focus on innovation and customer support, Roofing Roll Former remains dedicated to sustainability and environmental responsibility. The TRF-550 Roll Former is designed to minimize material wastage and energy consumption, aligning with the company's commitment to promoting eco-friendly practices within the industry.As the construction industry continues to evolve, Roofing Roll Former stands at the forefront of innovation, delivering solutions that meet the demands of modern roofing projects. The introduction of the TRF-550 Roll Former further solidifies the company's position as a trusted partner for contractors, architects, and builders seeking reliable and efficient roofing solutions.With its proven track record of excellence, Roofing Roll Former is poised to make a significant impact with the launch of the TRF-550 Roll Former. The company's unwavering dedication to quality, innovation, and customer satisfaction ensures that it will continue to be a leading force in the roofing industry for years to come.

Glazed Tile Roll Forming Machine - Industrial Steel Rolling Machines for Metal Roofing Sheet Production

Title: ZhongTuoCN Revolutionizes Roofing Industry with Advanced Glazed Tile Roll Forming MachineIntroduction:ZhongTuoCN, a renowned leader in the steel rolling machine industry, has unveiled its latest product, the Color Steel Glazed Roof Tile Roll Forming Machine. This advanced machinery has revolutionized the roofing industry by enabling the efficient production of high-quality metal glazed tiles. With its cutting-edge technology and precision engineering, ZhongTuoCN is empowering manufacturers to meet growing demands for durable and aesthetically pleasing roofing solutions.1. Meeting the Rising Demand for Glazed Roofing Tiles:The demand for glazed roofing tiles has been steadily increasing due to their exceptional durability, weather resistance, and stunning visual appeal. Recognizing this trend, ZhongTuoCN's engineers have developed a state-of-the-art roll forming machine specifically designed to cater to this niche segment. Manufacturers can now produce glazed tiles efficiently, ensuring timely delivery and meeting customer expectations.2. Cutting-Edge Technology Enhances Efficiency:The Color Steel Glazed Roof Tile Roll Forming Machine stands out for its advanced features, guaranteeing optimal efficiency. Equipped with state-of-the-art automation technology, this innovative machine minimizes human intervention, reducing labor costs and increasing productivity. With high-speed forming capabilities, it guarantees a smooth and streamlined production process, allowing manufacturers to meet large-scale orders efficiently.3. Unparalleled Precision and Durability:ZhongTuoCN's Glazed Tile Roll Forming Machine is meticulously engineered to deliver unmatched precision and durability. Its robust frame, constructed from high-quality steel, ensures long-term stability and reliability. The rollers are made from top-grade materials, facilitating seamless tile formation without any deformities. This ensures that every finished tile exhibits consistent dimensions and exceptional surface quality.4. Flexibility in Tile Design and Customization:In addition to its standard features, the Color Steel Glazed Roof Tile Roll Forming Machine provides manufacturers with unparalleled flexibility in tile design and customization. By incorporating adjustable features in the machine, manufacturers can easily tailor the dimensions, profile, and curvature of the glazed tiles to meet various customer requirements. This adaptability sets ZhongTuoCN's machinery apart from its competitors and allows clients to offer unique and personalized roofing solutions.5. Strict Quality Control and After-Sales Support:ZhongTuoCN prioritizes quality control throughout the manufacturing process. Each component of the Glazed Tile Roll Forming Machine undergoes stringent testing to ensure optimal performance and durability. Additionally, ZhongTuoCN provides comprehensive after-sales support, including installation guidance, training programs, and 24/7 technical assistance. This commitment to customer satisfaction has earned the company an excellent reputation in the industry.Conclusion:With the introduction of the Color Steel Glazed Roof Tile Roll Forming Machine, ZhongTuoCN has reaffirmed its position as a pioneer in the steel rolling machine industry. This cutting-edge technology guarantees exceptional efficiency, precision, and customization options for manufacturers in the roofing sector. By empowering clients to meet the rising demand for glazed tiles, ZhongTuoCN is revolutionizing the roofing industry and offering an unparalleled solution for businesses worldwide.

Single Layer Color Steel Roll Forming Machine: All You Need to Know

Introducing a Revolutionary Single Layer Color Steel Roll Forming MachineThe [Company Name] is proud to announce the launch of their latest innovation in the field of metal forming equipment - the Single Layer Color Steel Roll Forming Machine. This state-of-the-art machine promises to revolutionize the process of creating color steel roofing and wall panels, offering unmatched precision, efficiency, and reliability.With a strong focus on research and development, [Company Name] has been at the forefront of metal forming technology for over a decade. The company's team of engineers and designers have worked tirelessly to create a machine that addresses the most common challenges faced by manufacturers in the industry. The result is a cutting-edge roll forming machine that sets new standards for quality and performance.One of the key features of the Single Layer Color Steel Roll Forming Machine is its advanced design, which allows for the rapid and precise shaping of color steel sheets. This is achieved through a combination of high-quality materials, innovative engineering, and precision manufacturing techniques. The machine is also equipped with a range of advanced control systems, enabling operators to fine-tune the production process and produce panels of the highest quality with minimal waste.In addition to its superior performance, the Single Layer Color Steel Roll Forming Machine also offers unparalleled flexibility. It is capable of producing a wide variety of panel designs, allowing manufacturers to meet the diverse needs of their customers. Whether it's a simple corrugated panel or a complex architectural profile, this machine can handle it with ease. This level of versatility is a game-changer for manufacturers, enabling them to take on a wider range of projects and expand their capabilities.Furthermore, the machine is designed with ease of use in mind. Its intuitive interface and user-friendly controls make it simple for operators to set up and operate the machine, reducing the need for extensive training and minimizing the risk of errors. This not only saves time and money but also ensures consistent quality in every panel produced.The launch of the Single Layer Color Steel Roll Forming Machine represents a major milestone for [Company Name]. It reflects the company's commitment to innovation and its dedication to providing the industry with the most advanced and reliable equipment available. With this new machine, [Company Name] is poised to set new benchmarks for quality, efficiency, and customer satisfaction in the metal forming industry.In order to ensure that customers can make the most of this groundbreaking technology, [Company Name] is offering comprehensive support and after-sales service. This includes installation assistance, training programs, and ongoing maintenance and technical support. This further underscores the company's commitment to customer success and satisfaction.As the global demand for high-quality color steel panels continues to grow, the launch of the Single Layer Color Steel Roll Forming Machine couldn't have come at a better time. Manufacturers in various industries, from construction to automotive, are now able to access a solution that will enable them to stay ahead of the competition and meet the evolving needs of their clients.In conclusion, the Single Layer Color Steel Roll Forming Machine from [Company Name] is a game-changing innovation that is set to redefine the way color steel panels are manufactured. With its cutting-edge technology, unmatched versatility, and user-friendly design, this machine is poised to become an indispensable asset for manufacturers around the world. For those looking to take their metal forming capabilities to the next level, the Single Layer Color Steel Roll Forming Machine is the ultimate solution.

Z Purlin Roll Forming Machine: A Comprehensive Guide to Roll Forming Z Purlins for Structural Support

NEW PURLIN ROLL FORMING MACHINE PROMISES EFFICIENCY AND PRECISION[City], [Date] - The development of technology has revolutionized various industries, and the manufacturing sector is no exception. One of the latest innovations in the field of manufacturing machinery is the new Z Purlin Roll Forming Machine, designed to provide enhanced efficiency, accuracy, and reliability in the production of Z-shaped purlins. This advanced machine is set to transform the purlin manufacturing industry, meeting the increasing demand for high-quality construction materials.A leader in manufacturing equipment, [Company Name] has introduced its latest addition to the industry - the Z Purlin Roll Forming Machine. With its state-of-the-art features and cutting-edge technology, this machine promises to streamline the process of creating Z-shaped purlins, reducing manual labor and increasing productivity.The Z Purlin Roll Forming Machine is designed to withstand heavy-duty industrial usage, ensuring durability and longevity. It boasts an ergonomic design that allows for easy operation, making it accessible even to less experienced operators. Equipped with a user-friendly interface, the machine offers a seamless experience, and its automated functions contribute to the overall efficiency of production.Precision and accuracy are crucial in the manufacturing of Z-shaped purlins, and this is where the Z Purlin Roll Forming Machine truly excels. With its advanced roll-forming technology, it enables the production of perfectly shaped purlins with consistent dimensions. The machine optimizes material usage, minimizing waste and reducing costs for manufacturers. Additionally, its high-speed production capabilities enable rapid turnaround times, meeting the time-sensitive demands of the construction industry.Incorporating safety features is of paramount importance in any industrial machinery, and the Z Purlin Roll Forming Machine lives up to this expectation. Enhanced safety measures have been integrated into its design, safeguarding operators and preventing potential accidents. The machine complies with international safety regulations, ensuring a secure environment for workers.While the Z Purlin Roll Forming Machine offers numerous benefits for manufacturers, it also delivers advantages to the end-users. By utilizing this advanced technology, construction companies can obtain consistently high-quality Z-shaped purlins for their projects. The superior strength and structural integrity of these purlins enhance the overall stability and durability of buildings, guaranteeing a longer lifespan.Moreover, the versatility of the Z Purlin Roll Forming Machine allows for the production of purlins of various sizes and shapes. This flexibility caters to the diverse requirements of different construction projects, providing a custom solution to architects, engineers, and contractors alike.The implementation of this cutting-edge technology by the manufacturing industry marks a significant step towards improvement and progress. By investing in modern machinery such as the Z Purlin Roll Forming Machine, manufacturers can stay competitive in the market and meet the rising demands of customers.As [Company Name] continues to redefine manufacturing equipment, its commitment to innovation and customer satisfaction remains unwavering. With the introduction of the Z Purlin Roll Forming Machine, the company aims to revolutionize the manufacturing process and set new industry standards.In conclusion, the new Z Purlin Roll Forming Machine brings efficiency, precision, and reliability to the purlin manufacturing industry. This advanced machinery promises to streamline production, improve product quality, and cater to the diverse needs of different construction projects. As technology continues to evolve, manufacturers can rely on [Company Name] to deliver cutting-edge solutions that optimize their operations and drive industry growth.

Discover High-Quality Standing Seam Metal Roof Suppliers for Resilient, Weather-Tight, and Fire-Resistant Home Roofs

When it comes to roofing options for your home, there are a lot of choices out there. However, few can match the durability and versatility of standing seam metal roofs. That's why many homeowners are turning to standing seam metal roof suppliers (without brand names) to get the best products for their homes.One of the key benefits of a standing seam metal roof is its weather resistance. Whether you're dealing with heavy rain, high winds, or snow and ice storms, a standing seam metal roof can stand up to the elements. Unlike other roofing materials, such as asphalt shingle or wood shake roofs, standing seam metal roofs are designed to shed water quickly and resist damage from wind, hail, and other types of weather-related events.Another major advantage of standing seam metal roofs is their fire resistance. Unlike other roofing materials that can catch fire easily, such as wood shingles or asphalt shingles, metal roofs are much more fire-resistant. This is because metal is an inherently non-flammable material, which means that a standing seam metal roof can help protect your home in case of a fire.But perhaps one of the most appealing aspects of a standing seam metal roof is its aesthetic appeal. With its clean, modern lines and sleek design, a standing seam metal roof can be a striking addition to any home. And because standing seam metal roofs come in a variety of colors and finishes, you can easily customize your roof to match your home's style and color scheme.So where can you find the best standing seam metal roof suppliers (without brand names) for your home? Look for companies that specialize in manufacturing high-quality metal roofing products, such as standing seam roll formers. These machines are designed to create high-quality metal roofing panels that are perfect for standing seam roofs, ensuring that your roof is weather-tight, durable, and attractive for years to come.In conclusion, if you're looking for an affordable, durable, and attractive roofing option for your home, consider a standing seam metal roof. And be sure to work with reputable standing seam metal roof suppliers (without brand names) to get the best products and service for your needs. By choosing the right roofing materials and working with the right professionals, you can enjoy a beautiful, long-lasting roof for your home.

Discover the Latest Innovation in Glazed Steel Roofing Tile Roll Former!

Glazed Steel Roofing Tile Roll Former Takes the Market with Impressive FeaturesThe roofing industry is always in need of new technologies to improve the performance and longevity of roofing materials. The glazed steel roofing tile roll former machine seems to be the answer to this demand. The equipment has impressed many clients with its features and the quality of the final roofing tiles it produces.The machine is designed to roll-form steel or aluminum coils into glazed roofing tiles of various colors and profiles. It uses a patented technology for crafting the tiles, which involves a series of steps such as steel decoiling, feeding, molding, pressing, cutting, and shearing. The result is perfectly shaped roofing tiles, ready for installation on site.One of the advantages of the glazed steel roofing tile roll former is its speed. The equipment can produce up to 20 meters of roofing tiles per minute, which means the production line can output over 1,000 square meters of roofing tiles per hour. This speed is a significant improvement over traditional roofing tile production methods, which rely on manual labor.Another feature that differentiates this machine from other roll-formers is its precision. The glazed steel roofing tile roll former uses advanced servo systems and automatic controls to ensure the accuracy and consistency of the roofing tiles. The machine is also equipped with a touch screen interface that allows operators to monitor the production process and make adjustments as needed.The glazed steel roofing tile roll former is also versatile. It can produce an array of roofing tile profiles that cater to different architectural styles and preferences. The machine can manufacture tiles that replicate the look of natural materials such as slate, tile, or wood without compromising their durability and resistance to weathering.Moreover, this equipment is easy to operate and maintain. The machine has a quick-change system that enables operators to switch between different tile profiles and colors easily. It also has a self-lubrication system that reduces the need for manual lubrication. Additionally, the machine's structure is made of high-quality materials that ensure its longevity and durability.The success story of the glazed steel roofing tile roll former would not be complete without mentioning the company behind it. The manufacturer, a Chinese enterprise with over a decade of experience in the production of roll-forming equipment, has invested in research and development to create innovative solutions for the roofing industry.The company, which stands out for its commitment to quality and customer service, has a team of experts that oversees the entire production process and ensures the final product meets the required standards. It also provides after-sales service to its clients to ensure their satisfaction and the optimal performance of the machine.In conclusion, the glazed steel roofing tile roll former is a modern and efficient solution for the roofing industry's needs. Its features, such as speed, precision, versatility, ease of use, and durability, make it a valuable investment for anyone in the business of producing roofing tiles. Combined with the manufacturer's expertise and commitment to quality, this machine's success in the market is not by chance.