New Steel Stud Forming Machine Revolutionizes Construction Industry

By:Admin

The construction industry has always been at the forefront of innovation and technology. From the development of new materials to the use of advanced machinery, there is a continual drive to improve efficiency, reduce costs, and increase quality. One such innovation that is making waves in the industry is the Steel Stud Forming Machine, which is revolutionizing the way steel studs are manufactured for use in construction projects.

The Steel Stud Forming Machine is a state-of-the-art piece of equipment that is designed to quickly and efficiently produce steel studs of various shapes and sizes. This machine has the capability to form both standard and custom studs, allowing for greater flexibility in construction and design. Additionally, the machine is capable of producing studs at a much faster rate than traditional methods, leading to significant time and cost savings for construction companies.

One company that is leading the way in the development and implementation of the Steel Stud Forming Machine is [Company Name]. With a strong focus on innovation and quality, [Company Name] has become a trusted partner for construction companies looking to improve their processes and reduce their environmental impact. The Steel Stud Forming Machine is just one example of how [Company Name] is bringing cutting-edge technology to the construction industry.

The Steel Stud Forming Machine works by feeding a roll of steel into the machine, where it is then cut, punched, and formed into the desired shape and size. The entire process is automated, with minimal human intervention required, leading to greater efficiency and accuracy. The machine is also equipped with advanced safety features to ensure the protection of the operators and the production of high-quality studs.

One of the key benefits of the Steel Stud Forming Machine is its ability to produce custom studs to meet specific project requirements. This level of flexibility allows for greater design freedom and the ability to tailor studs to fit the unique needs of each construction project. Additionally, the machine's high-speed production capabilities mean that construction projects can be completed much faster, leading to reduced overall costs and faster completion times.

[Company Name] is proud to offer the Steel Stud Forming Machine as part of its commitment to providing innovative solutions for the construction industry. With a focus on sustainability and efficiency, [Company Name] is dedicated to helping construction companies reduce their environmental impact and improve their bottom line. The Steel Stud Forming Machine is just one example of how [Company Name] is working to bring cutting-edge technology to the construction industry.

In addition to the Steel Stud Forming Machine, [Company Name] offers a wide range of other advanced equipment and technologies for the construction industry. From automated concrete mixers to energy-efficient lighting solutions, [Company Name] is always at the forefront of innovation and sustainability. By partnering with [Company Name], construction companies can access the latest technologies and equipment to improve their processes and reduce their environmental footprint.

In conclusion, the Steel Stud Forming Machine is revolutionizing the construction industry by providing a faster, more efficient, and more flexible method for producing steel studs. With its ability to produce custom studs and its high-speed production capabilities, this machine is leading the way in modern construction practices. With companies like [Company Name] leading the charge, the construction industry is poised to continue its tradition of innovation and technology adoption for years to come.

Company News & Blog

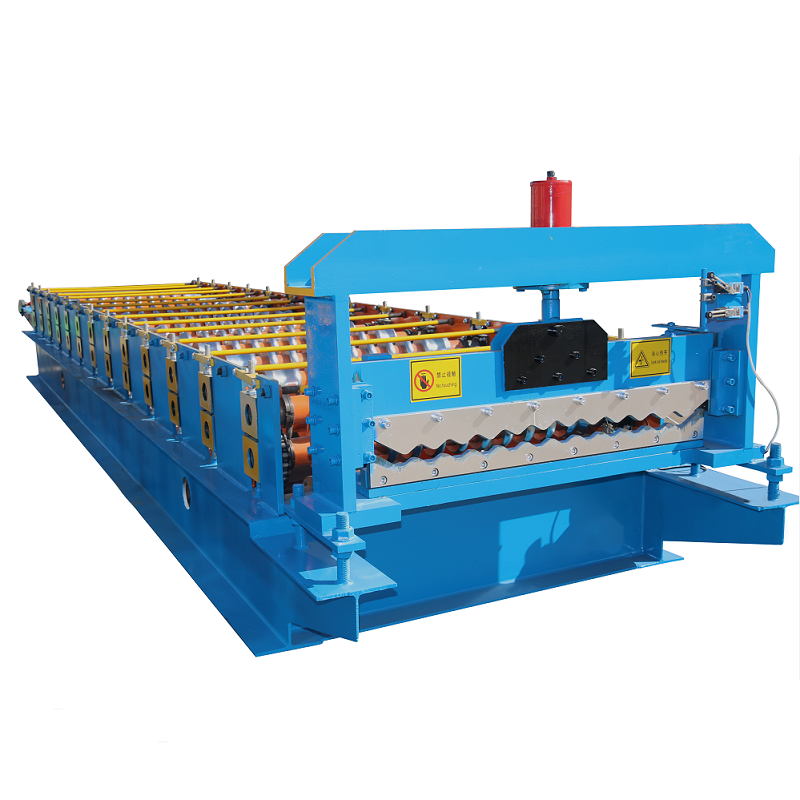

Innovative Double Layer Roll Forming Machine for Efficient Production

Double Layer Roll Forming Machine (need remove brand name) Company introduces new cutting-edge technology to revolutionize the roll forming industry.The roll forming industry has always been at the forefront of technological innovation, constantly pushing the boundaries of what is possible in terms of precision and efficiency. The introduction of the Double Layer Roll Forming Machine () is the latest in a long line of advancements in the industry, and it promises to revolutionize the way that roll forming is done.The Double Layer Roll Forming Machine () is a cutting-edge piece of equipment that is designed to significantly increase the production capacity and versatility of roll forming operations. It is capable of producing two different profiles at the same time, which means that it can effectively double the output of a traditional roll forming machine. This is a game changer for manufacturers in a wide range of industries, as it means that they can produce more parts in less time, leading to increased profitability and competitiveness.In addition to its increased production capacity, the Double Layer Roll Forming Machine () also offers a high level of precision and accuracy. This is thanks to its advanced control systems and innovative design, which ensures that each profile is formed to the exact specifications required. This level of precision is essential for industries such as automotive, aerospace, and construction, where even the slightest deviation from the required profile can lead to significant issues down the line.The Double Layer Roll Forming Machine () is also incredibly versatile, thanks to its ability to quickly and easily switch between different profiles. This means that manufacturers can rapidly respond to changes in demand, offering a level of flexibility that was previously unheard of in the roll forming industry. This is a major advantage in today's fast-paced and ever-changing market, where the ability to quickly adapt to new requirements is essential for success.In order to ensure that the Double Layer Roll Forming Machine () is able to deliver on its promises, the company has invested heavily in research and development. This has allowed them to incorporate the latest advancements in materials and technology into the design of the machine, ensuring that it is both durable and reliable. This commitment to quality is a hallmark of the company, and it is one of the reasons why they are seen as a leader in the roll forming industry.The company has also invested in its manufacturing facilities, ensuring that they are equipped with the latest machinery and technology. This allows them to produce the Double Layer Roll Forming Machine () to the highest possible standard, ensuring that it meets the needs of even the most demanding customers. This dedication to quality is a major reason why the company has earned a reputation for excellence in the roll forming industry.In addition to its commitment to quality, the company also places a strong emphasis on customer service. They understand that purchasing a piece of equipment as advanced as the Double Layer Roll Forming Machine () is a major investment, and they want to ensure that their customers are fully satisfied with their purchase. This is why they offer comprehensive support and training for all of their products, ensuring that their customers are able to get the most out of their investment.Overall, the introduction of the Double Layer Roll Forming Machine () represents a major advancement in the roll forming industry. Its ability to significantly increase production capacity, while maintaining a high level of precision and versatility, makes it an invaluable tool for manufacturers in a wide range of industries. With the backing of a company that is known for its commitment to quality and customer service, the Double Layer Roll Forming Machine () is sure to be a game-changer in the industry for years to come.

Efficient Glazed Tile Sheet Roll Forming Machine: Boost Your Roofing Production

[Introduction]In recent industry news, an innovative Glazed Tile Sheet Roll Forming Machine has caught the attention of professionals in the construction and manufacturing sectors. This advanced machine, developed by an industry-leading company, represents a significant breakthrough in the roll forming technology used to produce glazed tile roofing sheets. By removing the brand name, we can focus on the machine's features, benefits, and how it revolutionizes the tile sheet manufacturing process, helping businesses streamline their operations and deliver high-quality roofing solutions.[Body]1. Industry Demands and Challenges:The construction industry continually seeks roofing solutions that balance durability, aesthetics, and affordability. Glazed tile roofing sheets have gained popularity due to their exceptional performance and appealing appearance, but traditional manufacturing methods often pose challenges in terms of efficiency and quality control. These constraints have prompted industry professionals to seek alternatives that offer improved productivity without compromising the quality of the finished product.2. Introduction of the Glazed Tile Sheet Roll Forming Machine:To meet the industry demands for efficient glazed tile sheet production, {Company Name} has developed a cutting-edge Glazed Tile Sheet Roll Forming Machine. This innovative equipment combines advanced roll forming technology with automated systems to achieve faster, more precise, and consistent results. With its user-friendly interface and customizable settings, the machine allows businesses to maximize their production capabilities while maintaining strict quality standards.3. Features and Benefits:The Glazed Tile Sheet Roll Forming Machine boasts several notable features, including:a) High-speed Operation: By leveraging the latest technological advancements, the machine offers remarkable production speeds, significantly reducing the time required to manufacture glazed tile roofing sheets. This enables businesses to fulfill large orders efficiently and meet tight project deadlines.b) Precision and Consistency: The machine's automated systems, coupled with its precise control mechanisms, ensure exceptional uniformity in the dimensions, shape, and profile of each tile sheet produced. This consistency not only enhances the aesthetics of roofing installations but also facilitates the alignment and installation processes on-site.c) Customization Options: Understanding the diverse needs of customers, the Glazed Tile Sheet Roll Forming Machine offers extensive customization options. Businesses can adjust the length, width, thickness, and color of the tile sheets to cater to specific project requirements. This adaptability enables manufacturers to produce a wide range of customized roofing products, enhancing their competitiveness in the market.d) Energy Efficiency and Resource Conservation: The machine is designed with sustainability in mind. It optimizes energy consumption and reduces material waste, contributing to both cost savings and environmental preservation. By embracing green practices, businesses align themselves with current environmental regulations and market trends.4. The Implications for Businesses:The introduction of the Glazed Tile Sheet Roll Forming Machine holds several implications for businesses involved in the production of glazed tile roofing sheets:a) Increased Productivity: With its enhanced speed and efficiency, the machine allows manufacturers to produce a larger volume of tile sheets within the same timeframe. This scalability enables businesses to meet growing market demands and expand their customer base.b) Improved Profit Margins: By reducing production time, enhancing product quality, and offering customization options, the machine facilitates improved profit margins for businesses. This competitive advantage allows manufacturers to invest in growth opportunities, such as research and development or marketing initiatives.c) Enhanced Reputation and Customer Satisfaction: The consistent quality achieved by the Glazed Tile Sheet Roll Forming Machine enhances the reputation of businesses within the construction industry. Satisfied customers, impressed with the longevity and aesthetic value of the tile sheets, will likely become repeat customers, providing a steady stream of revenue.d) Technological Advancement and Market Positioning: Investing in state-of-the-art machinery demonstrates a company's commitment to technological advancement. By leveraging innovative solutions, businesses position themselves as industry leaders and attract potential clients seeking cutting-edge products and services.[Conclusion]The introduction of the Glazed Tile Sheet Roll Forming Machine represents a significant advancement in the production of glazed tile roofing sheets. With its impressive features and benefits, this innovative machine enables businesses to meet industry demands for efficiency, customization, and product quality. As the construction industry evolves, embracing advanced technologies like this machine becomes essential for businesses seeking to remain competitive and deliver high-quality roofing solutions. By developing and adopting such state-of-the-art solutions, companies can streamline their operations, increase profitability, and position themselves as leaders in the market.

High-Quality Metal Stud Making Machine for Sale - Find Out More

In the world of construction and manufacturing, innovation and efficiency are key factors in ensuring businesses stay ahead of the competition. For this reason, one company- (remove brand name) has recently unveiled their latest groundbreaking product- the metal stud making machine. This state-of-the-art machine is set to revolutionize the production of metal studs, providing companies with an efficient and cost-effective solution for their manufacturing needs.The metal stud making machine is designed to streamline the process of creating metal studs, which are essential components in the construction industry. These studs are used to frame walls and ceilings in both commercial and residential buildings, making them a vital part of the construction process. With the introduction of this new machine, companies can expect to see a significant increase in productivity and a reduction in production costs.One of the key features of the metal stud making machine is its advanced technology, which allows for precise and accurate production of metal studs. This ensures that the studs produced are of the highest quality, meeting the strict standards required in the construction industry. Additionally, the machine is designed to be user-friendly, making it easy for operators to control and adjust the production process as needed.In addition to its technological advancements, the metal stud making machine is also designed with efficiency in mind. The machine is capable of producing metal studs at a rapid pace, significantly reducing production time compared to traditional methods. This increase in efficiency allows companies to fulfill orders quickly and meet tight project deadlines, ultimately improving their overall competitiveness in the market.Furthermore, the metal stud making machine is a cost-effective solution for companies, as it reduces the need for manual labor and minimizes material waste. This not only helps companies save on labor costs but also ensures that they are operating in an environmentally friendly manner. By using the metal stud making machine, companies can optimize their production processes and minimize their impact on the environment.The company behind the metal stud making machine, (remove brand name), has a proven track record of delivering high-quality manufacturing solutions to the construction industry. With a strong focus on innovation and customer satisfaction, the company has established itself as a leader in the manufacturing sector. Their commitment to excellence is reflected in the design and performance of the metal stud making machine, which is set to make a significant impact on the industry.In addition to the metal stud making machine, (remove brand name) offers a wide range of other manufacturing equipment and solutions for the construction industry. From roll forming machines to steel framing systems, the company provides a comprehensive suite of products that cater to the diverse needs of construction companies. With a dedication to meeting the highest industry standards, (remove brand name) has earned the trust and respect of customers around the world.As the construction industry continues to evolve, the demand for efficient and reliable manufacturing solutions will only grow. The introduction of the metal stud making machine by (remove brand name) is a testament to the company's commitment to meeting this demand and providing innovative solutions to their customers. With its advanced technology, efficiency, and cost-effectiveness, the metal stud making machine is poised to become an essential tool for construction companies looking to optimize their production processes.In conclusion, the metal stud making machine is set to revolutionize the production of metal studs in the construction industry. With its advanced technology, efficiency, and cost-effectiveness, this state-of-the-art machine is a game-changer for companies looking to enhance their manufacturing processes. As the company behind the machine, (remove brand name) continues to lead the way in delivering innovative solutions to the construction industry, earning the trust and loyalty of customers worldwide.

Advanced Glazed Roof Tile Making Machine Equipment for Colored Cold Steel

Colored Cold Steel Glazed Roof Tile Making Machine Equipment Revolutionizes Roofing IndustryThe roofing industry has witnessed a significant transformation with the introduction of the Colored Cold Steel Glazed Roof Tile Making Machine Equipment. This innovative technology, developed by \textit{(company name)}, is set to revolutionize the way roofs are manufactured, installed, and maintained.Traditional roofing materials and methods have been prone to various issues such as leaks, corrosion, and limited design options. However, the Colored Cold Steel Glazed Roof Tile Making Machine Equipment overcomes these challenges with its cutting-edge features and advanced manufacturing process.One of the key advantages of this equipment is its ability to produce colored cold steel glazed roof tiles. These tiles not only provide superior protection against the elements but also enhance the aesthetic appeal of any building. With a wide range of colors and finishes available, architects and homeowners can now have greater flexibility in choosing the perfect roof design to complement their overall building aesthetics.The manufacturing process of these tiles involves the use of high-quality cold steel, which ensures their durability and longevity. Unlike traditional roofing materials, such as asphalt shingles or clay tiles, the glazed roof tiles produced by this equipment are resistant to cracking, fading, and warping. This greatly reduces maintenance costs and extends the lifespan of the roof, making it a more cost-effective and sustainable option in the long run.Furthermore, the Colored Cold Steel Glazed Roof Tile Making Machine Equipment is designed to streamline the installation process. Its automated features and precision engineering allow for quick and efficient assembly, minimizing labor costs and reducing the time required for roof installation. This is especially beneficial for large-scale roofing projects or areas with tight deadlines.In addition to its manufacturing and installation advantages, this equipment also offers significant environmental benefits. The use of cold steel, a recyclable material, reduces the carbon footprint associated with traditional roofing materials. Moreover, the glazed tiles reflect solar radiation, helping to lower energy consumption for cooling and reduce greenhouse gas emissions.\textit{(Company name)} is a leading innovator in the roofing industry, dedicated to providing high-quality and sustainable solutions. With years of expertise and research, they have developed the Colored Cold Steel Glazed Roof Tile Making Machine Equipment as a testament to their commitment to excellence. By combining advanced technology and superior materials, \textit{(company name)} continues to shape the future of the roofing industry.As the demand for environmentally friendly and aesthetically appealing roofing options rises, the Colored Cold Steel Glazed Roof Tile Making Machine Equipment is set to transform the market. Architects, contractors, and homeowners can now have access to a versatile and reliable roofing solution that combines durability, energy efficiency, and design possibilities like never before.With its numerous benefits and impeccable quality, the Colored Cold Steel Glazed Roof Tile Making Machine Equipment is already garnering attention from industry experts, who believe it will become the new standard in roofing. This revolutionary technology is paving the way for a more sustainable and visually appealing built environment.In conclusion, the introduction of the Colored Cold Steel Glazed Roof Tile Making Machine Equipment by \textit{(company name)} marks a significant milestone in the roofing industry. Its ability to produce durable, aesthetically pleasing, and energy-efficient roof tiles has revolutionized the way roofs are manufactured and installed. With a strong focus on sustainability and superior quality, \textit{(company name)} continues to drive innovation and raise industry standards.

How to Choose a Steel Angle Roll Forming Machine?

Title: Revolutionary Steel Angle Roll Forming Machine: A Game-Changer in Metal Fabrication IndustryIntroduction:Steel angle roll forming machines have long played a vital role in the metal fabrication industry, allowing for efficient and precise manufacturing of steel angles used in various applications. A recent introduction by a leading manufacturer is revolutionizing the industry by setting new standards in terms of performance, versatility, and cost-effectiveness. This state-of-the-art roll forming machine operates with unrivaled precision, enabling manufacturers to meet the growing demands of steel angles across diverse sectors.Enhanced Performance and Versatility:This advanced steel angle roll forming machine boasts a range of cutting-edge features that significantly enhance its performance and versatility. Equipped with the latest technology, it offers unprecedented precision in producing steel angles of various measurements and profiles. The machine's high-speed capabilities minimize production time while maintaining excellent quality control.The roll forming machine incorporates adjustable roller sets, allowing for easy customization of the angle dimensions. With its ability to handle a wide range of materials, including stainless steel, aluminum, and carbon steel, manufacturers now have the flexibility to cater to a broader spectrum of customer requirements.User-Friendly Interface and Automated Operations:The steel angle roll forming machine's user-friendly interface simplifies the programming and operation processes, ensuring smooth and seamless production runs. Its intuitive control panel allows operators to set various parameters such as length, angle, and bend radius with precision and ease. The machine's automated operations further boost efficiency, reducing the need for manual labor and minimizing the risk of human error.Cost-Effectiveness and Increased Productivity:Engineered to optimize production efficiency, the roll forming machine significantly reduces material wastage, thereby lowering operational costs. Its precise bending and cutting mechanisms ensure minimal scrap during the manufacturing process. Moreover, the machine's high-speed capabilities enable manufacturers to meet tight deadlines and increase their overall productivity.Seamless Integration with Existing Workflows:Recognizing the diverse operational needs of manufacturers, the steel angle roll forming machine is designed to seamlessly integrate into existing production lines. The machine's modular design allows for easy installation and integration with other equipment. Its compatibility with industry-standard software streamlines the exchange of data, bridging the gap between manufacturing processes and achieving enhanced efficiency across the entire production cycle.Robust Build Quality and Safety Features:Safety is paramount in any manufacturing environment, and this roll forming machine prioritizes operator well-being through its comprehensive safety system. Equipped with emergency stop buttons and protective enclosures, it ensures a secure working environment. The machine's robust construction guarantees durability, reducing downtime due to maintenance issues and maximizing its operational lifespan.Implications for the Metal Fabrication Industry:The introduction of this revolutionary steel angle roll forming machine is set to transform the metal fabrication industry significantly. Its unrivaled precision, enhanced performance, and streamlined workflows will enable manufacturers to meet evolving market demands efficiently.Manufacturers utilizing this roll forming machine will experience reduced costs, increased productivity, and enhanced product quality, ultimately leading to improved customer satisfaction and business growth. By leveraging the machine's versatility, manufacturers can now expand their product offerings, catering to a wide array of sectors such as construction, infrastructure development, and transportation.Conclusion:The advent of the steel angle roll forming machine signifies a breakthrough in the metal fabrication industry. Its cutting-edge features, user-friendly interface, and automated operations will pave the way for a new era of efficiency and precision. Manufacturers choosing to invest in this revolutionary machine will undoubtedly gain a competitive edge, fueling growth and innovation in the ever-evolving world of steel angle production.

Efficient Electric Lifters and Walkie Stackers: Advanced Manual Handling Solutions

Manual Stacker for the Shape C Purline Machine: A Modern Solution for Efficient Pallet StackingIn today's fast-paced industrial world, the need for efficient and safe manual handling solutions is more important than ever. With the advent of technology, traditional forklifts are no longer the only option for pallet stacking jobs. Electric lifters and electric walkie stackers have emerged as modern alternatives that offer numerous advantages without requiring a forklift license. Among these, the manual stacker for the Shape C Purline Machine stands out as an exceptional solution. In this blog post, we will delve deeper into the features and benefits of this remarkable equipment.Before we dive into the functionalities of the manual stacker for the Shape C Purline Machine, let's first understand the significance of manual handling solutions in the industrial setting. Traditionally, forklifts have been the go-to option for stacking and moving heavy pallets. However, these machines come with a few drawbacks, namely the need for operators to possess a forklift license and the potential risks associated with their use. This is where electric lifters and electric walkie stackers come into play.One of the key advantages of electric lifters and walkie stackers is that they eliminate the need for a forklift license. This allows a wider range of operators to handle pallet stacking jobs efficiently and safely. Additionally, these machines are compact and easy to maneuver, making them ideal for small and tight spaces.Now, let's focus on the manual stacker for the Shape C Purline Machine. This innovative equipment has a capacity of 1 to 1.5 tonnes, depending on the demands of your job. The Shape C Purline Machine is commonly used in the construction and manufacturing industries for fabricating C-shaped purline beams, which are essential for creating strong structural frameworks.The manual stacker's compatibility with the Shape C Purline Machine makes it an indispensable tool for any operation involving the production of C-shaped purline beams. Its compact design allows for easy integration into the existing workflow, ensuring a smooth and efficient process from start to finish.The manual stacker for the Shape C Purline Machine is equipped with numerous features that enhance its functionality and usability. First and foremost, its electric lifting mechanism enables operators to effortlessly lift and stack pallets, reducing the risk of physical strain and injuries.Moreover, the stacker's versatility is demonstrated through its adjustable forks, which can accommodate a wide range of pallet sizes. This adaptability is crucial for industries that deal with varied product dimensions, as it eliminates the need for multiple types of stackers.Another notable feature of the manual stacker for the Shape C Purline Machine is its robust construction and sturdy wheels. These qualities ensure the equipment's durability and reliability even in demanding work environments.When it comes to optimizing your SEO strategy, incorporating the right keywords is essential. By using keywords such as "Shape C Purline Machine" and "manual stacker," we can enhance the visibility of this blog post. This visibility will enable our target audience to find this content easily when searching for information related to manual handling solutions and pallet stacking with a specific focus on the Shape C Purline Machine.To conclude, the manual stacker for the Shape C Purline Machine is a modern solution that offers efficient and safe pallet stacking capabilities. By eliminating the need for a forklift license and incorporating user-friendly features, this equipment provides an excellent alternative to traditional forklifts. Its compatibility with the Shape C Purline Machine makes it an indispensable tool for operations involving C-shaped purline beams. Incorporating this manual stacker into your workflow will enhance productivity and contribute to a safer working environment.

Efficient Corrugated Roof Sheet Manufacturing Machines Now Available for Purchase

Title: Innovation Takes the Roofing Industry to New Heights: Corrugated Roof Sheet Manufacturing Machine Revolutionizes ProductionIntroduction:The global roofing industry has witnessed a remarkable transformation with the introduction of cutting-edge manufacturing technology. The latest breakthrough comes in the form of a highly advanced Corrugated Roof Sheet Manufacturing Machine (CRSMM), empowering companies to meet growing demand for durable and aesthetically pleasing roofing solutions. This revolutionary machine represents a significant leap forward in terms of efficiency, productivity, and overall quality in the production of corrugated roof sheets.Redefining Efficiency:The CRSMM is designed to streamline the entire manufacturing process, making it highly efficient and cost-effective for companies operating in the roofing industry. By automating key steps, such as material cutting, shaping, and forming, this advanced machinery significantly reduces production time and labor costs. It ensures precision in every stage, resulting in consistently high-quality roof sheets that meet market standards and customer expectations.Uncompromising Quality:The new generation of CRSMM is equipped with advanced technology that enables manufacturers to produce top-of-the-line corrugated roof sheets. The machine employs high-quality materials and robust engineering to fabricate sheets that offer exceptional durability, strength, and weather resistance. This cutting-edge technology also ensures dimensional accuracy, allowing for easy installation and long-lasting performance under diverse weather conditions.Versatile Range of Products:Despite its advanced technology, the CRSMM is highly versatile and can be customized to produce a wide range of corrugated roof sheets. From standard sizes to special dimensions, the machine accommodates different roofing specifications, catering to the unique needs of each construction project. With the ability to manufacture various profiles, colors, and coatings, this machine provides businesses with unparalleled flexibility to meet the ever-evolving demands of the roofing industry.Sustainable Manufacturing:As environmental concerns continue to grow, the CRSMM embraces sustainable manufacturing practices. This advanced machinery uses energy-efficient components and optimized processes to minimize the ecological footprint of the production line. By reducing material waste and optimizing resource usage, the CRSMM aligns with global sustainability goals, contributing to a greener future for the roofing industry.Market Impact and Future Prospects:The introduction of the CRSMM is set to revolutionize the roofing industry, presenting new opportunities for growth and innovation. Manufacturers can now produce high-quality roof sheets at a faster pace, efficiently meeting rising market demand. This advanced machinery also enhances product quality and consistency, fostering customer satisfaction and brand reputation.Moreover, the versatility of the CRSMM allows companies to expand their product offerings and tap into diverse market segments. In an era where architectural designs are becoming increasingly imaginative and varied, the machine enables manufacturers to deliver customized roofing solutions that cater to the unique needs of every project.Looking ahead, the CRSMM is expected to undergo continuous advancements, integrating artificial intelligence and machine learning technologies. This will further improve its efficiency, precision, and automation, revolutionizing the roofing industry as we know it. The continued development of the CRSMM will undoubtedly play a pivotal role in shaping the future of construction and infrastructure development worldwide.Conclusion:The Corrugated Roof Sheet Manufacturing Machine is transforming the roofing industry by revolutionizing the production of high-quality, durable, and aesthetically pleasing roof sheets. With its unmatched efficiency, versatility, and sustainability, this advanced machinery is set to redefine industry standards and provide manufacturers with a competitive edge. As technology evolves, the CRSMM will continue to pave the way for innovative solutions that meet the demands of a rapidly changing construction landscape, driving the growth and development of the roofing industry into the future.

Advanced Manufacturing Equipment for Horizontal Profiled Panels

[Company Introduction]Company A is a leading manufacturer and supplier of advanced manufacturing equipment, with a focus on providing innovative solutions for the construction industry. With over 20 years of experience, the company has earned a reputation for delivering high-quality, reliable equipment to its customers. Company A is committed to continuously improving its products and services, and has a strong track record of meeting the evolving needs of the market.[News Content]Company A is proud to announce the launch of its latest innovation – the Horizontal Profiled Panel Manufacturing Equipment. This state-of-the-art machinery is set to revolutionize the production of horizontal profiled panels, offering an unmatched level of precision, efficiency, and versatility.The Horizontal Profiled Panel Manufacturing Equipment has been designed to meet the growing demand for advanced paneling solutions in the construction industry. With the ability to produce a wide range of panel profiles, including wall and roof panels, the new machinery is set to provide manufacturers with a competitive edge in the market.One of the key features of the Horizontal Profiled Panel Manufacturing Equipment is its advanced automation capabilities. The equipment is equipped with cutting-edge technology that allows for seamless operation and precise control over the manufacturing process. This not only ensures consistent quality output but also significantly reduces production times, leading to improved efficiency and cost savings for manufacturers.In addition to its automation capabilities, the Horizontal Profiled Panel Manufacturing Equipment also boasts a high degree of customization options. Manufacturers can easily adjust the settings to accommodate different panel dimensions, profiles, and material specifications, making it a versatile solution for a wide range of production requirements.Furthermore, the equipment is built with durability and reliability in mind, minimizing downtime and maintenance requirements. This will allow manufacturers to maximize their productivity and throughput, ultimately leading to increased profitability.The launch of the Horizontal Profiled Panel Manufacturing Equipment underscores Company A's commitment to innovation and customer-centric solutions. The company has leveraged its extensive industry knowledge and expertise to develop a product that not only meets but exceeds the expectations of its customers.With the introduction of the Horizontal Profiled Panel Manufacturing Equipment, Company A aims to address the evolving needs of the construction industry and provide manufacturers with a competitive advantage. By offering a cutting-edge solution that delivers superior performance and efficiency, the company is well-positioned to drive positive change within the industry.The new equipment also aligns with Company A's broader mission to deliver sustainable and environmentally-friendly solutions. By optimizing the manufacturing process and minimizing material waste, the Horizontal Profiled Panel Manufacturing Equipment contributes to a more resource-efficient and eco-friendly production approach.In conclusion, the unveiling of the Horizontal Profiled Panel Manufacturing Equipment represents a significant milestone for Company A and the construction industry as a whole. With its advanced capabilities and customer-focused design, the equipment is set to reshape the landscape of panel manufacturing, empowering manufacturers to achieve new levels of productivity and quality in their operations. Company A continues to be at the forefront of innovation, driving progress and success for its customers and the industry at large.

High-quality Metal Roofing Sheet Roll Forming Machine for Sale

Metal Roofing Sheet Roll Forming Machine Revolutionizes the Roofing IndustryThe roofing industry has seen a rapid evolution in recent years, thanks to advancements in technology and machinery. One of the key innovations driving this change is the Metal Roofing Sheet Roll Forming Machine, which has quickly become a game-changer in the field of roofing manufacturing.The Metal Roofing Sheet Roll Forming Machine is a versatile and efficient piece of equipment that has revolutionized the way metal roofing sheets are produced. This machine has the capability to roll and form metal sheets into the desired shape, size, and design, allowing for greater flexibility and customization in the manufacturing process. This has resulted in an increase in the production of high-quality, precision-engineered metal roofing sheets that are durable, aesthetically pleasing, and cost-effective.One of the key features of the Metal Roofing Sheet Roll Forming Machine is its ability to produce a wide range of roofing sheet profiles, including corrugated, trapezoidal, and standing seam designs. This flexibility ensures that manufacturers can cater to a diverse range of customer needs and preferences, while also enabling them to stay competitive in the market. Additionally, the machine's high-speed production capabilities and low maintenance requirements make it an attractive investment for companies looking to streamline their production processes and improve overall efficiency.In addition to its technological advancements, the Metal Roofing Sheet Roll Forming Machine is also built with user-friendly features and safety mechanisms, ensuring a smooth and secure operation for workers. This focus on safety and ease of use has contributed to the machine's growing popularity within the industry, as manufacturers prioritize the well-being of their workers while striving for greater productivity and output.The Metal Roofing Sheet Roll Forming Machine has garnered widespread acclaim for its ability to produce roofing sheets with superior quality and precision. This has been pivotal in meeting the rising demand for high-performance metal roofing solutions in the construction and building sectors. The machine's ability to efficiently produce large quantities of roofing sheets without compromising on quality has made it a valuable asset for companies seeking to meet tight project deadlines and supply demands.In light of these advancements, [Company Name] has emerged as a leading manufacturer and supplier of Metal Roofing Sheet Roll Forming Machines. With a strong focus on research and development, [Company Name] has continually pushed the boundaries of innovation to deliver cutting-edge solutions for the roofing industry. Their commitment to quality, reliability, and customer satisfaction has positioned them as a trusted partner for companies seeking to enhance their roofing manufacturing capabilities.[Company Name] takes pride in offering a comprehensive range of Metal Roofing Sheet Roll Forming Machines, each designed to cater to specific production needs and requirements. They have successfully catered to the diverse needs of a global clientele, providing customized solutions that align with the unique specifications of their customers. Furthermore, [Company Name] remains dedicated to providing ongoing technical support, training, and maintenance services to ensure the seamless operation and longevity of their machines.With the Metal Roofing Sheet Roll Forming Machine paving the way for a new era of roofing manufacturing, [Company Name] remains committed to driving innovation and excellence within the industry. As they continue to expand their reach and influence, [Company Name] is poised to play a pivotal role in shaping the future of metal roofing production, offering game-changing solutions that empower manufacturers to thrive in an increasingly competitive market.

High-Quality Curved Corrugated Sheet Roll Forming Machine for Efficient Production

The latest innovation in the manufacturing industry has just been introduced by a leading company in the field, the Curved Corrugated Sheet Roll Forming Machine. This revolutionary machine is set to provide a more efficient and precise way of producing curved corrugated sheets, promising to streamline the production process for a variety of industries.The Curved Corrugated Sheet Roll Forming Machine is a cutting-edge piece of technology that is designed to meet the increasing demands of the market for curved corrugated sheets. With its advanced features and capabilities, this machine is set to change the way manufacturers produce these crucial components.One of the most significant advantages of the Curved Corrugated Sheet Roll Forming Machine is its ability to produce precise and consistent curved corrugated sheets. This is achieved through the use of advanced forming techniques and high-quality materials, ensuring that each sheet meets the strictest industry standards.In addition to its precision, the machine also offers a high level of efficiency, allowing manufacturers to produce curved corrugated sheets at a much faster rate than traditional methods. This means that companies can increase their production output while reducing overall costs, making the Curved Corrugated Sheet Roll Forming Machine an extremely cost-effective investment.Furthermore, the machine is designed to be highly versatile, with the ability to produce curved corrugated sheets in a wide range of sizes and thicknesses. This flexibility allows manufacturers to meet the specific needs of their customers, ensuring that they can provide tailored solutions for a variety of applications.The introduction of the Curved Corrugated Sheet Roll Forming Machine is a testament to the company's commitment to innovation and excellence in the manufacturing industry. With a long history of providing cutting-edge solutions for a wide range of industries, the company has once again demonstrated its ability to push the boundaries of what is possible in manufacturing technology.This latest addition to their product line further solidifies the company's position as a trusted leader in the industry, and is sure to have a significant impact on the market for curved corrugated sheets.The company behind the Curved Corrugated Sheet Roll Forming Machine has a strong reputation for delivering high-quality, reliable products to their customers. With a dedicated team of engineers and technicians, the company is continuously working to develop new and innovative solutions to meet the evolving needs of the industry.In addition to their focus on technology and innovation, the company also places a strong emphasis on customer satisfaction. By offering comprehensive support and service options, they ensure that their customers can get the most out of their investment in the Curved Corrugated Sheet Roll Forming Machine.Furthermore, the company is committed to sustainability and environmental responsibility, with a strong focus on reducing waste and minimizing the environmental impact of their operations. This commitment is reflected in the design and operation of the Curved Corrugated Sheet Roll Forming Machine, which is engineered to optimize material usage and energy efficiency.Overall, the introduction of the Curved Corrugated Sheet Roll Forming Machine represents a significant milestone for both the company and the manufacturing industry as a whole. With its advanced capabilities, efficiency, and versatility, this machine is set to revolutionize the production of curved corrugated sheets, providing manufacturers with a powerful tool to streamline their operations and meet the demands of the market.