6 Tips for Choosing the Right Sheet Metal Form Roller for Your Project

By:Admin

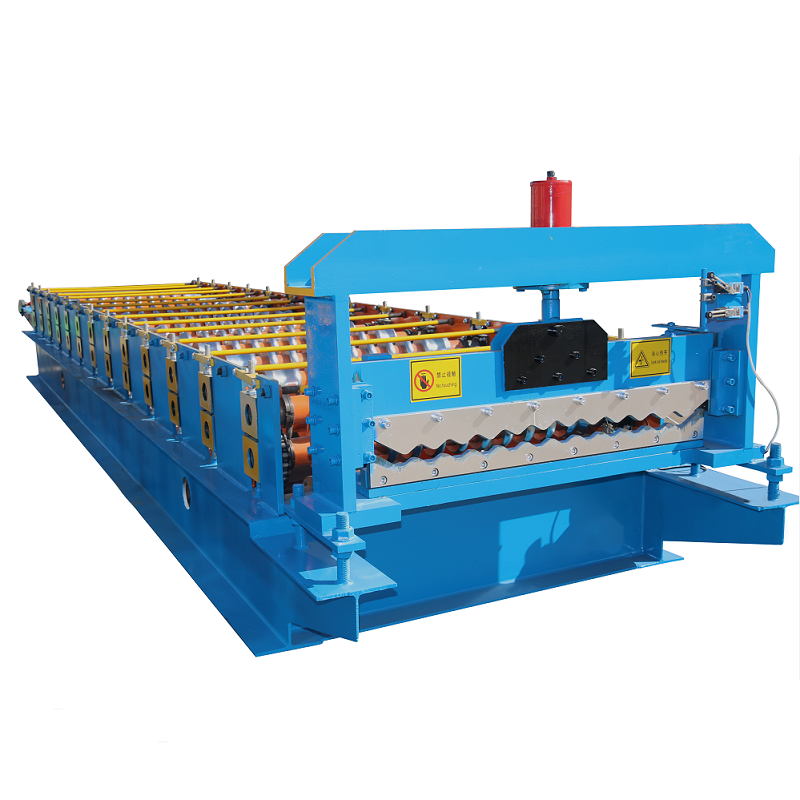

In this regard, {Company Name} is a leading manufacturer of form rollers, and their latest innovation in this field is set to revolutionize the sheet metal forming industry. With a strong reputation for high-quality products and cutting-edge technology, {Company Name} has been at the forefront of the industry for over a decade.

The newest form roller from {Company Name} is designed to offer increased precision, efficiency, and versatility in sheet metal forming processes. Utilizing advanced materials and innovative engineering, this form roller is capable of delivering superior performance and durability, making it an indispensable tool for manufacturers in a wide range of industries.

One of the key features of this new form roller is its enhanced precision. With state-of-the-art technology and a meticulous attention to detail in the manufacturing process, {Company Name} has ensured that this form roller can achieve the most intricate and exacting specifications. This level of precision is crucial in sheet metal forming, where even the smallest deviation can result in a defective final product.

Moreover, the new form roller is also designed to be highly efficient. By reducing the time and energy required for sheet metal forming, manufacturers can improve their overall productivity and reduce production costs. This is particularly important in today's competitive market, where efficiency and cost-effectiveness are key factors in maintaining a competitive edge.

Another standout feature of the new form roller is its versatility. It is capable of handling a wide variety of materials, including steel, aluminum, and other metals commonly used in the manufacturing industry. This versatility makes the form roller from {Company Name} a valuable investment for manufacturers dealing with diverse materials and production requirements.

In addition to its impressive technical specifications, the new form roller from {Company Name} also boasts a user-friendly design. With intuitive controls and a focus on safety, this form roller is easy to operate and maintain, allowing manufacturers to streamline their production processes without compromising on worker safety or well-being.

The release of this innovative form roller underscores {Company Name}'s commitment to driving advancements in the sheet metal forming industry. By continually pushing the boundaries of what is possible in this field, {Company Name} has solidified its reputation as a trusted and forward-thinking partner for manufacturers around the world.

In conclusion, the new form roller from {Company Name} represents a significant leap forward in the sheet metal forming industry. With its emphasis on precision, efficiency, versatility, and user-friendliness, this form roller is poised to set new standards for quality and performance in sheet metal forming processes. As manufacturers continue to seek ways to improve their production capabilities, {Company Name} remains a steadfast ally, providing them with the tools they need to thrive in a constantly evolving industry.

Company News & Blog

Steel Angle Roll Forming Machine: Key Features and Applications

Steel Angle Roll Forming Machine brings new prospects for efficient and quality steel forming processesSteel fabrication and construction industries have always been in need of efficient and reliable machines for various processes, especially in the forming of steel angles. With technological advancements, the introduction of Steel Angle Roll Forming Machine, developed by the renowned {Company Name}, has brought new prospects for efficient and quality steel forming processes.{Company Name} is a leading manufacturer of roll forming machines with a strong reputation for providing high-quality and innovative solutions to the steel fabrication industry. The company has a rich history of delivering cutting-edge technology and meeting the diverse needs of its clients.The Steel Angle Roll Forming Machine has been developed keeping in mind the specific demands of the steel fabrication industry. The machine is designed to streamline the process of forming steel angles with precision and efficiency. It is equipped with advanced features and controls that ensure high productivity and consistent quality of the formed steel angles.One of the key features of the Steel Angle Roll Forming Machine is its versatility. The machine is capable of forming steel angles of various sizes and thicknesses, making it suitable for a wide range of applications. This flexibility allows steel fabrication companies to meet the diverse requirements of their projects without the need for multiple machines.Furthermore, the Steel Angle Roll Forming Machine is built for durability and reliability. It is constructed using high-quality materials and components, ensuring long-term performance and low maintenance requirements. This reliability is crucial for steel fabrication companies, as it minimizes downtime and maximizes productivity.The machine also boasts a user-friendly interface, making it easy to operate and maintain. This is essential for ensuring that operators can quickly adapt to the machine and optimize its performance for different forming requirements.In addition to the technical capabilities of the Steel Angle Roll Forming Machine, {Company Name} also provides comprehensive support and services to its clients. The company offers on-site installation and training, as well as ongoing maintenance and technical assistance, ensuring that clients can maximize the benefits of the machine throughout its lifecycle.The introduction of the Steel Angle Roll Forming Machine has garnered significant attention in the steel fabrication and construction industries. The machine has been praised for its ability to enhance the efficiency and quality of steel forming processes, ultimately contributing to the overall productivity and success of steel fabrication projects.Moreover, the machine is also being recognized for its potential to reduce costs and waste in steel fabrication processes. By enabling precise and efficient forming of steel angles, the machine helps minimize material waste and rework, leading to cost savings and improved sustainability in steel fabrication operations.The Steel Angle Roll Forming Machine is expected to revolutionize the way steel angles are formed in the industry. With its advanced capabilities, durability, and comprehensive support, it has garnered widespread interest from steel fabrication companies looking to enhance their capabilities and stay ahead in a competitive market.In conclusion, the Steel Angle Roll Forming Machine developed by {Company Name} represents a significant advancement in the steel fabrication industry. Its innovative features, reliability, and comprehensive support services make it a valuable asset for steel fabrication and construction companies. As the demand for efficient and high-quality steel forming processes continues to grow, the machine is poised to play a pivotal role in meeting the evolving needs of the industry.

Durable Standing Seam Roof Machine for Efficient Roofing

Standing Seam Roof Machine Revolutionizes Roofing IndustryThe roofing industry has seen a revolution with the introduction of the state-of-the-art Standing Seam Roof Machine by a leading manufacturer in the field. This innovative machine has been designed with precision and advanced technology to meet the growing demands of the roofing industry.The Standing Seam Roof Machine is a game-changer for roofing professionals as it offers efficiency, durability, and unmatched precision in producing standing seam roofs. The machine features a cutting-edge design that allows for seamless and fast production of standing seam roofs, meeting the high standards of quality and performance.This revolutionary machine is the result of years of research and development by a dedicated team of engineers and experts. With an unwavering commitment to excellence, the company has set a new benchmark in the industry with its Standing Seam Roof Machine. The machine is built with high-quality materials and components, ensuring durability and long-term performance.One of the key features of the Standing Seam Roof Machine is its versatility. It is capable of producing standing seam roofs of various widths and profiles, catering to the diverse needs of roofing projects. This flexibility makes it an ideal choice for roofing contractors and professionals who require a reliable and efficient solution for their projects.In addition to its versatility, the machine is also equipped with advanced automation and control systems, allowing for precise and accurate production of standing seam roofs. This not only enhances the efficiency of the production process but also ensures the consistency of the final product.The company behind the Standing Seam Roof Machine has a long-standing reputation for delivering high-quality and innovative solutions to the roofing industry. Their commitment to excellence and customer satisfaction has earned them a trusted position in the market. With the introduction of the Standing Seam Roof Machine, they have once again solidified their leadership in the industry.The company takes pride in its customer-centric approach, offering comprehensive technical support and training to ensure that roofing professionals can fully harness the capabilities of the Standing Seam Roof Machine. Their team of technical experts is readily available to provide assistance and guidance, guaranteeing a seamless integration of the machine into the customers' operations.Furthermore, the company's dedication to sustainability is reflected in the design and production of the Standing Seam Roof Machine. It has been engineered to minimize waste, energy consumption, and environmental impact, aligning with the growing demand for eco-friendly solutions in the roofing industry.The introduction of the Standing Seam Roof Machine has garnered widespread attention in the roofing industry, with professionals recognizing its potential to streamline operations and elevate the quality of standing seam roofs. Its impact is not only limited to production efficiency but also extends to the overall performance and longevity of standing seam roofs, offering a compelling value proposition to roofing professionals.In conclusion, the Standing Seam Roof Machine is a testament to the relentless pursuit of innovation and excellence by the company. With its cutting-edge design, advanced technology, and commitment to customer satisfaction, the machine has set a new standard in the roofing industry. It represents a significant advancement that is poised to reshape the production of standing seam roofs, empowering roofing professionals to deliver exceptional results.

How Glazed Steel Roofing Tile Corrugating Machines Improve Color Steel Production

Color Steel Glazed Steel Roofing Tile Corrugating Machine Enters the MarketThe demand for high-quality and durable roofing materials is on the rise in various parts of the world. One of the most popular roofing materials, especially in areas that experience harsh weather conditions, is color steel glazed steel roofing tiles. These tiles not only provide excellent insulation but also add aesthetic appeal to any structure.To meet the increasing demand for color steel glazed steel roofing tiles, () introduces a new corrugating machine. The machine adopts the latest technology, from uncoiling and feeding to curving and cutting, to produce high-quality and perfect roofing tiles. The tiles have a glossy appearance, offering an elegant and sophisticated look to your residential or commercial building.The new machine produces roofing tiles that are suitable for different installation needs. Whether you need tiles for large warehouses, shopping malls, or residential homes, the machine can adjust to your specifications. You can select various sizes, colors, and patterns to customize the roofing tiles to suit your needs.The roofing tiles produced by () are strong, durable, and resistant to harsh weather conditions. They can withstand high winds, heavy rainfall, and hailstorms. They are also corrosion-resistant, making them perfect for buildings in coastal areas.Apart from their functional benefits, the color steel glazed steel roofing tiles produced by () also provide thermal insulation, noise reduction, and fire resistance. They are energy-efficient, reducing your heating or cooling costs throughout the year.The company's production line uses high-quality materials and advanced technology to ensure that they produce roofing tiles of the highest quality. They have a team of experienced engineers and technicians who carry out regular maintenance and quality checks to ensure that all machines are in top condition.The new corrugating machine is easy to operate, making it perfect for both small-scale and large-scale production. The machine is fully automated, reducing human error and improving the overall output. You can set the machine to produce a certain number of roofing tiles at a particular time, ensuring that your production schedule is on track.() has a reputation for producing high-quality and long-lasting roofing materials, from tiles to metal sheets and galvanized steel pipes. They have won various awards and recognition for their quality products, including the ISO 9001 certification.In addition to their quality products, () also offers excellent customer service. They have a team of dedicated customer service representatives who are always ready to assist with any inquiries or concerns. They offer free consultation services to help you choose the right roofing materials for your project.The new corrugating machine is expected to increase the company's production capacity, meeting the growing demand for color steel glazed steel roofing tiles. The machine is also expected to enrich their product line, enabling them to cater to a wider range of customers.Overall, the introduction of the new corrugating machine by () is a game-changer in the roofing industry. It offers a new level of efficiency, quality, and affordability, making it ideal for contractors, architects, and property owners who want durable and stylish roofing tiles. With their commitment to quality and customer service, () is poised to become a market leader in the roofing industry.

Roof Panel Glazed Tile Roll Forming Machine with 5.5kw Motor for Sale - High-Quality Former Machine Available

ZhongHeng Machine Manufacture Co., Ltd announces the sale of its latest product, the Roof Panel Glazed Tile Roll Forming Machine/Former Machine with 5.5kw motor. The company boasts of over 20 years of experience in manufacturing roll forming machines, and they have established themselves as a reputable manufacturer in the industry.The Roof Panel Glazed Tile Roll Forming Machine/Former Machine is a top-of-the-line product that produces high-quality glazed tiles with precision and accuracy. The machine is equipped with a 5.5kw motor, which enables it to work efficiently and effectively in producing tiles. It is designed with advanced technology, which guarantees the production of accurate and uniform tiles.This machine has a high production capacity, producing up to 10 meters per minute. It has a roll forming speed of 12-15m/min, which ensures quick and timely delivery of orders. The machine has a high level of automation, which means that it requires minimal manual intervention.The Roll Forming Machine has a high level of efficiency and accuracy in the production process. It is designed to produce consistent and uniform tiles, which is critical in ensuring their quality. It also has minimal waste, which saves on production costs and maximizes profits.The Roof Panel Glazed Tile Roll Forming Machine/Former Machine has a robust and durable design, ensuring its longevity and reliability. The machine is made of high-quality materials, which are both corrosion and rust-resistant, ensuring that it remains in perfect condition for years of use.According to a spokesperson for ZhongHeng Machine Manufacture Co., Ltd, the company is committed to producing high-quality roll forming machines that are efficient and reliable. He stated, “Our company is always at the forefront of technology, and our products are designed to meet the needs of our customers. We are proud of our reputation as a leading roll forming machine manufacturer in China, and we will continue to deliver quality products that our customers can rely on.”In conclusion, the Roof Panel Glazed Tile Roll Forming Machine/Former Machine with 5.5kw motor is a testament to ZhongHeng Machine Manufacture Co., Ltd’s commitment to producing high-quality roll forming machines. The machine’s advanced technology, efficiency, and accuracy make it a top choice for anyone looking to produce high-quality glazed tiles. With over twenty years of experience and a reputation as a leading manufacturer of roll forming machines in China, ZhongHeng Machine is the go-to company for all roll forming machine needs.

High-Quality Floor Decking Roll Forming Machine for Sale

Floor Decking Roll Forming Machine has been revolutionizing the construction industry with its innovative and efficient solutions. The machine, designed and manufactured by a leading company in the industry, is a game-changer in the field of floor decking and has been widely adopted by construction companies around the world.The Floor Decking Roll Forming Machine is a state-of-the-art equipment that is used to produce floor decking panels, which are essential components in building construction. The machine is designed to roll form, cut, and stack metal sheets into the desired shape and size, making the process of floor decking production faster, more accurate, and more cost-effective. With its advanced technology and precise engineering, the machine is able to produce high-quality floor decking panels that meet industry standards and specifications.The company behind the Floor Decking Roll Forming Machine is a renowned manufacturer of roll forming machines and other construction equipment. With over 20 years of experience in the industry, the company has gained a reputation for delivering top-of-the-line products that are reliable, durable, and efficient. The company's commitment to innovation and excellence has positioned it as a leader in the field, and its products are trusted by construction professionals around the world.The Floor Decking Roll Forming Machine is a testament to the company's dedication to providing cutting-edge solutions for the construction industry. Its commitment to research and development has resulted in the creation of a machine that has revolutionized the way floor decking panels are produced, making the process faster, more efficient, and more cost-effective. With its advanced features and capabilities, the machine has helped construction companies improve their productivity and streamline their operations, ultimately leading to cost savings and increased profitability.One of the key features of the Floor Decking Roll Forming Machine is its versatility. The machine is capable of producing a wide range of floor decking panels in different shapes, sizes, and thicknesses, allowing construction companies to meet the specific requirements of their projects. This versatility makes the machine an invaluable asset for construction companies of all sizes, as it enables them to take on diverse projects and deliver high-quality results.In addition to its versatility, the Floor Decking Roll Forming Machine is also known for its ease of use and maintenance. The machine is equipped with user-friendly controls and interfaces, making it easy for operators to set up and operate the machine with minimal training. Its durable construction and reliable performance also minimize the need for maintenance, reducing downtime and enhancing productivity.Furthermore, the company prides itself on its commitment to customer satisfaction. It provides comprehensive support and service for its products, ensuring that customers receive the assistance they need to maximize the performance and lifespan of their equipment. With a global network of service centers and technical experts, the company is able to provide responsive support to customers around the world, further enhancing the value of its products.In conclusion, the Floor Decking Roll Forming Machine is a groundbreaking innovation that has transformed the construction industry. With its advanced technology, versatility, and reliability, the machine has become an essential tool for construction companies seeking to improve their efficiency and productivity. Combined with the company's dedication to innovation and customer satisfaction, the Floor Decking Roll Forming Machine is sure to continue making a significant impact on the construction industry for years to come.

High-Quality Aluminum Profile Polishing Machine for Metal Finishing

Aluminum Profile Polishing Machine Helps Company Achieve High-Quality ProductsIn the fast-paced world of manufacturing, companies are constantly striving to enhance the quality of their products while also increasing efficiency. One crucial aspect of achieving this goal is the use of advanced machinery that can streamline production processes and improve the overall quality of final products. One company that has successfully incorporated cutting-edge technology into its operations is {Company Name}, a leading manufacturer of aluminum profiles.{Company Name} has recently implemented a state-of-the-art Aluminum Profile Polishing Machine, which has significantly improved the company's ability to produce high-quality aluminum profiles for a variety of applications. The machine, which has been carefully integrated into the company's production line, is capable of polishing aluminum profiles to a mirror-like finish, ensuring that the final products meet the highest standards of quality.The decision to invest in the Aluminum Profile Polishing Machine was driven by {Company Name}'s commitment to delivering exceptional products to its customers. By incorporating this advanced technology into its operations, the company has been able to elevate the quality of its aluminum profiles, setting it apart from its competitors in the industry.The Aluminum Profile Polishing Machine is equipped with advanced polishing techniques and precision controls, allowing {Company Name} to achieve a level of consistency and excellence that was previously unattainable. This has not only resulted in a significant improvement in the overall appearance of the aluminum profiles but has also enhanced their durability and resistance to corrosion, making them suitable for a wide range of applications in various industries.Furthermore, the integration of the Aluminum Profile Polishing Machine has had a notable impact on {Company Name}'s production efficiency. The machine's automated processes and efficient operation have helped to streamline the polishing process, reducing production lead times and increasing the company's overall output capacity. As a result, {Company Name} has been able to meet the growing demand for its high-quality aluminum profiles, without compromising on quality or consistency.The introduction of the Aluminum Profile Polishing Machine has also had a positive effect on the company's workforce. By automating certain aspects of the polishing process, {Company Name} has been able to redeploy its skilled workers to other areas of the production line, where their expertise and experience can create additional value. This has not only improved overall operational efficiency but has also enhanced employee satisfaction and morale within the organization.{Company Name} is proud to be at the forefront of technological innovation within the industry, and the successful incorporation of the Aluminum Profile Polishing Machine is a testament to the company's commitment to continuous improvement. By embracing advanced machinery and processes, {Company Name} is positioning itself as a leader in the manufacturing of high-quality aluminum profiles, meeting the ever-evolving needs of its customers and setting new standards for excellence in the industry.Moving forward, {Company Name} remains dedicated to investing in cutting-edge technology and equipment that will further enhance its production capabilities and product offerings. By staying ahead of the curve and embracing innovation, {Company Name} is poised to maintain its position as a trusted provider of premium aluminum profiles, delivering exceptional value to its customers and driving continued growth and success in the industry.

Get the Latest Ridge Forming Machine for Your Construction Needs

Ridge Forming Machine Revolutionizing the Roofing IndustryIn the ever-evolving world of construction and roofing, innovations and technological advancements continue to transform the way we build and maintain our homes and buildings. One such innovation that is revolutionizing the roofing industry is the Ridge Forming Machine, a state-of-the-art equipment that is streamlining the process of creating ridges on roofing materials, resulting in faster and more efficient construction.The Ridge Forming Machine, developed by a leading company in the industry, is designed to meet the increasing demand for quality and precision in roofing construction. Using advanced technology and precision engineering, this machine is capable of forming ridges on a variety of roofing materials, including metal, asphalt, and composite shingles. This versatility makes it an indispensable tool for roofing contractors and construction companies.The company behind this groundbreaking innovation has been a pioneer in the roofing industry for over three decades. With a commitment to excellence and a focus on innovation, they have consistently delivered high-quality products and solutions to their customers. The Ridge Forming Machine is a testament to their dedication to pushing the boundaries of what is possible in the roofing industry.One of the key features of the Ridge Forming Machine is its ability to form uniform and precise ridges on roofing materials. This is achieved through the use of advanced technology and precision engineering, which ensures that every ridge is consistent in size and shape. This level of precision is essential for creating durable and weather-resistant roofs that will stand the test of time.Another important aspect of the Ridge Forming Machine is its efficiency and speed. By automating the ridge forming process, this machine is capable of significantly reducing the time and labor required to complete a roofing project. This not only translates to cost savings for contractors and builders but also allows for faster project completion, enabling them to take on more projects and increase their overall productivity.Furthermore, the Ridge Forming Machine is designed with user-friendly features that make it easy to operate and maintain. This means that even inexperienced operators can quickly learn how to use the machine, reducing the need for extensive training and supervision. Additionally, the machine is built to withstand the rigors of construction sites, ensuring its durability and long-term reliability.The introduction of the Ridge Forming Machine has already made a significant impact on the roofing industry. Contractors and builders who have incorporated this technology into their operations have reported increased efficiency, reduced labor costs, and higher customer satisfaction. As word of the machine's benefits spreads, it is expected to become a standard tool for roofing projects of all sizes.Looking ahead, the company behind the Ridge Forming Machine is committed to further enhancing its capabilities and expanding its range of applications. With ongoing research and development, they aim to introduce new features and improvements that will continue to set the standard for roofing equipment. As the construction industry embraces the benefits of this innovative machine, it is poised to become an essential tool for any roofing project.In conclusion, the Ridge Forming Machine is a game-changer for the roofing industry. Its advanced technology, precision engineering, and user-friendly design make it a valuable asset for contractors and builders seeking to enhance their efficiency and productivity. As this innovation continues to gain traction in the market, it is clear that the future of roofing construction is being shaped by the capabilities of this groundbreaking machine.

Advanced Roll Forming Machine for Colored Metal Steel Sheets

Title: Innovative Colored Metal Steel Sheet Roll Forming Machine Poised to Revolutionize the Construction IndustryIntroduction:In a significant technological breakthrough, a leading manufacturing company has unveiled a cutting-edge Colored Metal Steel Sheet Roll Forming Machine. The state-of-the-art machinery is set to revolutionize the construction industry by streamlining the process of producing colored metal steel sheets. With unrivaled efficiency and precision, this innovative machine promises to transform the way steel sheets are manufactured and used in various construction applications.I. Background:The manufacturing industry has always been at the forefront of innovation, continuously striving to enhance productivity while maintaining the highest quality standards. The introduction of the Colored Metal Steel Sheet Roll Forming Machine showcases the company's commitment to revolutionize the construction sector by providing advanced solutions to meet market demands.II. Features and Functionality:The Colored Metal Steel Sheet Roll Forming Machine incorporates state-of-the-art technology, boasting a wide range of features that set it apart from conventional machinery. It has been meticulously designed and engineered to offer maximum efficiency, ease of use, and versatility to meet the changing needs of the construction industry.1. Advanced Roll Forming System:The machine employs an advanced roll forming system capable of producing a vast range of colored metal steel sheets. The system ensures high precision and accuracy during the roll forming process, resulting in sheets with consistent shape, dimensions, and surface finish.2. Customizable Profiles:By leveraging the machine's flexible capabilities, users can effortlessly customize various steel sheet profiles to cater to diverse construction requirements. These profiles can be easily adjusted, allowing for quick adaptation to different project specifications.3. Integrated Color Coating System:The Colored Metal Steel Sheet Roll Forming Machine is equipped with a sophisticated color coating system that ensures seamless application of vibrant colors onto the steel sheets. This feature enables the creation of visually appealing and long-lasting colored metal sheets, adding aesthetic value to any construction project.4. Energy-Efficient Operation:The machine incorporates an energy-efficient system that minimizes power consumption while maximizing productivity. This eco-friendly feature not only reduces operating costs but also contributes to a sustainable manufacturing process.III. Benefits and Market Impact:The introduction of the Colored Metal Steel Sheet Roll Forming Machine significantly enhances the overall efficiency and quality of steel sheet production, offering a wide array of benefits to construction professionals and manufacturers alike.1. Improved Productivity:With its advanced technology and streamlined functions, the machine enables faster production cycles, ensuring higher output and reduced lead times. This allows manufacturers to meet escalating market demands while maintaining stringent quality control.2. Cost Savings:The machine's energy-efficient operation and reduced material waste result in significant cost savings for manufacturers. Moreover, the customizable profiles cater to specific project requirements, minimizing material wastage and further optimizing resource utilization.3. Enhanced Durability:The use of high-quality colored metal steel sheets produced by this machine ensures enhanced durability and longevity of constructed structures. These steel sheets are resistant to corrosion, UV radiation, and extreme weather conditions, ensuring long-lasting performance and minimal maintenance costs.4. Aesthetically Pleasing:The availability of vibrant and customizable colors through the color coating system allows architects and designers to unleash their creativity. This feature paves the way for the development of visually appealing buildings and structures, adding value through aesthetic appeal.IV. Conclusion:The introduction of the Colored Metal Steel Sheet Roll Forming Machine signifies a groundbreaking leap forward in the construction industry. With its advanced technology and unmatched efficiency, this innovative machine promises to revolutionize the manufacturing of colored metal steel sheets, providing construction professionals with high-quality, customizable, and visually appealing solutions. As this technology gains traction, it is expected to reshape the construction landscape by empowering architects, engineers, and contractors to construct remarkable buildings that stand the test of time.

High-quality Color Steel Roll Forming Machine Factory delivers top-notch products

Color Steel Roll Forming Machine Factory, a leading manufacturer in the roll forming industry, is proud to announce the launch of their new state-of-the-art facility. With over [number] years of experience in the industry, the company has established a strong reputation for providing high-quality roll forming machines to customers worldwide.The new facility is equipped with the latest technology and machinery to ensure the production of top-of-the-line roll forming machines. The company has invested heavily in research and development to create innovative and efficient machines that meet the evolving needs of the industry.The factory boasts a team of highly skilled engineers and technicians who are dedicated to pushing the boundaries of roll forming technology. With a focus on precision engineering and quality control, the company ensures that every machine that leaves the facility meets the highest standards of performance and reliability.In addition to manufacturing roll forming machines, the company also offers a range of services including installation, training, and after-sales support. This comprehensive approach ensures that customers are supported throughout the entire lifecycle of their machine, from the initial purchase to long-term maintenance.The company's commitment to customer satisfaction has earned them a loyal client base and a reputation for excellence in the industry. By consistently delivering superior machines and exceptional service, Color Steel Roll Forming Machine Factory has become a trusted partner to businesses in a wide range of industries.Furthermore, the company is dedicated to sustainability and environmentally friendly practices. The new facility has been designed with energy efficiency in mind, and the company strives to minimize its environmental impact throughout the manufacturing process.As the demand for roll forming machines continues to grow, Color Steel Roll Forming Machine Factory is well-positioned to meet the needs of customers around the world. The company has a global presence, with a network of distributors and partners in key markets, allowing them to provide efficient and responsive service to customers wherever they are located.The launch of the new facility represents an exciting new chapter for the company, as they continue to lead the way in roll forming technology. With their unwavering commitment to innovation, quality, and customer satisfaction, Color Steel Roll Forming Machine Factory is poised for continued success in the industry.In conclusion, the new facility is a testament to the company's dedication to excellence and their position as a leader in the roll forming industry. With their cutting-edge technology, skilled team, and commitment to customer satisfaction, Color Steel Roll Forming Machine Factory is set to exceed the expectations of their clients and uphold their reputation as a top manufacturer in the industry.

High-Quality Horizontal Profiled Sheet Forming Equipment for Efficient Manufacturing

Horizontal Profiled Sheet Forming Equipment to Boost Production EfficiencyThe demand for high-quality profiled sheet metal products continues to grow in various industries, making it essential for manufacturing companies to have advanced and efficient equipment to meet the requirements of their customers. In response to this demand, [Company Name] is proud to announce the launch of its latest Horizontal Profiled Sheet Forming Equipment, designed to enhance production efficiency and deliver superior quality products.[Company Name] has been a leading manufacturer of sheet metal forming equipment for over two decades. The company has built a solid reputation for providing innovative and reliable solutions to meet the diverse needs of its customers. With a team of experienced engineers and professionals, [Company Name] has developed a wide range of state-of-the-art equipment that is known for its precision, durability, and performance.The new Horizontal Profiled Sheet Forming Equipment is a testament to [Company Name]'s commitment to continuous innovation and meeting the evolving needs of the industry. With its advanced features and capabilities, the equipment offers manufacturers the ability to produce a wide range of profiled sheet metal products with exceptional accuracy and efficiency.One of the key highlights of the Horizontal Profiled Sheet Forming Equipment is its versatility. The equipment can handle various types of sheet metal, including steel, aluminum, and other alloys, making it suitable for a wide range of applications across different industries. This versatility allows manufacturers to take on diverse projects and meet the unique requirements of their clients with ease.In addition to its versatility, the Horizontal Profiled Sheet Forming Equipment boasts advanced automation and control systems that streamline the production process. The equipment is equipped with intelligent sensors and programming interfaces that allow for precise and efficient operation, reducing the risk of errors and minimizing downtime. This level of automation not only speeds up production but also ensures consistent and high-quality output.Furthermore, the Horizontal Profiled Sheet Forming Equipment is designed with the operator in mind, featuring user-friendly interfaces and safety features that prioritize the well-being of the workforce. The equipment is easy to set up and operate, allowing manufacturers to maximize productivity without compromising on safety.With the introduction of the Horizontal Profiled Sheet Forming Equipment, [Company Name] aims to empower manufacturers to elevate their production capabilities and deliver superior products to their customers. By investing in this advanced equipment, manufacturers can improve their efficiency, reduce production costs, and enhance their competitiveness in the market.The launch of the Horizontal Profiled Sheet Forming Equipment reflects [Company Name]'s ongoing commitment to providing cutting-edge solutions that meet the evolving needs of the sheet metal forming industry. The company continues to invest in research and development, leveraging the latest technologies and industry insights to design and manufacture equipment that sets new standards for performance and reliability.As a pioneer in the field of sheet metal forming equipment, [Company Name] is dedicated to supporting manufacturers in achieving their production goals and exceeding customer expectations. By partnering with [Company Name] and incorporating its Horizontal Profiled Sheet Forming Equipment into their operations, manufacturers can stay ahead of the curve and thrive in an increasingly competitive market.In conclusion, the launch of the Horizontal Profiled Sheet Forming Equipment by [Company Name] marks a significant milestone in the sheet metal forming industry. With its advanced features, versatility, and user-friendly design, the equipment is set to revolutionize production processes and help manufacturers deliver high-quality profiled sheet metal products efficiently and cost-effectively. As [Company Name] continues to lead the way in innovation, manufacturers can look forward to a future of enhanced productivity and success in meeting the demands of their customers.