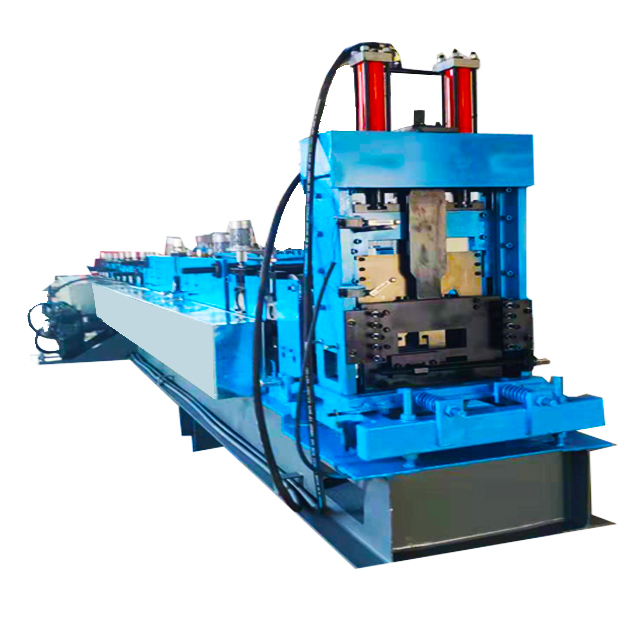

Top-rated Horizontal Profiled Panel Bending Machine for Efficient Manufacturing

By:Admin

Metal fabrication industry is constantly evolving with new technologies and machines that enhance efficiency and productivity. The latest innovation in this industry is the Horizontal Profiled Panel Bending Machine, which offers a new way to bend and shape metal panels with precision and speed. This advanced machine is making waves in the metal fabrication industry, revolutionizing the way metal components are produced and opening up new possibilities for design and construction.

The Horizontal Profiled Panel Bending Machine is a game-changer for metal fabrication companies, providing them with the ability to create complex and intricate metal panels with ease. This machine is capable of bending metal panels in a horizontal orientation, which allows for a wider range of shapes and designs to be achieved. This not only expands the creative possibilities for designers and architects, but also improves the efficiency of the fabrication process, reducing the time and labor required to produce custom metal components.

One of the key features of the Horizontal Profiled Panel Bending Machine is its precision and accuracy. This machine is equipped with advanced technology that ensures the bending process is carried out with the highest level of precision, resulting in perfectly shaped metal panels every time. This level of precision is essential for industries such as construction and architecture, where accuracy and quality are of utmost importance.

In addition, the Horizontal Profiled Panel Bending Machine is designed for versatility, allowing it to bend a wide range of metal materials, including aluminum, steel, and copper. This versatility makes it a valuable asset for metal fabrication companies that work with diverse materials and require a machine that can accommodate their specific needs.

The company behind the Horizontal Profiled Panel Bending Machine, {}, is a leading manufacturer of metal fabrication machinery with a strong reputation for innovation and quality. With decades of experience in the industry, {} has developed a deep understanding of the needs of metal fabrication companies and has utilized this knowledge to create cutting-edge machines that streamline the fabrication process and improve the quality of the end products.

{} is known for its commitment to research and development, constantly seeking out new technologies and methods to improve its machines and stay ahead of the competition. The Horizontal Profiled Panel Bending Machine is a testament to this commitment, incorporating the latest advancements in machine technology to provide metal fabrication companies with a powerful tool for creating high-quality metal components.

With the Horizontal Profiled Panel Bending Machine, {} aims to empower metal fabrication companies to take their production capabilities to the next level and bring their creative visions to life. By providing a machine that combines precision, versatility, and efficiency, {} is helping to drive innovation in the metal fabrication industry and open up new possibilities for what can be achieved with metal.

In conclusion, the Horizontal Profiled Panel Bending Machine is a groundbreaking innovation in the metal fabrication industry, offering a new way to bend and shape metal panels with precision and efficiency. {}'s commitment to excellence and innovation has resulted in a machine that is setting a new standard for metal fabrication, providing companies with the tools they need to push the boundaries of design and construction. As the industry continues to evolve, machines like the Horizontal Profiled Panel Bending Machine will play a crucial role in shaping the future of metal fabrication.

Company News & Blog

High-Quality Half Omega Steel Furring Channel Roll Former for Efficient Construction

The demand for light steel furring channel roll forming machines has been growing steadily in the construction industry. These machines play a vital role in the production of resilient furring channel keels, which are essential components for constructing reliable and durable steel frame structures. As such, the importance of high-quality, efficient, and reliable roll forming machines cannot be overstated.In response to this market demand, [Company Name] has introduced its latest innovation: the Light Steel Half Omega Steel Furring Channel Roll Former Resilient Furring Channel Keel Roll Forming Machine. This state-of-the-art machine has been designed and manufactured with precision engineering to meet the needs of modern construction projects.The [Company Name] Light Steel Half Omega Steel Furring Channel Roll Former Resilient Furring Channel Keel Roll Forming Machine is equipped with advanced technology and features that ensure high-speed production, superior quality, and long-term reliability. Its ability to produce resilient furring channel keels with precision and efficiency makes it an indispensable asset for construction companies and steel frame manufacturers.With a focus on durability and performance, the roll forming machine is constructed using high-quality materials and components. Its robust design and engineering ensure minimal maintenance requirements, reducing downtime and increasing productivity. Additionally, the machine is user-friendly, with intuitive controls and easy setup procedures, making it suitable for operators of all skill levels.One of the key highlights of the [Company Name] Light Steel Half Omega Steel Furring Channel Roll Former Resilient Furring Channel Keel Roll Forming Machine is its versatility. It can produce a wide range of furring channel keel profiles, catering to the diverse needs of construction projects. Whether it's for residential, commercial, or industrial applications, this roll forming machine delivers exceptional results across the board.Furthermore, the machine's production capacity and speed are impressive, ensuring that large volumes of furring channel keels can be manufactured within tight project timelines. This is particularly beneficial for construction companies working on time-sensitive projects where efficient production is crucial.[Company Name] has a strong reputation for delivering reliable and innovative roll forming solutions to the market. With a commitment to continuous research and development, the company has consistently raised the bar in terms of quality, performance, and customer satisfaction. The introduction of the Light Steel Half Omega Steel Furring Channel Roll Former Resilient Furring Channel Keel Roll Forming Machine is a testament to [Company Name]'s dedication to meeting the evolving needs of the construction industry.As a company, [Company Name] is not only focused on providing cutting-edge machinery but also on building long-term partnerships with its clients. The company offers comprehensive support services, including installation, training, and aftersales assistance, ensuring that customers can maximize the benefits of their investment in the roll forming machine.In conclusion, the introduction of the Light Steel Half Omega Steel Furring Channel Roll Former Resilient Furring Channel Keel Roll Forming Machine by [Company Name] is set to make a significant impact in the construction industry. Its advanced capabilities, reliability, and versatility position it as a game-changer in the production of resilient furring channel keels. With [Company Name]'s track record of excellence and commitment to customer satisfaction, the roll forming machine is bound to set new standards for efficiency and quality in construction projects.

Roll Forming Machines for Metal Roof and Drywall Studs and Track

If you are involved in the construction industry, you probably know how important it is to have the right equipment to get the job done quickly and efficiently. One of the most essential pieces of equipment that you need is a metal stud making machine.There are many different types of metal stud making machines on the market, but the most popular ones are those that are designed to produce high-quality metal studs and tracks used in drywall installation and house making. These machines are known for their precision, accuracy, and speed, making them the perfect tools for any construction project.One of the best things about metal stud making machines is that they are incredibly versatile. They can be used to produce a wide range of metal studs and tracks, including those made from steel, aluminum, and other metals. This means that you can use them for a variety of different projects, from small-scale jobs like installing a new drywall partition to large commercial construction projects.Metal stud making machines come in a range of sizes and configurations to meet the needs of different construction businesses. Some machines are designed to be portable, while others are more stationary. Some machines are designed to produce only metal studs, while others can produce both studs and tracks.To ensure that you are getting the best metal stud making machine for your needs, it is important to do your research and compare different models and brands. Look for a machine that is easy to use, has a high level of automation, and can produce high-quality metal studs quickly and efficiently.One popular brand of metal stud making machines is Alibaba. Their drywall stud roll forming machine is designed to produce high-quality studs and tracks for drywall installation and house framing. This machine is easy to operate and can produce metal studs and tracks in a range of different sizes and configurations.Another popular brand of metal stud making machine is Jobsite Roll Forming Equipment. Their machines are designed to produce metal studs and tracks for a range of different applications, including both residential and commercial construction projects. These machines are known for their precision and speed, making them the perfect choice for any construction business.In conclusion, if you are in the construction industry and looking to invest in a metal stud making machine, there are plenty of options to choose from. Whether you are looking for a portable machine or a more stationary model, there is sure to be a machine that fits your needs. Just be sure to do your research and compare different brands and models to find the best machine for your construction business.

Guide to Choosing the Right Floor Deck Profile for Your Project

Floor Deck Profile is an essential component in construction projects, providing structural support and stability to buildings. This key product is offered by a leading company in the construction industry, which has been serving the market with high-quality building materials for many years.The floor deck profile is a key element in the construction of commercial and residential buildings, providing a stable base for concrete slabs. It is typically made from galvanized steel, making it resistant to corrosion and ensuring the longevity of the building structure. The profile comes in various shapes and sizes to suit different construction requirements, and can be customized to meet specific project needs.The company, with its extensive experience and expertise in the construction industry, has been providing top-notch floor deck profiles to construction projects of various scales. With a strong focus on quality and innovation, the company has earned a solid reputation in the market, becoming a trusted supplier for builders and contractors.One of the key advantages of the floor deck profile offered by the company is its durability and strength. Made from high-quality materials and manufactured using advanced technology, the profile is designed to withstand heavy loads and harsh environmental conditions. This ensures the safety and structural integrity of the building, providing peace of mind to both builders and occupants.In addition to its exceptional durability, the floor deck profile also offers excellent fire resistance. This is a crucial feature in building construction, as it helps to enhance the safety of the building and protect the occupants in the event of a fire. The company's commitment to providing safe and reliable building materials is evident in the quality of its floor deck profile.Furthermore, the company's floor deck profile is designed with ease of installation in mind. With a user-friendly design and precise manufacturing, the profile can be easily installed, saving time and labor costs for construction projects. This efficiency is highly valued by builders and contractors, contributing to the overall success of the construction project.Moreover, the company takes pride in its commitment to sustainability and environmental responsibility. The floor deck profile is manufactured using eco-friendly processes and materials, minimizing its impact on the environment. This aligns with the growing trend towards sustainable construction practices, making the company a preferred choice for environmentally conscious builders and developers.With a strong emphasis on customer satisfaction, the company provides comprehensive support to its clients, offering technical guidance and assistance throughout the project. This dedication to customer service has helped to build long-term relationships with clients and establish the company as a reliable partner in the construction industry.In conclusion, the floor deck profile offered by the company plays a vital role in the construction of buildings, providing strength, durability, and safety. With its high-quality materials, innovative design, and commitment to customer satisfaction, the company has established itself as a leading supplier of floor deck profiles in the construction industry. As the demand for sustainable and reliable building materials continues to grow, the company is well-positioned to meet the needs of construction projects and contribute to the success of future developments.

Revolutionary Glazed Tile Corrugation Equipment Boosts Manufacturing Efficiency

[Company Name] Introduces Innovative Glazed Tile Corrugation Equipment Revolutionizing the Construction Industry[City, Date] - [Company Name], a leading provider of cutting-edge machinery and equipment, is pleased to announce the launch of its state-of-the-art Glazed Tile Corrugation Equipment. This groundbreaking machinery is set to revolutionize the construction industry by streamlining the production process and providing superior quality glazed tile products.Glazed tile has always been a popular choice for both residential and commercial buildings due to its aesthetic appeal and durability. However, the traditional manufacturing process is labor-intensive, time-consuming, and often leads to inconsistent quality. With the introduction of their innovative Glazed Tile Corrugation Equipment, [Company Name] aims to address these challenges and significantly enhance the production efficiency and quality of glazed tiles.The Glazed Tile Corrugation Equipment boasts a range of advanced features that set it apart from the competition. The precise and automated corrugation process ensures consistent and uniform patterns, eliminating human error and resulting in flawless glazed tiles. The integrated control system allows for easy configuration and operation, reducing the learning curve and maximizing productivity.Furthermore, the equipment's cutting-edge technology enables it to handle a variety of tile sizes, shapes, and colors, giving manufacturers the flexibility to cater to diverse customer demands. This adaptability is an essential quality in an industry that increasingly emphasizes customization and personalization.In addition to its exceptional performance, the Glazed Tile Corrugation Equipment also prioritizes safety and sustainability. Equipped with multiple safety features, such as emergency stop buttons and protective barriers, [Company Name] ensures the well-being of operators and minimizes the risk of accidents. Furthermore, the machinery is designed with energy-efficient mechanisms, reducing power consumption and minimizing its environmental impact.[Company Name] has a proven track record of delivering high-quality machinery and equipment to various industries, and the introduction of the Glazed Tile Corrugation Equipment is yet another testimony to their commitment to innovation. Their team of experienced engineers and technicians has tirelessly worked to develop this cutting-edge solution, combining their expertise with market research to meet the evolving needs of the construction industry."We are thrilled to unveil our Glazed Tile Corrugation Equipment," said [Spokesperson], the CEO of [Company Name]. "This machinery is a game-changer for manufacturers, enabling them to streamline their production processes and elevate the quality of their glazed tile products. We believe that this equipment will revolutionize the construction industry and open up new possibilities for our customers."The Glazed Tile Corrugation Equipment is compatible with both new and existing production lines, offering manufacturers a seamless transition. With its user-friendly interface and superior performance, this equipment is an investment in efficiency, quality, and profitability for businesses.In conclusion, the introduction of [Company Name]'s Glazed Tile Corrugation Equipment showcases their unwavering commitment to innovation and providing cutting-edge solutions to the construction industry. As the demand for glazed tiles continues to grow, this machinery will undoubtedly play a pivotal role in meeting customer expectations and driving industry growth.For more information about the Glazed Tile Corrugation Equipment and its features, visit [Company Name]'s website or reach out to their sales team.About [Company Name]:[Company Name] is a leading provider of innovative machinery and equipment across diverse industries. With a focus on research and development, they aim to deliver cutting-edge solutions that streamline processes and enhance productivity. Their commitment to excellence and customer satisfaction has made them a trusted partner for businesses worldwide.

Innovative Roll Making Machine for Improved Production Efficiency

Roll making machine is an important piece of equipment in the manufacturing industry. It is used to produce various types of rolls that are essential in the production of a wide range of products, including paper, plastic, textiles, and metal sheets.One company that has been leading the way in the development and production of roll making machines is {}. With over 20 years of experience in the industry, they have become a trusted name in the market and have earned a reputation for delivering high-quality, reliable, and efficient machines.The roll making machines produced by {} are known for their advanced technology, precision engineering, and durable construction. They are designed to meet the specific needs of each customer and are customizable to ensure that they can handle a wide range of roll making applications.One of the key features of {}'s roll making machines is their versatility. They are capable of producing different types of rolls, including embossed, perforated, and laminated rolls, and can accommodate various materials, such as paper, plastic, and metal. This versatility makes them ideal for manufacturers who need a single machine to handle multiple roll making processes.Another important aspect of {}'s roll making machines is their efficiency. They are designed to optimize the production process, with features such as quick changeover capabilities, automatic tension control, and advanced monitoring systems. This ensures that the machines can produce high-quality rolls with minimal downtime, helping manufacturers to increase their productivity and reduce their operating costs.In addition to their advanced technology and efficiency, {}'s roll making machines are also known for their reliability. They are built to withstand the demands of continuous operation and are equipped with robust components and high-quality materials to ensure long-term performance and durability.Furthermore, {} offers comprehensive customer support and after-sales service for their roll making machines. Their team of experienced engineers and technicians is available to provide installation, training, maintenance, and troubleshooting services, ensuring that their customers can get the most out of their machines and minimize any potential downtime.With a commitment to continuous innovation and improvement, {} is constantly developing new technologies and refining their roll making machines to meet the evolving needs of the industry. Their dedication to excellence has earned them a loyal customer base and has positioned them as a leader in the roll making machine market.As the demand for high-quality rolls continues to grow across various industries, the roll making machines produced by {} are poised to play a crucial role in helping manufacturers meet this demand. With their advanced technology, efficiency, reliability, and comprehensive support, {}'s roll making machines are a valuable asset for any company looking to enhance their roll production capabilities.In conclusion, the roll making machines produced by {} are a testament to the company's commitment to innovation, quality, and customer satisfaction. With their advanced technology, efficiency, and reliability, these machines are a valuable asset for manufacturers in various industries and are helping to drive the production of high-quality rolls around the world.

Innovative Ways to Incorporate Corrugated Metal into Your Home Design

Corrugated Metal Ideas For The Home: A Stylish and Sustainable ChoiceIn today's world, where sustainability and functionality are valued more than ever, it's no surprise that corrugated metal has become a popular choice for home décor and design. With its many versatile uses and inherent qualities, corrugated metal has emerged as a go-to option for homeowners looking to add a unique touch to their living spaces. From roofing to wall accents, furniture to garden sheds, this lightweight, portable, and corrosion-resistant material offers endless possibilities. In this blog post, we explore some innovative corrugated metal ideas for the home, highlighting its benefits, design inspirations, and the ease of using corrugated metal rollers for various projects.Benefits of Corrugated Metal in Home Design:1. Lightweight and Portable: Corrugated metal sheets or rolls are incredibly lightweight, making them easy to handle and transport. This feature is particularly beneficial for homeowners who might want to install or relocate structures and accents periodically. Whether you're building a garden shed, a privacy screen, or an outdoor kitchen, the lightweight nature of corrugated metal allows for effortless installation and customization.2. Corrosion-Resistant and Durable: When it comes to long-lasting materials, corrugated metal is a winner. Its resilient composition provides excellent resistance against corrosion, rust, and other environmental factors. Corrugated metal not only withstands harsh weather conditions but also ensures your investment will last for years to come. This durability makes it a cost-effective choice, eliminating the need for frequent repairs or replacements.3. Economical and Low Maintenance: Corrugated metal is a budget-friendly option that offers significant savings in the long run. Its affordable price, coupled with its longevity, reduces maintenance and replacement costs over time. Unlike traditional roofing materials that may require constant upkeep, corrugated metal requires minimal maintenance, making it an ideal choice for homeowners looking for both cost-effectiveness and durability.4. Eco-Friendly and Recyclable: Sustainability is a key consideration for many homeowners today. With corrugated metal, you can rest assured that you are making an eco-conscious choice. In addition to being easy to recycle, corrugated metal is often made from recycled materials itself. By utilizing this material in your home design, you can reduce your carbon footprint and make a positive impact on the environment.Design Inspirations and Ideas:1. Roofing: Corrugated metal roofs are popular for their sleek and modern aesthetic. The distinctive ridges of the metal add character to any architectural style, be it contemporary or industrial. Moreover, the durability of corrugated metal ensures that your roof will remain intact and visually appealing for years to come. Its lightweight nature also reduces stress on the overall structure of the building.2. Walls and Facades: Corrugated metal can be used to create stunning wall accents, both indoors and outdoors. Whether it's a feature wall in your living room or an eye-catching façade for your home exterior, the combination of corrugated metal and other materials, such as wood or concrete, can create a visually striking contrast. Additionally, you can choose to paint or patina the metal to further enhance its aesthetic appeal.3. Furniture and Décor: Corrugated metal can be incorporated into furniture design, adding an industrial and rustic touch to your home. From coffee tables to kitchen countertops, the possibilities are endless. Its durability and resistance to wear make it a great choice for high-traffic areas or outdoor furniture, where longevity is essential. Corrugated metal accents, such as barn doors or room dividers, can also lend a trendy farmhouse vibe to any interior space.4. Garden Sheds and Structures: Want to add a touch of elegance to your garden or backyard? Consider using corrugated metal in constructing garden sheds, pergolas, or fences. The fascinating texture and sleek lines of the metal will instantly elevate the overall look of your outdoor space. Moreover, its lightweight nature ensures effortless installation and easy customization options such as painting or staining to match your existing garden theme.Using Corrugated Metal Rollers for DIY Projects:While corrugated metal sheets offer a wide range of benefits and visual appeal, the process of shaping and creating custom sizes can be challenging. This is where corrugated metal rollers come into play. These tools are specifically designed to shape and roll corrugated metal sheets according to your desired specifications. They provide the flexibility and accuracy needed to achieve precise results. Whether you're looking to create a curved accent wall or custom roofing, corrugated metal rollers allow for easy manipulation and ensure a smooth, professional finish.In conclusion, corrugated metal has become a favored choice for homeowners looking to incorporate sustainability, style, and longevity into their home design. Its lightweight, corrosion-resistant, and eco-friendly qualities make it an ideal material for various projects. From roofs to walls, furniture to garden accents, the possibilities are endless when it comes to using corrugated metal in your home. By utilizing corrugated metal rollers, you can unleash your creativity and easily shape this versatile material to fit your unique visions. So, why not consider adding a touch of industrial charm to your living space? Embrace the corrugated metal trend and make a bold statement in your home today.

Ultimate Guide to Roof Sheet Forming Machine: Everything You Need to Know

Roof Sheet Forming Machine: Revolutionizing the Construction IndustryInnovations in technology have led to significant advancements in the construction industry, and one such breakthrough is the development of the Roof Sheet Forming Machine. This state-of-the-art equipment has revolutionized the way roofing sheets are manufactured, offering a more efficient and cost-effective solution for construction projects.The Roof Sheet Forming Machine, also known as the Roll Forming Machine, is a key product offered by **Company**, a leading manufacturer and supplier of construction machinery. With a strong focus on research and development, **Company** has been at the forefront of providing cutting-edge solutions to the construction industry for over a decade. The Roof Sheet Forming Machine is one of their flagship products, designed to meet the growing demand for high-quality roofing materials.The machine is equipped with advanced technology that allows for the continuous and automated production of roofing sheets. It can process various materials such as steel, aluminum, and copper, and is capable of producing sheets in different sizes and profiles to meet the specific requirements of construction projects. This versatility makes it an ideal choice for roofing contractors and builders who are looking for customized solutions for their projects.One of the key features of the Roof Sheet Forming Machine is its high efficiency. The automated production process significantly reduces the time and labor required to manufacture roofing sheets, ultimately leading to cost savings for the users. This efficiency also translates to increased productivity, allowing for a higher output of roofing materials in a shorter span of time.Moreover, the machine is designed for ease of use and maintenance, making it a practical choice for both small-scale and large-scale construction operations. Its user-friendly interface and robust construction ensure smooth operation and longevity, minimizing downtime and maintenance costs.The Roof Sheet Forming Machine is also environmentally friendly, as it reduces material waste and energy consumption during the production process. This aligns with **Company**'s commitment to sustainability and responsible manufacturing, reflecting their dedication to providing eco-friendly solutions to the construction industry.Furthermore, **Company** offers comprehensive support and after-sales services for the Roof Sheet Forming Machine, including installation, training, and technical assistance. This ensures that clients can maximize the full potential of the machine and maintain its optimal performance throughout its lifespan.As the construction industry continues to evolve, the Roof Sheet Forming Machine is set to play a crucial role in shaping the future of roofing material production. Its innovative technology, efficiency, and versatility make it an indispensable asset for construction companies looking to stay ahead in a competitive market.In conclusion, the Roof Sheet Forming Machine offered by **Company** represents a significant advancement in the construction machinery sector. Its cutting-edge technology, efficiency, and environmental sustainability make it a compelling solution for meeting the evolving needs of the construction industry. As **Company** continues to drive innovation in the field, the Roof Sheet Forming Machine stands as a testament to their dedication to providing top-quality solutions for the modern construction landscape.

High-Quality Aluminum Profile Bending Machine for Efficient Production

Aluminum Profile Bending Machine Revolutionizing the IndustryIn today's fast-paced and rapidly evolving manufacturing industry, precision and efficiency are key factors in staying competitive. Companies are constantly seeking innovative solutions that can streamline their production process and deliver high-quality products to their customers. One such solution that is revolutionizing the industry is the Aluminum Profile Bending Machine, a cutting-edge technology that is transforming the way aluminum profiles are manipulated and formed.The Aluminum Profile Bending Machine, developed by a leading manufacturer in the industry, is a state-of-the-art piece of equipment designed to provide precise and efficient bending of aluminum profiles. With its advanced technology and high-performance capabilities, this machine has quickly become a game-changer for manufacturers seeking to enhance their production processes and deliver superior products to their customers.The Aluminum Profile Bending Machine offers a wide range of benefits that are redefining the industry standard. One of the key advantages of this machine is its ability to bend aluminum profiles with unparalleled precision. The machine's advanced bending capabilities ensure that the profiles are formed with utmost accuracy and consistency, resulting in high-quality end products that meet the most stringent industry standards.In addition to its precision, the Aluminum Profile Bending Machine also offers unmatched efficiency. Its advanced automation features and intuitive controls allow manufacturers to significantly reduce their production times and optimize their workflow. This not only increases productivity but also reduces operational costs, making it a highly cost-effective solution for manufacturers looking to enhance their competitiveness in the market.Furthermore, the Aluminum Profile Bending Machine is incredibly versatile, capable of bending a wide variety of aluminum profiles with different shapes and sizes. Its flexibility and adaptability make it a valuable asset for manufacturers who produce a diverse range of products, enabling them to streamline their production processes and meet the unique needs of their customers.The company behind the Aluminum Profile Bending Machine is renowned for its commitment to excellence and innovation. With a strong focus on research and development, the company has consistently pushed the boundaries of technology to deliver cutting-edge solutions that empower manufacturers to achieve new levels of productivity and quality.Founded on the principles of quality, reliability, and customer satisfaction, the company has earned a reputation as a trusted partner for manufacturers seeking advanced solutions to enhance their production processes. Its Aluminum Profile Bending Machine is a testament to its dedication to innovation and excellence, providing manufacturers with a powerful tool to elevate their manufacturing capabilities and stay ahead of the competition.Looking ahead, the company remains committed to driving innovation in the industry and continuing to develop groundbreaking solutions that address the evolving needs of manufacturers. With a relentless pursuit of excellence and a deep understanding of the industry's challenges and opportunities, the company is poised to shape the future of manufacturing with its innovative technologies and unwavering commitment to customer success.In conclusion, the Aluminum Profile Bending Machine is a game-changing technology that is revolutionizing the manufacturing industry. With its unparalleled precision, efficiency, and versatility, this machine is empowering manufacturers to elevate their production processes and deliver superior products to their customers. Backed by a company with a proven track record of excellence and innovation, the Aluminum Profile Bending Machine is setting new standards for quality and performance in the industry, and its impact is poised to be felt for years to come.

Boost Your Roofing Projects with a High-Quality Corrugated Iron Machine

In today's world, where businesses are expanding at a rapid pace, the demand for sturdy and durable construction materials is at an all-time high. Corrugated iron sheets are widely used for roofing and fencing due to their strength and longevity. However, producing these sheets is a tedious and time-consuming task. To ease this process, a state-of-the-art Corrugated Iron Machine was introduced by a renowned company.The machine boasts an innovative design that enables it to produce high-quality corrugated iron sheets quickly and efficiently. Its robust frame is made of high-quality materials to support its heavy-duty operations. The machine's internal structure has been engineered to perfection, ensuring that it operates with minimal wear and tear. Additionally, the machine is fitted with top-of-the-line electrical and mechanical parts to ensure its durability and reliability.The company behind this revolutionary machine is one of the leading manufacturers of industrial equipment for the construction sector. They are known for their cutting-edge machinery, which is designed to streamline construction processes and boost productivity. With years of experience in the industry, they understand their customers' needs and demands and strive to offer them the best possible solutions.The Corrugated Iron Machine's features highlight its versatility and adaptability. It can produce corrugated sheets of varying thickness, length, and width, ensuring that it satisfies the diverse needs of its users. Through a simple yet intuitive interface, the machine can be easily adjusted to accommodate different settings, making it ideal for small and large-scale manufacturers. Moreover, the machine's energy-efficient nature ensures that it consumes minimal electricity, making it an eco-friendly option.One of the primary benefits of the Corrugated Iron Machine is its ability to increase productivity and reduce labour costs. With the traditional method, producing a single corrugated sheet could take hours and required a team of workers. However, with this machine, a single operator can produce up to hundreds of corrugated sheets within a few hours. It is highly beneficial for manufacturers as it enables them to increase their production output while minimizing labour costs.The Corrugated Iron Machine's low maintenance requirement is a testament to its robustness and reliability. The machine has been designed to operate with minimal maintenance. Its internal parts are easily accessible should any maintenance need arise, and its user-friendly interface ensures that operators can carry out routine maintenance without any hassle.The machine's ergonomic design ensures that it is easy to operate and maintain. Its built-in safety features ensure that operators are safe while operating the machine. Additionally, the machine's structure is designed to reduce noise levels, creating a comfortable working environment for the operator.To conclude, the introduction of the Corrugated Iron Machine is a significant milestone for the construction industry. Its ability to produce high-quality corrugated sheets quickly and efficiently has revolutionized the manufacturing process. The machine's durability, low maintenance requirement, and energy-efficient nature not only benefit the user but also the environment. As the demand for sturdy construction materials continues to rise, the Corrugated Iron Machine is sure to be a game-changer, ensuring that manufacturers can keep up with the increasing demand.

High-Quality Corrugated Sheet Making Machine for Efficient Production

Corrugated Sheet Making Machine Brings Innovation to Packaging IndustryThe packaging industry is constantly evolving, with new technologies and machinery transforming the way products are packaged and shipped. One such innovation is the Corrugated Sheet Making Machine, which has revolutionized the production of corrugated sheets for packaging purposes. This machine, developed by a leading machinery manufacturer, has made it easier and more efficient to produce high-quality corrugated sheets, meeting the growing demand for sustainable packaging solutions.The Corrugated Sheet Making Machine is a sophisticated piece of equipment that is capable of producing corrugated sheets in various sizes and styles. It is designed to handle a wide range of materials, including paper, cardboard, and other sustainable packaging materials, making it a versatile solution for packaging manufacturers. The machine's advanced technology allows for fast and precise production, ensuring that the corrugated sheets meet industry standards for strength and durability.One of the key benefits of the Corrugated Sheet Making Machine is its ability to produce custom-designed corrugated sheets, giving packaging manufacturers the flexibility to meet the unique requirements of their clients. This allows for the creation of innovative and eye-catching packaging solutions that can help products stand out on store shelves and attract consumer attention. In addition, the machine's high production capacity means that large orders can be fulfilled quickly and efficiently, making it a valuable asset for packaging companies with high-volume production needs.In addition to its advanced production capabilities, the Corrugated Sheet Making Machine is also designed with sustainability in mind. It is equipped with energy-saving features that reduce electricity consumption and minimize waste, making it an environmentally friendly solution for packaging manufacturers. This aligns with the company's commitment to sustainability and responsible manufacturing practices, ensuring that their machinery not only meets industry standards but also contributes to a more sustainable future for the packaging industry.The company behind the Corrugated Sheet Making Machine is a renowned manufacturer of packaging machinery, known for its innovative solutions and commitment to quality. With decades of experience in the industry, the company has earned a reputation for excellence and reliability, delivering machinery that meets the evolving needs of packaging manufacturers around the world. Their dedication to innovation and customer satisfaction has made them a trusted partner for businesses seeking cutting-edge solutions for their packaging production needs.The introduction of the Corrugated Sheet Making Machine represents a significant milestone for the company, demonstrating their continued investment in research and development to bring new and improved machinery to the market. This latest innovation is a testament to their ongoing commitment to driving progress in the packaging industry and providing packaging manufacturers with the tools they need to succeed in an increasingly competitive market.As the demand for sustainable packaging solutions continues to grow, the Corrugated Sheet Making Machine is set to play a pivotal role in meeting this demand and empowering packaging manufacturers to create innovative, eco-friendly packaging solutions. With its advanced technology, customizable production capabilities, and commitment to sustainability, this machine is poised to reshape the future of packaging production, setting new standards for efficiency, quality, and environmental responsibility.In conclusion, the Corrugated Sheet Making Machine represents a game-changing innovation for the packaging industry, offering packaging manufacturers a state-of-the-art solution for producing high-quality corrugated sheets. With its advanced technology, customizable production capabilities, and sustainability features, this machine is set to drive progress in the packaging industry and meet the growing demand for eco-friendly packaging solutions. The company's dedication to innovation and customer satisfaction has once again set a new standard for excellence in the packaging machinery market, demonstrating their commitment to empowering businesses with the tools they need to succeed.