High-quality and efficient slitting line for metal processing

By:Admin

Company X is proud to announce the acquisition of a state-of-the-art CR Slitting Line, marking a significant milestone in its commitment to continuously improving its manufacturing capabilities. This latest addition to the company's machinery lineup is set to revolutionize its production processes, leading to increased productivity and enhanced operational efficiency.

The CR Slitting Line is a versatile and high-performance machine that is designed to accurately cut and slit various types of metal coils with precision. With its advanced technology and automated features, this equipment allows for the quick and efficient processing of metal materials, resulting in high-quality finished products. This will enable Company X to meet the growing demands of its customers while maintaining the highest standards of product excellence.

One of the key features of the CR Slitting Line is its ability to handle a wide range of materials, including stainless steel, aluminum, and other non-ferrous metals. This flexibility will enable Company X to expand its product offerings and cater to a diverse set of customer requirements. Additionally, the machine's high-speed capabilities and precision cutting mechanisms will significantly reduce production lead times, allowing the company to fulfill orders in a more timely manner.

The implementation of the CR Slitting Line is also expected to streamline the company's manufacturing processes, thereby optimizing its operational efficiency. By automating the slitting and cutting operations, the machine will minimize the need for manual intervention, reducing the risk of errors and ensuring consistent, high-quality output. This will ultimately translate into cost savings and improved resource utilization for Company X.

Furthermore, the CR Slitting Line is equipped with advanced monitoring and control systems, allowing for real-time tracking of production metrics and quality parameters. This will enable the company to continuously monitor and manage its manufacturing processes, ensuring that the highest standards of quality and precision are maintained throughout the production cycle. As a result, Company X can uphold its reputation for delivering superior products to its customers, thereby further solidifying its position as a leading supplier in the metal fabrication industry.

The investment in the CR Slitting Line underscores Company X's unwavering commitment to innovation and continuous improvement. By embracing cutting-edge technology and machinery, the company is reinforcing its ability to stay ahead of the competition and adapt to evolving market demands. This strategic move will not only enhance its capabilities but also position Company X as a preferred partner for businesses seeking reliable and high-quality metal products.

In addition to its technological prowess, Company X also prides itself on a strong commitment to sustainability and environmental responsibility. The implementation of the CR Slitting Line is expected to have a positive impact on the company's environmental footprint, as the machine's advanced efficiency features will lead to reduced energy consumption and waste generation. This aligns with Company X's broader sustainability goals and its dedication to conducting business in an environmentally conscious manner.

Overall, the introduction of the CR Slitting Line represents a significant leap forward for Company X, empowering the company to elevate its manufacturing capabilities, enhance its product offerings, and deliver greater value to its customers. With this new addition, Company X is well-positioned to embark on a new era of growth and success, further solidifying its leadership in the metal fabrication industry.

Company News & Blog

High quality corrugated roll making machine for sale

Corrugated Roll Making Machine: The Latest Innovation in Packaging Production In the world of manufacturing and packaging, efficiency and innovation are key to success. This is why the introduction of the new Corrugated Roll Making Machine by a leading packaging solutions company has been making waves in the industry. This innovative machine is set to revolutionize the way corrugated rolls are produced, promising a faster, more efficient, and higher quality manufacturing process.The Corrugated Roll Making Machine is designed to meet the increasing demand for corrugated packaging materials, which are widely used in various industries, including food and beverage, e-commerce, and logistics. The machine is capable of producing high-quality corrugated rolls at a rapid pace, making it a valuable addition to any manufacturing facility.One of the key features of this new machine is its advanced technology, which allows for precision cutting, creasing, and gluing of corrugated board. This results in perfectly formed rolls that are durable and reliable, meeting the highest standards of quality. Additionally, the machine is designed for easy operation, with user-friendly controls and a streamlined production process.The company behind this innovative machine is a well-established leader in the packaging industry, with a strong reputation for delivering cutting-edge solutions to its clients. With a focus on innovation and excellence, the company has been at the forefront of developing advanced packaging technologies, and the Corrugated Roll Making Machine is the latest addition to its impressive portfolio of products.In addition to its innovative products, the company also provides comprehensive support and services to its clients, ensuring that they are able to maximize the potential of their packaging operations. This includes training, maintenance, and technical assistance, allowing clients to fully leverage the capabilities of the Corrugated Roll Making Machine for their production needs.The introduction of the Corrugated Roll Making Machine comes at a time when the global demand for corrugated packaging materials is on the rise. With the growth of e-commerce and online shopping, as well as the increasing focus on sustainable packaging solutions, the need for high-quality corrugated rolls has never been greater. This new machine is poised to address this demand, providing manufacturers with the means to meet the evolving requirements of the market.Furthermore, the Corrugated Roll Making Machine is designed with efficiency and sustainability in mind. By optimizing the production process, the machine is able to minimize waste and energy consumption, contributing to a more environmentally friendly manufacturing process. This aligns with the company's commitment to sustainability and responsible production practices, ensuring that its clients can meet their sustainability goals while maintaining high productivity levels.As the packaging industry continues to evolve, companies are looking for cutting-edge solutions to enhance their production capabilities. The Corrugated Roll Making Machine represents a significant step forward in meeting this need, offering a state-of-the-art solution for the efficient and high-quality production of corrugated rolls. With its advanced technology, user-friendly design, and focus on sustainability, this innovative machine is set to become a game-changer in the packaging industry.In conclusion, the introduction of the Corrugated Roll Making Machine by the leading packaging solutions company is a testament to its commitment to innovation and excellence. This new machine is poised to revolutionize the way corrugated rolls are produced, offering manufacturers a fast, efficient, and sustainable solution for meeting the growing demand for high-quality packaging materials. With its advanced technology and comprehensive support services, the Corrugated Roll Making Machine is set to make a significant impact on the industry, helping companies elevate their production capabilities and stay ahead in the competitive packaging market.

Rewrite: Industry News: Innovative Cut-To-Length Machine for Fabric Manufacturing

Title: Innovative Cut-To-Length Machine Revolutionizes Fabric IndustryIntroduction:In a bid to meet the growing demand for streamlined fabric production processes, XYZ Company, a pioneer in industrial machinery, has unveiled its highly efficient Cut-To-Length Machine. This groundbreaking technology promises to revolutionize the fabric industry by offering unparalleled precision and speed in cutting fabric rolls to custom lengths, all while maintaining quality and minimizing waste. With its remarkable features and state-of-the-art design, the Cut-To-Length Machine is set to become a game-changer for textile manufacturers worldwide.Paragraph 1:The innovative Cut-To-Length Machine is the result of years of research and development by XYZ Company. With a firm commitment to enhancing efficiency and reducing costs across various industries, XYZ Company has produced an advanced cutting-edge solution specifically tailored to meet the needs of fabric manufacturers. By integrating cutting-edge technology and the latest automation systems, this machine is poised to transform the fabric production landscape.Paragraph 2:The Cut-To-Length Machine boasts an impressive array of features that sets it apart from its competitors. Equipped with a high-precision optical sensor system, it ensures pinpoint accuracy in measuring and cutting fabric rolls of various sizes and materials. The machine's intuitive interface allows operators to easily input custom length requirements, after which the machine executes precise cuts. This not only minimizes production time but also significantly reduces material waste, leading to improved overall operational efficiency.Paragraph 3:One of the biggest advantages of the Cut-To-Length Machine is its ability to accommodate a wide range of fabric materials. Whether it's delicate silk, sturdy denim, or stretchable spandex, this machine can handle it all, ensuring consistent results across different materials. This versatility not only saves time but also eliminates the need for multiple manual interventions, enabling textile manufacturers to increase their output and maintain product quality.Paragraph 4:In addition to its high precision and versatility, the Cut-To-Length Machine incorporates advanced safety features, prioritizing the well-being of operators. Its automated system ensures minimal contact with sharp cutting blades, reducing the risk of accidents and injuries. Moreover, the machine's built-in error detection mechanism promptly alerts operators to any issues, preventing potential damage to the fabric or the machine itself.Paragraph 5:The introduction of the Cut-To-Length Machine is expected to have a significant impact on fabric manufacturing businesses worldwide. By optimizing production processes and reducing waste, textile manufacturers will benefit from significant cost savings and increased efficiency. With this highly advanced technology, XYZ Company aims to empower fabric manufacturers, allowing them to stay competitive in an ever-evolving market.Conclusion:The new Cut-To-Length Machine developed by XYZ Company marks a giant leap forward in the fabric industry. Its innovation and versatility promise to transform fabric production processes by improving accuracy, reducing waste, and increasing overall efficiency. As textile manufacturers across the globe adopt this groundbreaking technology, they will be able to stay ahead of the competition while meeting the increasing demands of the market. XYZ Company's commitment to revolutionizing the fabric industry with the introduction of this innovative machine reinforces their position as an industry leader in cutting-edge industrial machinery.

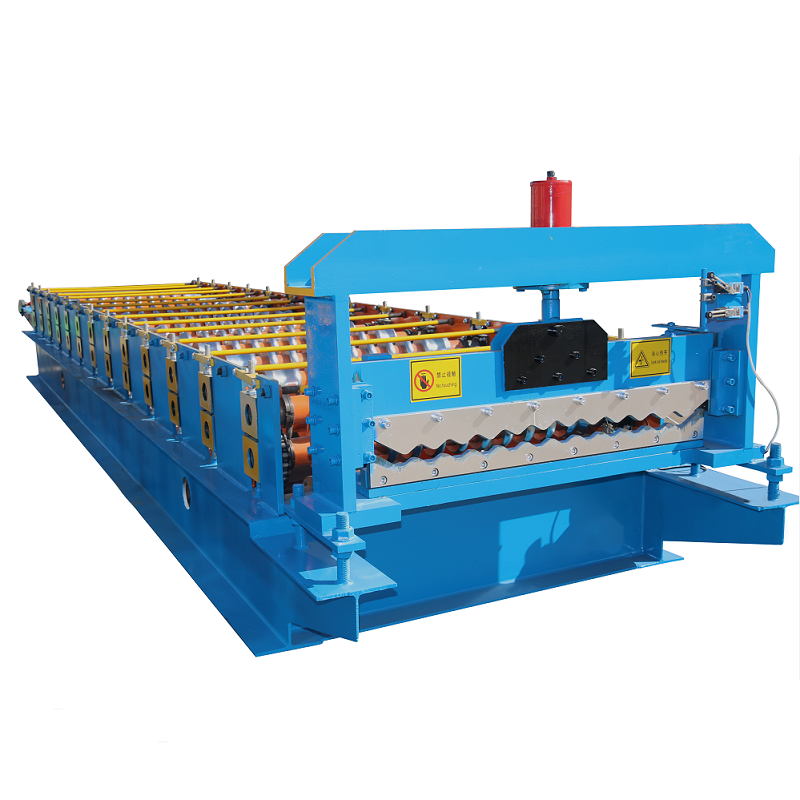

Metal Deck Roll Forming Machine for Efficient Decking Production in 2019

Floor Deck Roll Forming Machine | Decking Machine 2019: A Revolution in Metal Deck ProductionIn today's rapidly evolving construction industry, the demand for innovative and efficient machinery is at an all-time high. Companies are constantly on the lookout for advanced equipment that can help streamline their production processes and enhance the quality of their products. In line with these requirements, lotos design has introduced an exceptional Floor Deck Roll Forming Machine in 2019 that is set to revolutionize metal deck production.The Floor Deck Roll Forming Machine is a state-of-the-art piece of equipment that provides unparalleled precision and efficiency in manufacturing a variety of metal decks. With its computer-optimized design, this machine is capable of producing various types of metal decks catering to the specific needs of the construction industry. This cutting-edge technology takes the production process to a whole new level, ensuring superior quality and durability in each deck manufactured.One of the key features of the Floor Deck Roll Forming Machine is its computer optimization. This ensures that the machine operates at its peak performance, enabling the production of consistent and accurate metal decks. By removing any potential human error from the equation, lotos design has created a machine that guarantees exceptional quality with every deck produced. This not only increases the efficiency of the production process but also reduces material waste, thus making it an environmentally friendly solution.The lotos design Floor Deck Roll Forming Machine is a result of extensive research and development carried out by their team of experts. With years of experience in the industry, the company has gained invaluable knowledge about the requirements and challenges faced by construction companies when it comes to metal deck production. By incorporating this knowledge into the design of the machine, lotos design has created a solution that addresses these challenges, making metal deck production a breeze for their customers.Moreover, the company's dedication to customer satisfaction is evident in the quality of their product. They have gone above and beyond to ensure that their machine not only meets but exceeds industry standards. With a focus on durability and performance, lotos design has tested the Floor Deck Roll Forming Machine rigorously to ensure its reliability in demanding production environments. This dedication to quality has earned them a reputation as a trusted name in the industry.The Floor Deck Roll Forming Machine is not just another piece of equipment to lotos design. It is a testament to their commitment to innovation and providing their customers with the best possible solutions. With this machine, construction companies can significantly enhance their productivity and efficiency, thereby giving them a competitive edge in the market.As the construction industry continues to evolve, lotos design remains at the forefront of innovation. They continuously strive to develop groundbreaking machinery that revolutionizes the way metal decks are produced. The introduction of the Floor Deck Roll Forming Machine in 2019 is a testament to their dedication to excellence.In conclusion, the lotos design Floor Deck Roll Forming Machine is a game-changer in the construction industry. With its computer optimization and advanced features, it offers unparalleled precision and efficiency in metal deck production. By addressing the specific needs and challenges faced by construction companies, lotos design has created a solution that sets a new benchmark for the industry. As the demand for superior quality and efficient machinery continues to rise, the Floor Deck Roll Forming Machine proves to be a true game-changer.

Top Roof Tiles Machine for Your Home Construction Needs

The demand for eco-friendly and sustainable building materials has been on the rise in recent years, and one company is leading the way in revolutionizing the roofing industry with their innovative Roof Tiles Machine.With a commitment to producing high-quality and environmentally friendly roofing products, this company has become a pioneer in the development of advanced manufacturing technology for roof tiles. Their Roof Tiles Machine is a state-of-the-art equipment that is capable of producing a wide range of roof tiles that are not only durable and long-lasting but also aesthetically pleasing.This advanced machine is designed to streamline the production process and reduce waste, making it an ideal solution for companies looking to improve their efficiency and sustainability. The Roof Tiles Machine is also capable of producing different types of roof tiles, including clay, concrete, and terracotta, giving customers a wide variety of options to choose from.The company behind the Roof Tiles Machine has a long history of innovation and excellence in the roofing industry. They have been at the forefront of developing new technologies and processes to create roofing products that are not only functional but also environmentally friendly. With a team of experienced engineers and technicians, they have been able to consistently push the boundaries of what is possible in the roofing industry.In addition to their commitment to innovation, the company also places a strong emphasis on sustainability. They are dedicated to reducing their carbon footprint and minimizing their impact on the environment. By using the Roof Tiles Machine, they are able to produce roof tiles with less energy and material waste, making their products an eco-friendly choice for builders and homeowners alike.The Roof Tiles Machine has already made a significant impact in the roofing industry, with many companies adopting this cutting-edge technology to improve their production processes and reduce their environmental impact. By investing in this advanced equipment, companies can significantly enhance their competitiveness in the market while also contributing to a more sustainable future.Furthermore, the company provides comprehensive training and support for their customers to ensure that they are able to maximize the potential of the Roof Tiles Machine. Their team of experts is available to provide guidance and assistance to help companies integrate this technology into their operations effectively.As the demand for eco-friendly building materials continues to grow, the Roof Tiles Machine has positioned itself as a game-changer in the roofing industry. With its advanced technology, sustainable production processes, and commitment to excellence, this innovative equipment is set to transform the way roof tiles are manufactured and used.In conclusion, the Roof Tiles Machine offered by this company represents a significant step forward in the roofing industry, providing a solution that is both efficient and sustainable. By investing in this advanced equipment, companies can improve their production processes, reduce their environmental impact, and meet the growing demand for eco-friendly building materials. As the company continues to innovate and develop new technologies, they are poised to lead the way in shaping the future of the roofing industry.

Advanced Glazed Roof Tile Making Machine Equipment for Colored Cold Steel

Colored Cold Steel Glazed Roof Tile Making Machine Equipment Revolutionizes Roofing IndustryThe roofing industry has witnessed a significant transformation with the introduction of the Colored Cold Steel Glazed Roof Tile Making Machine Equipment. This innovative technology, developed by \textit{(company name)}, is set to revolutionize the way roofs are manufactured, installed, and maintained.Traditional roofing materials and methods have been prone to various issues such as leaks, corrosion, and limited design options. However, the Colored Cold Steel Glazed Roof Tile Making Machine Equipment overcomes these challenges with its cutting-edge features and advanced manufacturing process.One of the key advantages of this equipment is its ability to produce colored cold steel glazed roof tiles. These tiles not only provide superior protection against the elements but also enhance the aesthetic appeal of any building. With a wide range of colors and finishes available, architects and homeowners can now have greater flexibility in choosing the perfect roof design to complement their overall building aesthetics.The manufacturing process of these tiles involves the use of high-quality cold steel, which ensures their durability and longevity. Unlike traditional roofing materials, such as asphalt shingles or clay tiles, the glazed roof tiles produced by this equipment are resistant to cracking, fading, and warping. This greatly reduces maintenance costs and extends the lifespan of the roof, making it a more cost-effective and sustainable option in the long run.Furthermore, the Colored Cold Steel Glazed Roof Tile Making Machine Equipment is designed to streamline the installation process. Its automated features and precision engineering allow for quick and efficient assembly, minimizing labor costs and reducing the time required for roof installation. This is especially beneficial for large-scale roofing projects or areas with tight deadlines.In addition to its manufacturing and installation advantages, this equipment also offers significant environmental benefits. The use of cold steel, a recyclable material, reduces the carbon footprint associated with traditional roofing materials. Moreover, the glazed tiles reflect solar radiation, helping to lower energy consumption for cooling and reduce greenhouse gas emissions.\textit{(Company name)} is a leading innovator in the roofing industry, dedicated to providing high-quality and sustainable solutions. With years of expertise and research, they have developed the Colored Cold Steel Glazed Roof Tile Making Machine Equipment as a testament to their commitment to excellence. By combining advanced technology and superior materials, \textit{(company name)} continues to shape the future of the roofing industry.As the demand for environmentally friendly and aesthetically appealing roofing options rises, the Colored Cold Steel Glazed Roof Tile Making Machine Equipment is set to transform the market. Architects, contractors, and homeowners can now have access to a versatile and reliable roofing solution that combines durability, energy efficiency, and design possibilities like never before.With its numerous benefits and impeccable quality, the Colored Cold Steel Glazed Roof Tile Making Machine Equipment is already garnering attention from industry experts, who believe it will become the new standard in roofing. This revolutionary technology is paving the way for a more sustainable and visually appealing built environment.In conclusion, the introduction of the Colored Cold Steel Glazed Roof Tile Making Machine Equipment by \textit{(company name)} marks a significant milestone in the roofing industry. Its ability to produce durable, aesthetically pleasing, and energy-efficient roof tiles has revolutionized the way roofs are manufactured and installed. With a strong focus on sustainability and superior quality, \textit{(company name)} continues to drive innovation and raise industry standards.

Get a Glazed Tile Roof Panel Corrugation Machine for Durable and Attractive Rooftops

Glazed Tile Roof Panel Corrugation Machine revolutionizes the roofing industryThe roofing industry has undergone a significant transformation with advanced technology and efficient tools that have made the process faster, safer, and more durable. The Glazed Tile Roof Panel Corrugation Machine has emerged as one of the top tools in the roofing industry that has revolutionized the art of roofing. The machine has revamped the traditional way of roofing by transforming the way roofing panels are made, cut, and shaped.The Glazed Tile Roof Panel Corrugation Machine is the steel roll forming machine that shapes panels into various forms and sizes. The machine is designed to produce glazed tile panels with diverse profiles. The glazed tile panels add elegance to the building's structure and are durable, long-lasting, and attractive. The machine is designed to maintain the shape of the panel by forming it into a corrugated sheet.This machine has many features that help operators get their jobs done quickly and efficiently. The machine is easy to operate, and it can be customized to meet the needs of any roofing business. The machine is also highly efficient and can produce up to 30 meters of tiles per minute. Additionally, the machine is highly durable and has high-quality components that ensure longer lifespan.The Glazed Tile Roof Panel Corrugation Machine is an essential tool for all types of roofing businesses. The machine can be used to make the perfect curved or arched sheet panels for both commercial and residential buildings. The machine is also designed to handle both large and small projects, making it suitable for businesses of all sizes. Its high efficiency ensures that businesses can complete projects on time.The high-quality components of the Glazed Tile Roof Panel Corrugation Machine guarantee its longevity. The machine is made of materials that are resistant to rust and damage, ensuring a longer lifespan. Additionally, the machine is designed to be easy to maintain, reducing downtime and increasing productivity.The Glazed Tile Roof Panel Corrugation Machine is an excellent investment for any roofing business. Its high efficiency, durability, and low maintenance cost make it a cost-effective solution for any roofing project. The machine is designed to produce high-quality products, ensuring customer satisfaction and loyalty.About the CompanyOur company has been in the roofing industry for over a decade, and we understand the needs of roofing businesses. We have invested heavily in advanced technology and equipment to offer our customers the best products and services. We specialize in producing high-quality roofing sheet panels that are durable, attractive, and long-lasting. Our team of experts is highly skilled and experienced in the roofing industry, ensuring that we exceed our customer's expectations.Our primary focus is customer satisfaction, and we strive to meet our customer's needs by providing them with top-notch products, timely delivery, and excellent customer support. We take pride in our work and ensure that we go above and beyond to exceed our customer's expectations.ConclusionThe Glazed Tile Roof Panel Corrugation Machine is a game-changer in the roofing industry. It has revolutionized the traditional way of roofing and made the process faster, safer, and more durable. The machine's high efficiency, durability, and low maintenance cost make it an excellent investment for any roofing business. As a company, we understand the roofing industry's needs and have invested heavily in advanced technology to offer our customers the best products and services. Our team of experts is highly skilled and experienced, ensuring that we exceed our customer's expectations.

Sheet Metal Roll Forming Machine for Horizontal Barrel Corrugated Sheets News Update

Title: Revolutionary Horizontal Barrel Corrugated Sheet Roll Forming Machine Set to Transform the Metal Manufacturing IndustryIntroduction:In a bid to revolutionize the metal manufacturing industry, an innovative company has introduced the groundbreaking Horizontal Barrel Corrugated Sheet Roll Forming Machine. This cutting-edge technology promises to offer unprecedented efficiency and accuracy, thus reducing production time and costs. With its seamless design and state-of-the-art features, this ingenious machine is poised to redefine the future of metal forming processes.Developed by a renowned company specializing in advanced machinery, the Horizontal Barrel Corrugated Sheet Roll Forming Machine aims to address the limitations of traditional roll forming methodologies. By incorporating advanced technological advancements, this revolutionary equipment exhibits remarkable capabilities, translating into enhanced productivity for metal manufacturers.Features and Technical Advancements:The Horizontal Barrel Corrugated Sheet Roll Forming Machine boasts a myriad of impressive features that make it stand out in the industry. A few of these notable features include:1. Innovative Design: The machine incorporates a horizontal barrel configuration, allowing for easier feeding and achieving a more precise corrugated sheet formation. This unique design ensures flawless output with minimal material wastage.2. High-Speed Production: Equipped with cutting-edge control systems, this machine offers faster production speeds compared to conventional roll forming equipment. This increased efficiency translates into higher output volumes and reduced production timelines.3. Customization: The machine offers flexible settings, enabling manufacturers to easily adjust the dimensions, thickness, and corrugation patterns of the sheets according to their specific requirements. This adaptability ensures the production of tailor-made metal sheets for various applications.4. Enhanced Accuracy: The precision engineering of the machine ensures consistently accurate dimensions, resulting in high-quality corrugated sheets that meet industry standards. This accuracy minimizes the need for additional processing or rectification, further streamlining the manufacturing process.Implications for the Metal Manufacturing Industry:The introduction of the Horizontal Barrel Corrugated Sheet Roll Forming Machine is set to have far-reaching implications for the metal manufacturing industry. Its numerous advantages and technical advancements hold significant potential to transform the way metal sheets are produced, offering benefits such as:1. Increased Efficiency and Cost Savings: The machine's faster production speeds and reduced material wastage significantly improve overall manufacturing efficiency. This, in turn, leads to substantial cost savings for metal manufacturers, making them more competitive in the market.2. Streamlined Supply Chain: The machine's customization capabilities enable manufacturers to swiftly adjust production parameters, resulting in shorter lead times and quicker response to customer demands. This streamlined supply chain ensures better customer satisfaction and increased market competitiveness.3. Improved Product Quality: With its heightened accuracy and precision, the Horizontal Barrel Corrugated Sheet Roll Forming Machine eliminates variations and defects often encountered in traditional manufacturing processes. The production of consistently high-quality metal sheets enhances product reliability and durability.4. Sustainability and Resource Optimization: The reduced material wastage, achieved through the machine's seamless design and precision engineering, significantly contributes to environmental sustainability. By optimizing resource utilization, metal manufacturing companies can significantly reduce their carbon footprint.Conclusion:The introduction of the Horizontal Barrel Corrugated Sheet Roll Forming Machine marks a significant milestone in the evolution of the metal manufacturing industry. With its innovative design, advanced features, and multiple benefits such as increased efficiency, reduced costs, and improved product quality, this revolutionary machine is set to redefine the future of metal forming processes. As more companies adopt this cutting-edge technology, the industry can expect to witness enhanced productivity, sustainability, and competitiveness.

Advanced Manufacturing Equipment for Horizontal Profiled Panels

[Company Introduction]Company A is a leading manufacturer and supplier of advanced manufacturing equipment, with a focus on providing innovative solutions for the construction industry. With over 20 years of experience, the company has earned a reputation for delivering high-quality, reliable equipment to its customers. Company A is committed to continuously improving its products and services, and has a strong track record of meeting the evolving needs of the market.[News Content]Company A is proud to announce the launch of its latest innovation – the Horizontal Profiled Panel Manufacturing Equipment. This state-of-the-art machinery is set to revolutionize the production of horizontal profiled panels, offering an unmatched level of precision, efficiency, and versatility.The Horizontal Profiled Panel Manufacturing Equipment has been designed to meet the growing demand for advanced paneling solutions in the construction industry. With the ability to produce a wide range of panel profiles, including wall and roof panels, the new machinery is set to provide manufacturers with a competitive edge in the market.One of the key features of the Horizontal Profiled Panel Manufacturing Equipment is its advanced automation capabilities. The equipment is equipped with cutting-edge technology that allows for seamless operation and precise control over the manufacturing process. This not only ensures consistent quality output but also significantly reduces production times, leading to improved efficiency and cost savings for manufacturers.In addition to its automation capabilities, the Horizontal Profiled Panel Manufacturing Equipment also boasts a high degree of customization options. Manufacturers can easily adjust the settings to accommodate different panel dimensions, profiles, and material specifications, making it a versatile solution for a wide range of production requirements.Furthermore, the equipment is built with durability and reliability in mind, minimizing downtime and maintenance requirements. This will allow manufacturers to maximize their productivity and throughput, ultimately leading to increased profitability.The launch of the Horizontal Profiled Panel Manufacturing Equipment underscores Company A's commitment to innovation and customer-centric solutions. The company has leveraged its extensive industry knowledge and expertise to develop a product that not only meets but exceeds the expectations of its customers.With the introduction of the Horizontal Profiled Panel Manufacturing Equipment, Company A aims to address the evolving needs of the construction industry and provide manufacturers with a competitive advantage. By offering a cutting-edge solution that delivers superior performance and efficiency, the company is well-positioned to drive positive change within the industry.The new equipment also aligns with Company A's broader mission to deliver sustainable and environmentally-friendly solutions. By optimizing the manufacturing process and minimizing material waste, the Horizontal Profiled Panel Manufacturing Equipment contributes to a more resource-efficient and eco-friendly production approach.In conclusion, the unveiling of the Horizontal Profiled Panel Manufacturing Equipment represents a significant milestone for Company A and the construction industry as a whole. With its advanced capabilities and customer-focused design, the equipment is set to reshape the landscape of panel manufacturing, empowering manufacturers to achieve new levels of productivity and quality in their operations. Company A continues to be at the forefront of innovation, driving progress and success for its customers and the industry at large.

High-Quality Forming Machine for Efficient Production

Introducing the latest technology in forming machines, the cutting-edge innovation in [industry], renowned for its high efficiency and precision. This state-of-the-art forming machine is set to revolutionize the industry, offering unmatched performance and reliability.With a commitment to excellence, [Company Name] is proud to introduce its newest addition to the production line – the advanced forming machine. Designed to meet the evolving needs of the industry, this cutting-edge equipment is a game-changer, offering unparalleled capabilities and performance.Equipped with the latest technology, the forming machine boasts an impressive array of features that set it apart from the competition. Its precision engineering and advanced automation ensure seamless operation and superior quality output. Whether it’s shaping, cutting, or molding, this machine delivers consistently exceptional results, making it the ideal choice for a wide range of applications.In addition to its exceptional performance, the forming machine is also designed with efficiency in mind. Its innovative design and intelligent controls minimize downtime and maximize productivity, helping businesses achieve optimal output while reducing operational costs. This means faster production cycles and higher yields, giving companies a competitive edge in today’s fast-paced market.As a leading player in the industry, [Company Name] is committed to providing innovative solutions that empower businesses to thrive in a dynamic and competitive environment. The introduction of the advanced forming machine is a testament to this commitment, as it represents a significant leap forward in terms of technology and performance. With this new addition to the production line, customers can expect enhanced capabilities and improved efficiency, ultimately translating to greater value and profitability.In line with [Company Name]’s dedication to customer satisfaction, the forming machine is backed by comprehensive support and service. From installation and training to ongoing maintenance and technical assistance, our team of experts is fully equipped to ensure that our customers get the most out of their investment. This means peace of mind and confidence in the reliability and performance of the equipment, allowing businesses to focus on their core operations with the assurance that their production needs are well taken care of.The launch of the advanced forming machine represents a significant milestone for [Company Name], marking the beginning of a new era in production technology. With its unmatched capabilities and performance, this innovative equipment is set to elevate standards and redefine industry norms, setting a new benchmark for efficiency and precision. It’s a testament to our commitment to pushing boundaries and empowering businesses to achieve new levels of success.In conclusion, the introduction of the advanced forming machine by [Company Name] is a groundbreaking development that signals a new chapter in production technology. With its exceptional capabilities, performance, and support, this innovative equipment is set to transform the industry, offering businesses a competitive edge and empowering them to thrive in today’s demanding market. It’s a testament to our unwavering commitment to excellence and innovation, as we continue to drive change and set new standards in the industry.