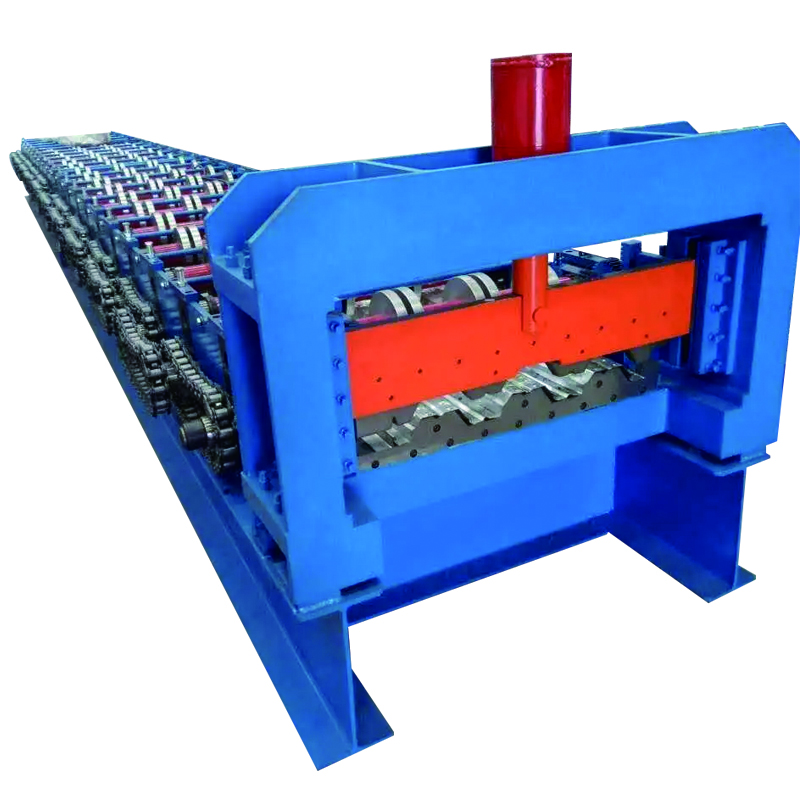

High-Quality Capping Roll Forming Machine for Efficient Production

By:Admin

The construction industry is constantly evolving, and with it, the demand for innovative and efficient machinery continues to grow. One such innovation that has recently made waves in the industry is the Capping Roll Forming Machine, a revolutionary solution that has the potential to transform the way construction companies operate.

The Capping Roll Forming Machine, developed by a pioneering manufacturing company, has been designed to streamline the process of forming capping materials used in construction projects. This state-of-the-art machine is capable of producing high-quality capping materials with precision and efficiency, making it an indispensable tool for construction companies looking to improve their productivity and cost-effectiveness.

The machine is equipped with advanced technology and features that set it apart from traditional roll forming equipment. Its high-speed capabilities and automated operation make it ideal for meeting the demands of large-scale construction projects, allowing companies to maximize their output while minimizing labor and material costs.

In addition to its efficiency, the Capping Roll Forming Machine also boasts a user-friendly interface and intuitive controls, making it accessible to operators of varying skill levels. This ease of use is a significant advantage for construction companies, as it enables them to integrate the machine seamlessly into their operations without the need for extensive training or retooling.

Furthermore, the machine's flexibility and adaptability make it suitable for a wide range of capping materials, including but not limited to metal, aluminum, and steel. This versatility makes it an attractive investment for construction companies with diverse project requirements, as it offers the ability to produce a variety of capping materials without the need for separate machinery.

The company behind the Capping Roll Forming Machine has a strong track record of delivering cutting-edge solutions to the construction industry. With a commitment to research and development, as well as a dedication to meeting the needs of their customers, they have established themselves as a trusted partner for construction companies seeking to modernize their operations.

In addition to their innovative products, the company also offers comprehensive support and maintenance services, ensuring that their customers can maximize the performance and longevity of their machinery. This commitment to customer satisfaction has earned them a reputation for reliability and excellence in the industry.

Looking ahead, the Capping Roll Forming Machine is poised to make a significant impact on the construction industry. As companies continue to seek out ways to improve their efficiency and competitiveness, this revolutionary solution offers a compelling opportunity to modernize their operations and stay ahead of the curve.

In conclusion, the Capping Roll Forming Machine represents a groundbreaking advancement in the construction industry, with the potential to revolutionize the way capping materials are produced. With its advanced technology, efficiency, and versatility, it is set to become an indispensable tool for construction companies looking to enhance their productivity and cost-effectiveness. Combined with the company's dedication to innovation and customer satisfaction, the Capping Roll Forming Machine is poised to make a lasting impact on the industry for years to come.

Company News & Blog

Metal Sheet Roof Roll Forming Machine: A Guide to Efficient Roof Panel Production

Metal Sheet Roof Roll Forming Machine Revolutionizes Roofing IndustryInnovative and high-performance metal sheet roof roll forming machines have emerged as game-changers in the roofing industry. These state-of-the-art machines offer an efficient and cost-effective solution for producing metal roofs, catering to the rising demand for sustainable and durable roofing materials. With advanced technology, precision engineering, and seamless operations, this machinery is transforming the construction landscape.Metal roofs have gained immense popularity due to their superior strength, longevity, and aesthetic appeal. They provide excellent protection against extreme weather conditions, including hail, wind, and fire. Recognizing the growing demand for metal roofs, companies have dedicated their efforts to developing advanced manufacturing equipment. Among them, the metal sheet roof roll forming machine has emerged as a leader, revolutionizing the production process.The secret to the success of the metal sheet roof roll forming machine lies in its efficient and automated operation. This cutting-edge equipment can accurately shape metal sheets into various roofing profiles, such as standing seam, corrugated, and trapezoidal roofs. The machine itself is composed of a series of rollers and dies that progressively bend and shape the metal sheet into the desired profile. With precise measurements and consistent quality, these machines can produce roof panels with high dimensional accuracy.One of the key advantages of these machines is their versatility. They can process a wide range of metal sheets, including galvanized steel, aluminum, and copper, ensuring flexibility in design options for architects and homeowners. Furthermore, the metal sheet roof roll forming machines can seamlessly accommodate various widths and thicknesses, allowing for customization based on specific project requirements. This adaptability has positioned these machines at the forefront of the roofing industry.Enhanced operational efficiency is another notable feature of the metal sheet roof roll forming machines. Equipped with advanced computer numerical control (CNC) systems, these machines can effortlessly adjust to different production settings, saving time and reducing material waste. Operators can easily input the required dimensions and specifications, and the machine would automatically make the necessary adjustments. This level of automation significantly increases productivity and reduces human error.The durability and reliability of the metal sheet roof roll forming machines are unmatched. Built with heavy-duty materials and precision-engineered components, these machines offer long-lasting performance with minimal maintenance. They are designed to withstand harsh working environments and operate continuously, ensuring uninterrupted production capabilities for roofing manufacturers.Moreover, manufacturers of metal sheet roof roll forming machines prioritize the safety of operators and the environment. The machines are equipped with safety features such as emergency stop buttons, protective covers, and sensors, ensuring a secure working environment. Additionally, these machines are designed to minimize energy consumption, contributing to sustainable manufacturing practices.Leading the industry in the production of metal sheet roof roll forming machines, {}, has gained international recognition for its cutting-edge technology and commitment to exceptional quality. With an extensive product range, they offer a variety of customizable options to meet the diverse needs of their customers. Their machines have been widely adopted by roofing manufacturers worldwide, enabling them to produce high-quality metal roofs efficiently.In conclusion, metal sheet roof roll forming machines have revolutionized the roofing industry by providing efficient, cost-effective, and sustainable solutions for metal roof production. These machines offer versatility, accuracy, and enhanced operational efficiency, ensuring high-quality metal roofs with precise dimensions. With the continuous advancements in technology and the commitment of manufacturers, metal sheet roof roll forming machines are set to reshape the construction landscape, offering architects and homeowners an attractive, durable, and eco-friendly roofing solution.

Standing Seam Roll Forming Machine: Advanced Technology for Efficient Metal Panel Manufacturing

Standing Seam Roll Forming Machine Empowers Companies to Enhance Their OperationsStanding seam roofs have been in demand for their sleek and modern appearance, as well as robust durability. These quintessential roofs require efficient machinery that will produce panels with impeccable precision, swiftly and consistently. With the advancement of technology, several reliable machines have been built, including the Standing Seam Roll Forming Machine, which offers top-notch performance and versatility.This high-quality equipment is designed by an industry-leading company focused on manufacturing roll forming machines with optimal technical support. The company has been in operation for years, and with their vast experience, they have created automated systems that meet their clients' unique needs. This Standing Seam Roll Forming Machine uses excellent technology to whip up roofing panels that are top-performing and visually appealing, which makes it a go-to solution for roofing companies.The Standing Seam Roll Forming Machine is electronically controlled and adjustable, making it efficient for creating panels of various sizes and shapes. It is also highly customizable and can be made to fit specific needs instantly without interfering with the machine's quality performance. It is engineered to handle a range of materials, as well as a vast variety of thicknesses, including aluminum, steel, and copper. Additionally, with the consistency in panel production, companies can save money by reducing waste and increasing productivity.The machine is powered using an electric motor, which makes it less cost-prohibitive due to the low cost of electricity. Further, it requires little in terms of maintenance, and its unique design allows for optimum power consumption by utilizing minimal electricity. With very few moving parts, the machine is straightforward to assemble and use. Also, it is built with high-quality materials, which ensures that it remains durable and lasts an extended period, even with minimal maintenance.The Standing Seam Roll Forming Machine comes with efficient technical support from the manufacturer. The engineers are available to offer technical expertise that assists clients in improving their operations. Moreover, clients receive continuous support in matters related to the machines' maintenance and repairs, and spare parts are readily available.Overall, the Standing Seam Roll Forming Machine is an indispensable asset for any roofing company. It is a smart investment that enhances operations, reduces production costs, and boosts profitability. It is reliable, efficient, and cost-friendly, and it ensures that companies remain competitive in their respective markets. Moreover, it is environmentally friendly due to its low power usage, as well as the ability to reduce waste and increase productivity.In conclusion, companies looking to improve their roofing operations ought to consider investing in the Standing Seam Roll Forming Machine. With a high quality, durable design, and customizable features, this machine provides the kind of precision and speed that will satisfy customers and boost productivity. Thanks to its robust engineering and excellent technical support, it is precisely the equipment that roofing companies need to stay on top of their game in the competitive roofing industry.

Boost Your Roofing Projects with a High-Quality Corrugated Iron Machine

In today's world, where businesses are expanding at a rapid pace, the demand for sturdy and durable construction materials is at an all-time high. Corrugated iron sheets are widely used for roofing and fencing due to their strength and longevity. However, producing these sheets is a tedious and time-consuming task. To ease this process, a state-of-the-art Corrugated Iron Machine was introduced by a renowned company.The machine boasts an innovative design that enables it to produce high-quality corrugated iron sheets quickly and efficiently. Its robust frame is made of high-quality materials to support its heavy-duty operations. The machine's internal structure has been engineered to perfection, ensuring that it operates with minimal wear and tear. Additionally, the machine is fitted with top-of-the-line electrical and mechanical parts to ensure its durability and reliability.The company behind this revolutionary machine is one of the leading manufacturers of industrial equipment for the construction sector. They are known for their cutting-edge machinery, which is designed to streamline construction processes and boost productivity. With years of experience in the industry, they understand their customers' needs and demands and strive to offer them the best possible solutions.The Corrugated Iron Machine's features highlight its versatility and adaptability. It can produce corrugated sheets of varying thickness, length, and width, ensuring that it satisfies the diverse needs of its users. Through a simple yet intuitive interface, the machine can be easily adjusted to accommodate different settings, making it ideal for small and large-scale manufacturers. Moreover, the machine's energy-efficient nature ensures that it consumes minimal electricity, making it an eco-friendly option.One of the primary benefits of the Corrugated Iron Machine is its ability to increase productivity and reduce labour costs. With the traditional method, producing a single corrugated sheet could take hours and required a team of workers. However, with this machine, a single operator can produce up to hundreds of corrugated sheets within a few hours. It is highly beneficial for manufacturers as it enables them to increase their production output while minimizing labour costs.The Corrugated Iron Machine's low maintenance requirement is a testament to its robustness and reliability. The machine has been designed to operate with minimal maintenance. Its internal parts are easily accessible should any maintenance need arise, and its user-friendly interface ensures that operators can carry out routine maintenance without any hassle.The machine's ergonomic design ensures that it is easy to operate and maintain. Its built-in safety features ensure that operators are safe while operating the machine. Additionally, the machine's structure is designed to reduce noise levels, creating a comfortable working environment for the operator.To conclude, the introduction of the Corrugated Iron Machine is a significant milestone for the construction industry. Its ability to produce high-quality corrugated sheets quickly and efficiently has revolutionized the manufacturing process. The machine's durability, low maintenance requirement, and energy-efficient nature not only benefit the user but also the environment. As the demand for sturdy construction materials continues to rise, the Corrugated Iron Machine is sure to be a game-changer, ensuring that manufacturers can keep up with the increasing demand.

High-Quality Standing Seam Roof Machine for Sale - Find Out More Here!

Standing Seam Roof Machine Revolutionizes Roofing IndustryThe roofing industry has experienced a significant transformation with the introduction of the innovative Standing Seam Roof Machine. This state-of-the-art equipment has revolutionized the way metal roofs are installed, offering a more efficient, cost-effective, and aesthetically pleasing solution for residential and commercial properties.The Standing Seam Roof Machine, developed by a leading manufacturing company in the industry, incorporates advanced technology and precision engineering to create high-quality standing seam metal roofs. The machine is designed to streamline the roof panel production process, allowing for faster installation and improved overall performance.One of the key features of the Standing Seam Roof Machine is its ability to produce custom-fit roof panels on-site, eliminating the need for off-site fabrication and reducing lead times significantly. This level of customization ensures a perfect fit for every project, resulting in a seamless and visually appealing finished product.In addition to its efficiency, the Standing Seam Roof Machine also offers cost savings for both contractors and property owners. With the ability to produce roof panels on-demand, there is reduced material waste and lower transportation costs, resulting in overall project cost reduction. This makes standing seam metal roofs more accessible and cost-effective for a wide range of applications.Furthermore, the Standing Seam Roof Machine is compatible with a variety of metal materials, including steel, aluminum, and copper, providing versatility in design and durability. This allows for greater design flexibility and the ability to match the aesthetic of any architectural style.The company behind the Standing Seam Roof Machine has a strong reputation for delivering high-quality and reliable equipment to the roofing industry. With a dedication to innovation and customer satisfaction, the company has become a trusted leader in the manufacturing of roofing machinery and equipment.The company's commitment to quality is evident in the Standing Seam Roof Machine, which is built to withstand the demands of the roofing environment. The machine is constructed with durable materials and undergoes rigorous testing to ensure long-term performance and reliability.In addition to the machine itself, the company provides comprehensive training and support for contractors and installers to ensure successful implementation and operation of the Standing Seam Roof Machine. This includes on-site training, technical support, and ongoing maintenance services, allowing for a seamless integration into existing roofing businesses.The introduction of the Standing Seam Roof Machine has generated significant interest and excitement within the roofing industry. Contractors, architects, and property owners alike are recognizing the many benefits of standing seam metal roofs, and the machine's efficiency and cost savings are making it an increasingly popular choice for new construction and retrofit projects.With its cutting-edge technology, precision engineering, and commitment to quality, the Standing Seam Roof Machine is poised to continue leading the transformation of the roofing industry. As the demand for high-performance, durable, and aesthetically pleasing roofing solutions continues to grow, the machine is well-positioned to meet and exceed the needs of the market.Overall, the Standing Seam Roof Machine represents a significant advancement in roofing technology, offering a game-changing solution for metal roof installation. With its efficiency, cost savings, and high-quality results, the machine is redefining the industry standards and setting a new benchmark for excellence in roofing.

China's Top Supplier and Manufacturer of High-Quality Light Keel Roll Forming Machine - Unveiling Impressive Products

Title: Light Keel Roll Forming Machine: Revolutionizing the Construction IndustryIntroductionIn recent years, the construction industry has witnessed a significant shift towards efficient and cost-effective building techniques. One innovation that has gained immense popularity is the Light Keel Roll Forming Machine. This advanced machinery has transformed the way light keel components are produced, offering numerous benefits over traditional manufacturing methods. In this blog post, we will explore the remarkable advantages of the Light Keel Roll Forming Machine and delve into its exceptional capabilities.1. Understanding Light Keel Roll Forming MachineThe Light Keel Roll Forming Machine represents the pinnacle of precision manufacturing in the construction industry. Designed by leading manufacturers in China, this machine utilizes cutting-edge technology to create light keel components with remarkable accuracy and efficiency. Unlike manual or semi-automatic forming processes, the Light Keel Roll Forming Machine automates the entire production procedure, eliminating the risk of human error and dramatically reducing time and labor costs.2. Enhanced Efficiency for Increased ProductivityBy implementing the Light Keel Roll Forming Machine, manufacturers can significantly boost their productivity. This machinery can seamlessly produce light keel components by swiftly transforming raw materials, such as steel coils, into precisely shaped profiles. With its high-speed production capability and uninterrupted workflow, the Light Keel Roll Forming Machine ensures a consistent output, meeting project deadlines and increasing overall efficiency.3. Customizable Design CapabilitiesWith the Light Keel Roll Forming Machine, customization options are limitless. Manufacturers can effortlessly adapt the machine's settings to create light keel components of varying lengths, widths, and thicknesses. This adaptability gives construction professionals the freedom to design and construct projects according to their exact specifications. Whether it's for residential, commercial, or industrial purposes, the Light Keel Roll Forming Machine enables the creation of tailor-made light keel structures.4. Unmatched Precision and ConsistencyOne of the key advantages of the Light Keel Roll Forming Machine is its unparalleled precision. The machine operates with meticulous accuracy, ensuring that each light keel component is shaped and cut to perfection. This consistency eliminates the need for additional manual adjustments or reworks, reducing material wastage and enhancing the overall product quality. The Light Keel Roll Forming Machine guarantees the production of uniform components that fit seamlessly within the construction process.5. Cost Savings and Increased ROIBy investing in the Light Keel Roll Forming Machine, manufacturers can experience substantial cost savings throughout the project lifecycle. The efficiency of this machinery drastically reduces labor costs and diminishes the need for additional manual labor. Moreover, the machine's precision minimizes material wastage, optimizing resource utilization and reducing overall expenses. The return on investment for the Light Keel Roll Forming Machine is undoubtedly impressive, making it an attractive option for construction companies of all sizes.ConclusionIn conclusion, the Light Keel Roll Forming Machine presents a revolutionary solution for the construction industry. Its advanced technology, efficiency, precision, and cost-saving benefits make it an invaluable asset for manufacturers worldwide. By harnessing the capabilities of the Light Keel Roll Forming Machine, construction professionals can streamline their production processes, deliver superior quality products, and ultimately remain at the forefront of innovation in the ever-evolving construction sector.Keywords: Light Keel Roll Forming Machine, light keel components, precision manufacturing, increased productivity, customization options, unmatched precision, cost savings, return on investment, construction industry.

Latest News: Powerful Corrugation Machine Unveiled for Color Steel Glazed Tile Roof Panels

Revolutionary Horizontal Profiled Panel Production Line Boosts Efficiency and Quality

Horizontal Profiled Panel Production Line Presents New Innovations in Manufacturing TechnologyWith a continuous focus on innovation and advanced manufacturing solutions, {Company Name}, a leading global provider of industrial machinery, is proud to introduce its state-of-the-art Horizontal Profiled Panel Production Line. This cutting-edge equipment offers significant advancements in the manufacturing process, promising improved efficiency, durability, and flexibility.The Horizontal Profiled Panel Production Line represents the culmination of years of research, development, and expertise in the field of industrial machinery. Designed to meet the diverse needs of various industries, this production line incorporates advanced technologies to streamline the manufacturing process of profiled panels, optimizing productivity and performance.One of the key features of this new production line is its horizontal orientation, which sets it apart from traditional vertical profiled panel lines. This configuration offers numerous benefits, including enhanced stability and balance during the manufacturing process. By utilizing a horizontal layout, {Company Name} has dramatically minimized vibrations and improved accuracy, leading to a significant reduction in material waste and ensuring consistent product quality.Moreover, the Horizontal Profiled Panel Production Line boasts a range of innovative components that further enhance its efficiency. Equipped with precision cutting tools and advanced laser-guided systems, the line ensures the precise and seamless shaping of panels. This precision allows for seamless integration of various profiled panel types, ranging from corrugated and trapezoidal to architectural and decorative panels. Such flexibility enables manufacturers to cater to the specific requirements of their customers while maintaining superior quality standards.The new production line also incorporates cutting-edge automation technologies to streamline the manufacturing process. Integrated robotic systems enable efficient material handling and reduce the need for human intervention, thereby increasing productivity and minimizing the risk of errors. Additionally, real-time monitoring systems and advanced quality control methods ensure continuous feedback and enable timely adjustments, guaranteeing that each panel meets the highest industry standards.In line with {Company Name}'s commitment to sustainability, the Horizontal Profiled Panel Production Line incorporates energy-saving features, reducing power consumption and minimizing the overall environmental impact. Through efficient energy management systems and smart utilization of resources, the line not only fulfills stringent environmental regulations but also enables manufacturers to significantly reduce operational costs.Furthermore, the Horizontal Profiled Panel Production Line is designed with user-friendliness in mind. An intuitive interface and user-friendly controls allow operators to easily navigate the production process, minimizing downtime and maximizing productivity. To ensure seamless integration into existing manufacturing facilities, {Company Name} offers extensive technical support and customization options according to the specific requirements of each customer.As a global leader in industrial machinery, {Company Name} has an extensive presence and a strong track record of delivering high-quality equipment to industries worldwide. The introduction of the Horizontal Profiled Panel Production Line further solidifies the company's commitment to pushing the boundaries of manufacturing technology and providing innovative solutions to its customers.In conclusion, {Company Name}'s revolutionary Horizontal Profiled Panel Production Line represents a significant leap in manufacturing technology. Through its horizontal orientation, innovative components, automation features, sustainability initiatives, and user-friendly design, this production line offers numerous benefits to manufacturers, including improved efficiency, product quality, and customization options. With this cutting-edge equipment, {Company Name} continues to empower industries across the globe to enhance their production capabilities and achieve unparalleled success.

Advanced Roll Forming Machine for Colored Metal Steel Sheets

Title: Innovative Colored Metal Steel Sheet Roll Forming Machine Poised to Revolutionize the Construction IndustryIntroduction:In a significant technological breakthrough, a leading manufacturing company has unveiled a cutting-edge Colored Metal Steel Sheet Roll Forming Machine. The state-of-the-art machinery is set to revolutionize the construction industry by streamlining the process of producing colored metal steel sheets. With unrivaled efficiency and precision, this innovative machine promises to transform the way steel sheets are manufactured and used in various construction applications.I. Background:The manufacturing industry has always been at the forefront of innovation, continuously striving to enhance productivity while maintaining the highest quality standards. The introduction of the Colored Metal Steel Sheet Roll Forming Machine showcases the company's commitment to revolutionize the construction sector by providing advanced solutions to meet market demands.II. Features and Functionality:The Colored Metal Steel Sheet Roll Forming Machine incorporates state-of-the-art technology, boasting a wide range of features that set it apart from conventional machinery. It has been meticulously designed and engineered to offer maximum efficiency, ease of use, and versatility to meet the changing needs of the construction industry.1. Advanced Roll Forming System:The machine employs an advanced roll forming system capable of producing a vast range of colored metal steel sheets. The system ensures high precision and accuracy during the roll forming process, resulting in sheets with consistent shape, dimensions, and surface finish.2. Customizable Profiles:By leveraging the machine's flexible capabilities, users can effortlessly customize various steel sheet profiles to cater to diverse construction requirements. These profiles can be easily adjusted, allowing for quick adaptation to different project specifications.3. Integrated Color Coating System:The Colored Metal Steel Sheet Roll Forming Machine is equipped with a sophisticated color coating system that ensures seamless application of vibrant colors onto the steel sheets. This feature enables the creation of visually appealing and long-lasting colored metal sheets, adding aesthetic value to any construction project.4. Energy-Efficient Operation:The machine incorporates an energy-efficient system that minimizes power consumption while maximizing productivity. This eco-friendly feature not only reduces operating costs but also contributes to a sustainable manufacturing process.III. Benefits and Market Impact:The introduction of the Colored Metal Steel Sheet Roll Forming Machine significantly enhances the overall efficiency and quality of steel sheet production, offering a wide array of benefits to construction professionals and manufacturers alike.1. Improved Productivity:With its advanced technology and streamlined functions, the machine enables faster production cycles, ensuring higher output and reduced lead times. This allows manufacturers to meet escalating market demands while maintaining stringent quality control.2. Cost Savings:The machine's energy-efficient operation and reduced material waste result in significant cost savings for manufacturers. Moreover, the customizable profiles cater to specific project requirements, minimizing material wastage and further optimizing resource utilization.3. Enhanced Durability:The use of high-quality colored metal steel sheets produced by this machine ensures enhanced durability and longevity of constructed structures. These steel sheets are resistant to corrosion, UV radiation, and extreme weather conditions, ensuring long-lasting performance and minimal maintenance costs.4. Aesthetically Pleasing:The availability of vibrant and customizable colors through the color coating system allows architects and designers to unleash their creativity. This feature paves the way for the development of visually appealing buildings and structures, adding value through aesthetic appeal.IV. Conclusion:The introduction of the Colored Metal Steel Sheet Roll Forming Machine signifies a groundbreaking leap forward in the construction industry. With its advanced technology and unmatched efficiency, this innovative machine promises to revolutionize the manufacturing of colored metal steel sheets, providing construction professionals with high-quality, customizable, and visually appealing solutions. As this technology gains traction, it is expected to reshape the construction landscape by empowering architects, engineers, and contractors to construct remarkable buildings that stand the test of time.

Innovative Roll Making Machine for Improved Production Efficiency

Roll making machine is an important piece of equipment in the manufacturing industry. It is used to produce various types of rolls that are essential in the production of a wide range of products, including paper, plastic, textiles, and metal sheets.One company that has been leading the way in the development and production of roll making machines is {}. With over 20 years of experience in the industry, they have become a trusted name in the market and have earned a reputation for delivering high-quality, reliable, and efficient machines.The roll making machines produced by {} are known for their advanced technology, precision engineering, and durable construction. They are designed to meet the specific needs of each customer and are customizable to ensure that they can handle a wide range of roll making applications.One of the key features of {}'s roll making machines is their versatility. They are capable of producing different types of rolls, including embossed, perforated, and laminated rolls, and can accommodate various materials, such as paper, plastic, and metal. This versatility makes them ideal for manufacturers who need a single machine to handle multiple roll making processes.Another important aspect of {}'s roll making machines is their efficiency. They are designed to optimize the production process, with features such as quick changeover capabilities, automatic tension control, and advanced monitoring systems. This ensures that the machines can produce high-quality rolls with minimal downtime, helping manufacturers to increase their productivity and reduce their operating costs.In addition to their advanced technology and efficiency, {}'s roll making machines are also known for their reliability. They are built to withstand the demands of continuous operation and are equipped with robust components and high-quality materials to ensure long-term performance and durability.Furthermore, {} offers comprehensive customer support and after-sales service for their roll making machines. Their team of experienced engineers and technicians is available to provide installation, training, maintenance, and troubleshooting services, ensuring that their customers can get the most out of their machines and minimize any potential downtime.With a commitment to continuous innovation and improvement, {} is constantly developing new technologies and refining their roll making machines to meet the evolving needs of the industry. Their dedication to excellence has earned them a loyal customer base and has positioned them as a leader in the roll making machine market.As the demand for high-quality rolls continues to grow across various industries, the roll making machines produced by {} are poised to play a crucial role in helping manufacturers meet this demand. With their advanced technology, efficiency, reliability, and comprehensive support, {}'s roll making machines are a valuable asset for any company looking to enhance their roll production capabilities.In conclusion, the roll making machines produced by {} are a testament to the company's commitment to innovation, quality, and customer satisfaction. With their advanced technology, efficiency, and reliability, these machines are a valuable asset for manufacturers in various industries and are helping to drive the production of high-quality rolls around the world.

Roll Forming Machine for Manufacturing Wall Panels

In recent years, there has been an increasing need for high-quality wall panels for use in a variety of applications, from commercial structures to residential homes. To meet this demand, a new system has been developed that has revolutionized the way that wall panels are manufactured. This system, known as the Wall Panel Roll Forming Machine, has quickly become one of the most popular and widely used technologies in the industry.The Wall Panel Roll Forming Machine is essentially a specialized piece of equipment that is designed to take a flat piece of raw material and transform it into a custom-fabricated wall panel. The machine operates on a continuous basis, allowing for a virtually uninterrupted flow of material and seamless production of large quantities of panels. This level of efficiency and consistency is critical for meeting the high demands of modern construction projects.Perhaps the most important aspect of the Wall Panel Roll Forming Machine is its versatility. It is capable of producing wall panels of virtually any size or shape, from standard rectangular panels to more complex designs with intricate curves and details. This opens up possibilities for architects and designers to create truly unique and impressive structures that were previously impossible to construct using traditional methods.One of the key advantages of the Wall Panel Roll Forming Machine is its automation. The technology used in the machine allows for precise control and accuracy in the manufacturing process. This reduces the need for human intervention, which not only increases efficiency but also reduces the chances of errors and defects in the final product. The end result is a high-quality wall panel that meets or exceeds all industry standards and is sure to provide years of reliable service.At the heart of the Wall Panel Roll Forming Machine is the roll forming process. In this process, a sheet of material is passed through a series of rollers that gradually bend and shape it into the desired form. The Wall Panel Roll Forming Machine uses a custom-designed set of rollers that are specifically tailored to the requirements of each individual project. This ensures maximum precision and accuracy in the finished product.Another key advantage of the Wall Panel Roll Forming Machine is its speed of production. Because the machine operates on a continuous basis, it is capable of producing large quantities of high-quality wall panels in a relatively short amount of time. This makes it an ideal solution for construction companies and contractors who need to meet tight deadlines and strict schedules.The Wall Panel Roll Forming Machine is also highly customizable. It can be tailored to fit the specific requirements of each individual project, allowing for a wide range of options in terms of materials, sizes, and shapes. This versatility makes it an ideal choice for architects and designers who need to create unique and innovative structures that require custom-made panels.In conclusion, the Wall Panel Roll Forming Machine is a cutting-edge technology that has changed the way that wall panels are manufactured. Its precision, speed, and versatility have made it an essential tool for construction companies and contractors who need to meet the demands of modern construction projects. With its automation and customization options, it is sure to continue to be a popular choice in the industry for years to come.