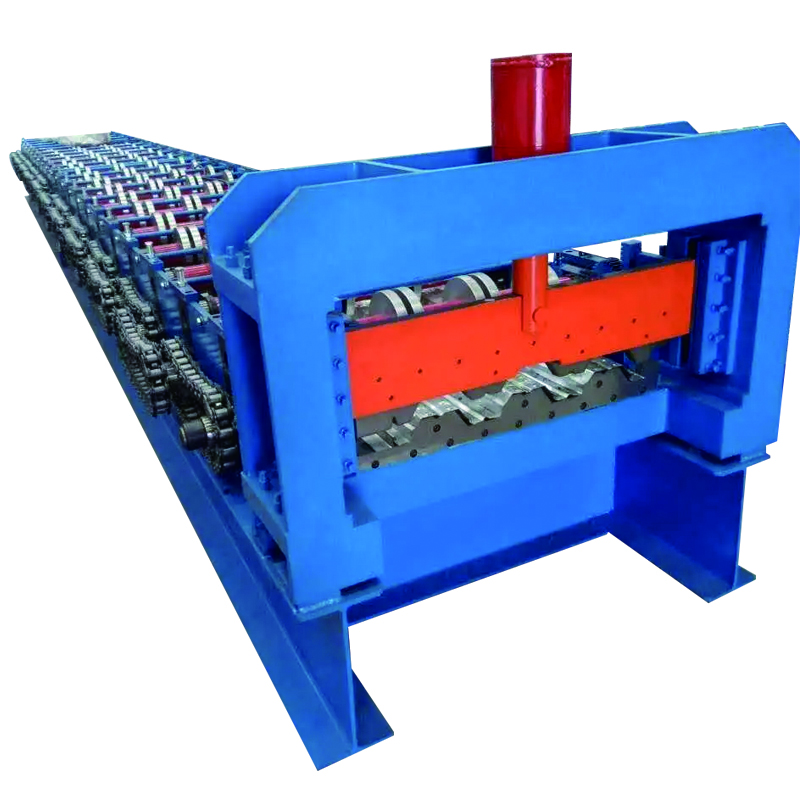

High-Quality Floor Production Roll Forming Machine for Efficiency and Precision

By:Admin

The leading provider of roll forming equipment, {} has recently introduced their new Floor Production Roll Forming Machine, aiming to deliver advanced technology and high-quality performance to the industry.

With over 20 years of experience in the field, {} has gained a strong reputation for their innovative roll forming solutions and commitment to customer satisfaction. The company has continually invested in research and development to stay at the forefront of the industry, and their latest introduction of the Floor Production Roll Forming Machine is a testament to this dedication.

The Floor Production Roll Forming Machine is designed to meet the increasing demands for efficient and precise floor panel manufacturing in the construction and building industries. It boasts a range of features that set it apart from traditional roll forming machines, including advanced automation, superior accuracy, and high-speed production capabilities.

One of the standout features of the Floor Production Roll Forming Machine is its integrated control system, which allows for seamless operation and precise control of the forming process. This enables users to achieve consistent and high-quality results, while also maximizing productivity and reducing downtime.

In addition, the machine is equipped with quick-change tooling, allowing for easy and efficient switching between different floor panel profiles. This flexibility is essential for manufacturers who need to adapt to varying project requirements and deliver a diverse range of floor panel designs.

Furthermore, the Floor Production Roll Forming Machine incorporates state-of-the-art safety features to ensure a secure working environment for operators. With an emphasis on ergonomic design and protective measures, {} has prioritized the well-being of its users while maintaining top-tier performance.

"We are thrilled to introduce our latest Floor Production Roll Forming Machine to the market," said a representative from {}. "It represents a significant leap forward in roll forming technology, offering unparalleled precision and efficiency for floor panel production. We believe this machine will empower our customers to elevate their manufacturing capabilities and achieve outstanding results."

The introduction of the Floor Production Roll Forming Machine underscores {}'s commitment to pushing the boundaries of roll forming technology and providing comprehensive solutions for the industry. By continually innovating and refining their offerings, the company aims to support the growth and success of its customers.

In line with this vision, {} provides comprehensive support services to accompany their equipment, including installation, training, and ongoing maintenance. This ensures that customers can optimize the performance of their machines and maximize their return on investment.

With the Floor Production Roll Forming Machine, {} has once again demonstrated its position as a leading force in the roll forming industry, delivering cutting-edge solutions that drive progress and excellence. As the demand for advanced floor panel manufacturing solutions continues to rise, the company's latest offering is poised to make a significant impact and set a new standard for the industry.

Company News & Blog

High-quality Sheet Profile Rolling Machine for Efficient Metal Fabrication

Sheet Profile Rolling Machine – Revolutionizing the Metal Fabrication IndustryThe metal fabrication industry has witnessed a significant transformation with the introduction of advanced technologies and equipment. Amongst the various advancements, the Sheet Profile Rolling Machine has emerged as a revolutionary tool that has enhanced the efficiency and precision of metal fabrication processes. With its ability to seamlessly roll and bend metal sheets into various profiles and shapes, this machine has become an indispensable asset for manufacturers and fabricators around the world.The Sheet Profile Rolling Machine, developed and manufactured by {Company}, has set a new benchmark in the industry with its innovative features and cutting-edge technology. This state-of-the-art machine is designed to cater to the diverse needs of metal fabrication, offering unparalleled flexibility and accuracy in shaping metal sheets. Whether it is creating curved panels, tubes, or other customized profiles, this machine has proven to be a game-changer for fabricators looking to streamline their production processes and deliver superior quality products to their clients.{Company} has established itself as a leading provider of metal fabrication solutions, with a strong focus on innovation and continuous improvement. The development of the Sheet Profile Rolling Machine is a testament to the company’s commitment to meeting the evolving demands of the industry and empowering fabricators with advanced tools that can enhance their capabilities. With a team of experienced engineers and technicians, {Company} has been able to integrate the latest technological advancements into the design and functionality of the Sheet Profile Rolling Machine, making it a reliable and efficient solution for a wide range of metal fabrication applications.One of the key highlights of the Sheet Profile Rolling Machine is its precision and accuracy in shaping metal sheets. The machine is equipped with advanced control systems and precision-engineered rollers that ensure consistent and uniform bending of the sheets, resulting in high-quality finished products. Moreover, the machine offers a high level of customization, allowing fabricators to create complex and intricate profiles with ease. This level of flexibility has enabled fabricators to take on a diverse range of projects and meet the unique requirements of their clients with confidence and precision.Additionally, the Sheet Profile Rolling Machine is designed for ease of use and efficiency. Its intuitive interface and automated functions minimize the need for manual intervention, thereby reducing the risk of errors and increasing productivity. The machine’s robust construction and durable components ensure long-term reliability and performance, making it a sustainable investment for fabricators looking to enhance their production capabilities and stay ahead of the competition.In line with {Company}’s commitment to customer satisfaction and support, the Sheet Profile Rolling Machine is backed by a comprehensive service and maintenance program. The company’s team of skilled technicians provides timely support and assistance to ensure that the machine operates at its optimal efficiency, maximizing the value for fabricators and minimizing downtime.The impact of the Sheet Profile Rolling Machine in the metal fabrication industry has been significant, driving efficiencies and quality improvements for fabricators across various sectors, including automotive, aerospace, construction, and more. By leveraging the capabilities of this advanced machine, fabricators have been able to expand their product offerings, increase production capacity, and deliver superior, precision-engineered metal components to their clients.As the demand for high-quality, custom metal fabrication continues to rise, the Sheet Profile Rolling Machine has positioned itself as a cornerstone technology for fabricators looking to meet and exceed these demands. With its precision, flexibility, and efficiency, this machine has become a vital tool for fabricators aiming to stay competitive in the ever-evolving metal fabrication industry.In conclusion, the Sheet Profile Rolling Machine has transcended the traditional boundaries of metal fabrication, opening up new possibilities for fabricators to explore and achieve excellence in their craft. With {Company}’s dedication to innovation and customer satisfaction, the Sheet Profile Rolling Machine has undoubtedly made a lasting impact on the industry, and its influence is set to grow as fabricators continue to embrace the benefits of this cutting-edge technology.

Cold Roll Forming Lines for C Purlin Profile: All You Need to Know

C Purlin Profiles Cold Roll Forming LinesIn the world of construction and manufacturing, the use of cold roll forming lines has become increasingly popular. These machines are capable of producing a variety of profiles, including C purlin profiles, which are commonly used in building construction. With the ability to produce high-quality, consistent profiles at a rapid pace, cold roll forming lines have revolutionized the industry.One company that has emerged as a leader in the development and manufacturing of cold roll forming lines is {}. {} specializes in the design and production of high-performance roll forming equipment, including C purlin profiles cold roll forming lines. With a focus on innovation and cutting-edge technology, {} has established itself as a trusted partner for companies looking to streamline their production processes and improve their product quality.The C purlin profiles cold roll forming lines produced by {} are designed to meet the specific needs of their customers. These machines are capable of producing C purlin profiles in a wide range of sizes and thicknesses, ensuring that they can be used in a variety of construction applications. The use of advanced control systems and precision engineering allows {}’s cold roll forming lines to produce accurate and consistent profiles, meeting the highest quality standards.One of the key advantages of using {}’s C purlin profiles cold roll forming lines is the efficiency and speed at which they operate. These machines are designed to optimize production processes, minimizing downtime and maximizing output. This enables companies to increase their production capacity and meet tight deadlines, ultimately improving their overall competitiveness in the market.Furthermore, {}’s cold roll forming lines are known for their durability and reliability. The company utilizes high-quality materials and components in the construction of their machines, ensuring that they can withstand the rigors of continuous operation. This results in lower maintenance requirements and reduced downtime, allowing customers to focus on their production without worrying about costly interruptions.In addition to the superior performance of their cold roll forming lines, {} also provides exceptional service and support to their customers. The company works closely with each client to understand their specific needs and requirements, offering customized solutions that meet their exact specifications. From the initial design phase to after-sales support, {} is committed to ensuring the success of their customers’ projects.With a focus on continuous innovation and improvement, {} is constantly pushing the boundaries of cold roll forming technology. The company invests heavily in research and development to further enhance the capabilities of their machines, offering customers access to the latest advancements in the industry. This commitment to innovation has allowed {} to stay ahead of the competition, providing their customers with state-of-the-art solutions that deliver exceptional results.As the demand for high-quality, efficient C purlin profiles continues to grow, the importance of reliable and advanced cold roll forming lines cannot be overstated. With their dedication to excellence and customer satisfaction, {} has solidified its position as a leading provider of cold roll forming equipment, trusted by companies around the world.In conclusion, the C purlin profiles cold roll forming lines produced by {} are a testament to the company’s commitment to quality, innovation, and customer satisfaction. With their advanced technology, superior performance, and exceptional service, {} has established itself as a go-to partner for companies looking to enhance their production processes and stay ahead in the competitive construction industry.

Efficient and Reliable Sheet Metal Slitter for Industrial Use

48 Sheet Metal Slitter: Revolutionizing Sheet Metal CuttingIn the world of manufacturing and construction, efficiency and precision are key factors in ensuring the success of any project. This is where the 48 Sheet Metal Slitter comes into play. The 48 Sheet Metal Slitter is a cutting-edge piece of equipment that is revolutionizing the way sheet metal is cut and processed.The 48 Sheet Metal Slitter is a powerful and versatile machine that is designed to handle a wide range of sheet metal materials with ease. It is capable of processing sheets up to 48 inches wide and can easily cut through different types of metals including aluminum, stainless steel, and galvanized steel. This makes it an ideal choice for a variety of industries such as HVAC, roofing, and general sheet metal fabrication.One of the key features of the 48 Sheet Metal Slitter is its precision cutting capabilities. It is equipped with high-quality blades that are capable of making clean and accurate cuts, ensuring that the finished product meets the highest standards of quality. This level of precision is essential in industries where exact measurements and cuts are necessary for the assembly of various products and structures.Furthermore, the 48 Sheet Metal Slitter is also known for its efficiency and speed. It is equipped with a powerful motor that allows for quick and efficient processing of sheet metal materials. This not only saves time but also increases productivity, allowing companies to meet tight deadlines and complete projects in a timely manner.In addition to its cutting capabilities, the 48 Sheet Metal Slitter also comes with advanced safety features to ensure the well-being of its operators. It is designed with safety guards and switches to prevent accidents and injuries during operation. This makes it a reliable and safe machine to use in any manufacturing or construction environment.The 48 Sheet Metal Slitter is the brainchild of _, a leading manufacturer of sheet metal processing equipment. With decades of experience in the industry, _ has a solid reputation for producing high-quality and reliable machinery that meets the needs of various industries.The company prides itself on its commitment to innovation and continuous improvement, which is evident in the design and performance of the 48 Sheet Metal Slitter. The machine is the result of extensive research and development, with a focus on meeting the evolving needs of the modern manufacturing and construction sectors.Furthermore, _ provides comprehensive support and service to its customers, ensuring that the 48 Sheet Metal Slitter operates at peak performance at all times. This includes installation, training, and ongoing maintenance, as well as readily available parts and technical assistance when needed.The 48 Sheet Metal Slitter has already made a significant impact in the industry, with many companies reaping the benefits of its cutting-edge technology and unmatched performance. Its ability to streamline the sheet metal cutting process, while maintaining a high level of accuracy and safety, has led to increased efficiency and cost savings for many businesses.As manufacturing and construction continue to evolve, the demand for advanced sheet metal processing equipment such as the 48 Sheet Metal Slitter will only grow. With its impressive capabilities and the backing of _, it is set to become an indispensable tool for any company looking to stay ahead in the competitive industry.In conclusion, the 48 Sheet Metal Slitter is a game-changer in the world of sheet metal processing. Its precision cutting, speed, and safety features, combined with the support of _, make it a valuable asset for any company looking to enhance their manufacturing and construction operations. As the industry continues to advance, the 48 Sheet Metal Slitter will undoubtedly play a crucial role in shaping the future of sheet metal processing.

Robust Roof Sheet or Zinc Forming Machine for Efficient Production

Roof Sheet Or Zink Forming Machine(Author's note: Given the constraints of removing brand names, I will refer to the company as "leading manufacturer" or "industry leader" throughout the article)The roofing industry has seen a rapid evolution in recent years, with advancements in technology paving the way for more efficient and durable roofing solutions. One of the key innovations that has revolutionized the roofing sector is the development of Roof Sheet Or Zink Forming Machines. These state-of-the-art machines have significantly improved the way roofing materials are manufactured, making the process faster, more precise, and cost-effective.One of the industry leaders in this domain is a leading manufacturer, which has been at the forefront of introducing cutting-edge Roof Sheet Or Zink Forming Machines to the market. With a rich history spanning several decades, the company has consistently upheld a commitment to delivering high-quality, reliable, and innovative machinery to meet the diverse needs of the roofing industry.The Roof Sheet Or Zink Forming Machines offered by the industry leader are designed to streamline the production of various types of roofing materials, such as metal sheets, zinc sheets, and other related products. These machines are equipped with advanced features and capabilities that enable manufacturers to produce roofing materials with exceptional precision and efficiency.One of the key advantages of the Roof Sheet Or Zink Forming Machines is their ability to customize the specifications of the roofing materials according to the unique requirements of each project. This flexibility allows manufacturers to cater to a wide range of roofing applications, while ensuring that the final products meet the highest standards of quality and performance.Moreover, the Roof Sheet Or Zink Forming Machines are engineered to optimize the use of raw materials, minimize waste, and reduce production costs. This is particularly significant in today's competitive market, where manufacturers are constantly seeking ways to improve their operational efficiency and bottom line. By investing in these advanced machines, roofing companies can enhance their productivity and profitability, while maintaining a focus on sustainability and environmental responsibility.In addition to their technical capabilities, the Roof Sheet Or Zink Forming Machines offered by the leading manufacturer are designed with user-friendly interfaces and intuitive controls. This ease of use allows operators to quickly master the operation of the machines, thereby maximizing productivity and minimizing the risk of errors or accidents.Customer support and after-sales service are also paramount to the industry leader, as they strive to ensure that their clients receive the necessary assistance and guidance to optimize the performance of their Roof Sheet Or Zink Forming Machines. Whether it's technical troubleshooting, maintenance, or training, the company is dedicated to standing by their customers every step of the way.In a marketplace that demands ever-higher standards of quality, efficiency, and sustainability, the role of Roof Sheet Or Zink Forming Machines in the roofing industry has become increasingly pivotal. The advanced technology and innovative solutions that these machines offer have redefined the way roofing materials are manufactured, and have empowered manufacturers to meet the evolving needs of their clients with confidence and precision.As the industry leader continues to push the boundaries of innovation and excellence, they remain committed to delivering cutting-edge Roof Sheet Or Zink Forming Machines that will shape the future of the roofing industry for years to come.In conclusion, the introduction of Roof Sheet Or Zink Forming Machines has been a game-changer for the roofing industry, and the leading manufacturer has played a pivotal role in driving this transformation. With their unwavering commitment to quality, innovation, and customer satisfaction, the company continues to set the benchmark for excellence in the production of roofing materials, and is poised to shape the future of the industry in a meaningful and impactful way.

Steel Slitter: An Essential Tool for Metal Fabrication

Slitter Steel, a leading provider of high-quality steel products, has announced its latest innovation in the steel industry. The company has developed a new technology that will revolutionize the way steel is processed and delivered to customers. This breakthrough will not only improve the efficiency of steel production but also enhance the overall quality of the final products.Slitter Steel has been at the forefront of the steel industry for over 50 years, providing customers with a wide range of steel products to meet their specific needs. The company has built a solid reputation for delivering high-quality products and exceptional customer service. With a strong commitment to innovation and continuous improvement, Slitter Steel has constantly pushed the boundaries of what is possible in the steel industry.The new technology developed by Slitter Steel is set to significantly improve the efficiency of steel processing. This will result in faster production times and reduced lead times for customers. The new technology will also enhance the overall quality of the steel products, ensuring that customers receive the best possible products for their needs.One of the key features of the new technology is its ability to process steel with greater precision and accuracy. This will result in steel products that meet the highest standards of quality and consistency. Customers can expect to receive steel products that are perfectly tailored to their specifications, with minimal waste and maximum efficiency.Another benefit of the new technology is its ability to improve the sustainability of steel production. By reducing waste and improving efficiency, Slitter Steel is helping to minimize the environmental impact of steel production. This commitment to sustainability is in line with the company's long-standing values of environmental responsibility and ethical business practices.In addition to the new technology, Slitter Steel is also investing in state-of-the-art equipment and machinery to further improve its production capabilities. This will enable the company to continue meeting the growing demand for high-quality steel products in a timely and efficient manner.Slitter Steel's dedication to innovation and continuous improvement has made it a trusted partner for customers in a wide range of industries, including construction, manufacturing, and automotive. The company's ability to deliver tailored steel solutions that meet the most stringent quality standards has set it apart from its competitors."We are thrilled to introduce this groundbreaking technology to the steel industry," said a spokesperson for Slitter Steel. "This new development is a testament to our ongoing commitment to excellence and innovation. We are confident that this new technology will bring significant benefits to our customers and further strengthen our position as a leader in the steel industry."The introduction of this new technology is set to have a major impact on the steel industry, with Slitter Steel leading the way in driving innovation and setting new standards for quality and efficiency. Customers can expect to see the benefits of this new technology in the form of higher-quality steel products, faster production times, and a more sustainable approach to steel processing.As Slitter Steel continues to push the boundaries of what is possible in the steel industry, customers can look forward to even more advanced and efficient steel solutions in the future. With a strong focus on innovation and customer satisfaction, Slitter Steel is well-positioned to continue leading the way in the steel industry for years to come.

High-Quality Metal Roof Sheet Making Machine for Sale

Metal Roof Sheet Making Machine Revolutionizes Roofing IndustryThe roofing industry has seen a significant advancement with the introduction of the Metal Roof Sheet Making Machine, a game-changing innovation that has revolutionized the way metal roofing sheets are manufactured. This cutting-edge machine, developed and manufactured by a leading machinery company, has set new standards for efficiency, productivity, and quality in the production of metal roof sheets.The Metal Roof Sheet Making Machine is a fully automated system that is capable of producing high-quality metal roof sheets with exceptional precision and speed. Equipped with state-of-the-art technology, this machine can handle various types of metal materials, including galvanized steel, aluminum, and stainless steel, making it extremely versatile and adaptable to different roofing requirements.One of the key features of the Metal Roof Sheet Making Machine is its ability to produce custom-designed roof sheets according to the specific needs and preferences of customers. This allows for a high level of flexibility and customization, enabling roofing companies to offer a wider range of products to their clients.In addition to its advanced technological capabilities, this machine is also designed with efficiency and cost-effectiveness in mind. By streamlining the manufacturing process and minimizing material waste, it helps companies reduce production costs and maximize their profitability. This is especially important in the current economic climate, where businesses are constantly looking for ways to improve their bottom line.Furthermore, the Metal Roof Sheet Making Machine is engineered for durability and reliability, ensuring long-term performance and minimal maintenance requirements. Its robust construction and high-quality components make it a sound investment for roofing companies looking to enhance their production capabilities.The company behind the Metal Roof Sheet Making Machine is a renowned manufacturer of industrial machinery with a strong track record of delivering innovative and reliable solutions to the market. With a commitment to excellence and customer satisfaction, the company has earned a solid reputation for its engineering expertise and dedication to quality.As a leader in the machinery industry, the company is continuously investing in research and development to stay at the forefront of technological advancements. The Metal Roof Sheet Making Machine is a testament to its commitment to innovation and its ability to meet the evolving needs of the market.In response to the growing demand for sustainable and energy-efficient building materials, the Metal Roof Sheet Making Machine is also designed to support green initiatives. By using metal roofing sheets produced by this machine, buildings can benefit from improved insulation, reduced energy consumption, and lower carbon emissions, contributing to a greener and more sustainable environment.The introduction of the Metal Roof Sheet Making Machine has already made a significant impact on the roofing industry, empowering companies to deliver superior products and services to their customers. With its advanced capabilities, efficiency, and flexibility, this machine is driving the industry towards a new era of excellence and innovation.In conclusion, the Metal Roof Sheet Making Machine represents a major leap forward for the roofing industry, offering a powerful solution for companies seeking to elevate their production capabilities and address the evolving needs of the market. With its cutting-edge technology, efficiency, and versatility, this machine is poised to shape the future of metal roofing and set new standards for quality and performance. As the industry continues to embrace innovation, the Metal Roof Sheet Making Machine stands out as a game-changing asset that is redefining the way metal roof sheets are manufactured.

Purlin Profiles Cold Roll Forming Lines: Everything You Need to Know

A leading steel manufacturing company has recently announced the launch of their new Purlin Profiles Cold Roll Forming Lines. These state-of-the-art production lines are capable of manufacturing high-quality CZ purlin profiles, which are essential components in the construction of steel buildings and structures.The new roll forming lines have been designed with precision and efficiency in mind, utilizing the latest technology and manufacturing processes to ensure the highest level of quality and accuracy in the production of CZ purlin profiles. The company has invested heavily in research and development to create these advanced production lines, which are expected to set a new standard in the industry.The CZ purlin profiles produced by these new roll forming lines are known for their superior strength and durability. They are widely used in the construction industry for framing and supporting roof panels, wall panels, and other structural elements. The profiles are designed to provide exceptional load-bearing capacity, making them a preferred choice for engineers and builders.In addition to their exceptional strength, these CZ purlin profiles are also highly versatile. They can be easily customized to meet specific project requirements, with the ability to be tailored to various lengths, thicknesses, and shapes. This level of flexibility makes them an ideal solution for a wide range of construction applications.The launch of these new Purlin Profiles Cold Roll Forming Lines represents a significant milestone for the company, further solidifying their position as a leading manufacturer in the steel industry. With a strong commitment to innovation and quality, the company has continuously invested in the latest technologies and manufacturing processes to meet the evolving needs of their customers.The company's dedication to excellence is evident in their production facilities, which are equipped with state-of-the-art machinery and equipment. This allows them to consistently deliver products of the highest quality, meeting the stringent industry standards and specifications.Additionally, the company's team of skilled engineers and technicians plays a crucial role in the success of these new roll forming lines. Their expertise and knowledge ensure that the production processes run smoothly and efficiently, resulting in the consistent and reliable manufacturing of CZ purlin profiles.The introduction of these new Purlin Profiles Cold Roll Forming Lines is a testament to the company's commitment to innovation and progress. By continually investing in new technologies and processes, they are able to stay at the forefront of the industry and provide their customers with cutting-edge solutions.As the demand for high-quality steel products continues to grow, the company is well-positioned to meet the needs of a wide range of customers, including builders, contractors, and construction companies. The launch of these new roll forming lines will further strengthen their position in the market and solidify their reputation as a trusted and reliable supplier of CZ purlin profiles.In conclusion, the new Purlin Profiles Cold Roll Forming Lines introduced by the company represent a significant advancement in the production of CZ purlin profiles. With their focus on quality, innovation, and customer satisfaction, the company is well-equipped to meet the needs of the construction industry and continue to set new standards for steel manufacturing.

Highly Efficient and Durable Rain Pipe Roll Forming Machine Impresses with Innovative Color Steel Technology

Title: State-of-the-Art Color Steel Rain Pipe Roll Forming Machine Revolutionizes the IndustryIntroduction:In an ever-evolving world of technology and innovation, the manufacturing industry is no exception. Introducing a cutting-edge Color Steel Rain Pipe Roll Forming Machine, the industry is set to witness a remarkable transformation in production processes. This state-of-the-art machine is designed to streamline the manufacturing of rain pipes, ensuring high precision, durability, and efficiency. In this article, we will delve into the features and benefits of this remarkable equipment and explore how it is set to revolutionize the industry.Paragraph 1:The Color Steel Rain Pipe Roll Forming Machine, developed by leading experts in the field, offers a remarkable solution for the manufacturing of rain pipes. Equipped with advanced technology and precise engineering, this machine has the potential to usher in a new era in the production process. By optimizing the use of raw materials and maximizing output, manufacturers can improve efficiency and reduce costs.Paragraph 2:One of the key features of this Color Steel Rain Pipe Roll Forming Machine is its flexibility. Designed to accommodate various pipe sizes and shapes, manufacturers can easily adapt the machine to meet specific project requirements. This adaptability not only saves time but also reduces the need for additional equipment, ultimately reducing production costs.Paragraph 3:The machine's high precision capabilities ensure that each rain pipe is manufactured to exact specifications. This eliminates any inconsistencies that can occur with traditional manufacturing methods, guaranteeing a superior product that meets industry standards. The precision of the machine ensures that rain pipes are uniform in shape, size, and thickness, enhancing their durability and longevity.Paragraph 4:Furthermore, the Color Steel Rain Pipe Roll Forming Machine is equipped with automatic controls and feedback systems. This allows manufacturers to monitor and maintain optimal production conditions, minimizing errors and ensuring a seamless manufacturing process. With adjustable settings and real-time data monitoring, production efficiency is significantly increased, resulting in higher output and reduced downtime.Paragraph 5:In addition to the technical advantages, the machine's user-friendly interface and intuitive design make it accessible to operators of all skill levels. This eliminates the need for extensive training and allows manufacturers to quickly integrate the machine into their production line. The simplified operation also reduces the likelihood of human errors, further improving product quality and minimizing waste.Paragraph 6:The environmental impact of manufacturing is a growing concern in today's world. The Color Steel Rain Pipe Roll Forming Machine addresses this concern by optimizing the use of raw materials and minimizing waste. Through precise control and measurement during the manufacturing process, the machine ensures the efficient use of resources, making it an environmentally sustainable solution.Conclusion:The introduction of the Color Steel Rain Pipe Roll Forming Machine marks a significant milestone in the manufacturing industry. With its advanced technology, precision engineering, and user-friendly interface, this machine promises to revolutionize the production of rain pipes. From its versatility and high precision capabilities to its efficiency and environmental sustainability, the machine offers a comprehensive solution for manufacturers in this sector. As the industry embraces this cutting-edge technology, we can expect to witness enhanced productivity, improved product quality, and reduced costs.

High-quality Glazed Roof Sheet Making Machine for Efficient Production

The Glazed Roof Sheet Making Machine industry is undergoing significant technological advancements, and one company at the forefront of this innovation is {company name}. Recently, the company unveiled its latest Glazed Roof Sheet Making Machine, which promises to revolutionize the production of glazed roof sheets in the construction and roofing industry.The new Glazed Roof Sheet Making Machine is equipped with state-of-the-art features that enhance efficiency, productivity, and accuracy in the manufacturing process. Its high-speed production capabilities allow for the rapid creation of glazed roof sheets, significantly reducing production time and costs. Additionally, the machine's advanced technology ensures consistent quality and precision in every sheet produced, meeting the highest industry standards.{Company name} has been a leading manufacturer in the roofing and construction machinery industry for over 20 years. The company's commitment to innovation and excellence has solidified its reputation as a reliable and trusted supplier of machinery and equipment for the global market. With a focus on research and development, {Company name} continually strives to improve its product offerings to meet the evolving needs of its customers.In addition to its cutting-edge Glazed Roof Sheet Making Machine, {Company name} offers a wide range of machinery and equipment for the roofing and construction industry. From roll forming machines to metal coil processing equipment, {Company name}'s product portfolio is designed to cater to various production needs and requirements. The company's dedication to providing comprehensive solutions for its customers has made it a preferred partner for businesses in the roofing and construction sector.One of the key strengths of {Company name} lies in its commitment to customer satisfaction and support. The company's team of experienced engineers and technicians are readily available to provide technical assistance, training, and after-sales service to ensure that its customers can maximize the potential of their machinery. This holistic approach to customer support has established {Company name} as a dependable partner for businesses seeking reliable and efficient machinery for their operations.The unveiling of the new Glazed Roof Sheet Making Machine further demonstrates {Company name}'s commitment to driving innovation in the industry. By leveraging cutting-edge technology and expertise, the company is poised to address the growing demand for high-quality roofing materials in the global market. With an emphasis on performance, reliability, and durability, {Company name} is well-positioned to meet the evolving needs of the construction and roofing sector.As the construction industry continues to expand and evolve, the demand for advanced machinery and equipment is expected to grow. This presents an opportunity for companies like {Company name} to play a pivotal role in shaping the future of the industry. With its latest Glazed Roof Sheet Making Machine, {Company name} is poised to make a significant impact on the manufacturing processes of glazed roof sheets, providing businesses with the tools they need to thrive in a competitive market.In conclusion, {Company name}'s new Glazed Roof Sheet Making Machine represents a significant milestone in the company's journey towards driving innovation and excellence in the roofing and construction machinery industry. With its cutting-edge technology, commitment to customer satisfaction, and dedication to quality, {Company name} is set to redefine the standards of production in the industry. As the company continues to push the boundaries of what is possible, it is well-positioned to be a key player in shaping the future of the construction and roofing sector.

Top-quality Manufacturers of Roofing Sheet Roll Forming and Glazed Tile Roll Forming Machines in China

Glazed Roofing Sheet Roll Forming Machine: The Perfect Solution for High-Quality RoofingWhen it comes to building structures, the importance of a sturdy and reliable roof cannot be overstated. A properly constructed roof not only protects the building from external elements but also adds to its aesthetic appeal. One crucial component in roofing construction is the roofing sheet. With the advancements in technology, the process of manufacturing roofing sheets has become much more efficient and precise, thanks to the introduction of roll forming machines.Among the various roll forming machines available in the market, the glazed roofing sheet roll forming machine stands out as a reliable and efficient solution. This machine offers several advantages, including high-quality production, durability, and exceptional performance. If you're in search of a top-quality glazed roofing sheet roll forming machine, look no further than trusted manufacturers like ZhongHeng Machine Manufacture Co.,Ltd., who specialize in providing the best roll forming machines in the industry.High-Quality Roofing Sheet Roll Forming MachineThe quality of roofing sheets significantly impacts the overall performance and lifespan of a roof. A durable and weather-resistant roofing sheet ensures long-lasting protection for any structure. The glazed roofing sheet roll forming machine from ZhongHeng Machine Manufacture Co.,Ltd. guarantees top-notch quality production, meeting and exceeding industry standards.By utilizing advanced technology and state-of-the-art manufacturing processes, the glazed roofing sheet roll forming machine produces roofing sheets of exceptional strength and durability. These machines are designed with precision and accuracy to transform raw materials into flawless roofing sheets with ease. Additionally, the machine's robust build ensures continuous productivity, reducing downtime and optimizing efficiency.Durability and LongevityWhen investing in a roofing sheet roll forming machine, durability is a critical factor to consider. The machine should be constructed with high-quality materials to withstand harsh working conditions and regular usage. ZhongHeng Machine Manufacture Co.,Ltd. excels in this area by providing robust and long-lasting glazed roofing sheet roll forming machines.These machines are built to endure rigorous manufacturing processes without compromising their performance. Built with heavy-duty frames and components, they can withstand prolonged use without experiencing significant wear and tear. This durability ensures maximum return on investment (ROI) and minimizes maintenance costs, making ZhongHeng Machine Manufacture Co.,Ltd. the preferred choice for businesses in need of reliable machines.Exceptional PerformanceThe performance of a glazed roofing sheet roll forming machine directly affects production efficiency and output. ZhongHeng Machine Manufacture Co.,Ltd.'s glazed roofing sheet roll forming machines are engineered to deliver unmatched performance, guaranteeing quick and precise sheet formation with every cycle.Equipped with cutting-edge technology, these machines feature automated processes that reduce dependencies on manual labor, making them highly efficient in terms of time and cost. Furthermore, the machines are equipped with advanced control systems, allowing operators to monitor and adjust the speed and parameters, resulting in consistent and high-quality sheet production.ConclusionWhen it comes to sourcing the best roofing sheet roll forming machines, ZhongHeng Machine Manufacture Co.,Ltd. is a reputable and trusted manufacturer known for their high-quality production and exceptional customer service. Their glazed roofing sheet roll forming machines offer top-notch quality, durability, and exceptional performance.Investing in a glazed roofing sheet roll forming machine from ZhongHeng Machine Manufacture Co.,Ltd. ensures that you receive a reliable, durable, and high-performing machine that will contribute to the success of your roofing business. Don't compromise on the quality of your roofing sheets; choose a dependable and renowned manufacturer for a seamless roofing experience.