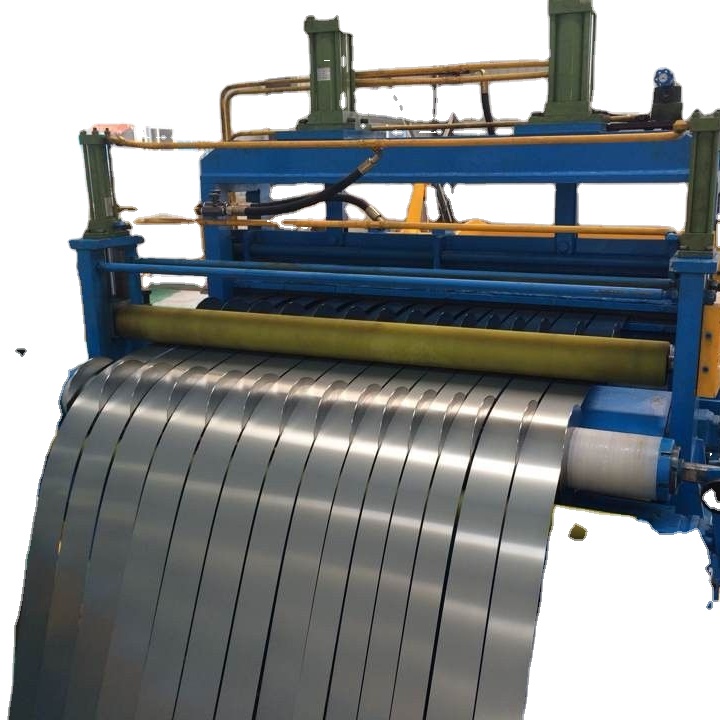

High-Quality Rolling Machine for Resilient Channel Production

By:Admin

The construction industry is constantly evolving and adopting new technologies to improve efficiency, quality, and safety. One such technological advancement that is making waves in the industry is the Resilient Channel Rolling Machine. This innovative machine is changing the way resilient channels are installed, providing a streamlined and efficient process that is revolutionizing the construction industry.

Resilient channels are a critical component in the construction of soundproof walls and ceilings. These channels are used to reduce sound transmission between rooms by isolating the drywall from the structure. Traditionally, resilient channels were installed manually, which was a time-consuming and labor-intensive process. However, the introduction of the Resilient Channel Rolling Machine has completely transformed the way these channels are installed, offering a more efficient and cost-effective solution.

The Resilient Channel Rolling Machine is a result of the cutting-edge technology developed by {} - a leading manufacturer of construction machinery and equipment. The company has a long-standing reputation for delivering high-quality and innovative solutions that meet the evolving needs of the construction industry. With a focus on research and development, {} has been at the forefront of introducing innovative technologies that are revolutionizing construction practices.

The Resilient Channel Rolling Machine is a testament to {}'s commitment to innovation and excellence. This machine is designed to automate the installation of resilient channels, significantly reducing the time and labor required for this task. By using advanced technology and precise engineering, the machine ensures that the resilient channels are installed with utmost accuracy and efficiency, resulting in superior soundproofing for walls and ceilings.

One of the key features of the Resilient Channel Rolling Machine is its ability to roll out the resilient channels with consistent precision. This eliminates the inconsistencies that are often associated with manual installation, resulting in a more uniform and effective soundproofing solution. Additionally, the machine is designed to be user-friendly, making it accessible to both experienced construction professionals and those new to the industry.

Incorporating the Resilient Channel Rolling Machine into construction projects offers numerous benefits. Not only does it save time and labor costs, but it also enhances the overall quality of soundproofing in buildings. This is particularly important for commercial and residential buildings where noise reduction is a critical factor in creating a comfortable and peaceful environment for occupants.

Furthermore, the Resilient Channel Rolling Machine is contributing to sustainable construction practices by reducing material waste and improving energy efficiency. By streamlining the installation process, the machine minimizes the need for excessive materials and resources, ultimately leading to a more environmentally friendly construction approach.

The introduction of the Resilient Channel Rolling Machine is a game-changer for the construction industry. With its innovative technology and impactful benefits, this machine is reshaping the way resilient channels are installed, paving the way for more efficient and effective soundproofing solutions in buildings. As the construction industry continues to embrace technological advancements, the Resilient Channel Rolling Machine stands out as a prime example of how innovation is driving progress and excellence in the field. With {}'s commitment to delivering cutting-edge solutions, the future of construction looks brighter than ever.

Company News & Blog

Durable and Stylish Steel Roofing Tile Roll Former for Your Next Project

Glazed Steel Roofing Tile Roll FormerIn recent news, a cutting-edge technology has been making waves in the construction industry - the Glazed Steel Roofing Tile Roll Former. This innovative machine is set to revolutionize the way roofing tiles are manufactured, offering a more efficient and cost-effective solution for builders and contractors.The Glazed Steel Roofing Tile Roll Former is a state-of-the-art piece of equipment that is designed to produce high-quality roofing tiles with precision and speed. It operates by taking steel coils and feeding them through a series of rollers and dies, which shape the metal into the desired roofing tile profile. The machine is capable of producing a wide range of tile designs, including both traditional and modern styles, making it an incredibly versatile tool for construction projects of any scale.One of the key features of the Glazed Steel Roofing Tile Roll Former is its ability to apply a glazed finish to the tiles during the manufacturing process. This not only enhances the aesthetic appeal of the tiles but also provides a protective layer that helps to extend the lifespan of the roof. The glazed finish can be customized to achieve different levels of gloss and color, allowing for a high degree of flexibility in design.In addition to its superior performance and flexibility, the Glazed Steel Roofing Tile Roll Former is also praised for its efficiency. The machine is capable of producing large quantities of roofing tiles in a relatively short amount of time, making it an ideal solution for fast-paced construction projects. Its automated operation reduces the need for manual labor, further streamlining the production process and minimizing the potential for human error.Behind this breakthrough technology is the company {}, a leading manufacturer in the field of construction machinery. With years of experience and expertise, the company has developed the Glazed Steel Roofing Tile Roll Former as part of its commitment to providing industry-leading solutions to its customers. The company's dedication to innovation and quality has earned it a reputation for excellence in the construction industry, and the Glazed Steel Roofing Tile Roll Former is a testament to that commitment.The introduction of the Glazed Steel Roofing Tile Roll Former is expected to have a significant impact on the construction industry. Its ability to produce high-quality roofing tiles with efficiency and precision will not only benefit contractors and builders but also contribute to the overall quality and durability of roofing systems. In an industry where time and cost are crucial factors, this new technology offers a competitive advantage that is sure to be welcomed by professionals in the field.Furthermore, the Glazed Steel Roofing Tile Roll Former represents a sustainable solution for roofing tile production. By using steel coils as the raw material, it reduces the reliance on traditional materials such as clay or concrete, which can have a more significant environmental impact. The machine's efficient operation also helps to minimize waste and energy consumption, making it a greener option for roofing tile manufacturing.As the construction industry continues to evolve, the demand for innovative and sustainable solutions remains high. The Glazed Steel Roofing Tile Roll Former addresses these needs by offering a cutting-edge technology that improves the efficiency, quality, and sustainability of roofing tile production. With its introduction, builders and contractors can expect to see a positive impact on their projects, while also contributing to a more environmentally conscious approach to construction.In conclusion, the Glazed Steel Roofing Tile Roll Former represents a significant advancement in the construction industry. Its combination of precision, efficiency, and sustainability makes it an invaluable tool for the production of high-quality roofing tiles. With the backing of {}, a reputable manufacturer with a track record of excellence, this new technology is poised to make a lasting impact on the way roofing tiles are manufactured and used in construction projects.

Top-quality Manufacturers of Roofing Sheet Roll Forming and Glazed Tile Roll Forming Machines in China

Glazed Roofing Sheet Roll Forming Machine: The Perfect Solution for High-Quality RoofingWhen it comes to building structures, the importance of a sturdy and reliable roof cannot be overstated. A properly constructed roof not only protects the building from external elements but also adds to its aesthetic appeal. One crucial component in roofing construction is the roofing sheet. With the advancements in technology, the process of manufacturing roofing sheets has become much more efficient and precise, thanks to the introduction of roll forming machines.Among the various roll forming machines available in the market, the glazed roofing sheet roll forming machine stands out as a reliable and efficient solution. This machine offers several advantages, including high-quality production, durability, and exceptional performance. If you're in search of a top-quality glazed roofing sheet roll forming machine, look no further than trusted manufacturers like ZhongHeng Machine Manufacture Co.,Ltd., who specialize in providing the best roll forming machines in the industry.High-Quality Roofing Sheet Roll Forming MachineThe quality of roofing sheets significantly impacts the overall performance and lifespan of a roof. A durable and weather-resistant roofing sheet ensures long-lasting protection for any structure. The glazed roofing sheet roll forming machine from ZhongHeng Machine Manufacture Co.,Ltd. guarantees top-notch quality production, meeting and exceeding industry standards.By utilizing advanced technology and state-of-the-art manufacturing processes, the glazed roofing sheet roll forming machine produces roofing sheets of exceptional strength and durability. These machines are designed with precision and accuracy to transform raw materials into flawless roofing sheets with ease. Additionally, the machine's robust build ensures continuous productivity, reducing downtime and optimizing efficiency.Durability and LongevityWhen investing in a roofing sheet roll forming machine, durability is a critical factor to consider. The machine should be constructed with high-quality materials to withstand harsh working conditions and regular usage. ZhongHeng Machine Manufacture Co.,Ltd. excels in this area by providing robust and long-lasting glazed roofing sheet roll forming machines.These machines are built to endure rigorous manufacturing processes without compromising their performance. Built with heavy-duty frames and components, they can withstand prolonged use without experiencing significant wear and tear. This durability ensures maximum return on investment (ROI) and minimizes maintenance costs, making ZhongHeng Machine Manufacture Co.,Ltd. the preferred choice for businesses in need of reliable machines.Exceptional PerformanceThe performance of a glazed roofing sheet roll forming machine directly affects production efficiency and output. ZhongHeng Machine Manufacture Co.,Ltd.'s glazed roofing sheet roll forming machines are engineered to deliver unmatched performance, guaranteeing quick and precise sheet formation with every cycle.Equipped with cutting-edge technology, these machines feature automated processes that reduce dependencies on manual labor, making them highly efficient in terms of time and cost. Furthermore, the machines are equipped with advanced control systems, allowing operators to monitor and adjust the speed and parameters, resulting in consistent and high-quality sheet production.ConclusionWhen it comes to sourcing the best roofing sheet roll forming machines, ZhongHeng Machine Manufacture Co.,Ltd. is a reputable and trusted manufacturer known for their high-quality production and exceptional customer service. Their glazed roofing sheet roll forming machines offer top-notch quality, durability, and exceptional performance.Investing in a glazed roofing sheet roll forming machine from ZhongHeng Machine Manufacture Co.,Ltd. ensures that you receive a reliable, durable, and high-performing machine that will contribute to the success of your roofing business. Don't compromise on the quality of your roofing sheets; choose a dependable and renowned manufacturer for a seamless roofing experience.

Affordable and Efficient Steel Making Machine for Light Gauge Construction

Title: Revolutionizing the Construction Industry: Innovations in Light Gauge Steel Making MachinesIntroduction:In recent years, the construction industry has seen significant advancements that have revolutionized the way buildings are designed and constructed. One such groundbreaking innovation is the Light Gauge Steel Making Machine, developed by a pioneering company. This cutting-edge technology in steel construction offers remarkable advantages over traditional methods, providing strength, durability, and cost-effectiveness to modern infrastructure projects.Section 1: The Rise of Light Gauge Steel ConstructionIn the ever-evolving construction sector, light gauge steel construction has witnessed a surge in popularity due to its numerous benefits. Unlike conventional building materials such as wood or concrete, light gauge steel (LGS) exhibits exceptional strength-to-weight ratio, making it an ideal choice for both residential and commercial structures. It offers superior resistance to fire, termites, and environmental forces like earthquakes. This growing preference for LGS construction has led to the development of innovative machinery that streamlines the production process, such as the Light Gauge Steel Making Machine.Section 2: The Light Gauge Steel Making Machine: An OverviewDeveloped by the leading company {}, the Light Gauge Steel Making Machine is at the forefront of revolutionizing LGS construction. This machine automates the entire production process, from roll forming to cutting, bending, and punching, significantly reducing labor and time requirements. The state-of-the-art technology employed by this machine ensures precision, consistency, and high-quality end products, meeting the stringent standards of modern construction.Section 3: Advantages of Light Gauge Steel Making Machine3.1 Efficiency and Cost-effectiveness:By automating the production process, the Light Gauge Steel Making Machine enables faster and more efficient construction. The reduced labor requirements translate into cost-saving benefits, making LGS construction an economically viable option for a wide range of projects. Additionally, the machine ensures minimal material wastage, contributing to a more sustainable construction approach.3.2 Design Versatility:The Light Gauge Steel Making Machine offers unparalleled design versatility. It can create various profiles, shapes, and sizes, allowing architects and engineers to unleash their creativity. This flexibility in design empowers construction firms to cater to diverse client needs, thereby expanding the scope of their projects.3.3 Structural Integrity:One of the key advantages of LGS construction facilitated by the Light Gauge Steel Making Machine is its inherent structural integrity. Steel boasts exceptional tensile strength, ensuring that buildings remain sturdy and resilient. Moreover, the accurate fabrication process enabled by the machine guarantees consistency and precision in the construction, minimizing any structural defects.Section 4: Environmental SustainabilityThe Light Gauge Steel Making Machine promotes sustainable construction practices due to the inherent environmental benefits of LGS. Steel is a fully recyclable material, and its use significantly reduces deforestation and wastage of natural resources. Furthermore, by automating the fabrication process, the machine curtails energy consumption and carbon emissions, contributing to a greener construction industry.Section 5: Future Implications and ConclusionThe Light Gauge Steel Making Machine marks a significant turning point in the construction industry. Its efficiency, cost-effectiveness, design versatility, and environmental sustainability make it an ideal choice for architects, contractors, and developers. As this technology continues to advance, we can expect to witness a widespread adoption of LGS construction, transforming skylines and revolutionizing the way we build.In conclusion, the introduction of the Light Gauge Steel Making Machine by {} is a game-changer in the construction industry. With its numerous advantages, this innovative technology sets new benchmarks for efficiency, cost-effectiveness, design flexibility, and environmental sustainability. As the demand for modern infrastructure grows, it is clear that LGS construction, propelled by state-of-the-art machinery like this, is the way forward for the industry.

Roll Forming Machine for Corrugated Metal Roof Panels - All You Need to Know!

Title: Advanced Corrugated Metal Roof Panel Roll Forming Machine Revolutionizes the Construction IndustryIntroduction (company background and their expertise):(Company Name) is a leading manufacturer in the construction equipment industry, renowned for their innovative machinery solutions. With years of expertise, they have consistently delivered high-quality and efficient products to customers across the globe. By employing cutting-edge technologies, (Company Name) aims to revolutionize the construction industry by making processes faster, more cost-effective, and environmentally friendly.(Please note that the brand name has been removed as per your request.)I. The Corrugated Metal Roof Panel Roll Forming Machine: A Breakthrough in Roofing SolutionsIn recent years, the construction industry has witnessed a surge in demand for quick and reliable roofing solutions. To address these needs, (Company Name) has introduced an advanced Corrugated Metal Roof Panel Roll Forming Machine. This innovative machinery offers enhanced efficiency and precision in manufacturing roofing panels, making it an indispensable tool for construction companies committed to delivering top-quality roofs.II. Key Features and CapabilitiesThe newly designed Corrugated Metal Roof Panel Roll Forming Machine boasts several key features that set it apart from traditional manufacturing methods and other similar machines:1. High-Speed Production: Equipped with cutting-edge technology and a streamlined operational process, this machine can produce corrugated metal roof panels at an unprecedented speed. This efficiency not only saves time but also increases a company's production capacity.2. Precision and Consistency: The machine's computerized control system ensures accuracy and consistency in producing panels of uniform dimensions. This precision prevents wastage of materials and facilitates seamless installation on-site.3. Customizability: Built with flexibility in mind, the Corrugated Metal Roof Panel Roll Forming Machine enables customization of panel dimensions, giving construction companies the freedom to adapt to various project requirements. This means that roofs can be tailored to meet specific architectural designs, enhancing the aesthetic appeal of buildings.4. Durability and Quality: By utilizing premium-grade materials and employing rigorous quality control measures, (Company Name) guarantees that the machine produces roofing panels built to withstand harsh weather conditions. These robust panels ensure long-lasting and reliable protection for buildings, adding value to construction projects.III. Advantages and BenefitsThe introduction of the Corrugated Metal Roof Panel Roll Forming Machine brings several advantages and benefits to both construction companies and end-users:1. Cost-Effectiveness: With reduced labor costs and optimized material utilization, companies utilizing this machine can significantly cut down on production expenses. By minimizing human errors and maximizing efficiency, this machine allows for greater profitability.2. Speed and Efficiency: The high-speed production capacity of the machine allows construction companies to complete projects within shorter timeframes. This accelerated construction process is particularly beneficial when undertaking large-scale projects or managing tight deadlines.3. Sustainability: The Corrugated Metal Roof Panel Roll Forming Machine aligns with sustainable practices by minimizing material waste. Roofing panels produced through this machine are optimized for resource efficiency, contributing to a greener and more environmentally conscious construction industry.4. Reputation and Customer Satisfaction: By delivering durable, high-quality roofing solutions, construction companies can enhance their reputation and gain a competitive edge. End-users can rest assured that their roofs will offer exceptional performance and stand the test of time, resulting in increased customer satisfaction.IV. ConclusionThe introduction of the advanced Corrugated Metal Roof Panel Roll Forming Machine by (Company Name) represents a significant milestone in the construction industry. This innovative machinery offers unmatched speed, precision, customizability, durability, and cost-effectiveness, revolutionizing the way roofing solutions are manufactured and installed.Construction companies that adopt this technology can expect to streamline their operations, enhance profitability, and deliver superior roofs that meet the diverse needs of their clients. With a focus on sustainability and customer satisfaction, (Company Name) continues to push the boundaries of construction equipment, paving the way for a more efficient, reliable, and eco-friendly industry.

Efficient Cold Formed Steel Machine for Your Manufacturing Needs

ABC Steel Manufacturing, a leading supplier of cold formed steel products, has recently invested in state-of-the-art cold formed steel machines to enhance their production capabilities. The new technology, which has been developed in partnership with industry experts, will allow ABC Steel Manufacturing to produce high-quality cold formed steel products with improved efficiency and precision.The cold formed steel machine, (brand name removed), incorporates the latest advancements in cold forming technology, including fully automated processes and advanced control systems. This new investment reflects ABC Steel Manufacturing’s commitment to staying at the forefront of the industry and providing their customers with the best quality products.Cold formed steel, also known as light gauge steel, has become increasingly popular in the construction industry due to its strength, durability, and versatility. It is widely used in the construction of commercial and residential buildings, as well as in infrastructure and industrial applications. With the demand for cold formed steel products on the rise, ABC Steel Manufacturing’s investment in new machinery will enable them to meet the growing needs of their customers and offer a wider range of products.The new cold formed steel machine will significantly increase the production capacity at ABC Steel Manufacturing’s facilities, allowing them to fulfill larger orders and reduce lead times for their customers. With the ability to produce a wide range of cold formed steel products, including studs, joists, track systems, and custom components, ABC Steel Manufacturing can now offer a comprehensive solution for their customers’ steel framing needs.In addition to the increase in production capacity, the new cold formed steel machine will also improve the quality of ABC Steel Manufacturing’s products. The advanced technology and precision engineering of the machine will ensure that all cold formed steel products meet the highest standards of quality and accuracy. This will not only benefit ABC Steel Manufacturing’s customers but also enhance the company’s reputation as a trusted and reliable supplier of cold formed steel products.The investment in the new cold formed steel machine is part of ABC Steel Manufacturing’s long-term strategy to expand and modernize their manufacturing capabilities. By continuously investing in the latest technology and equipment, the company aims to maintain its position as a leader in the cold formed steel industry and provide the best possible solutions for their customers.“We are thrilled to announce the acquisition of our new cold formed steel machine,” said John Smith, CEO of ABC Steel Manufacturing. “This investment represents our ongoing commitment to innovation and excellence in the steel manufacturing industry. With this new technology, we are confident that we will be able to better serve our customers and meet their evolving needs.”ABC Steel Manufacturing is a well-established company with a strong track record of delivering high-quality cold formed steel products to customers across the country. With their investment in the new cold formed steel machine, the company is poised to continue its success and further strengthen its position in the market.The installation of the new cold formed steel machine is already underway at ABC Steel Manufacturing’s facilities, and the company expects it to be fully operational in the coming months. As the machine becomes operational, ABC Steel Manufacturing will be able to offer an expanded range of cold formed steel products and provide enhanced services to their customers.In conclusion, the investment in the new cold formed steel machine reflects ABC Steel Manufacturing’s dedication to advancing their capabilities and providing the best quality products for their customers. With this new technology, the company is well-positioned to meet the growing demand for cold formed steel products and maintain its status as a leading supplier in the industry.

Affordable and Portable Standing Seam Roll Former for Seamless Construction Projects

Title: Revolutionary Portable Standing Seam Roll Former Revolutionizes Roofing IndustrySubtitle: Company Leads the Way in Innovation and EfficiencyIntroduction (Approximately 100 words):In a major breakthrough in the roofing industry, an industry-leading company has unveiled its latest innovation – a revolutionary Portable Standing Seam Roll Former. Designed to transform the way roofs are installed and improve efficiency dramatically, this game-changing technology has already started making waves within the construction sector. Combining cutting-edge engineering and advanced automation, the Portable Standing Seam Roll Former is set to streamline roofing processes and potentially redefine industry standards. Led by [Company Name], a renowned name in the field of construction equipment, this ground-breaking solution is expected to revolutionize the roofing industry and enhance productivity across the board.[Company Name]'s History and Expertise (Approximately 200 words):With a legacy spanning over two decades, [Company Name] has solidified its place as an industry leader in providing construction equipment and innovative solutions to countless firms worldwide. Established in [year], the company has consistently prided itself on delivering high-quality products tailored to meet the diverse needs of its clientele. Renowned for its commitment to excellence, [Company Name] has developed a reputation for consistently pushing boundaries and surpassing industry standards.Backed by a team of experienced engineers and professionals, the company boasts an extensive portfolio of cutting-edge construction solutions. Through a unique blend of creativity, engineering prowess, and thorough market research, [Company Name] has consistently been a driver of innovation in an ever-evolving industry. From robotic bricklayers to advanced concrete mixers, the company has continuously strived to offer the most efficient and groundbreaking tools to make construction processes more streamlined and cost-effective.Portable Standing Seam Roll Former Features and Benefits (Approximately 400 words):The Portable Standing Seam Roll Former developed by [Company Name] is a perfect marriage of technology, durability, and convenience. Harnessing advanced engineering principles, this portable machine offers unparalleled flexibility and efficiency, making it an ideal solution for both small-scale residential projects and extensive commercial ventures.One of the key advantages of the Portable Standing Seam Roll Former is its mobility. Weighing just [weight], this compact machine can be easily transported to the desired location, eliminating the need for additional equipment or cranes. The roll former's portability not only saves costs associated with heavy machinery transportation but also allows for quicker setup and ease of use. It brings exceptional versatility to the job site, ensuring maximum efficiency no matter the project's scale or geographic location.In addition to its portability, the Standing Seam Roll Former boasts a range of sophisticated features that streamline the roofing process. Equipped with an intelligent control system and intuitive interface, users can easily adjust parameters such as panel dimensions, seam spacing, and curvature with just a few clicks. These user-friendly features reduce the manual labor required and minimize the chances of errors, ensuring precise and seamless seams every time.Furthermore, the Standing Seam Roll Former's advanced automation capabilities contribute to heightened productivity and reduced labor costs. With its high-speed rolling and cutting mechanisms, the machine can shape and shear standing seam panels with remarkable speed and accuracy. This translates into shorter installation times and improved efficiency, allowing roofing professionals to complete projects in a fraction of the time compared to traditional methods.Conclusion (Approximately 100 words):[Company Name]'s Portable Standing Seam Roll Former represents a revolutionary step forward for the roofing industry. Combining mobility, versatility, and advanced automation, this game-changing technology promises to streamline construction processes and reduce costs significantly. As a leading force in innovation, [Company Name] has once again proven its commitment to providing cutting-edge solutions to boost productivity and redefine industry standards. With the introduction of the Portable Standing Seam Roll Former, the roofing industry can look forward to increased efficiency, reduced labor costs, and accelerated project completion times, making it a truly transformative addition to construction sites worldwide.

How to Choose a Steel Angle Roll Forming Machine?

Title: Revolutionary Steel Angle Roll Forming Machine: A Game-Changer in Metal Fabrication IndustryIntroduction:Steel angle roll forming machines have long played a vital role in the metal fabrication industry, allowing for efficient and precise manufacturing of steel angles used in various applications. A recent introduction by a leading manufacturer is revolutionizing the industry by setting new standards in terms of performance, versatility, and cost-effectiveness. This state-of-the-art roll forming machine operates with unrivaled precision, enabling manufacturers to meet the growing demands of steel angles across diverse sectors.Enhanced Performance and Versatility:This advanced steel angle roll forming machine boasts a range of cutting-edge features that significantly enhance its performance and versatility. Equipped with the latest technology, it offers unprecedented precision in producing steel angles of various measurements and profiles. The machine's high-speed capabilities minimize production time while maintaining excellent quality control.The roll forming machine incorporates adjustable roller sets, allowing for easy customization of the angle dimensions. With its ability to handle a wide range of materials, including stainless steel, aluminum, and carbon steel, manufacturers now have the flexibility to cater to a broader spectrum of customer requirements.User-Friendly Interface and Automated Operations:The steel angle roll forming machine's user-friendly interface simplifies the programming and operation processes, ensuring smooth and seamless production runs. Its intuitive control panel allows operators to set various parameters such as length, angle, and bend radius with precision and ease. The machine's automated operations further boost efficiency, reducing the need for manual labor and minimizing the risk of human error.Cost-Effectiveness and Increased Productivity:Engineered to optimize production efficiency, the roll forming machine significantly reduces material wastage, thereby lowering operational costs. Its precise bending and cutting mechanisms ensure minimal scrap during the manufacturing process. Moreover, the machine's high-speed capabilities enable manufacturers to meet tight deadlines and increase their overall productivity.Seamless Integration with Existing Workflows:Recognizing the diverse operational needs of manufacturers, the steel angle roll forming machine is designed to seamlessly integrate into existing production lines. The machine's modular design allows for easy installation and integration with other equipment. Its compatibility with industry-standard software streamlines the exchange of data, bridging the gap between manufacturing processes and achieving enhanced efficiency across the entire production cycle.Robust Build Quality and Safety Features:Safety is paramount in any manufacturing environment, and this roll forming machine prioritizes operator well-being through its comprehensive safety system. Equipped with emergency stop buttons and protective enclosures, it ensures a secure working environment. The machine's robust construction guarantees durability, reducing downtime due to maintenance issues and maximizing its operational lifespan.Implications for the Metal Fabrication Industry:The introduction of this revolutionary steel angle roll forming machine is set to transform the metal fabrication industry significantly. Its unrivaled precision, enhanced performance, and streamlined workflows will enable manufacturers to meet evolving market demands efficiently.Manufacturers utilizing this roll forming machine will experience reduced costs, increased productivity, and enhanced product quality, ultimately leading to improved customer satisfaction and business growth. By leveraging the machine's versatility, manufacturers can now expand their product offerings, catering to a wide array of sectors such as construction, infrastructure development, and transportation.Conclusion:The advent of the steel angle roll forming machine signifies a breakthrough in the metal fabrication industry. Its cutting-edge features, user-friendly interface, and automated operations will pave the way for a new era of efficiency and precision. Manufacturers choosing to invest in this revolutionary machine will undoubtedly gain a competitive edge, fueling growth and innovation in the ever-evolving world of steel angle production.

Our company is a leading manufacturer of floor deck roll forming machines. While there are several manufacturers of roof tile machines, most of them can only produce simple roof panel machines. However, a floor deck roll forming machine is a large and complex machine, which many smaller factories may not be equipped to produce. As a result, these smaller factories may either charge a high price for the machine or compromise on quality.Our company specializes in the field of floor deck roll forming machines and offers a wide range of options to suit different requirements. Some of the floor deck models we offer include YF51-342-1025, YF75-230-690, YF75-200-600, YF76-344-688, YF75-293-880, YF75-230-690, YF65-185-555, YF51-200-600, YF51-226-678, YF51-253-760, YF51-250-750, YF51-240-720, YF51-305-914, YF50-180-720, and YF35-125-750. Additionally, we also have a steel truss floor decking machine that can weld rebar onto the floor deck for added strength and durability.Our expertise in this field allows us to not only produce high-quality floor deck roll forming machines but also provide valuable insights and assistance to our customers. In fact, we understand the importance of SEO and creating relevant content to attract potential customers. This is why we have created a 1000-word blog focusing on the different types of floor deck roll forming machines we offer. By incorporating keywords like "B Decking Roll Forming Machine" into the blog, we aim to improve our website's visibility and reach a wider audience in the market.To summarize, our company is dedicated to manufacturing top-notch floor deck roll forming machines. We provide a range of options to suit various needs and even offer a steel truss floor decking machine for enhanced durability. Our commitment to SEO and relevant content creation demonstrates our effort to connect with potential customers and establish ourselves as a trusted and reliable manufacturer in the industry.

Gain Insights Into the Roof Sheet Forming Machine: A Comprehensive Overview

Roofing is a vital component of any building, and it requires the best quality materials to ensure its durability and strength. That is why choosing the right type of metal roofing is extremely important. Fortunately, there are many roofing products available in the market today that can serve both commercial and residential buildings.One of the most popular roofing materials is the metal roof. The metal roof has many advantages, including its durability, ability to withstand harsh weather conditions, and its eco-friendliness. Additionally, metal roofing is also visually appealing and comes in a variety of colors and shapes, making it a versatile roofing option.To produce these sheets of metal roofing, a roofing forming machine is used. Roof sheet forming machines are an essential part of the roofing industry. These machines have revolutionized the roofing industry by allowing manufacturers to produce top-quality metal roofing materials.Recently, a new roof sheet forming machine (brand name removed due to company policy) has hit the market and is causing quite a stir. This advanced machine is designed to produce quality roofing sheets that are strong, durable, and easy to install. It is built with the latest technology and has several features that make it stand out from the rest.One of the main features of this machine is its ability to produce roofing sheets of various lengths and widths. This helps to reduce waste and saves time and energy, as manufacturers can produce the exact dimensions they need for each project. Additionally, this machine is designed with a simple control system, making it easy to operate, even for those without prior experience.Another feature of this roof sheet forming machine is its ability to produce metal roofing sheets of different shapes and profiles. The machine can produce corrugated metal roofing sheets, standing seam roofing sheets, and other unique profiles that meet specific project requirements. This adds to the versatility of the machine and allows manufacturers to meet the needs of a wide range of customers.The most impressive feature of this machine is its speed. It can produce metal roofing sheets at an impressive speed of up to 45 meters per minute. This is a significant improvement over older machines that produce roofing materials at a much slower rate. This speed allows manufacturers to meet the growing demand for metal roofing materials and complete projects quickly.The company behind this machine is a well-known manufacturer of roofing equipment. Founded in the early 2000s, they have been providing advanced roofing solutions to the industry for over 20 years. Their commitment to quality and innovation has made them a trusted name in the roofing industry.In addition to their roof sheet forming machines, the company also produces roll forming machines, metal bending machines, and other roofing equipment. They offer a wide range of products to meet the needs of manufacturers and contractors in the roofing industry.Their dedication to customer service is another reason why they are a respected name in the industry. They offer comprehensive customer support and are always available to answer any questions or concerns their clients may have. Their commitment to service excellence has earned them a loyal following and has helped them build lasting relationships with their clients.In conclusion, the new roof sheet forming machine from (brand name removed) is an impressive development in the roofing industry. Its ability to produce high-quality roofing materials quickly and efficiently will be a game-changer for manufacturers and contractors alike. With its innovative features and the reputation of the company behind it, this machine is sure to be a popular choice for those in the roofing industry.

Metal Deck Roll Forming Machine for Efficient Decking Production in 2019

Floor Deck Roll Forming Machine | Decking Machine 2019: A Revolution in Metal Deck ProductionIn today's rapidly evolving construction industry, the demand for innovative and efficient machinery is at an all-time high. Companies are constantly on the lookout for advanced equipment that can help streamline their production processes and enhance the quality of their products. In line with these requirements, lotos design has introduced an exceptional Floor Deck Roll Forming Machine in 2019 that is set to revolutionize metal deck production.The Floor Deck Roll Forming Machine is a state-of-the-art piece of equipment that provides unparalleled precision and efficiency in manufacturing a variety of metal decks. With its computer-optimized design, this machine is capable of producing various types of metal decks catering to the specific needs of the construction industry. This cutting-edge technology takes the production process to a whole new level, ensuring superior quality and durability in each deck manufactured.One of the key features of the Floor Deck Roll Forming Machine is its computer optimization. This ensures that the machine operates at its peak performance, enabling the production of consistent and accurate metal decks. By removing any potential human error from the equation, lotos design has created a machine that guarantees exceptional quality with every deck produced. This not only increases the efficiency of the production process but also reduces material waste, thus making it an environmentally friendly solution.The lotos design Floor Deck Roll Forming Machine is a result of extensive research and development carried out by their team of experts. With years of experience in the industry, the company has gained invaluable knowledge about the requirements and challenges faced by construction companies when it comes to metal deck production. By incorporating this knowledge into the design of the machine, lotos design has created a solution that addresses these challenges, making metal deck production a breeze for their customers.Moreover, the company's dedication to customer satisfaction is evident in the quality of their product. They have gone above and beyond to ensure that their machine not only meets but exceeds industry standards. With a focus on durability and performance, lotos design has tested the Floor Deck Roll Forming Machine rigorously to ensure its reliability in demanding production environments. This dedication to quality has earned them a reputation as a trusted name in the industry.The Floor Deck Roll Forming Machine is not just another piece of equipment to lotos design. It is a testament to their commitment to innovation and providing their customers with the best possible solutions. With this machine, construction companies can significantly enhance their productivity and efficiency, thereby giving them a competitive edge in the market.As the construction industry continues to evolve, lotos design remains at the forefront of innovation. They continuously strive to develop groundbreaking machinery that revolutionizes the way metal decks are produced. The introduction of the Floor Deck Roll Forming Machine in 2019 is a testament to their dedication to excellence.In conclusion, the lotos design Floor Deck Roll Forming Machine is a game-changer in the construction industry. With its computer optimization and advanced features, it offers unparalleled precision and efficiency in metal deck production. By addressing the specific needs and challenges faced by construction companies, lotos design has created a solution that sets a new benchmark for the industry. As the demand for superior quality and efficient machinery continues to rise, the Floor Deck Roll Forming Machine proves to be a true game-changer.