Latest Advancements in Curved Corrugated Sheet Roll Forming Machines Unveiled

By:Admin

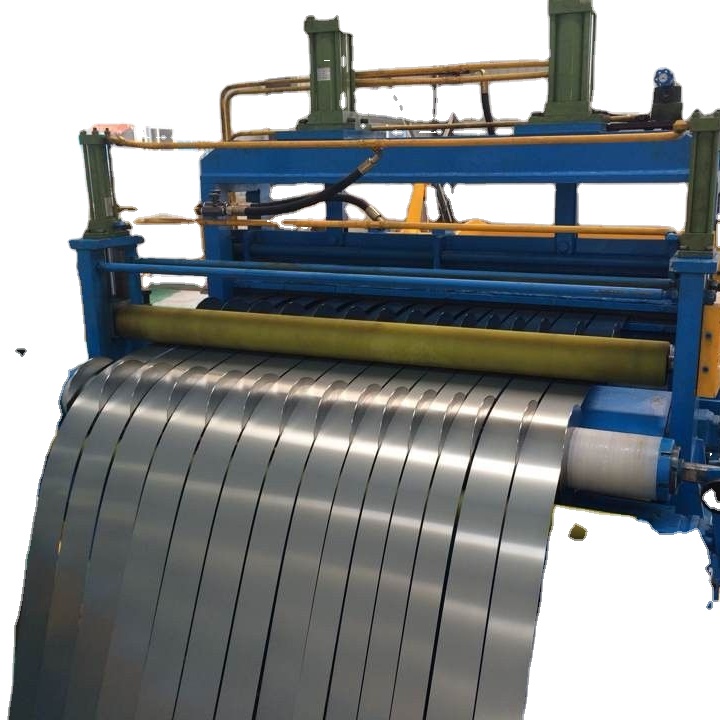

Curved Corrugated Sheet Roll Forming Machines are revolutionizing the production of roofing solutions. This innovative technology is designed to provide businesses with a streamlined, high-capacity system that is capable of producing curved corrugated sheets at an unprecedented rate. With a focus on efficiency and performance, these state-of-the-art machines are quickly becoming the industry standard.

As a leader in the manufacture of roll forming machines, (Brand Name Removed) is at the forefront of this exciting new trend. With a range of machines specifically designed for the production of curved corrugated sheets, (Brand Name Removed) is setting the standard for quality and efficiency.

At the heart of (Brand Name Removed)'s curved corrugated sheet roll forming machines is a cutting-edge computer-controlled system. This system ensures that every panel is produced to a consistent, high-quality standard. The system also features advanced roll forming technology, resulting in straight, easy-to-handle panels that are pre-cut and ready to install on-site.

The efficiency of these machines is further enhanced by their high-speed production capabilities. With a capacity of up to 180 panels per hour, these machines can keep pace with even the most demanding production requirements. And because they are designed with ease of use in mind, operators can quickly and easily configure the machine to produce different panel types and sizes as needed.

But it's not just the technology that sets (Brand Name Removed)'s curved corrugated sheet roll forming machines apart. The company has also invested heavily in its research and development team, ensuring that each machine is built to the highest standards of quality. This approach has allowed (Brand Name Removed) to consistently exceed customer expectations when it comes to durability, reliability, and overall performance.

To ensure that its customers are fully supported, (Brand Name Removed) also offers a comprehensive range of after-sales services. These services include technical support, maintenance, and training, making it easy for customers to keep their machines running at peak performance over the long term.

With a proven track record of success and a commitment to excellence, (Brand Name Removed) is the ideal choice for businesses looking to invest in a curved corrugated sheet roll forming machine. Whether you're a small business looking to expand your product range or a large corporation seeking to streamline your production processes, (Brand Name Removed)'s products and services are sure to meet your needs.

So why wait? If you're ready to take your production capabilities to the next level, contact (Brand Name Removed) today to learn more about their curved corrugated sheet roll forming machines. With their industry-leading technology, commitment to quality, and comprehensive after-sales support, you can be confident that you're making a wise investment for the future of your business.

Company News & Blog

Roll Forming Machines for Metal Roof and Drywall Studs and Track

If you are involved in the construction industry, you probably know how important it is to have the right equipment to get the job done quickly and efficiently. One of the most essential pieces of equipment that you need is a metal stud making machine.There are many different types of metal stud making machines on the market, but the most popular ones are those that are designed to produce high-quality metal studs and tracks used in drywall installation and house making. These machines are known for their precision, accuracy, and speed, making them the perfect tools for any construction project.One of the best things about metal stud making machines is that they are incredibly versatile. They can be used to produce a wide range of metal studs and tracks, including those made from steel, aluminum, and other metals. This means that you can use them for a variety of different projects, from small-scale jobs like installing a new drywall partition to large commercial construction projects.Metal stud making machines come in a range of sizes and configurations to meet the needs of different construction businesses. Some machines are designed to be portable, while others are more stationary. Some machines are designed to produce only metal studs, while others can produce both studs and tracks.To ensure that you are getting the best metal stud making machine for your needs, it is important to do your research and compare different models and brands. Look for a machine that is easy to use, has a high level of automation, and can produce high-quality metal studs quickly and efficiently.One popular brand of metal stud making machines is Alibaba. Their drywall stud roll forming machine is designed to produce high-quality studs and tracks for drywall installation and house framing. This machine is easy to operate and can produce metal studs and tracks in a range of different sizes and configurations.Another popular brand of metal stud making machine is Jobsite Roll Forming Equipment. Their machines are designed to produce metal studs and tracks for a range of different applications, including both residential and commercial construction projects. These machines are known for their precision and speed, making them the perfect choice for any construction business.In conclusion, if you are in the construction industry and looking to invest in a metal stud making machine, there are plenty of options to choose from. Whether you are looking for a portable machine or a more stationary model, there is sure to be a machine that fits your needs. Just be sure to do your research and compare different brands and models to find the best machine for your construction business.

Roll Forming Machine for C/Z/U Channel Interchange: Discover China's Latest Product Innovation

Roll forming machines have become an essential tool in the manufacturing industry. They are used to create metal sheets of different shapes and sizes according to specific manufacturing requirements. One such machine that has gained immense popularity in recent times is the C/Z/U Channel Interchanged Roll Forming Machine.If you're in search of a reliable and efficient roll forming machine, look no further than China-Glorious.com. Here, you will find a range of machines that are designed to cater to different manufacturing needs. The C/Z/U Channel Interchanged Roll Forming Machine, in particular, has numerous features and benefits that make it a great investment for your business.What is a C/Z/U Channel Interchanged Roll Forming Machine?A C/Z/U Channel Interchanged Roll Forming Machine is a roll forming machine that can produce C-shaped, Z-shaped, and U-shaped channels from coiled steel. These channels are used in the construction of roofs, walls, flooring, and other structural components. The machine includes a series of rollers and cutting tools that produce the desired shape by gradually bending and forming the metal strip.Why Choose a C/Z/U Channel Interchanged Roll Forming Machine?The C/Z/U Channel Interchanged Roll Forming Machine is a versatile piece of equipment that comes with a host of benefits. Here are some of the reasons why you should consider investing in one:1. Faster Production - With a C/Z/U Channel Interchanged Roll Forming Machine, you can produce channels at a faster speed compared to traditional methods. This increased speed helps in meeting the demands of customers within a shorter time frame.2. Consistent Quality - The machine ensures consistent quality in every channel produced, which is essential in the construction industry. A consistent quality output also reduces waste, ensuring maximum utility of the raw materials.3. Cost-Effective - The machine requires less labor, materials, and maintenance costs, making it a cost-effective solution to mass-production. This means that investing in a C/Z/U Channel Interchanged Roll Forming Machine is a great way to save your business money over the long term.4. Flexibility - The machine can produce different sizes and shapes of channels, equipping manufacturers with more flexibility in their production line. Plus, a varied shape and size offering ensures that the manufacturer is well positioned to meet the needs of different customers.5. Durable - The machine is made from high-quality materials, so it has a longer lifespan than other equipment used for shaping metal channels. Therefore, making it an excellent return on investment due to an extended period of usage.6. Easy to Use - The machine comes with a well-detailed user manual that makes it easy to set up and operate.In conclusion, the C/Z/U Channel Interchanged Roll Forming Machine offers numerous advantages for manufacturers looking to increase their production output in a cost-effective and efficient manner while ensuring consistent quality. At China-Glorious.com, you can find a high-quality resilient channel rolling machine at an affordable price. Opt for this machine and take your production capabilities to the next level.

High-Quality Double Layer Roll Forming Machines at Low Prices

: The Solution for Improved Efficiency and PerformanceAs the global demand for quality steel roofing materials continues to increase, so does the need for efficient and high-performance roll forming machines. One such machine that has proven to be a game-changer in the metal roofing industry is the double layer color steel roll forming machine. In this blog post, we will delve deep into the features and benefits of this machine.What is a Double Layer Color Steel Roll Forming Machine?A double layer color steel roll forming machine is a type of roll forming equipment designed to produce two different metal sheets simultaneously. This machine is engineered to incorporate two sets of roll forming systems that work independently to produce two types of profiles without changing the roll tooling.The machine consists of a decoiling system, a double-layer roll former, a hydraulic cutting system, a programmable controller, and a stacking system. With its advanced design, the double layer roll forming machine can produce metal roofing panels at an incredible speed and with remarkable accuracy.Why Choose a Double Layer Roll Forming Machine?There are several reasons why a double layer roll forming machine is a smart investment for metal roofing manufacturers. Firstly, this machine simplifies processes and reduces downtime by producing two different profiles simultaneously. This approach saves valuable time for manufacturers, making them more productive and efficient.Moreover, the double layer roll forming machine produces consistent and uniform sheets. This ensures that the metal sheets meet the precise requirements of the end-user and helps to eliminate defects such as scratches, dents, or uneven surfaces. As a result, this leads to higher customer satisfaction and fewer product returns, reducing the overall costs.Another benefit of the double layer roll forming machine is its versatility. It can manufacture a wide range of metal roofing profiles such as corrugated sheets, trapezoidal sheets, and standing seam panels. This means that manufacturers can cater to various customer needs and demands while remaining competitive in the market.Features of a Double Layer Roll Forming MachineThe double layer roll forming machine comes with several features that make it stand out from other roll forming machines. Some of these features include:1. Multiple Profiles: The machine can produce up to 2 different profiles simultaneously, offering unmatched versatility and flexibility to manufacturers.2. High Precision: With its advanced hydraulic cutting system and programmable controller, the machine can produce metal sheets with high precision and without material wastage.3. High Efficiency: The machine can produce up to 35 meters of metal roofing sheets per minute, making it a highly efficient and profitable machine for metal roofing manufacturers.4. Easy to Operate: The double layer roll forming machine comes with a user-friendly interface that makes it easy for operators to set up and control the machine. It also requires low maintenance, reducing downtime, and repair costs.5. Robust and Durable: The machine is made of high-quality steel and other durable materials, ensuring it can withstand harsh working conditions and last for a long time.ConclusionThe double layer roll forming machine is an innovative and efficient solution to the increasing demand for quality metal roofing sheets. It offers manufacturers unmatched flexibility, efficiency, and precision, making it a highly profitable investment. Its advanced features, ease of maintenance, and durability are essential components needed for a successful metal roofing business. So, if you are searching for a reliable roller forming machine, get in touch with a double layer roll forming machine supplier today.

Get High-Quality Replacement Roof Tiles in Cambridge PE7

In the world of roofing, one of the most important components is the roof tile. Roof tiles come in a range of materials including clay, slate, and concrete. They serve as both a protective barrier for the top of a building and as a decorative element. If you live in or around the Cambridge area and are in need of replacement roof tiles, you have several options to consider.One popular option for replacement roof tiles in Cambridge is to go with a clay tile. Clay tiles are popular in many areas because of their durability, longevity, and aesthetic appeal. They can come in many different styles and colors, which can make them perfect for a range of architectural styles.If you are looking for a more cost-effective option, concrete roof tiles may be the right choice for you. Concrete roof tiles can also come in a range of styles and colors, and are durable and long-lasting. They are also easy to install, which can save you time and money.In addition to the types of roofing materials you choose, you should also consider the quality of the roof tiles themselves. If you go with a cheap or low-quality tile, you may find yourself in need of replacement sooner than you would like. To ensure that you get the best possible quality, make sure to work with a reputable supplier who can provide you with durable and reliable roof tiles.One way to ensure that you get the best quality roof tiles is to work with a supplier that uses the latest roofing technology. One such technology is the Roof Tiles Machine. This machine can create high-quality roof tiles that are both durable and attractive. They are made using state-of-the-art manufacturing techniques that ensure consistency and quality every time.The Roof Tiles Machine uses innovative technology to create custom-made roof tiles that match your specific needs and requirements. This means that you can choose from a range of colors, styles, and finishes to ensure that your roof not only protects your building but looks great too.The process of making roof tiles using the Roof Tiles Machine involves several different stages. First, the raw material is mixed with water and formed into the desired shape. Then, the tiles are dried and fired in a kiln to create a strong and durable final product.If you are in need of replacement roof tiles in the Cambridge area, it is important to find a supplier that uses the latest technology and manufacturing techniques. The Roof Tiles Machine is one such technology that can provide you with the high-quality roof tiles you need to protect your building and enhance its appearance.In conclusion, whether you are looking for replacement roof tiles in Cambridge or elsewhere, there are several factors to consider. The type of material you choose, the quality of the roof tiles themselves, and the manufacturing technology used by your supplier are all important considerations. By working with a reputable supplier who uses the latest technology, such as the Roof Tiles Machine, you can ensure that you get the best possible quality roof tiles for your building.

Top-quality Manufacturers of Roofing Sheet Roll Forming and Glazed Tile Roll Forming Machines in China

Glazed Roofing Sheet Roll Forming Machine: The Perfect Solution for High-Quality RoofingWhen it comes to building structures, the importance of a sturdy and reliable roof cannot be overstated. A properly constructed roof not only protects the building from external elements but also adds to its aesthetic appeal. One crucial component in roofing construction is the roofing sheet. With the advancements in technology, the process of manufacturing roofing sheets has become much more efficient and precise, thanks to the introduction of roll forming machines.Among the various roll forming machines available in the market, the glazed roofing sheet roll forming machine stands out as a reliable and efficient solution. This machine offers several advantages, including high-quality production, durability, and exceptional performance. If you're in search of a top-quality glazed roofing sheet roll forming machine, look no further than trusted manufacturers like ZhongHeng Machine Manufacture Co.,Ltd., who specialize in providing the best roll forming machines in the industry.High-Quality Roofing Sheet Roll Forming MachineThe quality of roofing sheets significantly impacts the overall performance and lifespan of a roof. A durable and weather-resistant roofing sheet ensures long-lasting protection for any structure. The glazed roofing sheet roll forming machine from ZhongHeng Machine Manufacture Co.,Ltd. guarantees top-notch quality production, meeting and exceeding industry standards.By utilizing advanced technology and state-of-the-art manufacturing processes, the glazed roofing sheet roll forming machine produces roofing sheets of exceptional strength and durability. These machines are designed with precision and accuracy to transform raw materials into flawless roofing sheets with ease. Additionally, the machine's robust build ensures continuous productivity, reducing downtime and optimizing efficiency.Durability and LongevityWhen investing in a roofing sheet roll forming machine, durability is a critical factor to consider. The machine should be constructed with high-quality materials to withstand harsh working conditions and regular usage. ZhongHeng Machine Manufacture Co.,Ltd. excels in this area by providing robust and long-lasting glazed roofing sheet roll forming machines.These machines are built to endure rigorous manufacturing processes without compromising their performance. Built with heavy-duty frames and components, they can withstand prolonged use without experiencing significant wear and tear. This durability ensures maximum return on investment (ROI) and minimizes maintenance costs, making ZhongHeng Machine Manufacture Co.,Ltd. the preferred choice for businesses in need of reliable machines.Exceptional PerformanceThe performance of a glazed roofing sheet roll forming machine directly affects production efficiency and output. ZhongHeng Machine Manufacture Co.,Ltd.'s glazed roofing sheet roll forming machines are engineered to deliver unmatched performance, guaranteeing quick and precise sheet formation with every cycle.Equipped with cutting-edge technology, these machines feature automated processes that reduce dependencies on manual labor, making them highly efficient in terms of time and cost. Furthermore, the machines are equipped with advanced control systems, allowing operators to monitor and adjust the speed and parameters, resulting in consistent and high-quality sheet production.ConclusionWhen it comes to sourcing the best roofing sheet roll forming machines, ZhongHeng Machine Manufacture Co.,Ltd. is a reputable and trusted manufacturer known for their high-quality production and exceptional customer service. Their glazed roofing sheet roll forming machines offer top-notch quality, durability, and exceptional performance.Investing in a glazed roofing sheet roll forming machine from ZhongHeng Machine Manufacture Co.,Ltd. ensures that you receive a reliable, durable, and high-performing machine that will contribute to the success of your roofing business. Don't compromise on the quality of your roofing sheets; choose a dependable and renowned manufacturer for a seamless roofing experience.

Top-rated Roll Forming Machine for Roofing Sheet Production: Ultimate Guide

Title: Roofing Sheet Roll Forming Machine Redefines the Manufacturing ProcessIntro:Innovation has always been at the forefront of the manufacturing industry, constantly pushing the boundaries of what is possible. One such groundbreaking invention is the Roofing Sheet Roll Forming Machine developed by an industry-leading company, revolutionizing the roofing manufacturing process. This state-of-the-art machine not only enhances productivity but also ensures superior quality and durability of roofing sheets. With its introduction into the market, the way roofing materials are produced is set to change forever.I. Need for Revolutionizing Roofing Sheet Manufacturing: Roofing sheets are an essential component in the construction industry, providing protection against harsh weather conditions while enhancing the aesthetic appeal of buildings. Traditionally, manufacturing such sheets involves many time-consuming and labor-intensive processes, resulting in increased costs and longer production time. However, with the advent of the Roofing Sheet Roll Forming Machine, these challenges are effectively addressed.II. Features and Functionality:This innovative machine consists of advanced technology and precision engineering, enabling the rapid and efficient transformation of raw materials into high-quality roofing sheets. Its automatic operation and computer-controlled interfaces eliminate human errors and reduce reliance on manual labor. The machine is equipped with a robust frame and special rollers that shape metal sheets into the desired dimensions and profiles sought by customers.III. Enhanced Efficiency and Productivity:The Roofing Sheet Roll Forming Machine significantly streamlines the production workflow, offering increased efficiency and productivity gains. By automating various processes, including sheet cut to length, roll forming, and sheet stacking, the machine enables swift and continuous manufacturing without compromising on quality. Additionally, its high-speed capabilities guarantee faster output, resulting in reduced lead times and improved customer satisfaction.IV. Superior Quality and Customizability:One of the key advantages of this machine is its ability to consistently produce roofing sheets of exceptional quality. By utilizing precise measurements and automated control systems, it ensures accuracy and consistency in the shape, size, and thickness of each sheet. Moreover, the machine allows for customization, offering customers a wide range of profiles, surface finishes, and color options according to their individual requirements.V. Economic and Environmental Benefits:The Roofing Sheet Roll Forming Machine not only benefits manufacturers but also has a positive impact on the economy and the environment. Its efficiency and increased productivity lead to cost savings by reducing labor requirements and optimizing material usage. Furthermore, the machine promotes sustainability by minimizing scrap and waste, contributing to the overall reduction of carbon footprint associated with the manufacturing process.VI. Market Impact and Future Prospects:With its introduction into the market, the Roofing Sheet Roll Forming Machine is expected to disrupt the roofing industry significantly. Manufacturers can now meet the increasing demand for high-quality roofing materials more efficiently, reducing costs and expanding production capacities. Additionally, the machine's flexibility allows for easy adaptation to emerging trends and customer preferences, ensuring its relevance in the ever-evolving construction industry.Conclusion:The Roofing Sheet Roll Forming Machine, developed by a renowned company, has ushered in a new era in roofing sheet manufacturing. Its innovative design and advanced features enable enhanced efficiency, superior quality, and customization options previously unheard of in the industry. This cutting-edge technology will undoubtedly transform the way roofing materials are manufactured, paving the way for increased productivity, reduced costs, and sustainable practices. As the construction industry continues to evolve, this machine is poised to play a pivotal role in meeting the demands of an ever-changing market.

Promotional Corrugated Pipe Machine and PC Solid, Transparent Sheet Manufacturing Line for Sale

Title: Unleashing the Innovation: Corrugated Sheet Manufacturing Machine Revolutionizes the Production ProcessIntroduction:In today's competitive industrial landscape, staying ahead is crucial for any business to thrive. The manufacturing industry continuously seeks innovative solutions to optimize production processes and enhance product quality. One such revolutionary machine, the Corrugated Sheet Manufacturing Machine, has taken the market by storm. In this blog post, we will delve into the various features and benefits of this powerhouse device and explore its applications across diverse industries.Understanding the Corrugated Sheet Manufacturing Machine:Developed by an industry-leading machinery manufacturer, this Corrugated Sheet Manufacturing Machine is designed to produce high-quality corrugated sheets efficiently and effectively. The machine utilizes state-of-the-art technology and cutting-edge automation processes to meet the requirements of various industries worldwide.Key Features and Specifications of the Machine:1. Increased Productivity:The Corrugated Sheet Manufacturing Machine boasts high production capacity, enabling businesses to meet increasing market demands effectively. With its advanced capabilities, it can produce corrugated sheets at an impressive speed, resulting in reduced lead times and increased profitability.2. Precision and Accuracy:The machine's advanced control systems ensure precise formation and cutting of corrugated sheets, guaranteeing uniform thickness and flawless finishes. This level of precision allows manufacturers to maintain the highest quality standards, meeting customer expectations consistently.3. Flexible Customization:One of the most significant advantages of this machine is its ability to adapt to different production requirements. Manufacturers can adjust settings to produce sheets of varying widths, materials, and thicknesses. This flexibility makes it suitable for a wide range of applications across diverse industries.4. Energy Efficiency:The Corrugated Sheet Manufacturing Machine incorporates energy-saving features, making it an eco-friendly choice. The machine optimizes power consumption while maintaining high productivity, reducing both operational costs and environmental impact.Applications of Corrugated Sheets:Corrugated sheets produced using this innovative machine find applications across multiple industries. Some key applications include:1. Packaging Industry:Corrugated sheets are widely used for packaging purposes due to their durability and lightweight design. The machine's ability to produce sheets of different sizes and materials allows packaging companies to cater to various customer requirements efficiently.2. Construction Sector:Corrugated sheets are utilized for roofing, wall cladding, and insulation purposes in the construction industry. With the machine's flexibility in producing custom sizes and thicknesses, construction companies can easily source corrugated sheets that meet their specific project needs.3. Advertising and Signage:The transparent, durable, and lightweight properties of corrugated sheets make them ideal for advertising and signage applications. The machine's precision enables the production of high-quality sheets suitable for printing eye-catching graphics, ensuring maximum visibility for promotional materials.Conclusion:The Corrugated Sheet Manufacturing Machine has revolutionized the production process in various industries, offering increased productivity, precision, and flexibility. With its ability to produce corrugated sheets of different sizes, materials, and thicknesses, the machine caters to the unique requirements of diverse industries.Investing in this innovative machine can empower businesses to stay ahead in the market, cut down costs, and enhance overall product quality. By incorporating the Corrugated Sheet Manufacturing Machine into their operations, manufacturers can unlock new opportunities for growth, sustainability, and customer satisfaction.Keywords: Corrugated Sheet Manufacturing Machine, Corrugated sheets, production process, innovation, precision, flexibility, applications, packaging industry, construction sector, advertising, signage.

Top Laser Cutting Machine for Various Metals: Mild Steel, Stainless Steel, Aluminum, and More

Laser Cutting Machine for Various Metals: A Flexible Solution for Precision CuttingIn today's metal fabrication industry, precision and efficiency are crucial to successful production. With a wide range of metals, including mild steel, stainless steel, and aluminum, being used in various applications, finding a reliable cutting solution becomes essential. One such solution that meets the demands of precision cutting on different metals is laser cutting technology.Laser cutting machines have revolutionized the metal fabrication industry with their ability to deliver accurate and clean cuts across a variety of materials. Whether it be sheet metal, tubes, or profiles, laser cutting machines provide the flexibility and precision needed for streamlined production processes. With their versatility, these machines have become a popular choice for manufacturers around the world, and the demand for high-quality laser cutting machines is only growing.One notable player in the market, a leading manufacturer of laser cutting machines suitable for cutting mild steel, stainless steel, aluminum, and more, is committed to providing cutting-edge solutions to the metal fabrication industry. With their advanced technology and expertise, they have established themselves as a trusted partner for all cutting needs.Their high-performance laser cutting machines stand out among the competition due to their ability to handle a wide range of metal materials. Whether it is stainless steel sheets for architectural panels or aluminum profiles for structural frameworks, these machines offer superior cutting precision that ensures excellent quality and a smooth finish. As businesses strive for cost-effective and efficient manufacturing processes, these laser cutting machines emerge as a game-changer.One of the notable features of these laser cutting machines is their versatility. By utilizing state-of-the-art laser technology, these machines can effortlessly cut through various thicknesses of metals, allowing manufacturers to undertake complex cutting tasks with ease. Additionally, the machines boast a high cutting speed, significantly reducing production time and increasing overall productivity. With features such as automatic material feeding and precise positioning, these machines make the cutting process highly efficient and user-friendly.Moreover, these laser cutting machines prioritize safety and reliability. Equipped with advanced safety features, such as protective enclosures and automatic shutdown functions, they ensure the well-being of operators and prevent any potential accidents. With built-in quality control mechanisms, these machines deliver consistently precise cuts, minimizing wastage and optimizing material utilization.Furthermore, these laser cutting machines focus on sustainability by incorporating eco-friendly practices. With their low power consumption and minimal environmental impact, they are ideal for manufacturers striving for greener production methods. By utilizing laser technology, these machines significantly reduce the use of traditional cutting tools, such as saw blades or milling machines, which results in less material wastage and fewer emissions.In conclusion, laser cutting machines have become an indispensable tool for the metal fabrication industry, allowing manufacturers to achieve precise cuts on various metals. With their flexibility, versatility, and emphasis on safety and sustainability, these machines offer a reliable and efficient solution for businesses across sectors. Investing in high-quality laser cutting machines eliminates the need for multiple cutting tools, streamlines production processes, and maximizes productivity. As the demand for precision cutting continues to increase, these laser cutting machines remain at the forefront of the industry, enabling manufacturers to meet and exceed customer expectations while staying competitive in the global market.Disclaimer: The company mentioned in this news article is used for illustrative purposes only and does not endorse or promote any specific brand.

Competitive Intelligence by Key Players in the Automatic Roll Forming Machine Market: Global Market Analysis and Size

Automatic Roll Forming Machine Market: Increasing Industrialization Driving Demand for C/Z Purlin Roll Forming MachinesThe global Automatic Roll Forming Machine market is expected to witness robust growth in the coming years, driven by increasing industrialization across the globe. The Automatic Roll Forming Machine is a highly versatile equipment that is used in industries such as construction, automotive, electronics, and aerospace, among others. It is used for forming metal sheets and strips into different shapes and sizes. Among the various types of Roll Forming Machines, C/Z Purlin Roll Forming Machine is a popular choice for manufacturing structures that require strong supports for roofing, cladding, and walls.C/Z Purlin Roll Forming Machine is a type of Roll Forming Machine that is designed specifically for producing C-shaped and Z-shaped purlins. These purlins are used for making pre-engineered steel buildings, industrial sheds, warehouses, and other structures. The machine works by feeding a strip of metal through a series of rollers that shape the metal into the desired profile. The final product is a strong, lightweight, and durable purlin that can withstand heavy loads and adverse weather conditions.Key Market Players in Automatic Roll Forming Machine MarketThe key market players in the Automatic Roll Forming Machine market include Bradbury Group, Framing Tech, Formtek Group, Gasparini Industries, HILALMAK, Howick, Isolaminas, JET USA, Knauer Engineering, L.B. Bohle Maschinen + Verfahren, M.Torres, Onward Machinery, PEP brainin, Taicang Keboer, TOX Pressotechnik, TRL Krosaki Refractories Limited, Xiamen Zheng Liming Metallurgical Machinery, and Yoder.Market SegmentationThe global Automatic Roll Forming Machine market can be segmented based on product type, application, and region.Based on Product Type, the market can be segmented into:• C/Z Purlin Roll Forming Machine• Corrugated Sheet Roll Forming Machine• Tile Roll Forming Machine• OthersBased on Application, the market can be segmented into:• Construction• Automotive• Electronics• Aerospace• OthersBased on Region, the market can be segmented into:• North America• Europe• Asia-Pacific• Middle East and Africa• South AmericaRegional AnalysisThe Asia-Pacific region is expected to dominate the Automatic Roll Forming Machine market in the forecast period, owing to the increasing demand for industrialization in countries such as China, India, and Japan. The region also has a large base of manufacturers and a significant consumer base for Roll Forming Machines. The North American and European markets are also expected to witness steady growth due to the increasing demand for lightweight and durable materials in the construction and automotive industries.ConclusionThe Automatic Roll Forming Machine market is expected to witness robust growth in the coming years, owing to the increasing demand for lightweight and durable materials in the construction, automotive, electronics, and aerospace industries. C/Z Purlin Roll Forming Machines are expected to witness significant demand, owing to the increasing demand for pre-engineered steel buildings, industrial sheds, and warehouses. The Asia-Pacific region is expected to dominate the market, owing to the increasing demand for industrialization in the region. The key market players in the market are Bradbury Group, Framing Tech, Formtek Group, Gasparini Industries, HILALMAK, among others.