Metal Roofing Panel Roll Forming Machine: What You Need to Know

By:Admin

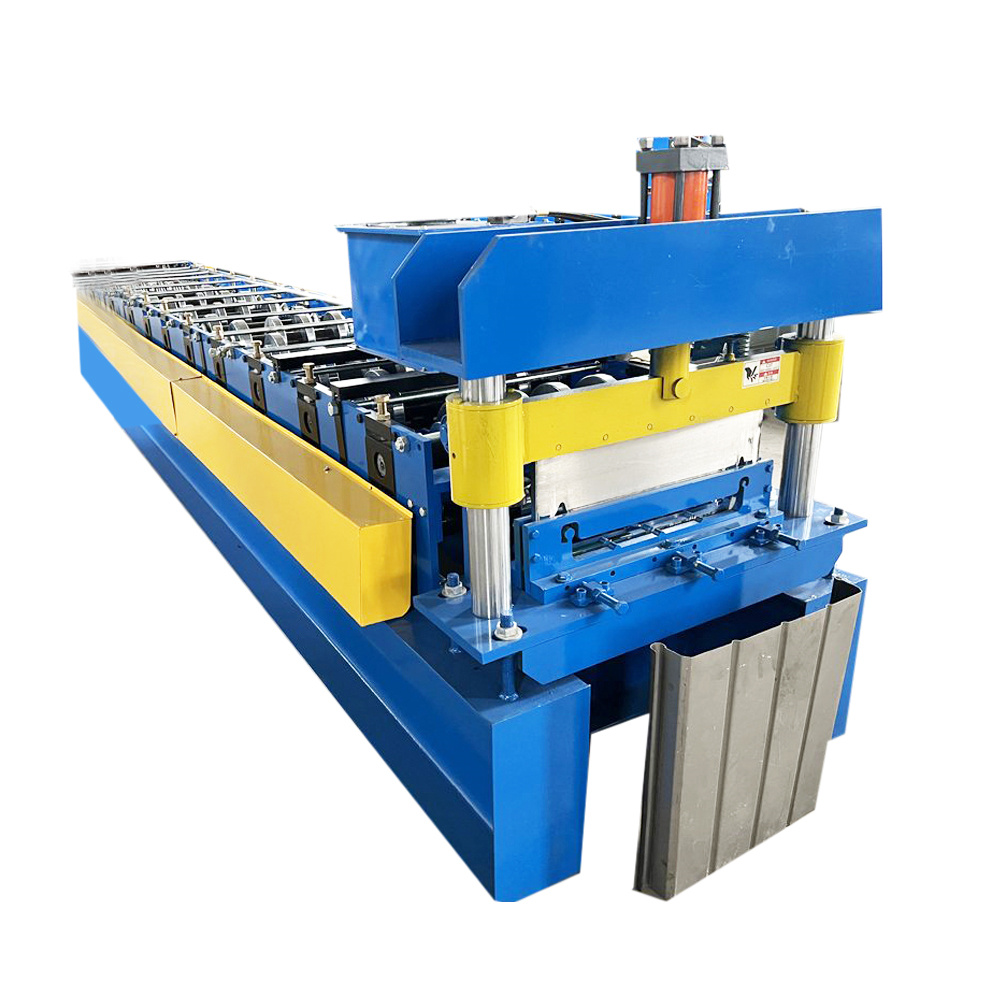

The Corrugated Roofing Panel Roll Forming Machine boasts a range of advanced features that set it apart from traditional roll forming equipment. With a cutting-edge design and engineering, this machine is capable of producing corrugated roofing panels with impeccable accuracy and consistency. Its high-speed production capabilities enable manufacturers to meet the demands of large-scale projects without compromising on quality or efficiency.

One of the key highlights of this machine is its versatility. It is equipped with adjustable tooling and flexible settings, allowing for the seamless production of various types of corrugated roofing panels. Whether it's for residential, commercial, or industrial applications, this machine can effortlessly adapt to different specifications and design requirements, making it an ideal solution for manufacturers with diverse production needs.

Additionally, the Corrugated Roofing Panel Roll Forming Machine is designed with user-friendly controls and intuitive interfaces, ensuring ease of operation and minimal training requirements for operators. This not only enhances productivity but also reduces the risk of errors and downtime, thereby maximizing the overall efficiency of the manufacturing process.

As a leader in the roll forming machinery industry, {} has a long-standing reputation for delivering cutting-edge solutions that align with the evolving needs of the market. With a strong focus on research and development, the company has continuously invested in advancing its technology and engineering capabilities, staying ahead of the curve when it comes to innovation and performance.

{} prides itself on its commitment to quality, reliability, and customer satisfaction. Every machine that comes out of their manufacturing facility undergoes rigorous testing and quality control measures to ensure that it meets the highest standards of excellence. This dedication to craftsmanship and precision has earned {} a loyal customer base and a solid reputation as a trusted supplier of roll forming equipment.

The launch of the Corrugated Roofing Panel Roll Forming Machine further solidifies {}'s position as an industry leader, offering a game-changing solution that promises to streamline and elevate the production of corrugated roofing panels. With its unparalleled performance and advanced capabilities, this machine is set to empower manufacturers to drive greater efficiency, productivity, and competitiveness in their operations.

In conclusion, the introduction of the Corrugated Roofing Panel Roll Forming Machine by {} represents a significant milestone in the roll forming machinery industry. With its cutting-edge technology, versatility, and user-friendly design, this machine has the potential to revolutionize the way corrugated roofing panels are manufactured, setting new benchmarks for quality, speed, and efficiency. As the demand for innovative and high-performance manufacturing solutions continues to grow, {} remains at the forefront, delivering tailored solutions that empower manufacturers to thrive in a dynamic and competitive market.

Company News & Blog

Metal Roofing Panel Roll Forming Machine: What You Need to Know

At the forefront of innovative and efficient manufacturing technology, {} has recently unveiled their latest product - a high-performance Corrugated Roofing Panel Roll Forming Machine. This state-of-the-art machine is designed to revolutionize the production process of corrugated roofing panels, offering enhanced speed, precision, and flexibility for manufacturers in the construction and roofing industry.The Corrugated Roofing Panel Roll Forming Machine boasts a range of advanced features that set it apart from traditional roll forming equipment. With a cutting-edge design and engineering, this machine is capable of producing corrugated roofing panels with impeccable accuracy and consistency. Its high-speed production capabilities enable manufacturers to meet the demands of large-scale projects without compromising on quality or efficiency.One of the key highlights of this machine is its versatility. It is equipped with adjustable tooling and flexible settings, allowing for the seamless production of various types of corrugated roofing panels. Whether it's for residential, commercial, or industrial applications, this machine can effortlessly adapt to different specifications and design requirements, making it an ideal solution for manufacturers with diverse production needs.Additionally, the Corrugated Roofing Panel Roll Forming Machine is designed with user-friendly controls and intuitive interfaces, ensuring ease of operation and minimal training requirements for operators. This not only enhances productivity but also reduces the risk of errors and downtime, thereby maximizing the overall efficiency of the manufacturing process.As a leader in the roll forming machinery industry, {} has a long-standing reputation for delivering cutting-edge solutions that align with the evolving needs of the market. With a strong focus on research and development, the company has continuously invested in advancing its technology and engineering capabilities, staying ahead of the curve when it comes to innovation and performance.{} prides itself on its commitment to quality, reliability, and customer satisfaction. Every machine that comes out of their manufacturing facility undergoes rigorous testing and quality control measures to ensure that it meets the highest standards of excellence. This dedication to craftsmanship and precision has earned {} a loyal customer base and a solid reputation as a trusted supplier of roll forming equipment.The launch of the Corrugated Roofing Panel Roll Forming Machine further solidifies {}'s position as an industry leader, offering a game-changing solution that promises to streamline and elevate the production of corrugated roofing panels. With its unparalleled performance and advanced capabilities, this machine is set to empower manufacturers to drive greater efficiency, productivity, and competitiveness in their operations.In conclusion, the introduction of the Corrugated Roofing Panel Roll Forming Machine by {} represents a significant milestone in the roll forming machinery industry. With its cutting-edge technology, versatility, and user-friendly design, this machine has the potential to revolutionize the way corrugated roofing panels are manufactured, setting new benchmarks for quality, speed, and efficiency. As the demand for innovative and high-performance manufacturing solutions continues to grow, {} remains at the forefront, delivering tailored solutions that empower manufacturers to thrive in a dynamic and competitive market.

C Shape Purlin Forming Machine: Latest News and Updates Revealed

article about the significance of the C Shape Purlin Forming Machine in the construction industry.C Shape Purlin Forming Machine Significantly Boosting The Construction IndustryThe construction industry has emerged as one of the most important industries contributing to the growth and development of the economy. With the rising demand for commercial and residential properties, the construction industry is poised for growth and expansion. However, the industry needs to innovate and adopt modern technologies to keep up with changing market trends. This is where the C Shape Purlin Forming Machine comes into play.The company, (brand name removed), is a leading manufacturer of C Shape Purlin Forming Machine that has revolutionized the construction industry. The machine is designed to create durable and high-quality C-shaped, cold-formed steel channels for use in various construction projects. With advanced technology, the C Shape Purlin Forming Machine offers numerous benefits to the construction industry, including:1. Cost-effectiveThe C Shape Purlin Forming Machine uses raw materials that are cost-effective and easily available in the market. The machine's production process requires no welding, thus saving labor time and cost compared to other traditional construction methods. The machine's high efficiency helps to reduce production costs, making the process more affordable and accessible to buyers.2. High-quality productsThe C Shape Purlin Forming Machine produces high-quality and durable C-shaped steel channels that are perfect for construction projects. The machine uses advanced manufacturing technologies to ensure the products meet strict quality standards. The C shaped steel channels produced have a high strength-to-weight ratio, making them ideal for use in various building projects.3. VersatilityThe C Shape Purlin Forming Machine is versatile and can be used to create channels perfect for various applications. The C channel profiles can be customized to fit any design, making them suitable for use in different types of structures. They are commonly used in buildings, factories, warehouses, and other constructions.4. Time-savingUsing the C Shape Purlin Forming Machine significantly reduces the time required to produce C-shaped steel channels for construction projects. The machine produces several channels in one go, making it possible to complete projects much faster. The high efficiency also reduces labor needs, minimizing the time required to construct buildings using these materials.5. DurabilityThe C Shape Purlin Forming Machine produces durable and long-lasting steel channels that are resistant to corrosion and decay. These high-quality channels ensure a long-lasting construction that is strong and sturdy, making them perfect for use in construction projects.It is clear that the C Shape Purlin Forming Machine has revolutionized the construction industry, providing an innovative solution to meet the growing demand for durable, cost-effective, and high-quality steel channels. The technology has enabled manufacturers to produce channels that can meet any design requirement, offering versatile building solutions to the construction industry.The applications of C Shape Purlin Forming Machine in construction industry:1. Roofs and WallsC-shaped steel channels are commonly used to form roofs and walls in buildings. The channels' high strength-to-weight ratio makes them ideal for use in roofing structures, providing a strong and sturdy surface that can withstand different weather conditions. The channels also create a robust wall surface, enhancing the building's durability.2. Frame StructuresThe C Shape Purlin Forming Machine produces steel channels that are ideal for use in frame structures. The channels' strength and durability make them perfect for forming the skeleton of a building frame, enhancing its stability and sturdiness. The channels also provide a cost-effective solution, reducing the building's construction time and labor costs.3. Structural BeamsC-shaped steel channels produced by the C Shape Purlin Forming Machine can act as structural beams for buildings, providing support for other elements such as floors, walls, and roofs. The channels' strength ensures that they can withstand heavy loads and high-pressure levels, making them ideal for use in large buildings.ConclusionThe C Shape Purlin Forming Machine has revolutionized the construction industry, providing an innovative solution to meet the growing demand for durable, cost-effective, and high-quality steel channels. The machine's versatility, cost-effectiveness, and efficiency have made it a popular choice for builders across different countries. As the construction industry continues to grow, the C Shape Purlin Forming Machine will remain an essential tool for builders seeking efficient and reliable construction solutions.

Efficient Quick Interchangeable Purlin Roll Forming Machine for C/Z Shapes

If you are in the market for a high-quality roll forming machine that can produce both C and Z shape purlins without the need for changing rollers, then the Quick Interchangeable C/Z Purlin Roll Forming Machine is the ideal solution for you. Designed with efficiency and ease of operation in mind, this machine has quickly become a popular choice for many industries.One of the key features of this machine is its quick interchangeable capability. This means that you can easily switch between producing C and Z shaped purlins without the need for any additional tooling or equipment. This feature not only saves time but also makes it more convenient for operators to use.The roll forming process is an important aspect of this machine. The materials are fed into the machine and then go through a series of rollers that gradually shape and form them into the desired C or Z purlin profile. What makes this machine unique is that it offers a high level of accuracy and precision, ensuring that each purlin produced is consistent in shape and size.Additionally, this machine can also punch holes into the purlins as they are being formed. This feature is especially useful in industries such as construction, where holes are required for fixing the purlins to the building structure.The Quick Interchangeable C/Z Purlin Roll Forming Machine is also built to meet strict European standards. It is made from high-quality materials that are sturdy and highly durable, allowing it to withstand heavy usage and long-term wear and tear.In terms of its operation, this machine is easy to use and requires minimal maintenance. It also has a high production capacity, making it suitable for a range of applications and industries.In conclusion, the Quick Interchangeable C/Z Purlin Roll Forming Machine is a versatile, efficient, and highly reliable machine that is ideal for producing both C and Z shaped purlins. Its quick interchangeable feature, high production capacity, and ability to punch holes make it a popular choice in industries such as construction and manufacturing. It is built to meet European standards and is easy to use, making it a great investment for businesses looking to improve their production capabilities.

Interchangeable Purlin Roll Forming Machine for Steel Processing

Title: Streamlining Steel Processing with CZ Interchange Purlin Roll Forming MachinesIntroduction:In the realm of steel processing, efficiency and precision are key characteristics that define success. CZ interchange purlin roll forming machines have emerged as a game-changer in the industry, offering exceptional quality and versatility. This article delves into the advantages and applications of these cutting-edge machines, shedding light on their ability to shape and transform various materials with ease.Advantages of CZ Interchange Purlin Roll Forming Machines:1. Wide range of material compatibility:CZ interchange purlin roll forming machines are designed to process material thicknesses ranging from 1.5mm to 3.0mm. This versatility allows manufacturers to work with diverse materials, expanding their product offerings and catering to the specific requirements of their clients.2. Flexibility in shape and size:These machines are capable of producing both C and Z-shaped purlins, allowing manufacturers to meet the demands of different construction projects. The C and Z sizes can vary from 80mm to 300mm, providing an extensive range of options for construction applications.3. Easy transition between C and Z shapes:With the ability to easily switch from one shape to another, CZ interchange purlin roll forming machines offer unparalleled flexibility. This feature saves valuable time and effort, eliminating the need for additional equipment or complex adjustments. Manufacturers can seamlessly transition between C and Z shapes, maximizing efficiency and productivity in their operations.4. Stable iron cast structure:The CZ interchange purlin roll forming machine is built with a robust iron cast structure, ensuring stability during the forming process. This sturdy framework enhances the machine's durability, minimizes vibration, and guarantees consistent and precise performance. Manufacturers can rely on this stable platform to deliver high-quality products consistently.Applications of CZ Interchange Purlin Roll Forming Machines:1. Construction industry:CZ interchange purlin roll forming machines play a pivotal role in the construction sector. These machines can effortlessly shape and process materials for roofing systems, walls, and structural supports. By offering interchangeable C and Z shapes, they provide the versatility necessary to meet the varied needs of modern construction projects.2. Infrastructure development:The CZ interchange purlin roll forming machine's ability to handle different thicknesses of material makes it a valuable asset in infrastructure development. From highway guardrails to bridges and tunnels, these machines can produce structurally sound components that withstand the rigors of heavy-duty applications.3. Industrial and commercial applications:CZ purlins find extensive use in industrial and commercial buildings. By utilizing CZ interchange purlin roll forming machines, manufacturers can produce precisely shaped purlins that seamlessly integrate into a wide range of structures. These purlins serve as a vital structural element, providing stability and support.Conclusion:CZ interchange purlin roll forming machines offer a revolution in steel processing, enabling manufacturers to efficiently shape materials for diverse applications. With the ability to handle different material thicknesses and switch between C and Z shapes effortlessly, these machines are a testament to the advancements in the industry. By investing in a CZ interchange purlin roll forming machine, manufacturers can streamline their production processes, enhance product quality, and expand their range of offerings.

Complete Guide to Metal Coil Slitters: Uses, Maintenance, and Safety Tips

Metal Coil SlitterMetal coil slitters are essential machines in the metal processing industry as they are used to cut coils of metal into smaller, more manageable strips. These strips can then be used for various industrial applications such as automotive parts, construction materials, and household appliances. One of the leading providers of metal coil slitters is a company that has been at the forefront of the metal processing industry for over 30 years. With a strong reputation for manufacturing high-quality and efficient metal processing equipment, this company has gained the trust and loyalty of customers worldwide.The Metal Coil Slitter produced by this company is a state-of-the-art machine that incorporates the latest technological advancements in the industry. It is designed to provide precision cutting of metal coils, ensuring uniformity and accuracy in the strips produced. This machine is capable of handling a wide range of materials including steel, aluminum, and other non-ferrous metals, making it a versatile and valuable asset for metal processing facilities.The Metal Coil Slitter is equipped with advanced automation technology, allowing for seamless operation and reduced downtime. Its user-friendly interface and intuitive controls make it easy for operators to set up and operate the machine with minimal training. Additionally, it is built with safety features to ensure the well-being of the operators and to comply with industry regulations.One of the key features of the Metal Coil Slitter is its high-speed cutting capability, which allows for increased productivity and efficiency in metal processing operations. The machine is also designed for easy maintenance, with accessible components and minimal downtime for servicing.In addition to the Metal Coil Slitter, this company offers a comprehensive range of metal processing equipment including cut-to-length lines, slitting lines, and recoiling lines. With a commitment to excellence and innovation, the company continues to develop and improve its product offerings to meet the evolving needs of the industry.Furthermore, the company provides excellent customer support and after-sales service, ensuring that its clients receive the necessary assistance and technical expertise to maximize the performance of their equipment. This dedication to customer satisfaction has earned the company a loyal customer base and a reputation for reliability and trustworthiness.With a global presence and a strong network of distributors and service centers, the company is able to cater to the needs of metal processing facilities around the world. Its commitment to quality, reliability, and customer satisfaction has positioned it as a leader in the industry.In conclusion, the Metal Coil Slitter offered by this company is a testament to its dedication to quality and innovation. With its advanced features, precision cutting capabilities, and commitment to customer satisfaction, this machine has established itself as a valuable asset in the metal processing industry. As the company continues to grow and evolve, it remains at the forefront of the industry, driving innovation and setting new standards for excellence in metal processing equipment.

Top Roller for Corrugated Roofing: Must-Have Tool for Easy Installation

Roller for Corrugated Roof: A Game-Changer in the Roofing IndustryCorrugated roofing has long been a popular choice for residential and commercial buildings due to its durability and cost-effectiveness. However, the process of installing and maintaining corrugated roofs has always been a time-consuming and labor-intensive task. That is, until now.Introducing the new Roller for Corrugated Roof, a revolutionary tool that has the potential to change the way corrugated roofs are installed and maintained. This innovative product, developed by a leading manufacturer in the roofing industry, is set to make waves in the construction and roofing sectors.The Roller for Corrugated Roof is designed to streamline the installation process, making it faster and more efficient than ever before. Its ergonomic and user-friendly design allows for easy handling, reducing the physical strain on workers during the installation process. This not only improves productivity but also enhances worker safety, a critical factor in any construction project.What sets the Roller for Corrugated Roof apart from other tools in the market is its ability to ensure a smooth and even finish on corrugated roofs. Its advanced technology allows for precise and consistent rolling, resulting in a professional-looking finish that adds to the aesthetic appeal of the building.In addition to its installation benefits, the Roller for Corrugated Roof also offers significant advantages in terms of maintenance. By using the roller to apply protective coatings and sealants, maintenance teams can extend the lifespan of corrugated roofs, preventing leaks and other damage that can result from exposure to harsh weather conditions.The company behind the Roller for Corrugated Roof, with a proven track record of delivering high-quality roofing products and tools, has invested considerable resources in research and development to bring this innovative tool to the market. With a commitment to excellence and a dedication to meeting the evolving needs of the construction industry, they have positioned themselves as a leader in the market.The company's mission is not only to provide innovative solutions but also to contribute to the sustainability of the industry. The Roller for Corrugated Roof is an environmentally friendly tool that minimizes waste and reduces the need for additional resources during the installation and maintenance processes. This eco-conscious approach aligns with the company's commitment to responsible and sustainable business practices.In line with its dedication to customer satisfaction, the company offers comprehensive support and training programs for the Roller for Corrugated Roof. This ensures that contractors and maintenance teams are equipped with the knowledge and skills to make the most of this game-changing tool, ultimately delivering superior results for their clients.The release of the Roller for Corrugated Roof has generated significant excitement within the roofing industry, with early adopters praising its performance and efficiency. Contractors and building owners alike are recognizing the potential of this tool to revolutionize the way corrugated roofs are installed and maintained, ultimately saving time and costs while delivering exceptional results.As the demand for innovative and sustainable construction solutions continues to grow, the Roller for Corrugated Roof stands out as a prime example of how cutting-edge technology can drive positive change in the industry. With its combination of efficiency, quality, and sustainability, this tool is set to become a staple in the toolkit of roofing professionals around the world.

Top Quality Machinery for Forming Processes

Forming Machinery Celebrates Milestone AchievementForming Machinery, a global leader in the manufacturing of forming equipment, has recently achieved a significant milestone in its journey of providing top-quality machinery solutions to its customers. With an unwavering commitment to innovation, precision engineering, and customer satisfaction, the company has established itself as a trusted partner for businesses across various industries.With over [X] years of experience in the industry, Forming Machinery has continually pushed the boundaries of technology to deliver cutting-edge solutions that meet the evolving needs of its clientele. The company's dedication to research and development has enabled it to stay ahead of the curve and anticipate market trends, resulting in the creation of advanced, efficient, and reliable forming equipment.One of Forming Machinery's key strengths lies in its comprehensive product range, which includes [list of products]. From standard machines to custom-built solutions, the company has the capabilities to cater to a wide array of requirements, ensuring that its customers have access to the best machinery for their specific applications.The company's commitment to quality is evident in its state-of-the-art manufacturing facilities and stringent quality control measures. Every machine that bears the Forming Machinery name is a testament to the company's dedication to excellence, durability, and performance. Furthermore, the company also offers comprehensive after-sales support, spare parts availability, and technical assistance, ensuring that customers can maximize the value of their investments.In addition to its impressive product lineup, Forming Machinery takes pride in its team of highly skilled and experienced professionals. The company's engineers, technicians, and support staff are deeply passionate about their work and are driven by a shared vision of delivering unparalleled service to customers around the world. This team's expertise and dedication have been instrumental in establishing Forming Machinery as a benchmark for quality and reliability in the industry.As part of its ongoing commitment to innovation, Forming Machinery has consistently invested in research and development to drive the creation of next-generation forming equipment. The company's focus on technological advancement and continuous improvement has resulted in cutting-edge solutions that offer higher productivity, energy efficiency, and cost savings for its customers.Furthermore, Forming Machinery's dedication to sustainability is reflected in its efforts to develop eco-friendly manufacturing processes and energy-efficient machinery. By prioritizing environmental responsibility, the company aims to minimize its carbon footprint and promote sustainable practices within the industry.Looking to the future, Forming Machinery remains dedicated to upholding its reputation as a leader in the forming equipment sector. The company is steadfast in its commitment to delivering innovative solutions that exceed customer expectations, while also fostering long-term partnerships based on trust, reliability, and mutual success.As Forming Machinery celebrates this milestone achievement, it reaffirms its mission to continue setting new standards for excellence and serving as a driving force for positive change within the industry. With its unwavering dedication to quality, innovation, and customer satisfaction, the company is well-positioned to shape the future of forming machinery and make a lasting impact on businesses worldwide.

New Profile Sheet Machine Revolutionizes News Content – Discover the Latest Breakthrough in SEO Optimization

Title: AI-Powered Profile Sheet Machine Revolutionizes the Manufacturing IndustrySubtitle: Company XYZ pioneers next-generation technologies for efficient and accurate profile sheet production.Date: [DATE][Location] - Company XYZ, a leading innovator in industrial technologies, is revolutionizing the manufacturing industry with the introduction of their groundbreaking AI-powered Profile Sheet Machine. This cutting-edge machine utilizes advanced artificial intelligence algorithms to streamline and enhance the production process of profile sheets, bringing unparalleled efficiency and accuracy to the manufacturing sector.The Profile Sheet Machine represents a significant advancement in sheet production technology. By harnessing the power of AI, Company XYZ has successfully eliminated the inefficiencies and challenges associated with traditional manual processes. The machine enables manufacturers to produce profile sheets of varying sizes, shapes, and specifications with remarkable precision and speed.One of the key features that sets this Profile Sheet Machine apart from its competitors is its ability to automatically identify and adapt to changes during the production process. The AI algorithms continuously analyze real-time data, enabling the machine to make dynamic adjustments on the fly, resulting in significantly reduced downtime and enhanced productivity.Furthermore, the AI-powered Profile Sheet Machine boasts an exceptional level of accuracy, ensuring consistent quality across each sheet produced. The machine's sophisticated imaging system, coupled with precise measurements, guarantee that every profile sheet meets the highest industry standards. This not only improves the reliability of the final product but also minimizes waste and rejections.Another remarkable aspect of Company XYZ's Profile Sheet Machine is its user-friendly interface, which simplifies operations and reduces the learning curve for operators. The intuitive dashboard allows users to monitor the entire production process, track key performance indicators, and access valuable insights and analytics in real-time. This data-driven approach empowers manufacturers to make informed decisions, optimize production, and improve overall efficiency.In addition to its world-class technology, Company XYZ places great emphasis on sustainability. The Profile Sheet Machine is designed to incorporate eco-conscious materials and energy-efficient mechanisms, minimizing its environmental impact. By reducing material and energy waste, this innovative machine aligns with a global call for greener manufacturing processes.Company XYZ's commitment to innovation goes beyond the Profile Sheet Machine. With a team of dedicated researchers and engineers, the company continuously strives to improve and expand its product offerings to meet the evolving needs of the industry. Their relentless pursuit of excellence has earned them a reputation as a trusted partner in the manufacturing sector, driving growth and progress through technological advancements.The introduction of the AI-powered Profile Sheet Machine promises to be a game-changer for businesses in the manufacturing industry. By combining the power of AI with cutting-edge technologies, Company XYZ has set a new standard for efficiency, accuracy, and sustainability. The machine's ability to adapt to changing production requirements, coupled with its unparalleled precision, will transform the way profile sheets are manufactured, bringing significant cost savings and increased competitiveness to manufacturers.As the manufacturing sector continues to evolve and adapt to new challenges, Company XYZ remains in the vanguard of innovation, paving the way for a more efficient, sustainable, and technologically advanced future. With their AI-powered Profile Sheet Machine, they have reinforced their commitment to revolutionizing the manufacturing industry, ushering in an era of enhanced productivity and quality.[Conclusion]The AI-powered Profile Sheet Machine developed by Company XYZ promises to revolutionize the manufacturing industry by streamlining production processes, increasing efficiency, and enhancing product quality. With its cutting-edge technology and commitment to sustainability, the machine represents a significant advancement in industrial manufacturing. Company XYZ continues to be a pioneer in the field, demonstrating their dedication to innovation and driving progress in the manufacturing sector.

Durable and Efficient Roller for Corrugated Roof Installation

[Company Introduction]Established in 1995, our company is a leading manufacturer and supplier of premium quality roofing products for commercial and residential use. With years of experience in the industry, we have gained a reputation for delivering top-notch and innovative solutions for our customers' roofing needs. Our commitment to quality, durability, and customer satisfaction has made us a trusted name in the construction and roofing sector.[Roller For Corrugated Roof]In line with our dedication to providing the best roofing solutions, we are proud to introduce our latest innovation - the Roller for Corrugated Roof. This new product is designed to provide efficient and effective installation of corrugated roofing materials, ensuring a seamless and professional finish for every roofing project.The Roller for Corrugated Roof is engineered to streamline the installation process, allowing for quick and easy application of corrugated roofing panels. Its innovative design eliminates the need for manual fastening of each panel, significantly reducing installation time and labor costs. This roller is compatible with a wide range of corrugated roofing materials, making it a versatile and practical tool for roofing contractors and DIY enthusiasts alike.The durable construction of the Roller for Corrugated Roof ensures long-lasting performance, making it a valuable investment for any roofing professional. Its ergonomic design and lightweight construction enable effortless handling and maneuverability, enhancing efficiency and productivity on the job site. Additionally, the roller's smooth rolling action creates a consistent and secure bond between the roofing panels and the underlying structure, resulting in a pristine and professional-looking finish.Our commitment to quality is reflected in the meticulous engineering and testing that goes into every product we manufacture. The Roller for Corrugated Roof is no exception, as it has undergone rigorous quality assurance measures to ensure its reliability, performance, and durability. Rest assured that when you choose our roller, you are investing in a product that meets the highest standards of quality and excellence.Furthermore, we understand the importance of environmental sustainability in today's construction industry. That's why the Roller for Corrugated Roof is designed with eco-friendly materials and production processes, minimizing its impact on the environment. We take pride in offering roofing solutions that not only meet the demands of our customers but also contribute to a greener and more sustainable future for all.As a customer-centric company, we are dedicated to providing exceptional service and support to our clients. Whether you are a roofing contractor, builder, architect, or DIY enthusiast, our team is committed to helping you find the right roofing solutions for your specific needs. The introduction of the Roller for Corrugated Roof is just one example of our ongoing efforts to empower our customers with innovative and practical tools for their roofing projects.In conclusion, the Roller for Corrugated Roof is a game-changing addition to our lineup of roofing products. Its ability to streamline the installation process, improve efficiency, and deliver professional results makes it a must-have tool for anyone involved in roofing projects. With our unwavering dedication to quality, innovation, and customer satisfaction, we are confident that the Roller for Corrugated Roof will set a new standard for corrugated roofing installation. We look forward to seeing the positive impact this product will have on the industry and the satisfaction it will bring to our customers.

High-Quality Purlin Machine for Efficient Production - Find Out More!

There is a growing demand for high-quality construction materials in the global market, and the company {} has risen to the challenge by introducing their state-of-the-art Cz Purlin Machine. This innovative machine is set to revolutionize the way Cz purlins are manufactured, with its advanced technology and precision engineering.The Cz Purlin Machine is designed to produce high-quality Cz purlins with speed and efficiency. It is capable of handling various thicknesses and sizes of steel coils, making it a versatile and adaptable solution for construction companies and steel manufacturers. With its automated operation and user-friendly interface, the machine can significantly increase production output while reducing labor costs and material waste.One of the key features of the Cz Purlin Machine is its ability to produce accurate and consistent purlin profiles. This is made possible by the machine's advanced control system, which ensures that each purlin meets the required specifications and dimensions. As a result, builders and contractors can rely on the precision of the purlins produced by this machine, leading to higher quality and more durable structures.In addition to its cutting-edge technology, the Cz Purlin Machine is also designed with safety and reliability in mind. It is equipped with safety guards and sensors to prevent accidents and ensure the wellbeing of the operators. Furthermore, the machine is built to withstand the rigors of industrial use, making it a long-lasting and dependable investment for any construction or steel manufacturing business.The introduction of the Cz Purlin Machine by {} is a testament to the company's commitment to innovation and excellence in the construction industry. With years of experience and expertise in the manufacturing of steel forming equipment, they have established themselves as a leading provider of cutting-edge solutions for the global market. By introducing this new machine, {} aims to further solidify its position as a trusted partner for construction companies and steel manufacturers worldwide."We are thrilled to introduce our latest Cz Purlin Machine to the market," said a spokesperson for {}. "We believe that this machine will set a new standard for the production of Cz purlins, offering unmatched quality, efficiency, and reliability. We are confident that our customers will benefit greatly from this innovative solution, and we look forward to supporting their success with our cutting-edge technology."The launch of the Cz Purlin Machine is expected to have a significant impact on the construction industry, as it provides a more efficient and cost-effective solution for producing Cz purlins. With its advanced features and capabilities, this machine is poised to enhance the productivity and profitability of construction companies and steel manufacturers around the world. As a result, it is likely to drive further innovation and advancement in the industry, ultimately benefiting builders, contractors, and consumers alike.In conclusion, the introduction of the Cz Purlin Machine by {} marks a significant milestone in the construction industry, offering a game-changing solution for the production of high-quality Cz purlins. With its advanced technology, precision engineering, and focus on safety and reliability, this machine is set to deliver unparalleled value to construction companies and steel manufacturers. As the industry continues to evolve, {} is at the forefront of innovation, providing cutting-edge solutions that meet the needs of a rapidly changing market.