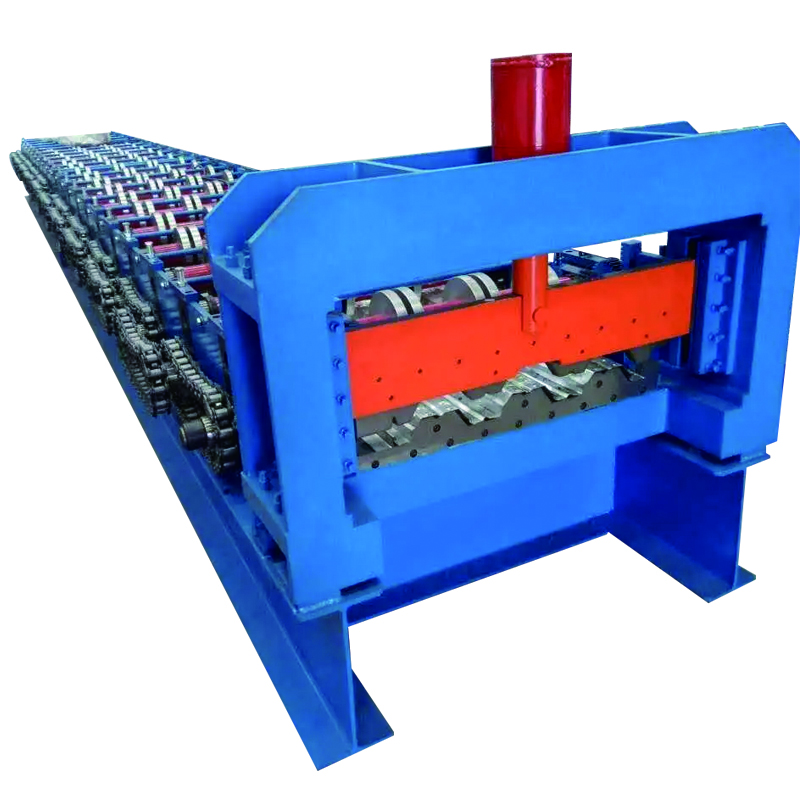

Metal Steel Roof Sheet Roll Forming Machine for Step Tile Production

By:Admin

The Step Tile Metal Steel Roof Sheet Roll Forming Machine is equipped with advanced technology and features that make it incredibly efficient and reliable. It is capable of producing a wide range of step tile profiles with varying dimensions and thicknesses, making it suitable for a variety of roofing applications. The machine is also highly automated, which reduces the need for manual intervention and ensures consistent and high-quality output.

In addition to its impressive capabilities, the Step Tile Metal Steel Roof Sheet Roll Forming Machine is also designed for ease of use and maintenance. Its user-friendly interface and intuitive controls make it easy for operators to set up and operate the machine, while its robust construction ensures long-term durability and minimal downtime. Furthermore, the machine is equipped with safety features that protect operators and workers from potential hazards, making it a safe and reliable choice for any manufacturing facility.

The company behind this innovative machine is a leading manufacturer of roll forming equipment, with a strong reputation for delivering high-quality and reliable products. With decades of experience in the industry, the company has a deep understanding of the unique needs and challenges of the construction and manufacturing sectors. Their commitment to innovation and excellence has led to the development of this state-of-the-art Step Tile Metal Steel Roof Sheet Roll Forming Machine, which promises to set new standards in the industry.

The launch of the Step Tile Metal Steel Roof Sheet Roll Forming Machine reflects the company's ongoing dedication to meeting the evolving needs of its customers. By providing cutting-edge solutions that streamline production processes and improve product quality, the company is helping its clients stay ahead of the competition and drive their business growth. With this new machine, the company aims to empower roofing manufacturers and construction firms to meet the growing demand for step tile metal steel roof sheets, while also enhancing their operational efficiency and profitability.

The Step Tile Metal Steel Roof Sheet Roll Forming Machine is expected to generate significant interest and excitement within the construction and manufacturing industries. Its advanced capabilities and impressive performance make it a valuable asset for any company involved in the production of step tile metal steel roof sheets. As the market for high-quality roofing materials continues to expand, this new machine is poised to become an indispensable tool for businesses looking to stay competitive and meet the demands of their customers.

In conclusion, the launch of the Step Tile Metal Steel Roof Sheet Roll Forming Machine represents a significant achievement for the company and a major step forward for the industry as a whole. With its advanced technology, user-friendly design, and exceptional performance, this machine is set to become the new benchmark for the production of step tile metal steel roof sheets. As the company continues to push the boundaries of innovation and excellence, it is poised to maintain its position as a trusted leader in the manufacturing sector.

Company News & Blog

BenQ's LK970 Blue Core Laser 4K Projector Installed by Bag&Baggage Productions for Theater and Venue in Oregon

Bag&Baggage Productions (B&B), a theater company based in Hillsboro, Oregon, recently completed the installation of the BenQ LK970 Blue Core 4K projector in their new theater and multipurpose venue, The Vault. This state-of-the-art projector enables B&B to project realistic set backgrounds, reducing the need for manual set designs and creating opportunities for digital content creators in the area.The theater industry is constantly evolving, and B&B recognized the potential of incorporating projection technology into their performances. By utilizing the BenQ LK970 Blue Core 4K projector, B&B is able to enhance their productions by projecting realistic set backgrounds. This eliminates the need for manual set designs, reducing both the scale and expense of traditional set construction, and saving on labor costs. In the past, theater companies relied heavily on physical sets to create the desired atmosphere for their performances. The process of constructing and changing sets during shows could be time-consuming and costly. However, with the introduction of projection technology like the BenQ LK970, theater companies can now project lifelike set backgrounds onto screens, eliminating the need for physical set changes.This transition to projection technology provides several benefits to B&B. Firstly, it allows for greater flexibility in terms of designing and modifying sets. Virtual set backgrounds can be easily changed with a few clicks, accommodating different scenes and settings seamlessly. The time and effort required for physical set changes is significantly reduced, allowing for smoother, more efficient productions.Moreover, projection technology offers cost savings to theater companies. Manual set designs can be expensive, requiring materials, labor, and storage space. By using a projector to create set backgrounds, B&B can reduce these costs and allocate resources to other aspects of their productions, such as costumes or lighting. Additionally, the labor required for set changes is minimized, freeing up staff to focus on other tasks.Beyond the benefits for theater productions, B&B is also utilizing the BenQ LK970 projector to create a state-of-the-art digital projection laboratory and film festival. The Vault serves as a hub for digital content creators in the area, providing a platform for them to showcase their work and interact with the local community. The high-quality projection capabilities of the BenQ LK970 allow for stunning visual displays, enhancing the viewing experience for both filmmakers and audiences.Overall, the installation of the BenQ LK970 Blue Core 4K projector at The Vault marks a pivotal moment for B&B. By embracing projection technology, the theater company is able to enhance their productions, reduce costs, and create opportunities for digital content creators in their community. This innovative approach showcases B&B's commitment to pushing the boundaries of traditional theater and embracing new technologies to enhance the overall theater-going experience. With the BenQ LK970, B&B is bringing a new level of realism and creativity to their performances while supporting the growth of the local digital content industry.

Advanced Steel Slitting Lines: Perfect for High-Volume Production

Steel Slitting Line: A Revolutionary Solution to Strengthen Your BusinessThe manufacturing industry is constantly evolving, and the need for advanced machines and technologies is at an all-time high. One such technology that has revolutionized the steel manufacturing industry is Steel Slitting Line. It is an intelligent solution that has transformed the way steel is produced, making it faster, precise, and more efficient. Not only does it reduce manufacturing costs, but it also ensures maximum output with minimum wastage.{Company Introduction} is proud to introduce its Steel Slitting Line, a state-of-the-art machine that guarantees a higher level of precision, speed, and reliability than its counterparts. Our Steel Slitting Line is designed to meet the needs of modern steel manufacturers, ensuring maximum output of high-quality steel products while reducing operating costs.A Steel Slitting Line is a specialized machine that allows manufacturers to cut steel coils into narrow widths, called strips, in a precise and efficient manner. It is capable of processing super-thin and high-strength materials that were once impossible to cut efficiently. The Steel Slitting Line machine can process a wide range of materials, from plain carbon steel to high-strength steel alloys, stainless steel, and non-ferrous metals. The ability to cut a variety of materials makes it a versatile solution for steel manufacturing firms.The Steel Slitting Line is made up of several components, including an entry coil car, decoiler, slitter, and recoiler. The entry coil car is used to load the steel coils onto the machine, while the decoiler unrolls the coil, and the slitter cuts the material into the desired width strips. The strips are then wound up into coils using the recoiler, ready to be used in downstream manufacturing processes. The Steel Slitting Line's precision and accuracy depend on the quality of each of these components, and our Steel Slitting Line is built with the finest materials and components to ensure the highest level of precision and accuracy.One of the most significant benefits of Steel Slitting Lines is the optimization of material utilization. The machine cuts steel coils into strips, which means that manufacturers can make smaller orders with minimum wastage. It also allows for maximum use of the material, which reduces manufacturing costs and minimizes the environmental impact of steel production. The Steel Slitting Line's high level of precision and accuracy means that it is possible to minimize or completely eliminate waste in some cases, depending on the manufacturer's quality standards.Another notable benefit of the Steel Slitting Line is the improved efficiency that it brings to steel production. It is capable of processing steel coils at high speeds, ensuring that manufacturers can produce high-quality steel products in large volumes within a short period. The machine's advanced technology allows for automatic adjustments to be made quickly, minimizing downtime and minimizing the need for human intervention. This results in faster production processes and improved productivity, which ultimately leads to increased revenue for the manufacturer.Safety is a top priority in the manufacturing industry, and Steel Slitting Lines are designed with safety in mind. Our Steel Slitting Line is built to meet international safety standards, ensuring that the machine is safe to operate and that all operators are adequately trained. We have put in place safety measures, such as emergency stop buttons, safety guards, and sensors, to ensure that operators are protected from any accidents that may occur during production.In conclusion, Steel Slitting Line machines are a game-changer in the steel industry, providing manufacturers with a range of benefits that improve efficiency, reduce costs, and increase revenue. At {Company Introduction}, we take pride in providing our customers with the best Steel Slitting Lines that meet their needs. Our machines are built with the highest quality materials, and our team of experienced engineers and designers ensures that the machines meet international standards. If you're looking to optimize your steel manufacturing process, {Company Name}'s Steel Slitting Line is the solution you need.

Top Tips for Efficient and Precise Purlin Roll Forming

Title: Purlin Roll Forming Technology Revolutionizing the Construction IndustryIntroduction:Purlin roll forming has emerged as a game-changing technology in the construction industry, offering a streamlined and efficient method for producing high-quality purlins, which are vital components in building construction. This innovative process has grown in popularity due to its ability to deliver customized purlins with exceptional structural integrity, all while reducing production time and costs. In this article, we will explore the benefits and applications of purlin roll forming and delve into how it is revolutionizing the construction sector.What is Purlin Roll Forming?Purlin roll forming involves the automated production of purlin profiles using a roll forming machine. Purlins are lightweight horizontal beams that provide structural support to roofs, walls, and ceilings in buildings. Traditionally, purlins were manufactured by welding together multiple pieces of sheet metal, resulting in time-consuming and costly processes. However, purlin roll forming eliminates these drawbacks by allowing for the continuous and precise production of purlins with minimal manual intervention.Benefits of Purlin Roll Forming:1. Efficiency: Purlin roll forming machines are designed for high-speed production, enabling manufacturers to produce large quantities of purlins in a shorter timeframe. With automated processes, fewer resources are required to operate the machinery, reducing labor costs and increasing overall efficiency.2. Customization: Purlin roll forming offers immense flexibility in designing customized purlins. Manufacturers can easily adjust the machine settings to produce purlins in various lengths, widths, and thicknesses, ensuring compatibility with diverse construction requirements. This ability to customize purlins to precise specifications enhances the structural integrity and overall quality of the building.3. Material Optimization: Purlin roll forming improves material utilization by reducing waste. With precise measurements and automated cutting, manufacturers can minimize leftover scraps, thereby maximizing the use of raw materials. This not only reduces material costs but also supports the construction industry's commitment towards sustainable practices.Application in Construction:Purlin roll forming finds its application across a wide range of construction projects, including commercial buildings, warehouses, agricultural structures, and residential complexes. The technology can produce purlins in various profiles such as C-shape, Z-shape, and Sigma shape, catering to different structural requirements.1. Commercial Buildings: Purlin roll forming plays a crucial role in constructing retail spaces, office buildings, and shopping centers. The technology ensures efficient production of purlins that provide strong structural support while maintaining architectural design aesthetics.2. Warehouses: Large industrial warehouses often require extensive purlin systems to support their expansive roofs. Purlin roll forming allows for the rapid production of purlins, ensuring timely completion of warehouse projects while maintaining structural integrity.3. Agricultural Structures: Purlin roll forming is highly sought after in the construction of agricultural structures, such as barns and sheds. The technology's efficiency and customizability enable farmers and agricultural entrepreneurs to construct durable structures that can withstand extreme weather conditions.4. Residential Complexes: Purlin roll forming is increasingly being adopted in the construction of apartment complexes, townhouses, and residential buildings. The technology offers architects and developers the flexibility to create custom purlin designs that align with specific structural requirements while adhering to aesthetic preferences.Conclusion:Purlin roll forming technology is transforming the construction industry, revolutionizing the way purlins are manufactured. With its efficiency, customization capabilities, and material optimization, purlin roll forming streamlines the production process, offering high-quality purlins at reduced costs. The technology has found widespread application in various construction projects, from commercial buildings to agricultural structures, thereby contributing to the industry's growth and development. As the construction sector embraces further advancements, purlin roll forming is poised to play an even more vital role in shaping the buildings of the future.

Corrugated Roof Tile Barrel Sheet Profiling Machine: Everything You Need to Know

Innovative Corrugated Roof Tile Barrel Sheet Profiling Machine Revolutionizes Manufacturing ProcessThe manufacturing industry is constantly evolving, with new technological advancements revolutionizing the way products are made. One such innovation is the Corrugated Roof Tile Barrel Sheet Profiling Machine, which has been developed by a leading company in the industry.This groundbreaking machine is designed to streamline the production of corrugated roof tiles, barrel sheets, and other similar roofing products. It utilizes advanced profiling technology to accurately shape and cut metal sheets, resulting in a precise and high-quality finished product. The use of this machine has dramatically reduced production time and labor costs, making it a game-changer for manufacturers in the roofing industry.The Corrugated Roof Tile Barrel Sheet Profiling Machine is equipped with a state-of-the-art control system, allowing for easy and precise operation. This ensures that each product is consistently manufactured to the highest standards, meeting the strict requirements of the industry. The machine is also highly versatile, capable of producing a wide range of designs and sizes to meet the diverse needs of customers.In addition to its advanced technological features, the machine is also designed with safety and efficiency in mind. It is equipped with safety guards and emergency stop mechanisms to protect operators and prevent accidents. Furthermore, the machine’s energy-efficient design helps reduce energy consumption, making it a sustainable choice for manufacturers.The company behind this innovative machine has a long history of excellence in the manufacturing industry. With a strong focus on research and development, they have consistently delivered cutting-edge solutions to meet the evolving needs of their customers. Their commitment to quality and innovation has earned them a reputation as a trusted leader in the industry.In addition to the Corrugated Roof Tile Barrel Sheet Profiling Machine, the company offers a wide range of other manufacturing equipment and solutions. From roll forming machines to metal cutting systems, they are dedicated to providing comprehensive and custom-tailored solutions to their clients. Their team of skilled engineers and technicians work closely with customers to develop the perfect manufacturing solution for their specific needs.Through their dedication to excellence and innovation, the company has established a strong global presence, serving clients in various industries around the world. Their commitment to quality and customer satisfaction has earned them numerous accolades and recognition within the industry.The introduction of the Corrugated Roof Tile Barrel Sheet Profiling Machine is yet another example of the company’s commitment to innovation and progress. By offering a groundbreaking solution to streamline the manufacturing process, they are helping their clients stay ahead of the competition and meet the growing demands of the market.In conclusion, the Corrugated Roof Tile Barrel Sheet Profiling Machine represents a significant advancement in the manufacturing industry. Its cutting-edge technology, precision engineering, and commitment to safety and efficiency make it a valuable asset for manufacturers in the roofing industry. As the company continues to push the boundaries of innovation, we can expect to see more groundbreaking solutions that will shape the future of manufacturing.

Sheet Metal Roll Forming Machine for Horizontal Barrel Corrugated Sheets News Update

Title: Revolutionary Horizontal Barrel Corrugated Sheet Roll Forming Machine Set to Transform the Metal Manufacturing IndustryIntroduction:In a bid to revolutionize the metal manufacturing industry, an innovative company has introduced the groundbreaking Horizontal Barrel Corrugated Sheet Roll Forming Machine. This cutting-edge technology promises to offer unprecedented efficiency and accuracy, thus reducing production time and costs. With its seamless design and state-of-the-art features, this ingenious machine is poised to redefine the future of metal forming processes.Developed by a renowned company specializing in advanced machinery, the Horizontal Barrel Corrugated Sheet Roll Forming Machine aims to address the limitations of traditional roll forming methodologies. By incorporating advanced technological advancements, this revolutionary equipment exhibits remarkable capabilities, translating into enhanced productivity for metal manufacturers.Features and Technical Advancements:The Horizontal Barrel Corrugated Sheet Roll Forming Machine boasts a myriad of impressive features that make it stand out in the industry. A few of these notable features include:1. Innovative Design: The machine incorporates a horizontal barrel configuration, allowing for easier feeding and achieving a more precise corrugated sheet formation. This unique design ensures flawless output with minimal material wastage.2. High-Speed Production: Equipped with cutting-edge control systems, this machine offers faster production speeds compared to conventional roll forming equipment. This increased efficiency translates into higher output volumes and reduced production timelines.3. Customization: The machine offers flexible settings, enabling manufacturers to easily adjust the dimensions, thickness, and corrugation patterns of the sheets according to their specific requirements. This adaptability ensures the production of tailor-made metal sheets for various applications.4. Enhanced Accuracy: The precision engineering of the machine ensures consistently accurate dimensions, resulting in high-quality corrugated sheets that meet industry standards. This accuracy minimizes the need for additional processing or rectification, further streamlining the manufacturing process.Implications for the Metal Manufacturing Industry:The introduction of the Horizontal Barrel Corrugated Sheet Roll Forming Machine is set to have far-reaching implications for the metal manufacturing industry. Its numerous advantages and technical advancements hold significant potential to transform the way metal sheets are produced, offering benefits such as:1. Increased Efficiency and Cost Savings: The machine's faster production speeds and reduced material wastage significantly improve overall manufacturing efficiency. This, in turn, leads to substantial cost savings for metal manufacturers, making them more competitive in the market.2. Streamlined Supply Chain: The machine's customization capabilities enable manufacturers to swiftly adjust production parameters, resulting in shorter lead times and quicker response to customer demands. This streamlined supply chain ensures better customer satisfaction and increased market competitiveness.3. Improved Product Quality: With its heightened accuracy and precision, the Horizontal Barrel Corrugated Sheet Roll Forming Machine eliminates variations and defects often encountered in traditional manufacturing processes. The production of consistently high-quality metal sheets enhances product reliability and durability.4. Sustainability and Resource Optimization: The reduced material wastage, achieved through the machine's seamless design and precision engineering, significantly contributes to environmental sustainability. By optimizing resource utilization, metal manufacturing companies can significantly reduce their carbon footprint.Conclusion:The introduction of the Horizontal Barrel Corrugated Sheet Roll Forming Machine marks a significant milestone in the evolution of the metal manufacturing industry. With its innovative design, advanced features, and multiple benefits such as increased efficiency, reduced costs, and improved product quality, this revolutionary machine is set to redefine the future of metal forming processes. As more companies adopt this cutting-edge technology, the industry can expect to witness enhanced productivity, sustainability, and competitiveness.

High-Quality Metal Roofing Sheet Roll Forming Machines

Roofing Sheet Roll Forming Machine Revolutionizing the Roofing IndustryRoofing is an essential part of any building, providing protection from the elements and adding structural integrity. The process of manufacturing roofing sheets has evolved over the years, and modern technology has played a significant role in revolutionizing the industry. One such technological advancement is the Roofing Sheet Roll Forming Machine, which has made the production of roofing sheets more efficient, cost-effective, and of higher quality.The Roofing Sheet Roll Forming Machine, offered by a leading manufacturing company in the industry, is a cutting-edge piece of equipment that has transformed the way roofing sheets are produced. This machine is designed to take flat metal coils and transform them into finished roofing sheets through a series of rolling, bending, and cutting processes. The result is a highly precise and uniform roofing sheet that meets the highest industry standards.The company behind this innovative machine, has been at the forefront of the roofing industry for over two decades. With a focus on quality, innovation, and customer satisfaction, they have established themselves as a trusted name in the market. Their commitment to excellence is evident in the Roofing Sheet Roll Forming Machine, which has set a new standard for efficiency and reliability in the production of roofing sheets.One of the key advantages of the Roofing Sheet Roll Forming Machine is its ability to produce roofing sheets in a variety of materials, including steel, aluminum, and copper. This versatility allows manufacturers to meet the diverse needs of their customers, whether it's for residential, commercial, or industrial applications. The machine is also highly customizable, with adjustable settings for sheet thickness, length, and profile, ensuring that each roofing sheet meets the specific requirements of the project.In addition to its flexibility, the Roofing Sheet Roll Forming Machine is also incredibly efficient. Its automated process minimizes manual labor, reduces waste, and improves production speed, resulting in cost savings for manufacturers. The machine's precision and repeatability also lead to a higher quality end product, with consistent dimensions and smooth finishes on every roofing sheet.Furthermore, the company's dedication to customer support and service ensures that their clients receive the assistance they need to maximize the potential of the Roofing Sheet Roll Forming Machine. From installation and training to ongoing maintenance and technical support, they are committed to helping their customers achieve success with this revolutionary piece of equipment.As a result of these innovations, the Roofing Sheet Roll Forming Machine has been widely adopted by manufacturers around the world. Its impact on the roofing industry has been significant, driving improvements in productivity, product quality, and overall competitiveness. Whether it's for a small-scale roofing business or a large manufacturing facility, this machine has proven to be a game-changer, propelling the industry into a new era of efficiency and innovation.In conclusion, the Roofing Sheet Roll Forming Machine offered by the company has redefined the production of roofing sheets, setting new standards for quality, efficiency, and versatility. By harnessing the latest in technology and engineering, they have delivered a machine that empowers manufacturers to meet the evolving demands of the market. With their ongoing commitment to excellence and customer satisfaction, they continue to lead the way in the roofing industry, driving forward a new era of progress and innovation.

Increased Demand for Curving Rolls for Corrugated Iron Sparks CNC Corro Curving Machine Sourcing

Title: Acra Machinery Meets Increasing Demand for Corrugated Iron Curving RollsIntroduction (100 words):Acra Machinery, a renowned supplier of industrial machinery, has recently experienced a surge in requests for curving rolls specifically designed to suit Corrugated Iron. Responding to market demand, the company has successfully sourced a state-of-the-art computer numerical control (CNC) curving machine. This cutting-edge technology, devoid of the brand name, ensures precise and efficient production of Corrugated Curving Rolls. Acra Machinery's ability to meet this rising demand bolsters the company's reputation as a reliable provider in the industrial machinery sector.Body (600 words):1. Rising Demand for Corrugated Iron Curving Rolls (150 words):Corrugated iron is widely used in the construction and architectural industries due to its durability, strength, and cost-effectiveness. As the demand for innovative and aesthetically pleasing architectural solutions continues to grow, there has been an increasing requirement for curved corrugated iron sheets. Curved corrugated iron provides enhanced structural integrity and design flexibility, enabling architects, builders, and designers to create unique and visually appealing structures.Recognizing this demand, Acra Machinery has been inundated with numerous requests for curving rolls specifically designed to suit corrugated iron. While traditional manual methods were previously employed to curve such rolls, the ever-expanding market required a more efficient and accurate solution. To meet these evolving demands, Acra Machinery sought to acquire a full CNC curving machine capable of meeting both functional and aesthetic requirements.2. Sourcing a State-of-the-Art Curving Machine (150 words):To address the increasing demand for curving rolls tailored to corrugated iron, Acra Machinery proactively researched and sourced a full CNC curving machine. This computer numerical control technology facilitates automated and precise curving of corrugated iron sheets. By removing the brand name, it is evident that Acra Machinery prioritizes the functionality and quality of the curving machine, ensuring optimal production outcomes for their clientele.The CNC curving machine acquired by Acra Machinery operates on advanced software, allowing for comprehensive customization options. Users can adjust the curvature, radius, and dimensions of the corrugated iron sheets according to their unique requirements. This versatility enables architects and builders to explore innovative design possibilities, breathing life into architectural visions and pushing the boundaries of construction.3. Unmatched Precision and Efficiency (150 words):The integration of the CNC curving machine into Acra Machinery's production processes has revolutionized the precision and efficiency with which corrugated iron curving rolls are manufactured. Through the automation provided by the CNC technology, manual errors are minimized, ensuring consistently accurate results.The CNC curving machine controls every aspect of the rolling process, optimizing efficiency and reducing production time significantly. This streamlined workflow positively impacts the delivery timelines for customers, allowing them to meet project deadlines more effectively.4. Strengthening Acra Machinery's Market Position (150 words):By successfully meeting the industry's escalating demand for curving rolls for corrugated iron, Acra Machinery has strengthened its position as a trusted provider of industrial machinery. The company's ability to source and utilize advanced CNC technology showcases its commitment to customer satisfaction and technological advancement. Acra Machinery's dedication to innovation and meeting market needs has not only elevated their status but also established them as an industry leader.Furthermore, by investing in state-of-the-art CNC curving technology, Acra Machinery is empowering architects, builders, and designers to realize their creative visions with precision. The enhanced opportunities for experimentation offered by these curving rolls will undoubtedly inspire new architectural designs and constructions.Conclusion (100 words):Acra Machinery's successful acquisition and utilization of a full CNC curving machine to cater to the growing demand for corrugated iron curving rolls marks a significant achievement in the industry. The company's commitment to meeting market needs and deploying modern technologies has bolstered its reputation as a trusted provider in the industrial machinery sector. With the introduction of these advanced curving rolls, Acra Machinery has enabled architects and builders to explore new possibilities for efficient and aesthetically pleasing architectural designs, setting the stage for future innovation in the construction industry.

High-Quality Corrugated Iron Machine for Sale: Find Your Perfect Solution Here

[Company Name] is proud to announce the launch of their latest innovation in the manufacturing industry - the new Corrugated Iron Machine. This state-of-the-art machine is set to revolutionize the production of corrugated iron sheets, offering increased efficiency, precision, and quality.The Corrugated Iron Machine is the result of years of research and development, drawing on [Company Name]'s expertise and experience in the manufacturing sector. The machine is designed to meet the growing demand for corrugated iron sheets, which are commonly used in construction, roofing, and structural projects.One of the key features of the Corrugated Iron Machine is its advanced technology, which allows for precise and uniform corrugation of iron sheets. This ensures that the finished products are of the highest quality, with consistent dimensions and excellent structural integrity. The machine also offers increased production capacity, allowing for higher output and faster turnaround times.In addition to its advanced technology, the Corrugated Iron Machine is also designed with ease of use and maintenance in mind. With user-friendly controls and a robust construction, the machine is built to withstand the rigors of heavy-duty industrial use, while also being easy to operate and maintain. This makes it a valuable asset for manufacturing facilities of all sizes."We are thrilled to introduce the new Corrugated Iron Machine to the market," said [Company Name] spokesperson. "This machine represents a significant advancement in the manufacturing of corrugated iron sheets, offering unparalleled precision, efficiency, and quality. We believe that it will have a positive impact on the industry and help our customers meet the growing demand for high-quality corrugated iron products."The launch of the Corrugated Iron Machine is the latest in a series of innovative products and solutions from [Company Name]. With a commitment to excellence and a focus on meeting the needs of their customers, the company has established itself as a leader in the manufacturing industry. Their dedication to research and development, as well as investment in cutting-edge technology, have allowed them to stay ahead of the competition and continue to deliver products that exceed industry standards.In addition to the Corrugated Iron Machine, [Company Name] offers a comprehensive range of equipment and machinery for the manufacturing sector. This includes metal forming machines, roll forming machines, and other custom solutions tailored to the specific needs of their customers. With a team of experienced engineers and technicians, they also provide expert support and service to ensure that their customers get the most out of their investments.As the demand for corrugated iron sheets continues to grow, the launch of the Corrugated Iron Machine could not have come at a better time. [Company Name] is confident that this innovative machine will help their customers meet this demand with ease, while also improving their production processes and overall efficiency.The Corrugated Iron Machine is now available for purchase, and [Company Name] is inviting interested parties to get in touch for more information. With its cutting-edge technology, user-friendly design, and focus on quality, this machine is set to make a significant impact on the manufacturing industry and set a new standard for the production of corrugated iron sheets.

Metal Sheet Roof Roll Forming Machine: A Guide to Efficient Roof Panel Production

Metal Sheet Roof Roll Forming Machine Revolutionizes Roofing IndustryInnovative and high-performance metal sheet roof roll forming machines have emerged as game-changers in the roofing industry. These state-of-the-art machines offer an efficient and cost-effective solution for producing metal roofs, catering to the rising demand for sustainable and durable roofing materials. With advanced technology, precision engineering, and seamless operations, this machinery is transforming the construction landscape.Metal roofs have gained immense popularity due to their superior strength, longevity, and aesthetic appeal. They provide excellent protection against extreme weather conditions, including hail, wind, and fire. Recognizing the growing demand for metal roofs, companies have dedicated their efforts to developing advanced manufacturing equipment. Among them, the metal sheet roof roll forming machine has emerged as a leader, revolutionizing the production process.The secret to the success of the metal sheet roof roll forming machine lies in its efficient and automated operation. This cutting-edge equipment can accurately shape metal sheets into various roofing profiles, such as standing seam, corrugated, and trapezoidal roofs. The machine itself is composed of a series of rollers and dies that progressively bend and shape the metal sheet into the desired profile. With precise measurements and consistent quality, these machines can produce roof panels with high dimensional accuracy.One of the key advantages of these machines is their versatility. They can process a wide range of metal sheets, including galvanized steel, aluminum, and copper, ensuring flexibility in design options for architects and homeowners. Furthermore, the metal sheet roof roll forming machines can seamlessly accommodate various widths and thicknesses, allowing for customization based on specific project requirements. This adaptability has positioned these machines at the forefront of the roofing industry.Enhanced operational efficiency is another notable feature of the metal sheet roof roll forming machines. Equipped with advanced computer numerical control (CNC) systems, these machines can effortlessly adjust to different production settings, saving time and reducing material waste. Operators can easily input the required dimensions and specifications, and the machine would automatically make the necessary adjustments. This level of automation significantly increases productivity and reduces human error.The durability and reliability of the metal sheet roof roll forming machines are unmatched. Built with heavy-duty materials and precision-engineered components, these machines offer long-lasting performance with minimal maintenance. They are designed to withstand harsh working environments and operate continuously, ensuring uninterrupted production capabilities for roofing manufacturers.Moreover, manufacturers of metal sheet roof roll forming machines prioritize the safety of operators and the environment. The machines are equipped with safety features such as emergency stop buttons, protective covers, and sensors, ensuring a secure working environment. Additionally, these machines are designed to minimize energy consumption, contributing to sustainable manufacturing practices.Leading the industry in the production of metal sheet roof roll forming machines, {}, has gained international recognition for its cutting-edge technology and commitment to exceptional quality. With an extensive product range, they offer a variety of customizable options to meet the diverse needs of their customers. Their machines have been widely adopted by roofing manufacturers worldwide, enabling them to produce high-quality metal roofs efficiently.In conclusion, metal sheet roof roll forming machines have revolutionized the roofing industry by providing efficient, cost-effective, and sustainable solutions for metal roof production. These machines offer versatility, accuracy, and enhanced operational efficiency, ensuring high-quality metal roofs with precise dimensions. With the continuous advancements in technology and the commitment of manufacturers, metal sheet roof roll forming machines are set to reshape the construction landscape, offering architects and homeowners an attractive, durable, and eco-friendly roofing solution.