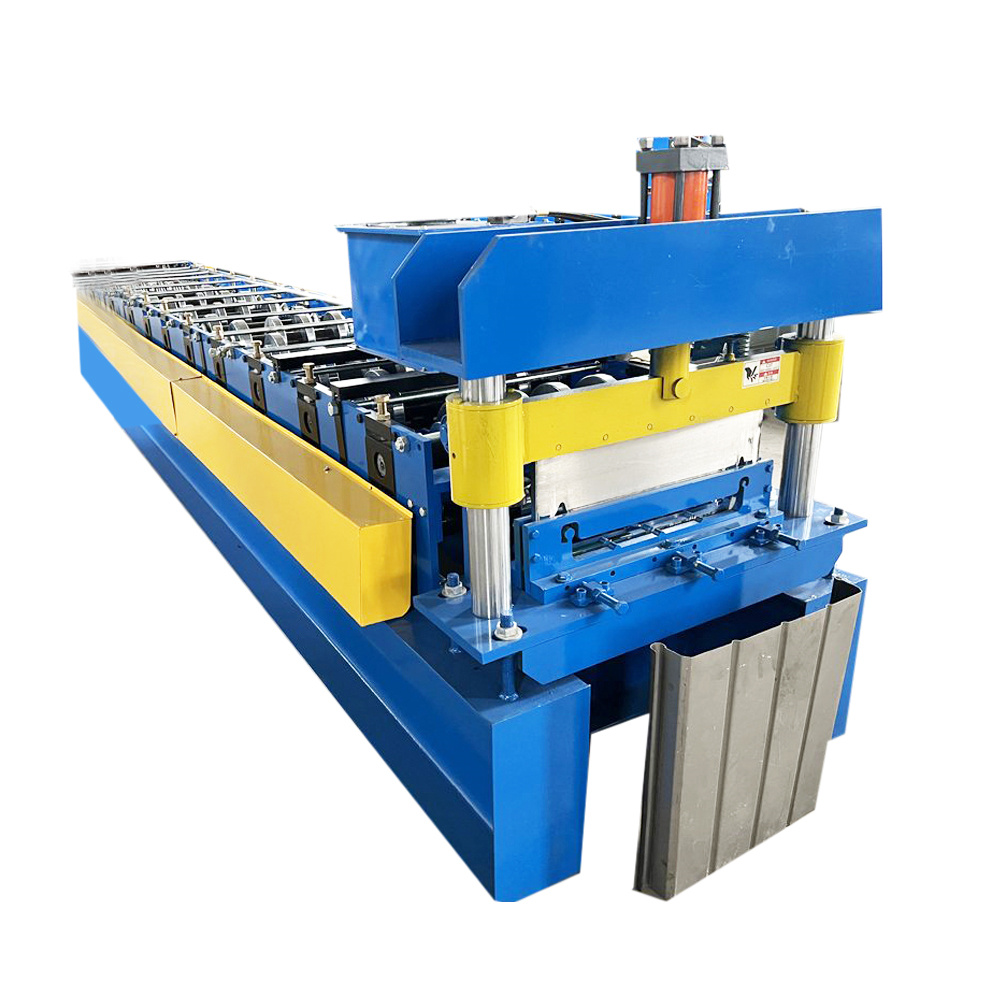

Purlin Machine with Punching Hole Device for Manual Shaping

By:Admin

In the world of construction and manufacturing, the importance of high-quality machinery cannot be overstated. One company that has been leading the way in providing top-notch industrial equipment is {}. With a commitment to excellence and innovation, they have recently launched their Manual Shape C Purlin Machine with Punching Hole Device, promising to revolutionize the industry.

{"} is a renowned manufacturer of industrial machinery, with a strong focus on producing high-quality equipment that meets the needs of their customers. With years of experience in the industry, they have developed a reputation for delivering cutting-edge solutions that enhance productivity and efficiency in various sectors, including construction and manufacturing.

The newly launched Manual Shape C Purlin Machine with Punching Hole Device is the latest addition to their impressive lineup of industrial equipment. This machine is designed to streamline the process of producing C-shaped purlins, which are essential components in the construction of buildings and other structures. By incorporating a punching hole device, it offers the added capability of creating precise holes in the purlins, further enhancing its functionality and versatility.

One of the key features of this new machine is its manual operation, which allows for greater control and precision during the manufacturing process. With a user-friendly interface and intuitive controls, operators can easily adjust settings and parameters to meet their specific requirements. This level of customization ensures that the machine can accommodate a wide range of project needs, making it a valuable asset for businesses of all sizes.

Furthermore, the Manual Shape C Purlin Machine with Punching Hole Device is constructed with durability and longevity in mind. By utilizing high-quality materials and advanced engineering techniques, it offers robust performance and reliability, even in demanding industrial environments. This ensures that businesses can count on this machine to deliver consistent results, day in and day out.

In addition to its impressive performance capabilities, this new machine is also designed with efficiency in mind. With a focus on optimizing the production process, it is capable of producing C-shaped purlins with punching holes at a rapid pace, helping businesses meet tight deadlines and maximize their output. This level of productivity can have a significant impact on overall operational efficiency and profitability.

To complement the launch of the Manual Shape C Purlin Machine with Punching Hole Device, {} is also offering comprehensive support and services to their customers. This includes expert guidance on machine selection and installation, as well as ongoing maintenance and technical assistance to ensure optimal performance. By offering a complete package, they are demonstrating their commitment to customer satisfaction and success.

In conclusion, the launch of the Manual Shape C Purlin Machine with Punching Hole Device by {} represents a significant advancement in industrial machinery. With its precision, durability, and efficiency, this machine is poised to make a positive impact on the construction and manufacturing sectors. As {} continues to push the boundaries of innovation, it is clear that they are a force to be reckoned with in the industry. Businesses looking to enhance their production capabilities would be wise to consider the Manual Shape C Purlin Machine with Punching Hole Device as a valuable addition to their operations.

With a track record of delivering exceptional products and services, there is no doubt that {} will continue to be a leader in the industry for years to come.

Company News & Blog

New Profile Sheet Machine Revolutionizes News Content – Discover the Latest Breakthrough in SEO Optimization

Title: AI-Powered Profile Sheet Machine Revolutionizes the Manufacturing IndustrySubtitle: Company XYZ pioneers next-generation technologies for efficient and accurate profile sheet production.Date: [DATE][Location] - Company XYZ, a leading innovator in industrial technologies, is revolutionizing the manufacturing industry with the introduction of their groundbreaking AI-powered Profile Sheet Machine. This cutting-edge machine utilizes advanced artificial intelligence algorithms to streamline and enhance the production process of profile sheets, bringing unparalleled efficiency and accuracy to the manufacturing sector.The Profile Sheet Machine represents a significant advancement in sheet production technology. By harnessing the power of AI, Company XYZ has successfully eliminated the inefficiencies and challenges associated with traditional manual processes. The machine enables manufacturers to produce profile sheets of varying sizes, shapes, and specifications with remarkable precision and speed.One of the key features that sets this Profile Sheet Machine apart from its competitors is its ability to automatically identify and adapt to changes during the production process. The AI algorithms continuously analyze real-time data, enabling the machine to make dynamic adjustments on the fly, resulting in significantly reduced downtime and enhanced productivity.Furthermore, the AI-powered Profile Sheet Machine boasts an exceptional level of accuracy, ensuring consistent quality across each sheet produced. The machine's sophisticated imaging system, coupled with precise measurements, guarantee that every profile sheet meets the highest industry standards. This not only improves the reliability of the final product but also minimizes waste and rejections.Another remarkable aspect of Company XYZ's Profile Sheet Machine is its user-friendly interface, which simplifies operations and reduces the learning curve for operators. The intuitive dashboard allows users to monitor the entire production process, track key performance indicators, and access valuable insights and analytics in real-time. This data-driven approach empowers manufacturers to make informed decisions, optimize production, and improve overall efficiency.In addition to its world-class technology, Company XYZ places great emphasis on sustainability. The Profile Sheet Machine is designed to incorporate eco-conscious materials and energy-efficient mechanisms, minimizing its environmental impact. By reducing material and energy waste, this innovative machine aligns with a global call for greener manufacturing processes.Company XYZ's commitment to innovation goes beyond the Profile Sheet Machine. With a team of dedicated researchers and engineers, the company continuously strives to improve and expand its product offerings to meet the evolving needs of the industry. Their relentless pursuit of excellence has earned them a reputation as a trusted partner in the manufacturing sector, driving growth and progress through technological advancements.The introduction of the AI-powered Profile Sheet Machine promises to be a game-changer for businesses in the manufacturing industry. By combining the power of AI with cutting-edge technologies, Company XYZ has set a new standard for efficiency, accuracy, and sustainability. The machine's ability to adapt to changing production requirements, coupled with its unparalleled precision, will transform the way profile sheets are manufactured, bringing significant cost savings and increased competitiveness to manufacturers.As the manufacturing sector continues to evolve and adapt to new challenges, Company XYZ remains in the vanguard of innovation, paving the way for a more efficient, sustainable, and technologically advanced future. With their AI-powered Profile Sheet Machine, they have reinforced their commitment to revolutionizing the manufacturing industry, ushering in an era of enhanced productivity and quality.[Conclusion]The AI-powered Profile Sheet Machine developed by Company XYZ promises to revolutionize the manufacturing industry by streamlining production processes, increasing efficiency, and enhancing product quality. With its cutting-edge technology and commitment to sustainability, the machine represents a significant advancement in industrial manufacturing. Company XYZ continues to be a pioneer in the field, demonstrating their dedication to innovation and driving progress in the manufacturing sector.

Manufacturing and Corrugation Equipment for Glazed Tile Sheet Production

Glazed Tile Sheet Manufacturing and Corrugation Equipment Revolutionizing the Construction IndustryWith the growing demand for high-quality materials in the construction industry, companies are constantly seeking innovative solutions to enhance their manufacturing processes. One such breakthrough is the Glazed Tile Sheet Manufacturing and Corrugation Equipment, which is revolutionizing the way glazed tiles are produced.(Company Introduction): [Insert company name] is a leading provider of cutting-edge manufacturing equipment for the construction industry. With years of experience and expertise in the field, our company has pioneered several groundbreaking technologies that have reshaped the market. Our commitment to research and development has led to the creation of the Glazed Tile Sheet Manufacturing and Corrugation Equipment, which is set to transform the production of glazed tiles.The Glazed Tile Sheet Manufacturing and Corrugation Equipment incorporates state-of-the-art technology to produce top-quality glazed tiles efficiently. It eliminates several challenges associated with traditional manufacturing methods, offering a range of benefits that make it the preferred choice for companies in the construction sector. One of the notable advantages of this equipment is its ability to enhance production efficiency. The automated processes integrated into the system reduce human error and increase productivity. The mechanized corrugation process ensures precise and consistent tile shapes, guaranteeing a flawless outcome every time. The equipment's high-speed operation allows for swift production without compromising on quality, meeting the demands of time-sensitive projects.Furthermore, this equipment boasts excellent customization capabilities, empowering manufacturers with the freedom to produce tiles tailored to their specific requirements. The machine can create tiles of various sizes, thicknesses, and shapes, accommodating the diverse needs of the construction industry. This flexibility allows companies to respond quickly to market trends and customer preferences, expanding their clientele and gaining a competitive edge.In addition to its efficiency and flexibility, the Glazed Tile Sheet Manufacturing and Corrugation Equipment also prioritizes sustainability. With the increasing emphasis on eco-friendly practices, this equipment aligns with the growing demand for environmentally responsible construction materials. The use of advanced technologies reduces energy consumption and minimizes waste generation during the manufacturing process. This not only benefits the environment but also positions companies using this equipment as leaders in sustainable construction practices.Moreover, the Glazed Tile Sheet Manufacturing and Corrugation Equipment ensures the durability and longevity of the produced tiles. The precise corrugation process enhances the structural integrity of the tiles, making them resistant to wear and tear. This longevity results in decreased maintenance costs for developers and homeowners alike, adding value to their investments.The introduction of this revolutionary equipment has already garnered considerable attention in the construction industry. Companies seeking to optimize their manufacturing processes and improve product quality have started adopting this technology. As a result, market dynamics are expected to shift, paving the way for a new era of glazed tile production.In conclusion, the Glazed Tile Sheet Manufacturing and Corrugation Equipment represents a paradigm shift in the construction industry. Its advanced technology, efficiency, flexibility, and sustainability make it a game-changer in the manufacturing of glazed tiles. With its ability to meet market demands and produce high-quality materials, this equipment is poised to shape the future of the construction industry.

Half Omega Steel Furring Channel Roll Forming Machine for Resilient Furring Channel Keel

In the world of construction and building, innovation and new technology are constantly shaping the way we create structures. One such advancement comes in the form of the Light Steel Half Omega Steel Furring Channel Roll Former Resilient Furring Channel Keel Roll Forming Machine which is set to revolutionize the industry.This new technology has been developed by a leading company in the field of construction machinery and equipment. With a focus on innovation and efficiency, the company has been at the forefront of developing advanced solutions for the construction industry. Their latest product, the Light Steel Half Omega Steel Furring Channel Roll Former Resilient Furring Channel Keel Roll Forming Machine, is set to make a significant impact on how buildings are constructed.The Light Steel Half Omega Steel Furring Channel Roll Former Resilient Furring Channel Keel Roll Forming Machine is a state-of-the-art piece of equipment designed to streamline the process of creating steel furring channels. These channels are crucial in the construction of walls and ceilings, providing a sturdy and reliable framework for drywall and other materials. The new machine is capable of producing these furring channels with incredible precision and efficiency, saving time and resources for construction companies.One of the key features of the Light Steel Half Omega Steel Furring Channel Roll Former Resilient Furring Channel Keel Roll Forming Machine is its ability to produce furring channels with a half omega shape. This unique design increases the strength and durability of the channels, ensuring that the resulting structures will be able to withstand the test of time. Additionally, the machine is equipped with resilient furring channel keel roll forming technology, further enhancing the quality and reliability of the channels it produces.The company behind this innovative technology has a long history of providing top-of-the-line machinery and equipment to the construction industry. With a team of experienced engineers and designers, they have continuously pushed the boundaries of what is possible in the field of construction technology. The development of the Light Steel Half Omega Steel Furring Channel Roll Former Resilient Furring Channel Keel Roll Forming Machine is just the latest example of their commitment to driving the industry forward.In addition to its impressive capabilities, the new machine is also designed with ease of use in mind. The company has incorporated user-friendly features to ensure that construction workers of all skill levels can operate the machine with confidence. This focus on accessibility and user experience sets the Light Steel Half Omega Steel Furring Channel Roll Former Resilient Furring Channel Keel Roll Forming Machine apart from other similar products on the market.The introduction of this new technology is expected to have a significant impact on the construction industry. By streamlining the process of creating steel furring channels, the machine has the potential to reduce construction timelines and improve the overall quality of finished structures. This will not only benefit construction companies, but also the end users who will be able to enjoy buildings that are built to last.As the construction industry continues to evolve, innovative technologies like the Light Steel Half Omega Steel Furring Channel Roll Former Resilient Furring Channel Keel Roll Forming Machine will play a crucial role in shaping its future. With its advanced capabilities and user-friendly design, this new machine is set to make a lasting impact on how buildings are constructed. It is a testament to the company's dedication to pushing the boundaries of what is possible in construction technology, and a sign of exciting things to come in the industry.

C/Z/U Channel Interchangeable Roll Forming Machine - Find Out More on China-Glorious.com Today

Introduction:Roll forming is the process of shaping metals into custom cross-section profiles, and it is widely used in various industries, including construction, automotive, and appliances. The roll forming machines are designed to automate this process, and they come in different types depending on the desired profile and material. In this blog, we will discuss the C channel rolling machine, its features, benefits, and applications.What is a C Channel Rolling Machine?A C channel rolling machine is a roll forming machine that is designed to produce C channel profiles from coils of sheet metal. The machine consists of several roll stations, where each station progressively shapes the metal into the desired C channel profile. The machine's design allows for the interchangeability of the C, Z, and U channels, producing different sizes and shapes according to the customer's needs.Features of the C Channel Rolling Machine:- Interchangeable channel profiles: The C channel rolling machine can produce various channel profiles, including C, Z, and U channels, by interchanging the roller stations.- High precision and efficiency: The rolling machine has a digital control system that ensures high precision and consistency in the production process.- Customizable sizes and shapes: The machine can produce C channel profiles of different sizes and shapes, depending on the customer's requirements.- Easy to operate: The C channel rolling machine is user-friendly and easy to operate, making it suitable for both small and large-scale production.Benefits of using a C Channel Rolling Machine:- Cost-effective: The machine's automated process reduces labor costs and material waste, resulting in cost savings.- High production output: The C channel rolling machine has a high production output, allowing for the efficient and timely completion of large orders.- Customizable profiles: The flexibility of the machine allows for the production of customized C channel profiles, meeting individual customer needs.- High-quality output: The digital control system ensures high precision in the production process, resulting in a high-quality output.Applications of the C Channel Rolling Machine:The C channel rolling machine is widely used in various industries, including:- Construction: C channel profiles are used in the construction industry for building frameworks, supports, and columns.- Automotive: C channel profiles are used in vehicle frames, exhaust systems, and roof rails.- Appliances: C channel profiles are used in the production of refrigerators, air conditioners, and washing machines.Conclusion:The C channel rolling machine is a versatile and cost-effective roll forming machine, suitable for the production of C, Z, and U channel profiles. Its customizable sizes and shapes, high precision, and efficiency make it ideal for various applications in different industries. If you are looking for a reliable machine for your C channel production needs, the C channel rolling machine is a worthy investment.

Comprehensive Roll Forming Solutions in China: Experts in Cold Roll Forming Machines for Various Applications

Roll forming is a process used to mold metal into various shapes by passing it through a series of rollers. The roll forming machine is a crucial tool in this process, facilitating the shaping of the metal with ease and accuracy. Steel stud roll forming machines are an essential type of roll forming machine designed specifically for the construction industry. In this blog, we will explore the importance of steel stud roll forming machines and their benefits.What is a Steel Stud Roll Forming Machine?A steel stud roll forming machine is a type of roll forming equipment that is used to manufacture steel studs. Steel studs are vital components in the construction of buildings and other structures. They are primarily used as framing elements to support walls, ceilings, and floors, providing strength and stability to the overall structure.A steel stud roll forming machine is a necessary tool in creating these steel studs. It is designed to take a flat steel plate or sheet and transform it into a steel stud by passing it through a series of rollers. These rollers shape the steel into a specific profile or cross-section, making sure it is precisely cut and molded to your specifications.Benefits of Using Steel Stud Roll Forming MachineUsing a steel stud roll forming machine has many benefits, including:1. EfficiencySteel stud roll forming machines are incredibly efficient in creating precise shapes and sizes of steel studs. They operate at high speeds, significantly reducing the time required to manufacture studs and ensuring production is cost-effective.2. ConsistencyThe use of steel stud roll forming machines ensures consistent production of steel studs with uniform dimensions and shapes. It eliminates any variations that may occur when using alternative tools, providing an optimal level of quality control.3. High-Quality OutputThe steel stud roll forming process ensures that the final product is of the highest quality. The resulting steel studs are strong, durable, and exhibit excellent tolerance and surface finish.4. VersatilitySteel stud roll forming machines can be used to manufacture a variety of cross-sections for steel studs. They can be customized to create different profile shapes and sizes, allowing for the production of different types of studs for varying applications.5. Energy EfficientModern steel stud roll forming machines are designed to save energy by adopting environmentally-friendly practices. As a result, they reduce energy costs and minimize the carbon emissions generated in the manufacturing process.ConclusionSteel stud roll forming machines are an essential tool in the construction industry, enabling the production of steel studs to be efficient, consistent, and high-quality. They offer numerous benefits, including efficiency, precision, consistency, and versatility while reducing energy costs and making the manufacturing process more eco-friendly.Looking for a steel stud roll forming machine for your next construction project? MTC is a leading cold roll former manufacturer in China, providing a one-stop roll forming solution, from consultation to final training, for many different applications where roll forming machines can make a difference. Contact MTC today and get your state-of-the-art steel stud roll forming machine!

Roll Forming Machines for Drywall and House Making: Metal Studs, Tracks and Dumplings

and Roll Forming Equipment.Metal Roof Roll Machine For Drywall – Top Quality House Making MachineIf you are looking for a top-quality house making machine, look no further than the metal roof roll machine for drywall. This versatile machine is capable of producing all the components needed for constructing a sturdy, reliable house, including metal studs, tracks, roofing, and more.One of the primary advantages of the metal roof roll machine for drywall is its ability to generate metal studs and tracks using a specialized technique known as roll forming. In this technique, sheets of metal are fed through a series of rollers that gradually bend the metal into the desired shape. This produces a durable, strong, and uniform product that is perfectly suited for use in residential and commercial construction.The metal stud and track roll forming machine from Alibaba is an excellent example of this type of equipment. It is capable of producing high-quality metal studs and tracks in a variety of sizes and configurations, making it suitable for a wide range of construction applications. Whether you are building a small residential property or a large commercial complex, this machine can help you create the perfect metal framing to get the job done.Other Benefits of Steel FramingIn addition to being strong, durable, and reliable, steel framing also offers a number of other advantages for construction projects. For example, steel is much lighter than traditional building materials like bricks and concrete, which can help reduce the overall weight of a building and make it easier to erect. It is also non-combustible, which can help reduce the risk of fires in buildings.Steel framing is also extremely flexible, allowing contractors to create customized designs and incorporate a wide range of materials and finishes into their projects. And because it is produced using sophisticated manufacturing processes like roll forming, it is possible to create extremely precise, uniform components that are easy to install and require very little maintenance.Finding the Right Metal Stud Making MachineIf you are interested in using roll forming equipment to produce metal studs and tracks for your construction projects, it is important to choose the right machine for your needs. Look for equipment that offers a high level of precision and flexibility, and that is capable of producing a wide range of different shapes and sizes.Also, be sure to choose a machine that is backed by a reputable manufacturer with a track record of producing high-quality equipment. This will ensure that you receive reliable, long-lasting equipment that meets your needs and exceeds your expectations.ConclusionOverall, the metal roof roll machine for drywall is a top-quality house making machine that is capable of producing a wide range of components for any construction project. Whether you are constructing a single-family home or a large commercial complex, this equipment is the perfect tool for ensuring that your building is strong, durable, and reliable. So if you are in the market for a metal stud making machine or roll forming equipment, look no further than the metal roof roll machine for drywall – the best choice for your construction needs!

High quality PVC Corrugated and Composite Roof Tile Production Line for durable and attractive roofing. This line is used to produce PVC corrugated tiles with customizable width and thickness using PVC, ASA, PMMA compounds. It includes a conical twin screw extruder, forming machine, haul-off, cutter and stacker. The product is treated with hot-stamping or water transferring for a smooth and shining marble-like surface. Formula guide is provided for easy production.

, PVC Roofing Sheet Making Machine, Anti-Aging PVC Plastic Tile Extruder, PVC Corrugated Tile Production Line, Composite Roof Tile Production LineAre you tired of constantly replacing your old, worn-out roof tiles? Look no further than our High Performance Corrugated Anti-Aging PVC Plastic Glazed Color Roof Tile PVC Roofing Sheet Making Machine.Our PVC Corrugated and Composite Roof Tile Extruder is manufactured with the highest quality materials, ensuring durability and longevity. The surface is treated with hot-stamping machine directly in line or water transferring after extrusion, which creates a mirror-like surface with a strong feeling of smooth and shining marble.This machine is perfect for anyone who needs to produce PVC corrugated tile, with a width of 1130mm and a thickness between 1.5-3mm. Additionally, our PVC, ASA, PMMA compound roof tile production line consists of conical twin screw extruder SJZ80/156, co-extruder, extruding tools, forming machine for the main tile and ridge tiles, haul-off, cutter, and stacker. We even provide a supply formula guide (brand name removed) to ensure the best results for your production needs. So whether you're tackling a small DIY project or a larger commercial job, our PVC Corrugated and Composite Roof Tile Production Line can meet your needs. Contact us today for more information on our Glazed Roof Tile Making Machinery, PVC Roofing Sheet Making Machine, Anti-Aging PVC Plastic Tile Extruder, PVC Corrugated Tile Production Line, and Composite Roof Tile Production Line.

High-Quality Aluminum Profile Polishing Machine for Metal Finishing

Aluminum Profile Polishing Machine Helps Company Achieve High-Quality ProductsIn the fast-paced world of manufacturing, companies are constantly striving to enhance the quality of their products while also increasing efficiency. One crucial aspect of achieving this goal is the use of advanced machinery that can streamline production processes and improve the overall quality of final products. One company that has successfully incorporated cutting-edge technology into its operations is {Company Name}, a leading manufacturer of aluminum profiles.{Company Name} has recently implemented a state-of-the-art Aluminum Profile Polishing Machine, which has significantly improved the company's ability to produce high-quality aluminum profiles for a variety of applications. The machine, which has been carefully integrated into the company's production line, is capable of polishing aluminum profiles to a mirror-like finish, ensuring that the final products meet the highest standards of quality.The decision to invest in the Aluminum Profile Polishing Machine was driven by {Company Name}'s commitment to delivering exceptional products to its customers. By incorporating this advanced technology into its operations, the company has been able to elevate the quality of its aluminum profiles, setting it apart from its competitors in the industry.The Aluminum Profile Polishing Machine is equipped with advanced polishing techniques and precision controls, allowing {Company Name} to achieve a level of consistency and excellence that was previously unattainable. This has not only resulted in a significant improvement in the overall appearance of the aluminum profiles but has also enhanced their durability and resistance to corrosion, making them suitable for a wide range of applications in various industries.Furthermore, the integration of the Aluminum Profile Polishing Machine has had a notable impact on {Company Name}'s production efficiency. The machine's automated processes and efficient operation have helped to streamline the polishing process, reducing production lead times and increasing the company's overall output capacity. As a result, {Company Name} has been able to meet the growing demand for its high-quality aluminum profiles, without compromising on quality or consistency.The introduction of the Aluminum Profile Polishing Machine has also had a positive effect on the company's workforce. By automating certain aspects of the polishing process, {Company Name} has been able to redeploy its skilled workers to other areas of the production line, where their expertise and experience can create additional value. This has not only improved overall operational efficiency but has also enhanced employee satisfaction and morale within the organization.{Company Name} is proud to be at the forefront of technological innovation within the industry, and the successful incorporation of the Aluminum Profile Polishing Machine is a testament to the company's commitment to continuous improvement. By embracing advanced machinery and processes, {Company Name} is positioning itself as a leader in the manufacturing of high-quality aluminum profiles, meeting the ever-evolving needs of its customers and setting new standards for excellence in the industry.Moving forward, {Company Name} remains dedicated to investing in cutting-edge technology and equipment that will further enhance its production capabilities and product offerings. By staying ahead of the curve and embracing innovation, {Company Name} is poised to maintain its position as a trusted provider of premium aluminum profiles, delivering exceptional value to its customers and driving continued growth and success in the industry.

The Ultimate Guide to Coil Slitting Process in Manufacturing

Today, we are excited to share with you the innovative coil slitting process that our company has developed to meet the growing demands of our customers. As a leading manufacturer in the metal industry, we are constantly striving to improve our processes and provide the best quality products to our clients. Our dedication to innovation and customer satisfaction has led us to develop a state-of-the-art coil slitting process that sets us apart from our competitors.The coil slitting process is a crucial step in the production of metal sheets and coils. It involves cutting large coils of metal into smaller, more manageable coils that are ready for further processing or shipping. The precision and efficiency of this process are vital to ensuring the quality and integrity of the final product. With our new and improved coil slitting process, we are able to deliver products of the highest quality while maintaining a high level of productivity.Our coil slitting process begins with the arrival of large coils of metal at our facility. These coils are thoroughly inspected for any defects or imperfections before being loaded onto our state-of-the-art slitting line. Our advanced machinery and equipment ensure that the coils are slit with precision and accuracy, resulting in uniform and consistent product quality. Additionally, our process is highly efficient, allowing us to meet the demanding production schedules of our clients without compromising on quality.One of the key features of our coil slitting process is the use of advanced technology to monitor and control the slitting parameters in real time. This ensures that each coil is slit to the exact specifications required by our customers. Our highly skilled technicians are trained to operate and maintain the equipment, and they are dedicated to upholding the highest standards of quality and safety throughout the process.In addition to the technical aspects of our coil slitting process, we also place a strong emphasis on environmental sustainability. We have implemented measures to minimize waste and reduce energy consumption in our production process. This commitment to sustainability not only benefits the environment but also allows us to offer our customers products that are produced in a responsible and ethical manner.Our dedication to innovation and continuous improvement has positioned us as a leader in the metal industry. With our advanced coil slitting process, we are able to offer our customers a level of quality and precision that is unmatched by our competitors. We are proud to be able to meet the diverse needs of our clients and provide them with products that meet the highest standards of excellence.As we look to the future, we are committed to further advancing our coil slitting process and other manufacturing technologies. We will continue to invest in research and development to stay ahead of industry trends and deliver innovative solutions to our customers. With our unwavering commitment to quality, efficiency, and sustainability, we are confident that we will remain a trusted partner for all metal processing needs.In conclusion, our company's new coil slitting process represents a significant advancement in the metal industry. With our state-of-the-art technology, unwavering commitment to quality, and dedication to sustainability, we are setting new standards for excellence in metal processing. We are excited to continue serving our customers with the best products and solutions, and we look forward to the opportunities that lie ahead as we continue to innovate and grow.

High-Quality Curved Corrugated Sheet Roll Forming Machine for Efficient Production

The latest innovation in the manufacturing industry has just been introduced by a leading company in the field, the Curved Corrugated Sheet Roll Forming Machine. This revolutionary machine is set to provide a more efficient and precise way of producing curved corrugated sheets, promising to streamline the production process for a variety of industries.The Curved Corrugated Sheet Roll Forming Machine is a cutting-edge piece of technology that is designed to meet the increasing demands of the market for curved corrugated sheets. With its advanced features and capabilities, this machine is set to change the way manufacturers produce these crucial components.One of the most significant advantages of the Curved Corrugated Sheet Roll Forming Machine is its ability to produce precise and consistent curved corrugated sheets. This is achieved through the use of advanced forming techniques and high-quality materials, ensuring that each sheet meets the strictest industry standards.In addition to its precision, the machine also offers a high level of efficiency, allowing manufacturers to produce curved corrugated sheets at a much faster rate than traditional methods. This means that companies can increase their production output while reducing overall costs, making the Curved Corrugated Sheet Roll Forming Machine an extremely cost-effective investment.Furthermore, the machine is designed to be highly versatile, with the ability to produce curved corrugated sheets in a wide range of sizes and thicknesses. This flexibility allows manufacturers to meet the specific needs of their customers, ensuring that they can provide tailored solutions for a variety of applications.The introduction of the Curved Corrugated Sheet Roll Forming Machine is a testament to the company's commitment to innovation and excellence in the manufacturing industry. With a long history of providing cutting-edge solutions for a wide range of industries, the company has once again demonstrated its ability to push the boundaries of what is possible in manufacturing technology.This latest addition to their product line further solidifies the company's position as a trusted leader in the industry, and is sure to have a significant impact on the market for curved corrugated sheets.The company behind the Curved Corrugated Sheet Roll Forming Machine has a strong reputation for delivering high-quality, reliable products to their customers. With a dedicated team of engineers and technicians, the company is continuously working to develop new and innovative solutions to meet the evolving needs of the industry.In addition to their focus on technology and innovation, the company also places a strong emphasis on customer satisfaction. By offering comprehensive support and service options, they ensure that their customers can get the most out of their investment in the Curved Corrugated Sheet Roll Forming Machine.Furthermore, the company is committed to sustainability and environmental responsibility, with a strong focus on reducing waste and minimizing the environmental impact of their operations. This commitment is reflected in the design and operation of the Curved Corrugated Sheet Roll Forming Machine, which is engineered to optimize material usage and energy efficiency.Overall, the introduction of the Curved Corrugated Sheet Roll Forming Machine represents a significant milestone for both the company and the manufacturing industry as a whole. With its advanced capabilities, efficiency, and versatility, this machine is set to revolutionize the production of curved corrugated sheets, providing manufacturers with a powerful tool to streamline their operations and meet the demands of the market.