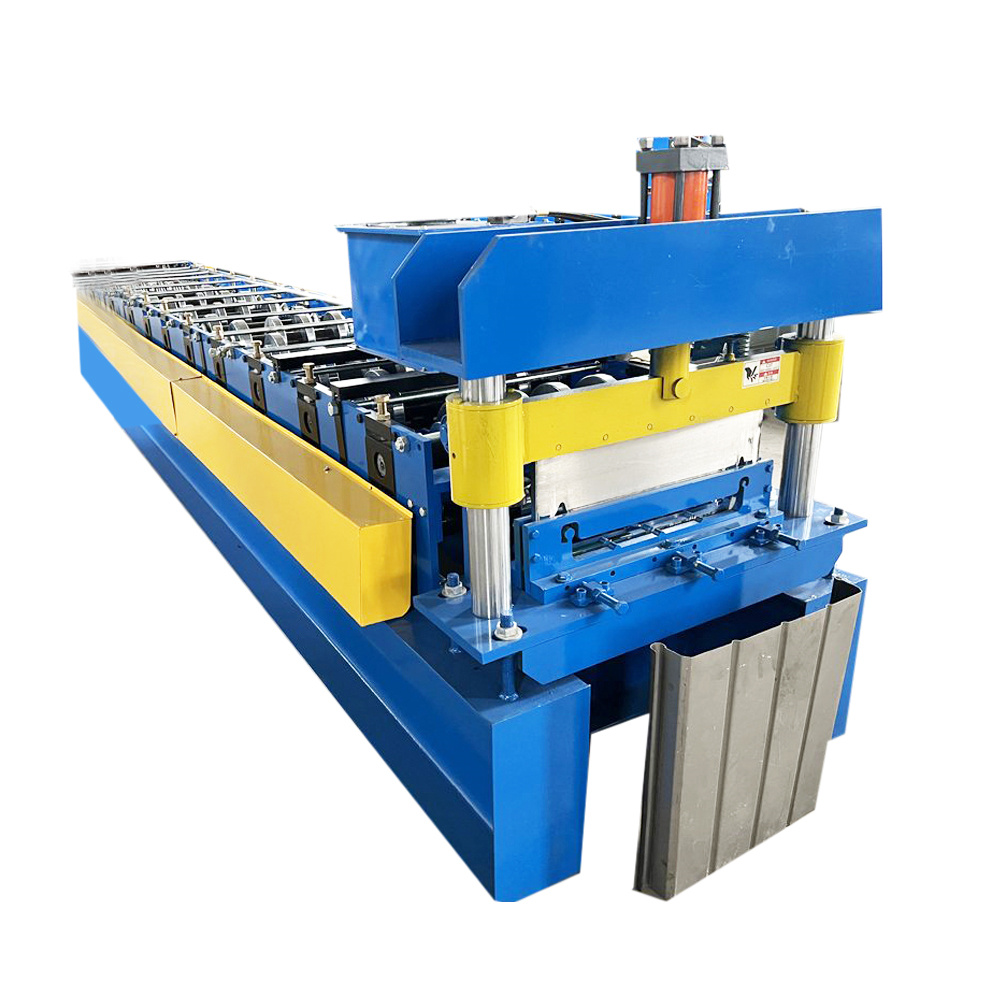

Purlin Profiles Cold Roll Forming Lines: Everything You Need to Know

By:Admin

The new roll forming lines have been designed with precision and efficiency in mind, utilizing the latest technology and manufacturing processes to ensure the highest level of quality and accuracy in the production of CZ purlin profiles. The company has invested heavily in research and development to create these advanced production lines, which are expected to set a new standard in the industry.

The CZ purlin profiles produced by these new roll forming lines are known for their superior strength and durability. They are widely used in the construction industry for framing and supporting roof panels, wall panels, and other structural elements. The profiles are designed to provide exceptional load-bearing capacity, making them a preferred choice for engineers and builders.

In addition to their exceptional strength, these CZ purlin profiles are also highly versatile. They can be easily customized to meet specific project requirements, with the ability to be tailored to various lengths, thicknesses, and shapes. This level of flexibility makes them an ideal solution for a wide range of construction applications.

The launch of these new Purlin Profiles Cold Roll Forming Lines represents a significant milestone for the company, further solidifying their position as a leading manufacturer in the steel industry. With a strong commitment to innovation and quality, the company has continuously invested in the latest technologies and manufacturing processes to meet the evolving needs of their customers.

The company's dedication to excellence is evident in their production facilities, which are equipped with state-of-the-art machinery and equipment. This allows them to consistently deliver products of the highest quality, meeting the stringent industry standards and specifications.

Additionally, the company's team of skilled engineers and technicians plays a crucial role in the success of these new roll forming lines. Their expertise and knowledge ensure that the production processes run smoothly and efficiently, resulting in the consistent and reliable manufacturing of CZ purlin profiles.

The introduction of these new Purlin Profiles Cold Roll Forming Lines is a testament to the company's commitment to innovation and progress. By continually investing in new technologies and processes, they are able to stay at the forefront of the industry and provide their customers with cutting-edge solutions.

As the demand for high-quality steel products continues to grow, the company is well-positioned to meet the needs of a wide range of customers, including builders, contractors, and construction companies. The launch of these new roll forming lines will further strengthen their position in the market and solidify their reputation as a trusted and reliable supplier of CZ purlin profiles.

In conclusion, the new Purlin Profiles Cold Roll Forming Lines introduced by the company represent a significant advancement in the production of CZ purlin profiles. With their focus on quality, innovation, and customer satisfaction, the company is well-equipped to meet the needs of the construction industry and continue to set new standards for steel manufacturing.

Company News & Blog

invention of a Revolutionary Machine that Manufactures Corrugated Metal Sheets

Title: New Machine Revolutionizes Production of Corrugated Metal SheetsIntroduction:With the continuous growth of the construction industry, the demand for durable and versatile building materials is on the rise. Corrugated metal sheets have been a popular choice for a wide range of applications due to their strength, flexibility, and cost-efficiency. Addressing the need for increased productivity and enhanced quality, a pioneering company in the industry has developed a cutting-edge machine that promises to revolutionize the production of corrugated metal sheets, significantly boosting efficiency and meeting the market's growing demands.Body:1. Meeting the Growing Demand:The global construction industry has experienced significant growth over the past few years, and with it, the demand for durable and reliable building materials has soared. Corrugated metal sheets, known for their excellent strength and long-lasting nature, have become a staple in the construction sector. However, traditional manufacturing methods could not always keep up with the mounting demand, leading to delays and potential supply shortages.2. Introducing the Revolutionary Machine:In response to these challenges, {Company Name} has unveiled a state-of-the-art machine that will transform the production of corrugated metal sheets. This innovative solution leverages advanced technology to streamline the manufacturing process, resulting in increased productivity, improved quality, and shorter lead times.3. Enhanced Efficiency:The new machine offers unparalleled efficiency by automating key aspects of the production process. It integrates cutting-edge robotics, precision engineering, and intelligent software algorithms to ensure precise and consistent corrugation patterns. This automation eliminates the need for manual labor, reducing production time and costs while minimizing human error.4. Optimized Flexibility:One of the standout features of this cutting-edge machine is its ability to produce corrugated metal sheets in various sizes, thicknesses, and designs. This versatility enables construction companies and architects to explore innovative designs and cater to the unique requirements of each project. Whether it is for roofing, cladding, or even decorative purposes, the machine ensures the production of customized corrugated metal sheets that perfectly fit the needs of the end-user.5. Unwavering Quality:To meet the ever-increasing demands for superior quality, {Company Name} has incorporated rigorous quality control measures into the machine's design. From raw material inspection to final product assessment, each production stage is thoroughly monitored to ensure that only top-grade corrugated metal sheets are manufactured. This commitment to quality ensures the longevity and reliability of the final product.6. Environmental Considerations:As the world becomes increasingly conscious of the environmental impact of industrial processes, the new machine addresses sustainability concerns. Equipped with energy-efficient components and designed to minimize waste, it helps reduce the overall carbon footprint of production while maximizing material utilization. By optimizing resource consumption, the machine contributes to a greener and more sustainable manufacturing process.7. Market Impact and Benefits:The introduction of this groundbreaking technology not only provides a solution to the production challenges faced by corrugated metal sheet manufacturers but also has broader implications for the construction industry. The enhanced efficiency and flexibility offered by the machine will meet the rising demand for corrugated metal sheets, providing contractors and builders access to quality materials to complete projects within tight deadlines.Conclusion:With the unveiling of their cutting-edge machine, {Company Name} has propelled the production of corrugated metal sheets to new heights. By combining advanced technology, automated processes, and a commitment to quality, this revolutionary innovation promises to meet the surging demand for durable and versatile building materials. With its emphasis on efficiency, flexibility, and sustainability, this new machine is set to redefine the market standards, pushing the construction industry towards exciting possibilities and endless creative potential.

High-Quality Standing Seam Roof Machine for Sale - Find Out More Here!

Standing Seam Roof Machine Revolutionizes Roofing IndustryThe roofing industry has experienced a significant transformation with the introduction of the innovative Standing Seam Roof Machine. This state-of-the-art equipment has revolutionized the way metal roofs are installed, offering a more efficient, cost-effective, and aesthetically pleasing solution for residential and commercial properties.The Standing Seam Roof Machine, developed by a leading manufacturing company in the industry, incorporates advanced technology and precision engineering to create high-quality standing seam metal roofs. The machine is designed to streamline the roof panel production process, allowing for faster installation and improved overall performance.One of the key features of the Standing Seam Roof Machine is its ability to produce custom-fit roof panels on-site, eliminating the need for off-site fabrication and reducing lead times significantly. This level of customization ensures a perfect fit for every project, resulting in a seamless and visually appealing finished product.In addition to its efficiency, the Standing Seam Roof Machine also offers cost savings for both contractors and property owners. With the ability to produce roof panels on-demand, there is reduced material waste and lower transportation costs, resulting in overall project cost reduction. This makes standing seam metal roofs more accessible and cost-effective for a wide range of applications.Furthermore, the Standing Seam Roof Machine is compatible with a variety of metal materials, including steel, aluminum, and copper, providing versatility in design and durability. This allows for greater design flexibility and the ability to match the aesthetic of any architectural style.The company behind the Standing Seam Roof Machine has a strong reputation for delivering high-quality and reliable equipment to the roofing industry. With a dedication to innovation and customer satisfaction, the company has become a trusted leader in the manufacturing of roofing machinery and equipment.The company's commitment to quality is evident in the Standing Seam Roof Machine, which is built to withstand the demands of the roofing environment. The machine is constructed with durable materials and undergoes rigorous testing to ensure long-term performance and reliability.In addition to the machine itself, the company provides comprehensive training and support for contractors and installers to ensure successful implementation and operation of the Standing Seam Roof Machine. This includes on-site training, technical support, and ongoing maintenance services, allowing for a seamless integration into existing roofing businesses.The introduction of the Standing Seam Roof Machine has generated significant interest and excitement within the roofing industry. Contractors, architects, and property owners alike are recognizing the many benefits of standing seam metal roofs, and the machine's efficiency and cost savings are making it an increasingly popular choice for new construction and retrofit projects.With its cutting-edge technology, precision engineering, and commitment to quality, the Standing Seam Roof Machine is poised to continue leading the transformation of the roofing industry. As the demand for high-performance, durable, and aesthetically pleasing roofing solutions continues to grow, the machine is well-positioned to meet and exceed the needs of the market.Overall, the Standing Seam Roof Machine represents a significant advancement in roofing technology, offering a game-changing solution for metal roof installation. With its efficiency, cost savings, and high-quality results, the machine is redefining the industry standards and setting a new benchmark for excellence in roofing.

Metal Forming Machine for Roofing: Your Ultimate Guide

Roofing Metal Forming Machine Revolutionizing Construction IndustryThe roofing industry is set to be revolutionized with the introduction of the latest technological innovation in metal forming machines. The new machine, developed by [Company Name], is set to change the way roofing materials are produced, making the process faster, more efficient and environmentally friendly.[Company Name] has been a leader in the manufacturing and production of metal forming machines for over 20 years. The company is renowned for its commitment to innovation and quality, and its latest offering is no exception. The new roofing metal forming machine is set to transform the construction industry by providing a sustainable and cost-effective solution for the production of roofing materials.The machine is capable of producing a wide range of roofing materials, including corrugated sheets, standing seam panels, and metal tiles, all of which are essential components in the construction of modern buildings. The versatility of the machine means that it can cater to the diverse needs of the construction industry, from residential to commercial projects.One of the standout features of the new machine is its ability to produce roofing materials at an unprecedented speed. By utilizing advanced technology and precision engineering, the machine is able to significantly reduce production times, allowing for faster completion of construction projects. This not only benefits the construction companies, but also contributes to the overall efficiency and productivity of the industry as a whole.In addition to its speed, the machine also boasts a high level of accuracy and consistency in the production of roofing materials. This ensures that the final products meet the highest quality standards, providing durability and longevity to the buildings they are used in. This level of precision is crucial in the construction industry, where quality and reliability are paramount.Furthermore, the machine is designed with sustainability in mind. It utilizes eco-friendly materials and energy-efficient processes to minimize its environmental impact. This aligns with the growing demand for sustainable practices in the construction industry, as more and more companies seek to reduce their carbon footprint and promote environmentally friendly practices.The introduction of the new roofing metal forming machine by [Company Name] is set to have a significant impact on the construction industry. Its innovative technology, speed, accuracy, and sustainability make it a game-changer in the production of roofing materials. The machine not only meets the current needs of the industry, but also sets a new standard for the future of construction.With its proven track record of delivering high-quality and reliable products, [Company Name] has once again demonstrated its commitment to driving innovation in the construction industry. The new machine is a testament to the company's dedication to providing cutting-edge solutions that meet the evolving needs of the market.As the demands for faster, more efficient, and sustainable construction practices continue to grow, the introduction of the roofing metal forming machine by [Company Name] comes at a crucial time. It is set to address these needs while setting a new benchmark for the industry as a whole.In conclusion, the new roofing metal forming machine by [Company Name] is poised to revolutionize the construction industry. Its innovative technology, combined with the company's commitment to quality and sustainability, makes it a game-changer in the production of roofing materials. This latest offering reaffirms [Company Name]'s position as a leader in the manufacturing and production of metal forming machines, and sets a new standard for the future of construction.

Steel Coil Slitter: The Ultimate Guide

Steel Coil Slitter: Enhancing Efficiency and Precision in Metal ProcessingIn the world of metal processing, precision and efficiency are essential components to ensuring high-quality products and optimal production capabilities. One company that has been at the forefront of innovation in this field is {}. With a strong commitment to excellence and a dedication to meeting the evolving needs of the industry, {} has recently introduced its latest innovation – the Steel Coil Slitter.The Steel Coil Slitter is a cutting-edge machine that has been designed to enhance efficiency and precision in the process of slitting steel coils. This state-of-the-art equipment is capable of processing large steel coils into narrower coils of various widths with exceptional accuracy and speed. By utilizing advanced technology and innovative engineering, the Steel Coil Slitter has set a new standard for performance and productivity in the metal processing industry.One of the key features of the Steel Coil Slitter is its ability to accommodate a wide range of coil widths and thicknesses, making it highly versatile and suitable for a variety of applications. This flexibility allows metal processing companies to streamline their operations and achieve greater levels of efficiency in their production processes. Additionally, the Steel Coil Slitter is equipped with precision cutting blades and advanced control systems that ensure consistent and accurate results, minimizing material waste and maximizing the yield of high-quality slit coils.Furthermore, the Steel Coil Slitter is designed with user-friendly interfaces and intuitive controls, facilitating ease of operation and reducing the need for extensive training. This user-centric approach reflects {}'s commitment to delivering innovative solutions that not only optimize performance but also simplify workflow and improve overall productivity.In addition to its impressive performance capabilities, the Steel Coil Slitter is also built with a strong emphasis on durability and reliability. {} has integrated robust construction and high-quality components into the design of the machine, ensuring that it can withstand the demands of heavy-duty industrial applications and deliver consistent results over an extended lifespan. This emphasis on long-term value and reliability underscores {}'s dedication to providing equipment that not only meets current needs but also anticipates future requirements.As a leader in the metal processing equipment industry, {} has a long-standing reputation for delivering cutting-edge solutions that empower metal fabricators, service centers, and other related businesses to achieve their production goals with precision and efficiency. The introduction of the Steel Coil Slitter further solidifies {}'s position as an innovative force in the industry, offering a solution that addresses the complexities and demands of modern metal processing operations.With a focus on continuous improvement and a deep understanding of the evolving needs of the industry, {} has remained dedicated to staying ahead of the curve through research, development, and the integration of the latest technological advancements. The Steel Coil Slitter is a testament to this ongoing commitment, providing metal processing companies with a powerful tool to enhance their capabilities and drive their success in an increasingly competitive market.In conclusion, the Steel Coil Slitter represents a significant advancement in the field of metal processing equipment, offering a compelling combination of precision, efficiency, and versatility. As {} continues to push the boundaries of innovation, it is poised to redefine the standards of excellence in the industry and empower its customers to achieve new levels of productivity and success. With the introduction of the Steel Coil Slitter, {} has once again demonstrated its dedication to delivering state-of-the-art solutions that meet the complex needs of modern metal processing operations.

Quality Corrugated Sheet Forming Equipment for Efficient Production

Corrugated Sheet Forming Equipment has revolutionized the packaging industry with its innovative and efficient machinery. As a leading manufacturer in the field, they have constantly pushed the boundaries of technology to provide high-quality equipment that meets the evolving needs of the market.With a strong focus on research and development, Corrugated Sheet Forming Equipment has consistently introduced cutting-edge solutions that have set new standards in the industry. Their commitment to innovation and customer satisfaction has made them a trusted name in the market.The company's production facilities are equipped with state-of-the-art technology and are operated by a team of highly skilled professionals. This allows them to maintain a high level of quality and consistency in their products, ensuring that their customers receive the best-in-class equipment.One of the key features of Corrugated Sheet Forming Equipment is its ability to produce a wide range of corrugated sheets with different shapes, sizes, and materials. This flexibility has allowed packaging manufacturers to meet the diverse needs of their customers and stay ahead of the competition.The company's equipment is designed for maximum efficiency, with features such as automated operation, fast changeover times, and minimal downtime. This not only improves the productivity of the packaging manufacturers but also reduces their operational costs.In addition to their technical capabilities, Corrugated Sheet Forming Equipment also places a strong emphasis on sustainability. Their machinery is designed to minimize waste and energy consumption, helping their customers reduce their environmental footprint and comply with regulations.The company's commitment to customer support is another factor that sets them apart from their competitors. With a worldwide network of service centers and a team of experienced technicians, they are able to provide timely support and maintenance services, ensuring that their customers' operations run smoothly.Furthermore, Corrugated Sheet Forming Equipment is constantly expanding its product range to meet the evolving needs of the market. They are also investing in new technologies and partnerships to stay at the forefront of innovation in the packaging industry.By consistently delivering reliable and innovative solutions, Corrugated Sheet Forming Equipment has earned the trust and loyalty of their customers. Their track record of success and commitment to excellence have established them as a market leader in the packaging machinery industry.As a company, Corrugated Sheet Forming Equipment is dedicated to providing value to its customers, employees, and the community. They are committed to upholding the highest standards of business ethics and corporate responsibility, ensuring that their operations have a positive impact on society.In conclusion, Corrugated Sheet Forming Equipment's innovative and efficient machinery has had a significant impact on the packaging industry. With a strong focus on technology, sustainability, and customer support, they have cemented their position as a leading manufacturer in the market. As they continue to push the boundaries of innovation, they will undoubtedly play a pivotal role in shaping the future of the packaging industry.

High-quality Glazed Tile Corrugation Machine for Color Steel Production

Color Steel Glazed Tile Corrugation Machine, a pivotal addition to the machinery market, has been creating waves in the industry with its advanced technology and efficient performance. This groundbreaking machine, designed and manufactured by a leading company in the sector, has been receiving widespread praise from professionals and customers alike for its unparalleled quality and precision.The Color Steel Glazed Tile Corrugation Machine is equipped with state-of-the-art features that set it apart from other machines in the market. Its innovative design and advanced technology allow for seamless production of high-quality glazed tiles with corrugated patterns, catering to the growing demand for aesthetically pleasing and durable roofing solutions.One of the key highlights of this machine is its ability to produce glazed tiles with a wide range of colors and patterns, allowing for customization according to the specific requirements of customers. This flexibility has made it a preferred choice for roofing contractors and manufacturers who are looking to offer a diverse range of options to their clients.Furthermore, the Color Steel Glazed Tile Corrugation Machine is engineered for optimal efficiency, with a high production capacity that enables swift and continuous manufacturing processes. This enables businesses to meet tight deadlines and fulfill large orders without compromising on quality, thereby boosting their overall productivity and profitability.In addition to its exceptional performance, the machine is also praised for its user-friendly interface and ease of operation. Its intuitive controls and simple setup make it accessible to operators of varying skill levels, allowing for seamless integration into production facilities without extensive training or technical expertise.The company behind the development of the Color Steel Glazed Tile Corrugation Machine is a renowned industry leader with a solid track record of delivering cutting-edge solutions for the manufacturing sector. With a strong focus on research and development, the company has consistently pushed the boundaries of innovation, bringing to market a range of machinery and equipment that has set new benchmarks for quality and efficiency.Founded on a commitment to excellence, the company has built a reputation for reliability and trustworthiness, earning the loyalty of a diverse clientele across the globe. Its dedication to customer satisfaction is reflected in its comprehensive after-sales support and technical assistance, ensuring that customers can maximize the potential of their investments in the Color Steel Glazed Tile Corrugation Machine.Moreover, the company's strong emphasis on sustainability and environmental responsibility is evident in the design and production of its machinery. The Color Steel Glazed Tile Corrugation Machine is optimized for energy efficiency and minimal waste, aligning with the company's vision for a more sustainable future for the manufacturing industry.As the demand for high-quality roofing solutions continues to rise, the Color Steel Glazed Tile Corrugation Machine stands at the forefront of innovation, offering a reliable and efficient solution for businesses seeking to meet this demand. Its impact on the industry is undeniable, with its advanced technology and exceptional performance setting a new standard for the production of glazed tiles.With its impressive capabilities and the backing of a reputable company, the Color Steel Glazed Tile Corrugation Machine is poised to transform the roofing industry, offering a game-changing solution that combines quality, efficiency, and sustainability. As it continues to gain traction in the market, it is expected to become an indispensable asset for businesses looking to stay ahead in a competitive and dynamic industry.

Rent a Wood Deck Sanding Machine for Your Next Project

Wood Deck Sanding Machine Rental Available for Homeowners and ContractorsFor homeowners and contractors looking to restore the beauty of their wooden decks, {Company Name} is now offering wood deck sanding machine rentals. With these rentals, individuals can easily sand and refinish their decks, saving time and money compared to hiring professional services.{Company Name} is a leading provider of rental equipment for construction, industrial, and residential projects. With a wide range of equipment available, {Company Name} aims to make it convenient for individuals to access the tools they need for their projects without having to make a significant investment in purchasing new equipment.The wood deck sanding machine rental is a valuable addition to {Company Name}'s rental offerings, as it allows homeowners and contractors to tackle deck refinishing projects with ease. Whether it's removing old paint, sanding down rough surfaces, or preparing the deck for a fresh coat of stain or sealant, the rental machine provides the power and efficiency needed to achieve professional results."We understand the challenges that homeowners and contractors face when it comes to maintaining and restoring wooden decks. Our goal is to provide access to high-quality equipment that can make these tasks more manageable and cost-effective," said [Spokesperson], [Title] at {Company Name}. "Our wood deck sanding machine rental is designed to help individuals achieve the results they desire without having to invest in expensive equipment or hire professional services."The wood deck sanding machine available for rent is a [Brand Name] model, known for its reliability and performance in sanding and refinishing applications. The machine features a powerful motor and a durable sanding drum that can effectively smooth out uneven surfaces, remove old coatings, and prepare the wood for refinishing. Additionally, the machine is designed for ease of use, with adjustable settings that allow users to customize the sanding process to their specific needs.In addition to providing the rental machine, {Company Name} also offers guidance and support to individuals who may be new to deck refinishing. The team is available to provide instructions on operating the machine, as well as tips for achieving the best results. This added support ensures that renters can approach their deck refinishing projects with confidence, knowing that they have access to the resources they need to succeed."Renting equipment from {Company Name} is more than just getting access to the tools. It's about gaining the knowledge and support to use the equipment effectively. We want our customers to feel empowered to take on their projects and achieve professional-quality results," [Spokesperson] added.With the availability of the wood deck sanding machine rental, homeowners can take on DIY refinishing projects at their own pace, avoiding the costs and potential scheduling constraints of hiring professional services. Contractors, on the other hand, can expand their range of services by offering deck refinishing without having to invest in additional equipment.The convenience of having access to a reliable wood deck sanding machine rental has already attracted attention from both individual homeowners and contractors in the area. Many have taken advantage of the rental option to achieve the results they desire for their wooden decks, while appreciating the cost savings and flexibility that come with renting equipment.As the demand for DIY home improvement projects continues to grow, {Company Name} remains committed to providing a wide range of rental equipment that can support the needs of homeowners and contractors alike. With the addition of the wood deck sanding machine rental, individuals can now confidently take on deck refinishing projects, knowing that they have the backing of a reputable rental company.For those interested in renting the wood deck sanding machine or exploring other rental options, {Company Name} encourages individuals to contact their nearest location or visit their website for more information. With a straightforward rental process and a commitment to customer satisfaction, {Company Name} is poised to help individuals achieve their project goals effectively and affordably.

Competitive Intelligence by Key Players in the Automatic Roll Forming Machine Market: Global Market Analysis and Size

Automatic Roll Forming Machine Market: Increasing Industrialization Driving Demand for C/Z Purlin Roll Forming MachinesThe global Automatic Roll Forming Machine market is expected to witness robust growth in the coming years, driven by increasing industrialization across the globe. The Automatic Roll Forming Machine is a highly versatile equipment that is used in industries such as construction, automotive, electronics, and aerospace, among others. It is used for forming metal sheets and strips into different shapes and sizes. Among the various types of Roll Forming Machines, C/Z Purlin Roll Forming Machine is a popular choice for manufacturing structures that require strong supports for roofing, cladding, and walls.C/Z Purlin Roll Forming Machine is a type of Roll Forming Machine that is designed specifically for producing C-shaped and Z-shaped purlins. These purlins are used for making pre-engineered steel buildings, industrial sheds, warehouses, and other structures. The machine works by feeding a strip of metal through a series of rollers that shape the metal into the desired profile. The final product is a strong, lightweight, and durable purlin that can withstand heavy loads and adverse weather conditions.Key Market Players in Automatic Roll Forming Machine MarketThe key market players in the Automatic Roll Forming Machine market include Bradbury Group, Framing Tech, Formtek Group, Gasparini Industries, HILALMAK, Howick, Isolaminas, JET USA, Knauer Engineering, L.B. Bohle Maschinen + Verfahren, M.Torres, Onward Machinery, PEP brainin, Taicang Keboer, TOX Pressotechnik, TRL Krosaki Refractories Limited, Xiamen Zheng Liming Metallurgical Machinery, and Yoder.Market SegmentationThe global Automatic Roll Forming Machine market can be segmented based on product type, application, and region.Based on Product Type, the market can be segmented into:• C/Z Purlin Roll Forming Machine• Corrugated Sheet Roll Forming Machine• Tile Roll Forming Machine• OthersBased on Application, the market can be segmented into:• Construction• Automotive• Electronics• Aerospace• OthersBased on Region, the market can be segmented into:• North America• Europe• Asia-Pacific• Middle East and Africa• South AmericaRegional AnalysisThe Asia-Pacific region is expected to dominate the Automatic Roll Forming Machine market in the forecast period, owing to the increasing demand for industrialization in countries such as China, India, and Japan. The region also has a large base of manufacturers and a significant consumer base for Roll Forming Machines. The North American and European markets are also expected to witness steady growth due to the increasing demand for lightweight and durable materials in the construction and automotive industries.ConclusionThe Automatic Roll Forming Machine market is expected to witness robust growth in the coming years, owing to the increasing demand for lightweight and durable materials in the construction, automotive, electronics, and aerospace industries. C/Z Purlin Roll Forming Machines are expected to witness significant demand, owing to the increasing demand for pre-engineered steel buildings, industrial sheds, and warehouses. The Asia-Pacific region is expected to dominate the market, owing to the increasing demand for industrialization in the region. The key market players in the market are Bradbury Group, Framing Tech, Formtek Group, Gasparini Industries, HILALMAK, among others.

High-Quality Roof Panel Machine for Snap Lock Panels

Snap Lock Roof Panel Machine revolutionizes the roofing industryIn a major breakthrough for the roofing industry, a leading company has introduced a state-of-the-art Snap Lock Roof Panel Machine that is set to revolutionize the way roofs are installed and maintained. This remarkable piece of equipment has the potential to change the landscape of the roofing industry by streamlining the installation process and improving the overall quality and longevity of roofs.The Snap Lock Roof Panel Machine, developed by the innovative team at the company, is designed to produce high-quality snap lock roof panels that are not only durable and long-lasting, but also easy to install. This machine is equipped with advanced technology and precision engineering to ensure that the roof panels produced are of the highest standard and meet the specific requirements of each project.The company behind this groundbreaking technology is a leading manufacturer and supplier of roofing solutions, with a strong reputation for delivering top-quality products to customers across the globe. With a commitment to innovation and excellence, the company has consistently pushed the boundaries of what is possible in the roofing industry, and the introduction of the Snap Lock Roof Panel Machine is a testament to their dedication to driving advancements in the field.One of the key features of the Snap Lock Roof Panel Machine is its versatility and efficiency. The machine is capable of producing a wide range of snap lock roof panels in various sizes and designs, allowing for greater flexibility and customization in roofing projects. Furthermore, the automated nature of the machine ensures high levels of productivity, with the ability to produce a large volume of panels in a short amount of time, ultimately reducing installation time and labor costs for the customer.In addition to its impressive operational capabilities, the Snap Lock Roof Panel Machine also prioritizes durability and resilience in its output. The roof panels produced by this machine are constructed from high-quality materials that are engineered to withstand the harshest weather conditions and provide long-term protection for any structure. This focus on durability not only ensures the longevity of the roof, but also reduces the need for frequent maintenance and repairs, ultimately saving time and money for the customer in the long run.The introduction of the Snap Lock Roof Panel Machine marks a significant advancement in the roofing industry, and its potential impact is already being felt by industry professionals and customers alike. By offering a more efficient, cost-effective, and durable roofing solution, this machine is poised to set a new standard for roof installation and maintenance, and is expected to be widely adopted by contractors and builders looking to deliver superior results to their clients.As the demand for innovative and reliable roofing solutions continues to grow, the company is proud to lead the way with the Snap Lock Roof Panel Machine. With a strong commitment to pushing the boundaries of what is possible in the industry, the company is confident that this machine will not only meet the needs of today's roofing projects, but also set the stage for future advancements in the field.In conclusion, the introduction of the Snap Lock Roof Panel Machine represents a significant milestone in the roofing industry, offering a game-changing solution for contractors, builders, and customers. With its advanced technology, versatility, and focus on durability, this machine is set to transform the way roofs are installed and maintained, and is poised to become a standard-bearer for excellence in the field. As the company continues to push the boundaries of innovation and quality, the Snap Lock Roof Panel Machine stands as a testament to their commitment to delivering superior roofing solutions to customers around the world.

Advanced Laser Cutting Machine for Precision Cutting - Coil/Sheet/CNC

A laser cutting machine is an innovative piece of equipment that has revolutionized the manufacturing industry. The LXN Revolution, a laser cutting machine by a well-known company, is one of the most sought after cutting machines in the market today. This machine caters to the cutting needs of different industries, from sheet cutting to coil cutting and CNC machining. The machine has made precision cutting quick and effortless, making it a reliable tool in modern manufacturing processes.Sheet and coil cutting machines, in particular, are essential in the manufacturing industry as they allow for mass production capabilities. The LXN Revolution laser cutting machine has made sheet and coil cutting more efficient than ever before, providing high-quality cuts at faster speeds than traditional cutting machines. This machine works by using a beam of a powerful laser to cut through a range of materials. Materials such as sheet metal, stainless steel, and aluminum are commonly cut using this machine.One of the reasons why the LXN Revolution laser cutting machine is a game-changer is its precision. This machine can create intricate cuts with pinpoint accuracy. As a result, manufacturers can achieve precise shapes, sizes, and designs with minimal errors. This high level of precision ensures that every piece of material that passes through the machine gets cut as intended, reducing the chances of waste materials and saving time and resources.Moreover, the LXN Revolution laser cutting machine has made the cutting of coils easier and more efficient than ever before. It can handle different types of coils with varying thicknesses and widths, making it highly versatile. The machine can also create several cuts from a single coil, which saves time and energy. As a result, manufacturers can increase their production output without sacrificing quality.In conclusion, the LXN Revolution laser cutting machine is a versatile and efficient machine that caters to the cutting needs of different industries. With its precision cutting capabilities, it has made sheet and coil cutting machines more efficient than ever before. Its versatility and capabilities can help manufacturers increase their production output while maintaining the high-quality levels of their products. If you are in the manufacturing industry, investing in this machine is a game-changer.