Quality Roof Tile and Sheeting Making Machines for Sale

By:Admin

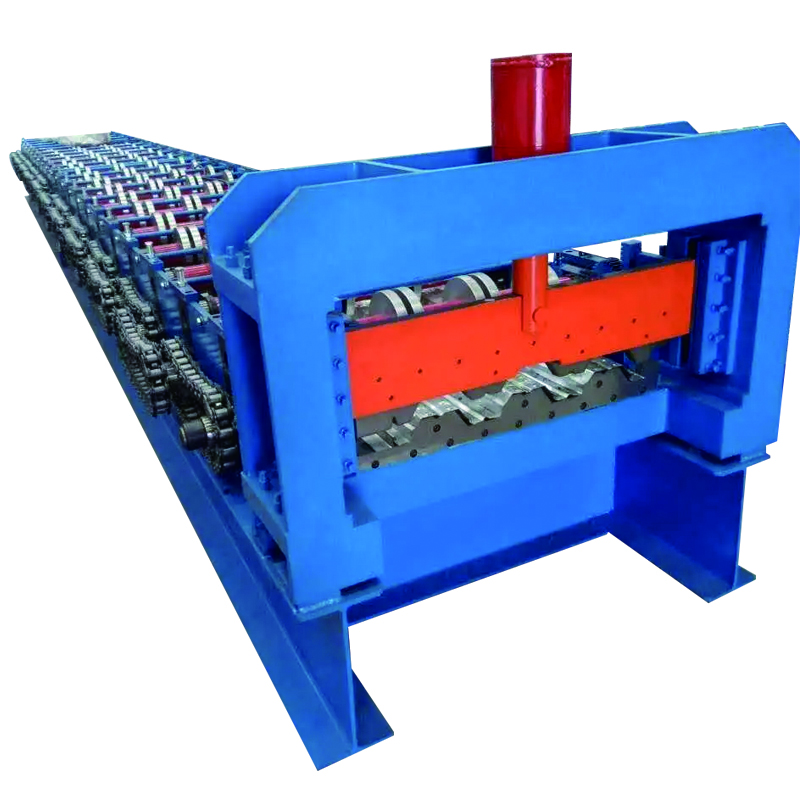

The roofing industry is constantly evolving, and with the introduction of the Roof Tiles And IBR Sheeting Making Machine, it is poised to enter a new era of efficiency and innovation. This state-of-the-art machine, developed by an industry-leading manufacturer, is set to revolutionize the production of roof tiles and IBR (Inverted Box Rib) sheeting.

The Roof Tiles And IBR Sheeting Making Machine is designed to streamline the manufacturing process, significantly increasing production capacity and reducing production costs. With this machine, roof tile and IBR sheeting manufacturers can expect to produce high-quality products at a faster rate, ultimately increasing their bottom line.

The machine is capable of producing a wide range of roof tiles and IBR sheeting, meeting the diverse needs of the roofing industry. It can create different profiles, sizes, and shapes, ensuring that manufacturers have the flexibility to cater to various customer preferences and market demands.

One of the key features of the machine is its automated operation, which minimizes the need for manual labor and reduces the potential for human error. This not only improves efficiency but also enhances the overall safety of the production process. Additionally, the machine is equipped with advanced technology that allows for precise and consistent production, ensuring that every roof tile and IBR sheeting meets the highest quality standards.

The manufacturer behind this innovative machine has a long-standing reputation for delivering cutting-edge solutions to the roofing industry. With a strong focus on research and development, they have consistently pushed the boundaries of traditional manufacturing processes, embracing new technologies to improve efficiency and productivity.

In addition to the Roof Tiles And IBR Sheeting Making Machine, the company offers a comprehensive range of roofing machinery and equipment, including roll forming machines, metal sheet bending machines, and more. Their commitment to innovation and customer satisfaction has earned them a loyal customer base and positioned them as a leader in the industry.

The introduction of the Roof Tiles And IBR Sheeting Making Machine comes at a time when the roofing industry is experiencing rapid growth and increasing demand for high-quality, durable roofing materials. With this machine, manufacturers can meet this demand head-on, positioning themselves as reliable suppliers in a competitive market.

Furthermore, the machine's energy-efficient design and sustainable production processes align with the industry's growing focus on environmental responsibility. By optimizing production and minimizing waste, manufacturers can reduce their environmental impact while also improving their operational efficiency.

As the global construction industry continues to expand, the demand for roof tiles and IBR sheeting is expected to rise. The Roof Tiles And IBR Sheeting Making Machine presents an opportunity for manufacturers to capitalize on this growth, delivering high-quality products that meet the evolving needs of the market.

In conclusion, the Roof Tiles And IBR Sheeting Making Machine represents a significant advancement in the roofing industry, offering manufacturers the tools they need to improve efficiency, increase production capacity, and meet the demands of a growing market. With its cutting-edge technology and commitment to innovation, this machine is set to transform the way roof tiles and IBR sheeting are produced, setting a new standard for quality and efficiency in the industry.

Company News & Blog

High-Quality Glazed Tile Roof Panel Corrugation Machine for Sale

In recent news, the prominent roofing company has introduced a state-of-the-art Glazed Tile Roof Panel Corrugation Machine, marking a significant advancement in the manufacturing of roofing materials. This new machine is set to revolutionize the industry by increasing production efficiency and offering a wider range of design options for customers.The Glazed Tile Roof Panel Corrugation Machine is a cutting-edge piece of technology that is designed to produce high-quality glazed tile roof panels with precision and speed. It is equipped with advanced features that allow for the seamless corrugation of metal panels, resulting in a finished product that is not only aesthetically pleasing but also highly durable and weather-resistant.One of the key advantages of this new machine is its ability to offer a wide variety of design options for customers. The machine is capable of creating different shapes, patterns, and sizes of glazed tile roof panels, giving customers the flexibility to choose the perfect roofing solution for their specific needs. This versatility sets the company apart in the industry and makes it a top choice for customers looking for customized, high-quality roofing materials.Furthermore, the Glazed Tile Roof Panel Corrugation Machine is designed to significantly increase production efficiency. Its innovative technology allows for faster production speeds and reduced material waste, resulting in cost savings for both the company and its customers. This not only boosts the company's overall productivity but also ensures that customers receive their orders in a timely manner.In addition to its advanced features, the Glazed Tile Roof Panel Corrugation Machine is backed by the company's years of experience and expertise in the roofing industry. The company has a strong reputation for delivering top-quality products and exceptional customer service, and this new machine further solidifies its position as a leader in the industry.With the introduction of the Glazed Tile Roof Panel Corrugation Machine, the company is poised to meet the growing demand for high-quality roofing materials in the market. The machine's advanced capabilities and the company's commitment to excellence make it a top choice for customers seeking superior roofing solutions.Overall, the Glazed Tile Roof Panel Corrugation Machine represents a significant advancement in the roofing industry, offering customers a wide range of design options, increased production efficiency, and top-quality products. The introduction of this new machine reaffirms the company's position as a leader in the industry and sets the stage for continued growth and success in the years to come.In conclusion, the introduction of the Glazed Tile Roof Panel Corrugation Machine by the company is a game-changer for the roofing industry. It represents a new era in the manufacturing of roofing materials, offering customers unmatched design options and superior quality products. With this new machine, the company is well-positioned to meet the needs of customers and continue its legacy of excellence in the industry.

High-quality C Z Shape Purlin Forming Machine for Sale - Everything You Need to Know

C Z Shape Purlin Forming Machine: Revolutionizing the Construction IndustryC Z shape purlin forming machine is a revolutionary piece of equipment that is set to transform the construction industry. This state-of-the-art machine is designed to produce high quality C and Z shaped purlins with unmatched precision and efficiency. The machine is equipped with advanced technology and cutting-edge features that make it an invaluable tool for any construction project.With the ability to produce a wide range of C and Z shaped purlins, this machine is highly versatile and can be used in a variety of construction applications. Whether it is for building warehouses, industrial buildings, or commercial structures, the C Z shape purlin forming machine is an essential piece of equipment that is redefining the way construction projects are carried out.The C Z shape purlin forming machine is designed to streamline the purlin production process, saving time and labor costs. It boasts a high level of automation, with features such as automatic feeding, punching, and cutting, that drastically reduce the need for manual intervention. This not only enhances the speed of production but also ensures consistency and precision in the purlin dimensions.In addition to its efficiency, the machine is also known for its durability and reliability. Built with high-quality materials and precision engineering, it is capable of withstanding the rigors of heavy-duty use in a construction environment. This makes it a long-term investment that offers a high return on investment for any construction company.The company behind this innovative machine is a leader in the manufacturing of construction equipment. With years of experience and a commitment to excellence, they have established themselves as a trusted provider of quality machinery for the construction industry. Their expertise and dedication to innovation have led to the development of the C Z shape purlin forming machine, which has quickly gained recognition for its performance and reliability.As a company, they are focused on meeting the evolving needs of the construction industry by delivering cutting-edge solutions that enhance efficiency and productivity. The C Z shape purlin forming machine is a testament to this commitment, as it has set new standards for purlin production in the construction sector. By offering a machine that is not only efficient but also versatile and reliable, they have positioned themselves as a key player in shaping the future of construction technology.With the demand for efficient and cost-effective construction solutions on the rise, the C Z shape purlin forming machine is poised to make a significant impact in the industry. Its ability to expedite the purlin production process while maintaining high quality standards is a game-changer for construction companies looking to stay ahead of the curve.In conclusion, the C Z shape purlin forming machine is a game-changing piece of equipment that is revolutionizing the construction industry. Its advanced technology, efficiency, and reliability make it an indispensable tool for any construction project. Coupled with the expertise and commitment to excellence of the company behind it, this machine is set to redefine the way purlins are produced and utilized in construction, setting new benchmarks in efficiency and performance.

High-Quality Replacement Roof Tiles for Your Cambridge Property - PE7 Area

Title: The Ultimate Guide to Roof Tiles: Types, Installation, and MaintenanceIntroduction:When it comes to protecting our homes, a well-maintained roof is essential. The type of roof tiles we choose plays a vital role in enhancing the aesthetics, durability, and overall value of our property. In this comprehensive guide, we will delve into the world of roof tiles, covering various types, the installation process, and essential maintenance tips. Whether you are a homeowner or a roofing professional, this blog post is here to acquaint you with everything you need to know about roof tiles!Types of Roof Tiles:1. Concrete Roof Tiles: These affordable and low-maintenance tiles are known for their durability and ability to withstand harsh weather conditions. Concrete roof tiles come in a variety of colors and styles, offering flexibility in design choices.2. Clay Roof Tiles: Clay roof tiles exude elegance and sophistication, enhancing the curb appeal of any property. Made from natural clay and kiln-fired, these tiles offer superior durability while reflecting heat effectively.3. Slate Roof Tiles: Known for their distinctive appearance, slate roof tiles are strong, fire-resistant, and highly durable. With a lifespan of over a century, these tiles offer exceptional longevity. Slate tiles are available in a range of colors and can be shaped to suit different architectural styles.4. Metal Roof Tiles: With their lightweight composition, metal roof tiles are ideal for various architectural designs. They are resistant to rust, insects, and UV radiation, making them an excellent option for long-lasting roofing solutions.Installation Process:Installing roof tiles requires a systematic approach to ensure proper functionality and longevity. Here are the key steps involved in the installation process:1. Inspection: Before installing any roof tiles, a preliminary inspection is crucial to identify any underlying issues or damage that require repairs.2. Roof Surface Preparation: The roof surface must be clean, free from debris, and properly waterproofed. This step includes installing underlayment to provide additional protection against moisture and improve thermal insulation.3. Tile Layout: Based on the selected tile pattern and design, layout lines are marked to guide the installation process and ensure precision.4. Tile Installation: Each tile is installed carefully, and proper fastening techniques are used to prevent tile shifting or damage during severe weather conditions. Contractor-grade adhesives and sealants are commonly employed for added stability.5. Ridge and Hip Installation: The finishing touches of installing ridge and hip tiles contribute to the overall aesthetic appeal and improve the roof's water shedding ability.Roof Tile Maintenance Tips:Regular maintenance is crucial to prolonging the life of your roof tiles and preventing major repairs. Here are some essential maintenance tips to consider:1. Inspect: Schedule periodic inspections to identify and address any visible or potential issues promptly.2. Clean Gutters: Clearing debris from gutters and downspouts ensures proper water flow and prevents overflowing, which can lead to roof leaks and damage.3. Trim Overhanging Trees: Overhanging branches can scrape and damage roof tiles during strong winds. Regular trimming will minimize this risk.4. Moss and Algae Removal: Moss and algae can compromise roof tiles' integrity and cause discoloration. Safely remove them to maintain the aesthetics and longevity of your roof.5. Professional Maintenance: Engage professional roofing contractors for comprehensive maintenance checks, especially for intricate tasks such as tile realignment and fixing damaged or cracked tiles.Conclusion:Choosing the right roof tiles, understanding the installation process, and implementing regular maintenance practices are key to ensuring a safe, durable, and attractive roof. From concrete and clay to slate and metal, various roof tile options are available to suit different styles and budgets. Whether you reside in Cambridge or the PE7 region, be sure to consult trusted roofing professionals who offer reliable replacement roof tiles for your project. Remember, a well-maintained roof not only protects your home but also adds value and visual appeal for years to come.Keywords: roof tiles, replacement, Cambridge, PE7, installation, maintenance, concrete, clay, slate, metal

Efficient and Controlled Solar Support Forming Machine for Solar Panel Mounting Brackets

Solar energy is a rapidly growing sector worldwide. With the demand for renewable energy sources soaring, the need for efficient and economical solar panel mounting solutions is higher than ever. The revolution of the solar energy industry also brought a new demand for equipment, and one of the most sought-after tools is the Solar Panel Mounting Bracket Roll Forming Machine. LOTOS 2O19 Solar Support Forming Machine has been introduced as a practical solution for creating solar panel mounting brackets without any hassle.The LOTOS 2O19 Solar Support Forming Machine is an excellent piece of machinery that can make the job of creating solar panel mounting brackets easier and faster. It is easy to control and handle, thanks to its advanced electrical controlling cabinet. The cabinet uses the latest technology, making the machine reliable and accurate. Its precision control system allows the operator to produce high-quality mounting brackets at a faster rate.The Solar Panel Mounting Bracket Roll Forming Machine is a game-changer for those who are looking to streamline their solar panel installation processes. The machine can roll form steel into solar panel mounting brackets with a uniform shape and size. The brackets are formed in long continuous lengths that are cut to the desired length, making the installation process faster and more efficient.The machine's utility is not just limited to the solar panel industry; it can also be used in fabrication and construction sites. The color steel solar mounting structure roll forming machine can be utilized for making various kinds of metal products such as roof trusses, studs, and decking. The machine's versatility makes it a valuable asset in any metal fabrication industry.One of the significant advantages of the LOTOS 2O19 Solar Support Forming Machine is that it is easy to operate, even for those with little knowledge of engineering processes. The machine comes with a user manual that is easy to follow and understand. The manual also provides useful tips on various maintenance routines to keep the machine working and in good condition. The easy-to-use interface allows even inexperienced operators to create high-quality mounting brackets in a matter of minutes.In conclusion, the LOTOS 2O19 Solar Support Forming Machine is a practical investment for anyone involved in the solar panel industry or metal fabrication. Its ability to roll form steel into solar panel mounting brackets at a uniform shape and size makes the installation process faster, more efficient, and reliable. Its versatility also makes it an essential tool in other industries that require metal fabrication services. The inclusion of the keywords Color Steel Solar Mounting Structure Roll Forming Machine in this blog will help in its SEO optimization, which can be helpful in reaching out to the target audience.

High-Quality Metal Roofing Sheet Roll Forming Machines

Roofing Sheet Roll Forming Machine Revolutionizing the Roofing IndustryRoofing is an essential part of any building, providing protection from the elements and adding structural integrity. The process of manufacturing roofing sheets has evolved over the years, and modern technology has played a significant role in revolutionizing the industry. One such technological advancement is the Roofing Sheet Roll Forming Machine, which has made the production of roofing sheets more efficient, cost-effective, and of higher quality.The Roofing Sheet Roll Forming Machine, offered by a leading manufacturing company in the industry, is a cutting-edge piece of equipment that has transformed the way roofing sheets are produced. This machine is designed to take flat metal coils and transform them into finished roofing sheets through a series of rolling, bending, and cutting processes. The result is a highly precise and uniform roofing sheet that meets the highest industry standards.The company behind this innovative machine, has been at the forefront of the roofing industry for over two decades. With a focus on quality, innovation, and customer satisfaction, they have established themselves as a trusted name in the market. Their commitment to excellence is evident in the Roofing Sheet Roll Forming Machine, which has set a new standard for efficiency and reliability in the production of roofing sheets.One of the key advantages of the Roofing Sheet Roll Forming Machine is its ability to produce roofing sheets in a variety of materials, including steel, aluminum, and copper. This versatility allows manufacturers to meet the diverse needs of their customers, whether it's for residential, commercial, or industrial applications. The machine is also highly customizable, with adjustable settings for sheet thickness, length, and profile, ensuring that each roofing sheet meets the specific requirements of the project.In addition to its flexibility, the Roofing Sheet Roll Forming Machine is also incredibly efficient. Its automated process minimizes manual labor, reduces waste, and improves production speed, resulting in cost savings for manufacturers. The machine's precision and repeatability also lead to a higher quality end product, with consistent dimensions and smooth finishes on every roofing sheet.Furthermore, the company's dedication to customer support and service ensures that their clients receive the assistance they need to maximize the potential of the Roofing Sheet Roll Forming Machine. From installation and training to ongoing maintenance and technical support, they are committed to helping their customers achieve success with this revolutionary piece of equipment.As a result of these innovations, the Roofing Sheet Roll Forming Machine has been widely adopted by manufacturers around the world. Its impact on the roofing industry has been significant, driving improvements in productivity, product quality, and overall competitiveness. Whether it's for a small-scale roofing business or a large manufacturing facility, this machine has proven to be a game-changer, propelling the industry into a new era of efficiency and innovation.In conclusion, the Roofing Sheet Roll Forming Machine offered by the company has redefined the production of roofing sheets, setting new standards for quality, efficiency, and versatility. By harnessing the latest in technology and engineering, they have delivered a machine that empowers manufacturers to meet the evolving demands of the market. With their ongoing commitment to excellence and customer satisfaction, they continue to lead the way in the roofing industry, driving forward a new era of progress and innovation.

High-quality Glazed Tile Corrugation Machine for Color Steel Production

Color Steel Glazed Tile Corrugation Machine, a pivotal addition to the machinery market, has been creating waves in the industry with its advanced technology and efficient performance. This groundbreaking machine, designed and manufactured by a leading company in the sector, has been receiving widespread praise from professionals and customers alike for its unparalleled quality and precision.The Color Steel Glazed Tile Corrugation Machine is equipped with state-of-the-art features that set it apart from other machines in the market. Its innovative design and advanced technology allow for seamless production of high-quality glazed tiles with corrugated patterns, catering to the growing demand for aesthetically pleasing and durable roofing solutions.One of the key highlights of this machine is its ability to produce glazed tiles with a wide range of colors and patterns, allowing for customization according to the specific requirements of customers. This flexibility has made it a preferred choice for roofing contractors and manufacturers who are looking to offer a diverse range of options to their clients.Furthermore, the Color Steel Glazed Tile Corrugation Machine is engineered for optimal efficiency, with a high production capacity that enables swift and continuous manufacturing processes. This enables businesses to meet tight deadlines and fulfill large orders without compromising on quality, thereby boosting their overall productivity and profitability.In addition to its exceptional performance, the machine is also praised for its user-friendly interface and ease of operation. Its intuitive controls and simple setup make it accessible to operators of varying skill levels, allowing for seamless integration into production facilities without extensive training or technical expertise.The company behind the development of the Color Steel Glazed Tile Corrugation Machine is a renowned industry leader with a solid track record of delivering cutting-edge solutions for the manufacturing sector. With a strong focus on research and development, the company has consistently pushed the boundaries of innovation, bringing to market a range of machinery and equipment that has set new benchmarks for quality and efficiency.Founded on a commitment to excellence, the company has built a reputation for reliability and trustworthiness, earning the loyalty of a diverse clientele across the globe. Its dedication to customer satisfaction is reflected in its comprehensive after-sales support and technical assistance, ensuring that customers can maximize the potential of their investments in the Color Steel Glazed Tile Corrugation Machine.Moreover, the company's strong emphasis on sustainability and environmental responsibility is evident in the design and production of its machinery. The Color Steel Glazed Tile Corrugation Machine is optimized for energy efficiency and minimal waste, aligning with the company's vision for a more sustainable future for the manufacturing industry.As the demand for high-quality roofing solutions continues to rise, the Color Steel Glazed Tile Corrugation Machine stands at the forefront of innovation, offering a reliable and efficient solution for businesses seeking to meet this demand. Its impact on the industry is undeniable, with its advanced technology and exceptional performance setting a new standard for the production of glazed tiles.With its impressive capabilities and the backing of a reputable company, the Color Steel Glazed Tile Corrugation Machine is poised to transform the roofing industry, offering a game-changing solution that combines quality, efficiency, and sustainability. As it continues to gain traction in the market, it is expected to become an indispensable asset for businesses looking to stay ahead in a competitive and dynamic industry.

High-Quality Roll Forming Machine for Wall Panel Manufacturing

Wall Panel Roll Forming MachineIn recent years, there has been a significant increase in demand for metal wall panels in various industries, including construction, automotive, and aerospace. To meet this growing demand, the need for efficient and high-quality wall panel roll forming machines has become more essential than ever. With this in mind, (company name) has recently launched its latest innovation in the form of a state-of-the-art Wall Panel Roll Forming Machine, designed to revolutionize the production of metal wall panels.The Wall Panel Roll Forming Machine boasts a range of advanced features that set it apart from traditional roll forming machines. One of the key highlights of this machine is its ability to produce wall panels with exceptional precision and consistency. This is achieved through the use of advanced technology and precision engineering, ensuring that every panel produced meets the highest quality standards.Furthermore, the Wall Panel Roll Forming Machine is designed for maximum efficiency, with a high-speed production capability that allows for increased output without compromising on quality. This means that manufacturers can now produce a greater volume of wall panels in a shorter amount of time, ultimately leading to improved productivity and profitability.In addition to its impressive performance capabilities, this machine also offers a high level of versatility. It is capable of producing a wide range of wall panel profiles, allowing manufacturers to cater to diverse customer requirements. This flexibility is further enhanced by the machine's easy-to-use control system, which allows for quick and seamless adjustments to be made to the panel production process.To further complement its cutting-edge technology, the Wall Panel Roll Forming Machine is also designed with a strong focus on durability and reliability. It is constructed using high-quality materials and components, ensuring that it can withstand the rigors of continuous, heavy-duty operation. This not only extends the machine's lifespan but also minimizes the need for maintenance, reducing downtime and associated costs.In line with (company name)'s commitment to customer satisfaction, the Wall Panel Roll Forming Machine is backed by comprehensive service and support. From installation and training to ongoing technical assistance, the company's team of experts is on hand to ensure that customers can maximize the potential of their investment.With the launch of the Wall Panel Roll Forming Machine, (company name) has once again demonstrated its position as a leading innovator in the roll forming industry. By combining cutting-edge technology with a focus on performance, versatility, and reliability, this new machine is set to redefine the production of metal wall panels and set a new standard for efficiency and quality.About (company name):(Company name) is a renowned manufacturer of roll forming machines, with a strong track record of delivering high-performance solutions to customers around the world. With a commitment to innovation, quality, and service, the company has established itself as a trusted partner for businesses seeking to enhance their production capabilities. As a provider of comprehensive roll forming solutions, (company name) is dedicated to meeting the evolving needs of its customers and driving the industry forward through continuous improvement and innovation.In summary, the Wall Panel Roll Forming Machine from (company name) represents a significant advancement in the production of metal wall panels. With its cutting-edge technology, exceptional performance, and comprehensive support, it is poised to make a lasting impact on the industry and set new benchmarks for efficiency and quality.

High-Quality Corrugated Iron Sheet Making Machine for Sale

Corrugated Iron Sheet Making Machine Revolutionizes Manufacturing IndustryIn the modern era, the manufacturing industry has seen significant advancements in technology, leading to increased efficiency and productivity. One such innovation that has revolutionized the industry is the Corrugated Iron Sheet Making Machine, a groundbreaking piece of equipment that has set new standards for the production of corrugated iron sheets. Developed by a leading manufacturing company, this state-of-the-art machine has garnered widespread attention for its cutting-edge design and capabilities.The Corrugated Iron Sheet Making Machine is a sophisticated piece of equipment that is designed to streamline the manufacturing process of corrugated iron sheets. It is utilized by numerous industries, including construction, automotive, and packaging, to produce high-quality corrugated iron sheets at an unprecedented pace. The machine’s advanced features and precise engineering have made it an indispensable tool for manufacturers looking to meet the ever-growing demand for corrugated iron sheets.The key to the machine’s success lies in its ability to automate and optimize the production process. With its advanced controls and robotics, the machine can seamlessly transform raw materials into finished corrugated iron sheets with minimal human intervention. This not only enhances productivity but also reduces the margin of error, resulting in consistently high-quality products. Additionally, the machine is capable of producing a wide range of corrugated iron sheet sizes and designs, catering to the diverse needs of different industries.The Corrugated Iron Sheet Making Machine has also proven to be environmentally friendly, as it minimizes waste and resource consumption. Its efficient use of raw materials and energy has resulted in a more sustainable manufacturing process, aligning with the growing global emphasis on eco-friendly practices. Furthermore, the machine's high-speed production capabilities contribute to reducing overall energy consumption, making it a cost-effective and environmentally sound investment for manufacturers.The company behind this groundbreaking technology, {}, has been at the forefront of the manufacturing industry for decades. With a focus on innovation and continuous improvement, the company has consistently developed cutting-edge solutions to address the evolving needs of the manufacturing sector. Leveraging its expertise in engineering and design, {} has successfully introduced the Corrugated Iron Sheet Making Machine as a game-changing product that has set new benchmarks for the industry.The company’s commitment to quality and reliability is reflected in the Corrugated Iron Sheet Making Machine, which has undergone rigorous testing and validation to ensure its performance and durability. Its robust construction and precision components are a testament to the company’s dedication to delivering superior products that withstand the rigors of industrial production. Moreover, {} provides comprehensive training and support services, ensuring that their clients can effectively integrate and optimize the machine within their manufacturing operations.The introduction of the Corrugated Iron Sheet Making Machine represents a significant milestone for the manufacturing industry, offering a glimpse into the future of automated and efficient production processes. Its impact on the industry is already evident, as manufacturers seek to adopt this transformative technology to stay ahead in an increasingly competitive market. As demand for corrugated iron sheets continues to rise, the Corrugated Iron Sheet Making Machine is poised to play a pivotal role in meeting this demand while setting new standards for efficiency and quality in manufacturing.In conclusion, the Corrugated Iron Sheet Making Machine has emerged as a game-changer for the manufacturing industry, offering unparalleled capabilities in the production of corrugated iron sheets. With its advanced technology, environmental sustainability, and the backing of a reputable company like {}, this machine is reshaping the manufacturing landscape and paving the way for a more efficient and sustainable future.

High-Quality Roof Panel Forming Machine for Efficient Roofing Production

In recent years, the demand for sustainable and energy-efficient housing solutions has been on the rise, leading to a growing interest in innovative construction technologies. One such technological advancement is the Roof Panel Forming Machine, a cutting-edge equipment that has the capability to revolutionize the way roofing solutions are manufactured and installed.The Roof Panel Forming Machine, offered by a leading company in the construction industry, utilizes state-of-the-art technology to produce high-quality roofing panels with precision and efficiency. With its advanced design and automated operation, this machine has the capability to significantly reduce the time and labor required to manufacture roofing panels, while also ensuring consistent quality and precision in every panel produced.The company behind the Roof Panel Forming Machine is a renowned industry leader with a strong focus on innovation and technological advancements. With years of experience and expertise in the construction sector, the company has established itself as a trusted provider of cutting-edge solutions for the building and construction industry.The Roof Panel Forming Machine is just one of the many innovative products offered by the company, which prides itself on its commitment to delivering high-quality, reliable, and efficient solutions to meet the evolving needs of the construction industry. In addition to its advanced technology and engineering expertise, the company also places a strong emphasis on sustainability, ensuring that its products are designed to minimize environmental impact and contribute to the development of more eco-friendly construction practices.With its dedicated team of professionals and its state-of-the-art manufacturing facilities, the company is well-equipped to meet the growing demand for advanced construction technologies, including the Roof Panel Forming Machine. The company's commitment to research and development, coupled with its focus on customer satisfaction, has enabled it to establish a strong presence in the global construction market, earning the trust and confidence of industry professionals and clients alike.In addition to its innovative products and cutting-edge technologies, the company also offers comprehensive support and after-sales services, ensuring that its clients receive the necessary assistance and guidance to maximize the potential of their investment in the Roof Panel Forming Machine. From installation and training to technical support and maintenance, the company is dedicated to ensuring the success of its clients and the seamless integration of its advanced construction solutions into their operations.As the demand for sustainable and energy-efficient construction solutions continues to grow, the Roof Panel Forming Machine offered by the company represents a significant leap forward in the construction industry. With its capacity to streamline the manufacturing process, enhance the quality of roofing solutions, and contribute to more sustainable construction practices, this innovative machine is poised to make a lasting impact on the industry.In conclusion, the Roof Panel Forming Machine, offered by the leading company in the construction industry, is a testament to the potential of advanced technologies to revolutionize the way we build and develop the infrastructure for the future. With its commitment to innovation, quality, and sustainability, the company is well-positioned to lead the way in delivering cutting-edge solutions that address the evolving needs of the construction sector and contribute to the development of more efficient, sustainable, and resilient building practices.