Sheet Metal Roll Forming: A Complete Guide to the Process

By:Admin

Sheet Metal Roll Forming Market To Showcase Continued Growth In Coming Years

The global sheet metal roll forming market is expected to witness significant growth over the coming years, driven by the increasing demand for efficient and cost-effective manufacturing processes in various industries such as automotive, construction, aerospace, and others. Sheet metal roll forming is a continuous bending operation in which a long strip of sheet metal is passed through a series of rolls and progressively formed into the desired shape.

The rise in construction activities, especially in emerging economies, is expected to be a major driver for the growth of the sheet metal roll forming market. As urbanization continues to increase, the demand for commercial and residential buildings is also on the rise, leading to increased use of sheet metal products in construction applications. Additionally, the automotive industry is also expected to contribute to the growth of the market, with an increasing focus on lightweight and fuel-efficient vehicles.

Furthermore, technological advancements in sheet metal roll forming processes are also expected to drive market growth. Manufacturers are increasingly investing in advanced roll forming machines and systems to improve efficiency, reduce lead times, and enhance productivity. These advancements are expected to make sheet metal roll forming a more attractive option for a wide range of applications.

Competitive Landscape

The global sheet metal roll forming market is highly competitive and fragmented, with the presence of several key players. Companies are focusing on strategic partnerships, product launches, and acquisitions to strengthen their market position and expand their product portfolio. For instance, {Company name} is one of the leading players in the sheet metal roll forming market, offering a wide range of roll forming machines and systems to cater to various industries.

Company Introduction:

{Company name} is a global leader in the design, manufacture, and supply of sheet metal roll forming equipment. With over 50 years of experience, the company has established a strong reputation for delivering high-quality, reliable, and efficient roll forming solutions to its customers worldwide. {Company name} offers a comprehensive range of roll formers, including standard and custom-designed systems, to meet the unique requirements of different industries.

The company's commitment to innovation and continuous improvement has enabled it to stay at the forefront of the sheet metal roll forming market. {Company name} continuously invests in research and development to develop advanced roll forming technologies that deliver superior performance and cost-effectiveness. The company's dedicated team of engineers and technicians work closely with customers to understand their specific needs and provide tailored solutions that optimize production processes and enhance product quality.

In addition to offering cutting-edge roll forming equipment, {Company name} also provides comprehensive technical support, training, and after-sales services to ensure customer satisfaction. The company's global presence and strong distribution network enable it to serve customers in various regions with unmatched expertise and support. With a focus on customer-centric approach and a commitment to excellence, {Company name} has become a trusted partner for businesses looking to enhance their sheet metal roll forming capabilities.

Outlook

The global sheet metal roll forming market is poised for significant growth in the coming years, driven by the increasing adoption of advanced roll forming technologies across various industries. As demand for efficient and cost-effective manufacturing processes continues to rise, sheet metal roll forming is expected to play a crucial role in meeting the needs of diverse applications. With leading players such as {Company name} driving innovation and setting new industry standards, the market is expected to witness continued evolution and expansion in the foreseeable future.

Company News & Blog

Portable Standing Seam Metal Roof Roll Forming Machine: Small Size Standing Seam Roof Panel Roll Forming Machine

: A Game-Changer for the Metal Roofing IndustryMetal roofing has been gaining popularity over the years due to its durability, longevity, and aesthetic appeal. However, installing a metal roof comes with a fair amount of challenges, including finding a reliable and efficient roll forming machine that can produce the necessary roofing panels onsite. Enter the Portable Standing Seam Roll Forming Machine.The Portable Standing Seam Roll Forming Machine, also known as KLS25-220-530, is a small size metal standing seam roof panel roll forming machine that is designed to produce high-quality roof panels quickly and efficiently. It features a compact design, making it easy to transport and set up on-site, making it the perfect solution for contractors who need to produce standing seam metal roof panels on the job site.The machine is designed to roll-form metal roofing panels with a standing seam profile, which provides superior weather resistance and no visible fasteners. The standing seam design also makes it easier to install the panels, reducing the installation time and minimizing the risk of leaks.One of the standout features of the Portable Standing Seam Roll Forming Machine is its ease of use. It comes with an intuitive control system that allows operators to adjust the roll-forming settings quickly and easily. The machine also has a hydraulic cutting system, which cuts the panels to the desired length accurately.The KLS25-220-530 is capable of producing roofing panels with a width of 220mm and a thickness of 0.4-0.6mm. The machine also has a roll-forming speed of up to 15 meters per minute, ensuring that you can produce high-quality panels quickly and efficiently.Moreover, the machine comes with a durable construction, ensuring that it can withstand harsh job site conditions. It is also designed with safety features such as protective covers and emergency stop buttons, ensuring that operators are protected while using the machine.In conclusion, the Portable Standing Seam Roll Forming Machine is a game-changer for the metal roofing industry. Its portability, ease of use, and ability to produce high-quality standing seam metal roof panels quickly and efficiently make it an excellent investment for contractors looking to save time and money on their metal roofing projects. Don't wait any longer; invest in the KLS25-220-530 today.

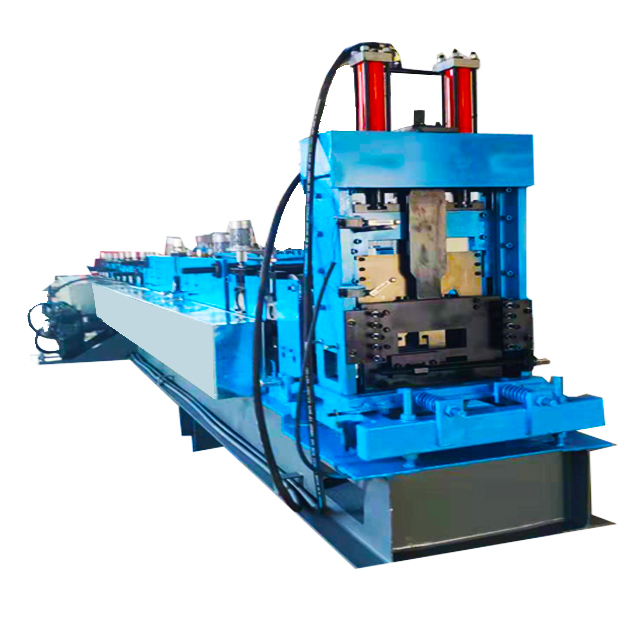

C Purlin Machine with Punching Hole Device: An Overview

C Purlin Machine With Punching Hole Device Leads the Innovation in Metal Forming IndustryThe metal forming industry is constantly evolving, and the demand for efficient and advanced machinery is growing rapidly. In response to this demand, a leading manufacturer of metal forming machinery has introduced a groundbreaking C Purlin Machine with a Punching Hole Device, setting a new standard for innovation and efficiency in the industry.The C Purlin Machine with Punching Hole Device is designed to streamline the production process of C-shaped steel purlins, a critical component in the construction of steel buildings, warehouses, and other structures. This machine not only shapes the steel into the desired C profile, but it also features a built-in punching hole device that allows for precise and efficient hole punching, saving time and labor costs.The company behind this innovative machine has a long-standing reputation for excellence in the design and manufacturing of metal forming equipment, with a commitment to pushing the boundaries of technological advancement in the industry. The introduction of the C Purlin Machine with Punching Hole Device is a testament to their dedication to providing cutting-edge solutions for the evolving needs of their customers.One of the most noteworthy features of this new machine is its advanced punching hole device, which is capable of creating precise and consistent holes in the steel purlins. This is a critical capability for many construction projects, as it ensures that the purlins can be easily assembled and installed with other components of the structure. The punching hole device is fully automated, allowing for high-speed and accurate hole punching, resulting in a significant boost to overall production efficiency.In addition to its innovative punching hole device, the C Purlin Machine is also designed for versatility and ease of use. It is capable of processing a wide range of steel materials, making it suitable for a variety of applications in the construction industry. The machine can be quickly and easily adjusted to accommodate different sizes and thicknesses of steel, providing a high level of flexibility for manufacturers.Furthermore, the machine is equipped with a user-friendly control system that allows for easy operation and monitoring of the production process. This intuitive interface streamlines the setup and operation of the machine, reducing the need for extensive training and minimizing the potential for error. This ease of use contributes to the overall efficiency of the production process, as it allows operators to maximize their productivity with minimal downtime.The introduction of the C Purlin Machine with Punching Hole Device represents a significant leap forward in the metal forming industry, offering a solution that combines precision, efficiency, and versatility in a single machine. It is poised to revolutionize the way steel purlins are manufactured, providing manufacturers with a competitive edge in an increasingly demanding market.As the global demand for steel structures continues to grow, the need for advanced and efficient metal forming machinery is more critical than ever. The introduction of the C Purlin Machine with Punching Hole Device addresses this need head-on, offering a solution that is engineered to meet the evolving requirements of the industry. With this innovative machine, manufacturers can expect to achieve higher levels of productivity, cost savings, and overall operational efficiency.In conclusion, the C Purlin Machine with Punching Hole Device is a game-changer in the metal forming industry, setting a new standard for innovation and performance. As the industry continues to adapt to the changing landscape of construction and manufacturing, this groundbreaking machine represents a significant step forward in the evolution of metal forming technology. With its advanced capabilities and user-friendly design, it is poised to make a lasting impact on the way steel purlins are produced, paving the way for a more efficient and competitive industry.

invention of a Revolutionary Machine that Manufactures Corrugated Metal Sheets

Title: New Machine Revolutionizes Production of Corrugated Metal SheetsIntroduction:With the continuous growth of the construction industry, the demand for durable and versatile building materials is on the rise. Corrugated metal sheets have been a popular choice for a wide range of applications due to their strength, flexibility, and cost-efficiency. Addressing the need for increased productivity and enhanced quality, a pioneering company in the industry has developed a cutting-edge machine that promises to revolutionize the production of corrugated metal sheets, significantly boosting efficiency and meeting the market's growing demands.Body:1. Meeting the Growing Demand:The global construction industry has experienced significant growth over the past few years, and with it, the demand for durable and reliable building materials has soared. Corrugated metal sheets, known for their excellent strength and long-lasting nature, have become a staple in the construction sector. However, traditional manufacturing methods could not always keep up with the mounting demand, leading to delays and potential supply shortages.2. Introducing the Revolutionary Machine:In response to these challenges, {Company Name} has unveiled a state-of-the-art machine that will transform the production of corrugated metal sheets. This innovative solution leverages advanced technology to streamline the manufacturing process, resulting in increased productivity, improved quality, and shorter lead times.3. Enhanced Efficiency:The new machine offers unparalleled efficiency by automating key aspects of the production process. It integrates cutting-edge robotics, precision engineering, and intelligent software algorithms to ensure precise and consistent corrugation patterns. This automation eliminates the need for manual labor, reducing production time and costs while minimizing human error.4. Optimized Flexibility:One of the standout features of this cutting-edge machine is its ability to produce corrugated metal sheets in various sizes, thicknesses, and designs. This versatility enables construction companies and architects to explore innovative designs and cater to the unique requirements of each project. Whether it is for roofing, cladding, or even decorative purposes, the machine ensures the production of customized corrugated metal sheets that perfectly fit the needs of the end-user.5. Unwavering Quality:To meet the ever-increasing demands for superior quality, {Company Name} has incorporated rigorous quality control measures into the machine's design. From raw material inspection to final product assessment, each production stage is thoroughly monitored to ensure that only top-grade corrugated metal sheets are manufactured. This commitment to quality ensures the longevity and reliability of the final product.6. Environmental Considerations:As the world becomes increasingly conscious of the environmental impact of industrial processes, the new machine addresses sustainability concerns. Equipped with energy-efficient components and designed to minimize waste, it helps reduce the overall carbon footprint of production while maximizing material utilization. By optimizing resource consumption, the machine contributes to a greener and more sustainable manufacturing process.7. Market Impact and Benefits:The introduction of this groundbreaking technology not only provides a solution to the production challenges faced by corrugated metal sheet manufacturers but also has broader implications for the construction industry. The enhanced efficiency and flexibility offered by the machine will meet the rising demand for corrugated metal sheets, providing contractors and builders access to quality materials to complete projects within tight deadlines.Conclusion:With the unveiling of their cutting-edge machine, {Company Name} has propelled the production of corrugated metal sheets to new heights. By combining advanced technology, automated processes, and a commitment to quality, this revolutionary innovation promises to meet the surging demand for durable and versatile building materials. With its emphasis on efficiency, flexibility, and sustainability, this new machine is set to redefine the market standards, pushing the construction industry towards exciting possibilities and endless creative potential.

High-Quality C Profile Roll Forming Machine for Efficient Production

C Profile Roll Forming Machine Market: OverviewThe global C Profile Roll Forming Machine market is expected to witness significant growth in the coming years, according to a new research report. The study, conducted by {company name}, indicates that the market is driven by the increasing demand for efficient and cost-effective manufacturing processes in various industries.C Profile Roll Forming Machine is a highly versatile machine used for manufacturing C-shaped metal profiles with high precision and speed. These machines are widely used in industries such as construction, automotive, and aerospace for producing metal components and profiles with various sizes and shapes.The report highlights the key factors driving the growth of the C Profile Roll Forming Machine market, including the increasing demand for lightweight and durable metal components in the automotive and aerospace industries. In addition, the growing trend of automation and digitization in manufacturing processes is expected to fuel the demand for C Profile Roll Forming Machines in the coming years.Furthermore, the research report provides an in-depth analysis of the market trends, growth drivers, challenges, and opportunities that are likely to impact the growth of the C Profile Roll Forming Machine market. The report also includes a comprehensive analysis of the competitive landscape, including the profiles of key players in the market.{Company name} is one of the leading manufacturers of C Profile Roll Forming Machines in the industry, with a strong focus on innovation and product development. The company has a wide range of C Profile Roll Forming Machines that are designed to meet the specific requirements of different industries.With a commitment to quality and customer satisfaction, {company name} has established itself as a trusted name in the C Profile Roll Forming Machine market. The company's state-of-the-art manufacturing facilities and a team of experienced engineers enable it to deliver high-quality machines that meet the highest standards of performance and reliability.{Company name}'s C Profile Roll Forming Machines are known for their superior precision, high speed, and flexibility, making them ideal for a wide range of applications. The company also offers customized solutions to meet the specific needs of its customers, ensuring that they get the best value for their investment.In addition to its strong focus on product quality, {company name} is also committed to providing excellent customer service and support. The company has a dedicated team of professionals who are available to assist customers with installation, training, and ongoing maintenance of their C Profile Roll Forming Machines.As the demand for efficient and cost-effective manufacturing processes continues to grow, {company name} is well positioned to capitalize on the opportunities in the C Profile Roll Forming Machine market. With a strong reputation for quality and reliability, the company is poised to maintain its leadership position in the industry and drive innovation in C Profile Roll Forming technology.The research report predicts that the global C Profile Roll Forming Machine market is expected to grow at a substantial rate in the coming years, driven by the increasing demand for metal components in various industries. With its focus on innovation, quality, and customer service, {company name} is well positioned to capitalize on this growth and continue to be a key player in the market.

Top Roof Sheet Rolling Machine for Efficient Metal Roofing

Roof Sheet Rolling Machine Revolutionizing the Construction IndustryThe construction industry is constantly evolving and advancing, and one of the latest innovations making waves in the market is the Roof Sheet Rolling Machine. This state-of-the-art machine has been hailed as a game-changer in the construction sector, offering a faster, more efficient, and cost-effective solution for producing high-quality and durable roofing sheets.The Roof Sheet Rolling Machine is designed to roll and shape metal sheets into various roofing profiles, such as corrugated, trapezoidal, and standing seam profiles. It is capable of processing a wide range of materials, including steel, aluminum, and copper, making it a versatile and adaptable tool for construction projects of all sizes and scales.One of the key features of the Roof Sheet Rolling Machine is its speed and efficiency. Traditional methods of producing roofing sheets involved manual labor and were time-consuming, labor-intensive, and often prone to human error. With the Roof Sheet Rolling Machine, these inefficiencies are a thing of the past. The machine is capable of rolling out large quantities of roofing sheets in a fraction of the time it would take using traditional methods, significantly increasing productivity and reducing labor costs.In addition to its speed and efficiency, the Roof Sheet Rolling Machine also offers superior precision and quality. The machine is equipped with advanced technology and precision engineering, ensuring that every roofing sheet produced is of the highest standard. This level of precision is essential in the construction industry, where the quality and durability of roofing materials are paramount.Furthermore, the Roof Sheet Rolling Machine is designed with user-friendly features that make it easy to operate and maintain. Its intuitive controls and programmable settings allow for seamless operation, while its robust construction and durable components ensure long-term reliability and minimal downtime.One of the leading manufacturers of Roof Sheet Rolling Machines is {}, a renowned company with a long-standing reputation for producing high-quality and innovative construction machinery.{} has been at the forefront of the construction machinery industry for over two decades, and their Roof Sheet Rolling Machines have become a staple in the market. The company’s commitment to research and development, coupled with their dedication to providing cutting-edge solutions for the construction sector, has solidified their position as a trusted and reliable supplier of Roof Sheet Rolling Machines.In addition to their superior product offerings, {} is also known for their exceptional customer service and support. With a global network of service centers and knowledgeable technical staff, the company is committed to ensuring that their customers receive the highest level of support and assistance throughout the entire lifecycle of their Roof Sheet Rolling Machines.The Roof Sheet Rolling Machine is quickly becoming a must-have tool for construction companies and roofing contractors around the world. Its ability to streamline the production process, improve the quality of roofing materials, and ultimately reduce costs has made it an invaluable asset in the construction industry.As the demand for efficient and high-quality roofing solutions continues to grow, the Roof Sheet Rolling Machine is positioned to play a significant role in shaping the future of the construction industry. With its advanced technology, precision engineering, and user-friendly design, it is revolutionizing the way roofing sheets are produced and is poised to become an indispensable tool for construction projects of all kinds.

Top Supplier and Manufacturer of Ungrouped Forming Machines in China - Products List Page-9

Global Market Leader in Sheet Roll Forming Introduces State-Of-The-Art Ungrouped Forming Machine(Company Name - No Brand Name) is proud to announce the launch of its latest innovation - the Ungrouped Forming Machine. As a global market leader in sheet roll forming, (Company Name - No Brand Name) has built its reputation on its cutting-edge technology and high-quality products. This new machine is no exception and promises to be a game-changer in the industry.The Ungrouped Forming Machine is a versatile and efficient machine that can produce a wide range of sheet metal products. It is designed to simplify the forming process and provide precision and accuracy every time. The machine is equipped with advanced technology that ensures quick and easy setup, reducing production time and increasing efficiency."Our new Ungrouped Forming Machine is a prime example of our commitment to innovation and excellence," said the company spokesperson. "We understand the need for our clients to remain competitive in the ever-changing market, and this machine is designed to do just that. Its versatility means it can produce a variety of sheet metal products, from roofing to wall cladding, to rain gutters and downspouts. And with its advanced technology, it provides accuracy, efficiency, and reliability every time."The machine's compact design allows it to fit comfortably in any workshop space, making it an ideal choice for small to medium-sized businesses. It is also easy to operate, reducing the need for skilled labor, and its low maintenance requirements keep costs down. Plus, the machine's durability ensures a longer lifespan, providing better value for money.(Undisclosed Name) is a long-standing manufacturer of sheet metal forming equipment, mainly focusing on roof panel forming machines, wall panel forming machines, standing seam roof panel machines, gutter forming machines, and other related equipment. The company's commitment to quality has resulted in (Company Name - No Brand Name) becoming a global leader in sheet metal roll forming equipment. They have a strong reputation for designing and manufacturing high-quality equipment that is built to last. Their machines are used by clients worldwide for a variety of applications, including residential, commercial, and industrial projects.(Undisclosed Name) clients have access to a comprehensive range of services, including design and layout assistance, installation support, and an aftersales service team that provides ongoing support and training. (Company Name - No Brand Name) understands the importance of providing exceptional customer service and support, and this is reflected in its commitment to delivering high-quality equipment that meets the needs of its clients.In conclusion, the launch of the Ungrouped Forming Machine is a significant milestone for (Company Name - No Brand Name). It is the latest addition to the company's extensive range of sheet metal forming equipment, and it promises to deliver exceptional results for clients worldwide. With its advanced technology, versatility, and efficiency, the machine is set to become a game-changer in the industry. (Company Name - No Brand Name) is proud to offer this innovative machine to its clients and is committed to providing exceptional customer service and support.

Boost Your Roofing Projects with a High-Quality Corrugated Iron Machine

In today's world, where businesses are expanding at a rapid pace, the demand for sturdy and durable construction materials is at an all-time high. Corrugated iron sheets are widely used for roofing and fencing due to their strength and longevity. However, producing these sheets is a tedious and time-consuming task. To ease this process, a state-of-the-art Corrugated Iron Machine was introduced by a renowned company.The machine boasts an innovative design that enables it to produce high-quality corrugated iron sheets quickly and efficiently. Its robust frame is made of high-quality materials to support its heavy-duty operations. The machine's internal structure has been engineered to perfection, ensuring that it operates with minimal wear and tear. Additionally, the machine is fitted with top-of-the-line electrical and mechanical parts to ensure its durability and reliability.The company behind this revolutionary machine is one of the leading manufacturers of industrial equipment for the construction sector. They are known for their cutting-edge machinery, which is designed to streamline construction processes and boost productivity. With years of experience in the industry, they understand their customers' needs and demands and strive to offer them the best possible solutions.The Corrugated Iron Machine's features highlight its versatility and adaptability. It can produce corrugated sheets of varying thickness, length, and width, ensuring that it satisfies the diverse needs of its users. Through a simple yet intuitive interface, the machine can be easily adjusted to accommodate different settings, making it ideal for small and large-scale manufacturers. Moreover, the machine's energy-efficient nature ensures that it consumes minimal electricity, making it an eco-friendly option.One of the primary benefits of the Corrugated Iron Machine is its ability to increase productivity and reduce labour costs. With the traditional method, producing a single corrugated sheet could take hours and required a team of workers. However, with this machine, a single operator can produce up to hundreds of corrugated sheets within a few hours. It is highly beneficial for manufacturers as it enables them to increase their production output while minimizing labour costs.The Corrugated Iron Machine's low maintenance requirement is a testament to its robustness and reliability. The machine has been designed to operate with minimal maintenance. Its internal parts are easily accessible should any maintenance need arise, and its user-friendly interface ensures that operators can carry out routine maintenance without any hassle.The machine's ergonomic design ensures that it is easy to operate and maintain. Its built-in safety features ensure that operators are safe while operating the machine. Additionally, the machine's structure is designed to reduce noise levels, creating a comfortable working environment for the operator.To conclude, the introduction of the Corrugated Iron Machine is a significant milestone for the construction industry. Its ability to produce high-quality corrugated sheets quickly and efficiently has revolutionized the manufacturing process. The machine's durability, low maintenance requirement, and energy-efficient nature not only benefit the user but also the environment. As the demand for sturdy construction materials continues to rise, the Corrugated Iron Machine is sure to be a game-changer, ensuring that manufacturers can keep up with the increasing demand.

How Glazed Tile Manufacturing Machine Can Transform Your Tile Production

Glazed Tile Manufacturing Machine Offers High-Quality and Efficient ProductionIn the world of construction, glazed tiles are becoming increasingly popular due to their durability, versatility, and aesthetic appeal. With the demand for high-quality glazed tiles on the rise, manufacturers are seeking ways to improve their production processes and ensure consistent quality in their products. This is where the Glazed Tile Manufacturing Machine comes in, offering a reliable and efficient solution for producing glazed tiles in large quantities.The Glazed Tile Manufacturing Machine, which is developed and manufactured by one of the leading engineering companies in the industry, is a state-of-the-art production system that combines cutting-edge technology and advanced machinery to create high-quality glazed tiles. Its fully automated operation minimizes the need for manual labor, allowing for increased efficiency and productivity in the production process.The machine is highly customizable, with various options for tile size, thickness, color, and texture. This allows manufacturers to produce a wide range of glazed tiles to meet the specific needs of their customers. The Glazed Tile Manufacturing Machine can produce up to 10,000 tiles per day, making it a cost-effective solution for large-scale production and reducing the need for multiple machines.The advanced technology used in the Glazed Tile Manufacturing Machine ensures consistent quality in each tile produced. The machine is equipped with sensors and advanced software that monitor every step of the production process, from mixing the raw materials to firing the tiles in the kiln. This ensures that each tile meets the required standards of quality, strength, and durability.The Glazed Tile Manufacturing Machine is also designed with ease of use and maintenance in mind. Its user-friendly interface and intuitive control system make it easy for operators to monitor and adjust the production process as needed. The machine also requires minimal maintenance, with automated cleaning and lubrication systems that help to prevent wear and tear on its components.One of the leading users of the Glazed Tile Manufacturing Machine is {} – a company that specializes in producing high-quality glazed tiles for the construction industry. According to the company's spokesperson, the Glazed Tile Manufacturing Machine has been instrumental in improving their production efficiency and product quality. "Since we started using the Glazed Tile Manufacturing Machine, we have been able to produce more tiles in less time, while maintaining consistent quality. This has helped us to meet the growing demand for our products and stay competitive in the market," said the spokesperson.In addition to its operational benefits, the Glazed Tile Manufacturing Machine is also environmentally friendly. Its advanced production processes and energy-efficient design help to reduce energy consumption and minimize waste in the production process. This makes it a sustainable solution for manufacturers who are looking to reduce their carbon footprint and promote eco-friendly practices.In conclusion, the Glazed Tile Manufacturing Machine is a game-changer for manufacturers in the construction industry who are looking to improve their production processes and keep up with the growing demand for glazed tiles. With its advanced technology, customizable options, and user-friendly design, the machine offers a reliable and efficient solution for producing high-quality glazed tiles in large quantities. As the construction industry continues to grow, the Glazed Tile Manufacturing Machine will undoubtedly play a pivotal role in meeting the demand for durable and versatile glazed tiles.

Cold Roll Forming Lines for C Purlin Profile: All You Need to Know

C Purlin Profiles Cold Roll Forming LinesIn the world of construction and manufacturing, the use of cold roll forming lines has become increasingly popular. These machines are capable of producing a variety of profiles, including C purlin profiles, which are commonly used in building construction. With the ability to produce high-quality, consistent profiles at a rapid pace, cold roll forming lines have revolutionized the industry.One company that has emerged as a leader in the development and manufacturing of cold roll forming lines is {}. {} specializes in the design and production of high-performance roll forming equipment, including C purlin profiles cold roll forming lines. With a focus on innovation and cutting-edge technology, {} has established itself as a trusted partner for companies looking to streamline their production processes and improve their product quality.The C purlin profiles cold roll forming lines produced by {} are designed to meet the specific needs of their customers. These machines are capable of producing C purlin profiles in a wide range of sizes and thicknesses, ensuring that they can be used in a variety of construction applications. The use of advanced control systems and precision engineering allows {}’s cold roll forming lines to produce accurate and consistent profiles, meeting the highest quality standards.One of the key advantages of using {}’s C purlin profiles cold roll forming lines is the efficiency and speed at which they operate. These machines are designed to optimize production processes, minimizing downtime and maximizing output. This enables companies to increase their production capacity and meet tight deadlines, ultimately improving their overall competitiveness in the market.Furthermore, {}’s cold roll forming lines are known for their durability and reliability. The company utilizes high-quality materials and components in the construction of their machines, ensuring that they can withstand the rigors of continuous operation. This results in lower maintenance requirements and reduced downtime, allowing customers to focus on their production without worrying about costly interruptions.In addition to the superior performance of their cold roll forming lines, {} also provides exceptional service and support to their customers. The company works closely with each client to understand their specific needs and requirements, offering customized solutions that meet their exact specifications. From the initial design phase to after-sales support, {} is committed to ensuring the success of their customers’ projects.With a focus on continuous innovation and improvement, {} is constantly pushing the boundaries of cold roll forming technology. The company invests heavily in research and development to further enhance the capabilities of their machines, offering customers access to the latest advancements in the industry. This commitment to innovation has allowed {} to stay ahead of the competition, providing their customers with state-of-the-art solutions that deliver exceptional results.As the demand for high-quality, efficient C purlin profiles continues to grow, the importance of reliable and advanced cold roll forming lines cannot be overstated. With their dedication to excellence and customer satisfaction, {} has solidified its position as a leading provider of cold roll forming equipment, trusted by companies around the world.In conclusion, the C purlin profiles cold roll forming lines produced by {} are a testament to the company’s commitment to quality, innovation, and customer satisfaction. With their advanced technology, superior performance, and exceptional service, {} has established itself as a go-to partner for companies looking to enhance their production processes and stay ahead in the competitive construction industry.

Roll Forming Machine for Manufacturing Wall Panels

In recent years, there has been an increasing need for high-quality wall panels for use in a variety of applications, from commercial structures to residential homes. To meet this demand, a new system has been developed that has revolutionized the way that wall panels are manufactured. This system, known as the Wall Panel Roll Forming Machine, has quickly become one of the most popular and widely used technologies in the industry.The Wall Panel Roll Forming Machine is essentially a specialized piece of equipment that is designed to take a flat piece of raw material and transform it into a custom-fabricated wall panel. The machine operates on a continuous basis, allowing for a virtually uninterrupted flow of material and seamless production of large quantities of panels. This level of efficiency and consistency is critical for meeting the high demands of modern construction projects.Perhaps the most important aspect of the Wall Panel Roll Forming Machine is its versatility. It is capable of producing wall panels of virtually any size or shape, from standard rectangular panels to more complex designs with intricate curves and details. This opens up possibilities for architects and designers to create truly unique and impressive structures that were previously impossible to construct using traditional methods.One of the key advantages of the Wall Panel Roll Forming Machine is its automation. The technology used in the machine allows for precise control and accuracy in the manufacturing process. This reduces the need for human intervention, which not only increases efficiency but also reduces the chances of errors and defects in the final product. The end result is a high-quality wall panel that meets or exceeds all industry standards and is sure to provide years of reliable service.At the heart of the Wall Panel Roll Forming Machine is the roll forming process. In this process, a sheet of material is passed through a series of rollers that gradually bend and shape it into the desired form. The Wall Panel Roll Forming Machine uses a custom-designed set of rollers that are specifically tailored to the requirements of each individual project. This ensures maximum precision and accuracy in the finished product.Another key advantage of the Wall Panel Roll Forming Machine is its speed of production. Because the machine operates on a continuous basis, it is capable of producing large quantities of high-quality wall panels in a relatively short amount of time. This makes it an ideal solution for construction companies and contractors who need to meet tight deadlines and strict schedules.The Wall Panel Roll Forming Machine is also highly customizable. It can be tailored to fit the specific requirements of each individual project, allowing for a wide range of options in terms of materials, sizes, and shapes. This versatility makes it an ideal choice for architects and designers who need to create unique and innovative structures that require custom-made panels.In conclusion, the Wall Panel Roll Forming Machine is a cutting-edge technology that has changed the way that wall panels are manufactured. Its precision, speed, and versatility have made it an essential tool for construction companies and contractors who need to meet the demands of modern construction projects. With its automation and customization options, it is sure to continue to be a popular choice in the industry for years to come.