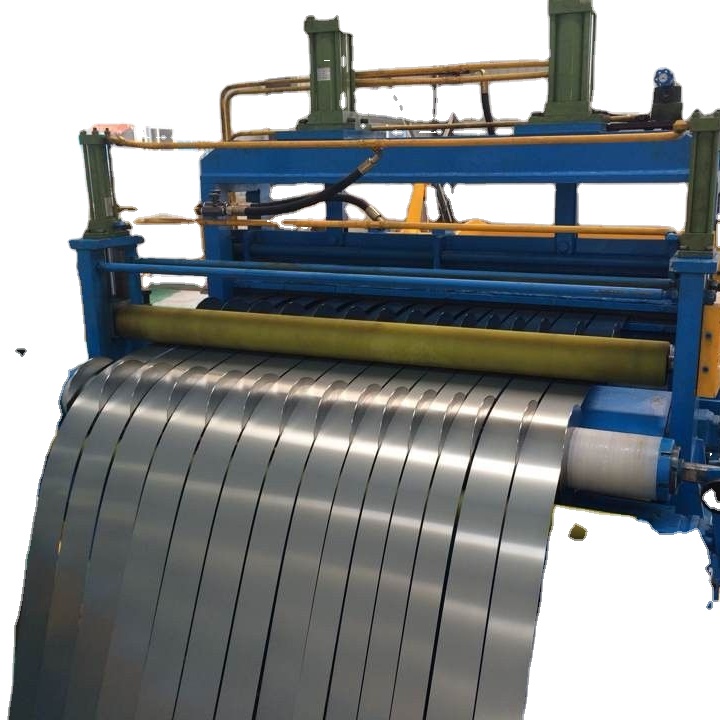

Steel Slitter: An Essential Tool for Metal Fabrication

By:Admin

Slitter Steel has been at the forefront of the steel industry for over 50 years, providing customers with a wide range of steel products to meet their specific needs. The company has built a solid reputation for delivering high-quality products and exceptional customer service. With a strong commitment to innovation and continuous improvement, Slitter Steel has constantly pushed the boundaries of what is possible in the steel industry.

The new technology developed by Slitter Steel is set to significantly improve the efficiency of steel processing. This will result in faster production times and reduced lead times for customers. The new technology will also enhance the overall quality of the steel products, ensuring that customers receive the best possible products for their needs.

One of the key features of the new technology is its ability to process steel with greater precision and accuracy. This will result in steel products that meet the highest standards of quality and consistency. Customers can expect to receive steel products that are perfectly tailored to their specifications, with minimal waste and maximum efficiency.

Another benefit of the new technology is its ability to improve the sustainability of steel production. By reducing waste and improving efficiency, Slitter Steel is helping to minimize the environmental impact of steel production. This commitment to sustainability is in line with the company's long-standing values of environmental responsibility and ethical business practices.

In addition to the new technology, Slitter Steel is also investing in state-of-the-art equipment and machinery to further improve its production capabilities. This will enable the company to continue meeting the growing demand for high-quality steel products in a timely and efficient manner.

Slitter Steel's dedication to innovation and continuous improvement has made it a trusted partner for customers in a wide range of industries, including construction, manufacturing, and automotive. The company's ability to deliver tailored steel solutions that meet the most stringent quality standards has set it apart from its competitors.

"We are thrilled to introduce this groundbreaking technology to the steel industry," said a spokesperson for Slitter Steel. "This new development is a testament to our ongoing commitment to excellence and innovation. We are confident that this new technology will bring significant benefits to our customers and further strengthen our position as a leader in the steel industry."

The introduction of this new technology is set to have a major impact on the steel industry, with Slitter Steel leading the way in driving innovation and setting new standards for quality and efficiency. Customers can expect to see the benefits of this new technology in the form of higher-quality steel products, faster production times, and a more sustainable approach to steel processing.

As Slitter Steel continues to push the boundaries of what is possible in the steel industry, customers can look forward to even more advanced and efficient steel solutions in the future. With a strong focus on innovation and customer satisfaction, Slitter Steel is well-positioned to continue leading the way in the steel industry for years to come.

Company News & Blog

Top Aluminum Extrusion Machine for Efficient Production

Aluminum Extrusion Machine is proud to announce the launch of their latest cutting-edge extrusion machine, which is set to revolutionize the aluminum extrusion industry. The company, known for its commitment to innovation and quality, has been at the forefront of the extrusion technology for over a decade and continues to push the boundaries of what is possible in this field.The new extrusion machine is the result of years of dedicated research and development, aimed at creating a machine that offers unparalleled precision, efficiency, and versatility. It is designed to meet the growing demands of the industry and to provide customers with a solution that can handle a wide range of extrusion processes with ease. From simple shapes to complex profiles, this machine is capable of delivering consistent, high-quality results every time.One of the key features of the new machine is its advanced control system, which allows for precise adjustment of the extrusion process parameters. This level of control ensures that the machine can handle a variety of aluminum alloys and profiles, without compromising on quality or efficiency. In addition, the machine is equipped with state-of-the-art heating and cooling systems, which further enhance its capability to handle even the most challenging extrusion tasks.The company's commitment to quality is evident in every aspect of the new extrusion machine. From the selection of materials to the manufacturing process, every detail has been carefully considered to ensure that the machine meets the highest standards of quality and reliability. This dedication to excellence is a hallmark of the company's ethos and is reflected in the performance of their machines.In addition to their cutting-edge technology, Aluminum Extrusion Machine also prides itself on its exceptional customer service. The company's team of experts are always available to provide support and guidance to customers, ensuring that they are able to make the most of their investment in the new extrusion machine. Whether it's assistance with installation, training, or troubleshooting, the company is dedicated to ensuring that their customers are completely satisfied with their experience.Furthermore, the company also offers a comprehensive range of accessories and spare parts for their extrusion machines, ensuring that customers have everything they need to keep their operations running smoothly. From die cleaning equipment to specialized tooling, Aluminum Extrusion Machine has everything covered, allowing customers to focus on their core business without worrying about the reliability of their equipment.As part of their commitment to sustainability, Aluminum Extrusion Machine is proud to offer energy-efficient solutions that help reduce the environmental impact of their operations. The new extrusion machine is designed to minimize energy consumption while maximizing productivity, helping customers to achieve their production goals while minimizing their carbon footprint.Looking to the future, Aluminum Extrusion Machine is committed to maintaining its position at the forefront of the industry. The company continues to invest in research and development, aiming to bring new innovations to the market that will further improve the efficiency and performance of their extrusion machines. With a focus on quality, reliability, and innovation, the company is well-positioned to continue leading the way in the aluminum extrusion industry for years to come.Overall, the launch of the new extrusion machine marks an important milestone for Aluminum Extrusion Machine, as they continue to cement their reputation as a leading provider of cutting-edge extrusion technology. With a strong focus on quality, innovation, and customer satisfaction, the company is poised to continue driving the industry forward and setting new standards for excellence.

Understanding the Significance and Benefits of C Purlins in Modern Construction

Title: Innovative C Purlins Revolutionize Construction Industry: A Game-Changing Solution by [Company Name]Introduction:[Company Name] has made a significant breakthrough in the construction industry with their revolutionary C Purlins. By combining cutting-edge technology and expertise, [Company Name] is transforming the way builders construct roofs, walls, and other infrastructure support systems. These innovative C Purlins have garnered substantial attention due to their superior strength, durability, and versatility, making them an invaluable addition to modern architectural projects. [Company Name]'s C Purlins - A Testament to Innovation: With a profound dedication to innovation, [Company Name] has engineered C Purlins that offer unmatched structural integrity while also adhering to stringent quality standards. These purlins are manufactured using high-quality galvanized steel, ensuring maximum durability and resistance against corrosion and other environmental factors.Strength and Stability:The C Purlins by [Company Name] have been optimized for strength and stability, making them ideal for modern construction practices. These purlins are designed to withstand heavy loads, making them suitable for a wide range of applications, such as industrial buildings, shopping centers, warehouses, and residential properties. Builders can trust these purlins to provide reliable structural support, ensuring long-lasting and safe infrastructure.Versatility and Flexibility:One of the distinctive features of [Company Name]'s C Purlins is their exceptional versatility and flexibility. Designed to accommodate diverse architectural requirements, these purlins can be easily customized to fit specific project needs. Whether it's adapting to unique geometries or incorporating multi-level support systems, [Company Name]'s C Purlins offer freedom of design, enabling architects and engineers to bring their visions to life.Ease of Installation:[Company Name] understands the importance of time efficiency in the construction industry. To cater to this need, they have simplified the installation process, making it easier for contractors and builders to work with their C Purlins. Their lightweight design and pre-punched holes facilitate quick and hassle-free installation, ensuring reduced labor costs and accelerated project timelines.Sustainable Solution:Recognizing the environmental impact of construction materials, [Company Name] has taken a significant step towards creating a sustainable future. Their C Purlins are made from recyclable materials, reducing the carbon footprint associated with infrastructure development. By adopting these environmentally-friendly purlins, builders can contribute to the preservation of our planet while also meeting their construction needs.Commitment to Quality:[Company Name] values impeccable quality, and this ethos is reflected in their C Purlins. The manufacturing process adheres to rigorous quality control measures, ensuring each purlin meets or exceeds industry standards. Builders and contractors can trust in the reliability, durability, and longevity of [Company Name]'s C Purlins, ensuring projects are built to last.Future Prospects:With their game-changing C Purlins, [Company Name] is set to disrupt the construction industry. As architects and engineers increasingly recognize the benefits of these purlins, the demand is expected to skyrocket. The company's relentless pursuit of innovation and commitment to customer satisfaction positions [Company Name] as a key player in the industry, driving growth and advancements in construction methodologies.Conclusion:[Company Name]'s C Purlins have taken the construction industry by storm, redefining structural support systems and setting new standards for strength, durability, and versatility. These purlins offer architects and builders a sustainable and efficient solution that meets their diverse project requirements. With their cutting-edge technology and unwavering commitment to quality, [Company Name] has firmly established itself as a leading provider of innovative construction products. The future of the construction industry has arrived with [Company Name]'s groundbreaking C Purlins.

Durable and Stylish Steel Roofing Tile Roll Former for Your Next Project

Glazed Steel Roofing Tile Roll FormerIn recent news, a cutting-edge technology has been making waves in the construction industry - the Glazed Steel Roofing Tile Roll Former. This innovative machine is set to revolutionize the way roofing tiles are manufactured, offering a more efficient and cost-effective solution for builders and contractors.The Glazed Steel Roofing Tile Roll Former is a state-of-the-art piece of equipment that is designed to produce high-quality roofing tiles with precision and speed. It operates by taking steel coils and feeding them through a series of rollers and dies, which shape the metal into the desired roofing tile profile. The machine is capable of producing a wide range of tile designs, including both traditional and modern styles, making it an incredibly versatile tool for construction projects of any scale.One of the key features of the Glazed Steel Roofing Tile Roll Former is its ability to apply a glazed finish to the tiles during the manufacturing process. This not only enhances the aesthetic appeal of the tiles but also provides a protective layer that helps to extend the lifespan of the roof. The glazed finish can be customized to achieve different levels of gloss and color, allowing for a high degree of flexibility in design.In addition to its superior performance and flexibility, the Glazed Steel Roofing Tile Roll Former is also praised for its efficiency. The machine is capable of producing large quantities of roofing tiles in a relatively short amount of time, making it an ideal solution for fast-paced construction projects. Its automated operation reduces the need for manual labor, further streamlining the production process and minimizing the potential for human error.Behind this breakthrough technology is the company {}, a leading manufacturer in the field of construction machinery. With years of experience and expertise, the company has developed the Glazed Steel Roofing Tile Roll Former as part of its commitment to providing industry-leading solutions to its customers. The company's dedication to innovation and quality has earned it a reputation for excellence in the construction industry, and the Glazed Steel Roofing Tile Roll Former is a testament to that commitment.The introduction of the Glazed Steel Roofing Tile Roll Former is expected to have a significant impact on the construction industry. Its ability to produce high-quality roofing tiles with efficiency and precision will not only benefit contractors and builders but also contribute to the overall quality and durability of roofing systems. In an industry where time and cost are crucial factors, this new technology offers a competitive advantage that is sure to be welcomed by professionals in the field.Furthermore, the Glazed Steel Roofing Tile Roll Former represents a sustainable solution for roofing tile production. By using steel coils as the raw material, it reduces the reliance on traditional materials such as clay or concrete, which can have a more significant environmental impact. The machine's efficient operation also helps to minimize waste and energy consumption, making it a greener option for roofing tile manufacturing.As the construction industry continues to evolve, the demand for innovative and sustainable solutions remains high. The Glazed Steel Roofing Tile Roll Former addresses these needs by offering a cutting-edge technology that improves the efficiency, quality, and sustainability of roofing tile production. With its introduction, builders and contractors can expect to see a positive impact on their projects, while also contributing to a more environmentally conscious approach to construction.In conclusion, the Glazed Steel Roofing Tile Roll Former represents a significant advancement in the construction industry. Its combination of precision, efficiency, and sustainability makes it an invaluable tool for the production of high-quality roofing tiles. With the backing of {}, a reputable manufacturer with a track record of excellence, this new technology is poised to make a lasting impact on the way roofing tiles are manufactured and used in construction projects.

Revolutionary Horizontal Profiled Panel Production Line Boosts Efficiency and Quality

Horizontal Profiled Panel Production Line Presents New Innovations in Manufacturing TechnologyWith a continuous focus on innovation and advanced manufacturing solutions, {Company Name}, a leading global provider of industrial machinery, is proud to introduce its state-of-the-art Horizontal Profiled Panel Production Line. This cutting-edge equipment offers significant advancements in the manufacturing process, promising improved efficiency, durability, and flexibility.The Horizontal Profiled Panel Production Line represents the culmination of years of research, development, and expertise in the field of industrial machinery. Designed to meet the diverse needs of various industries, this production line incorporates advanced technologies to streamline the manufacturing process of profiled panels, optimizing productivity and performance.One of the key features of this new production line is its horizontal orientation, which sets it apart from traditional vertical profiled panel lines. This configuration offers numerous benefits, including enhanced stability and balance during the manufacturing process. By utilizing a horizontal layout, {Company Name} has dramatically minimized vibrations and improved accuracy, leading to a significant reduction in material waste and ensuring consistent product quality.Moreover, the Horizontal Profiled Panel Production Line boasts a range of innovative components that further enhance its efficiency. Equipped with precision cutting tools and advanced laser-guided systems, the line ensures the precise and seamless shaping of panels. This precision allows for seamless integration of various profiled panel types, ranging from corrugated and trapezoidal to architectural and decorative panels. Such flexibility enables manufacturers to cater to the specific requirements of their customers while maintaining superior quality standards.The new production line also incorporates cutting-edge automation technologies to streamline the manufacturing process. Integrated robotic systems enable efficient material handling and reduce the need for human intervention, thereby increasing productivity and minimizing the risk of errors. Additionally, real-time monitoring systems and advanced quality control methods ensure continuous feedback and enable timely adjustments, guaranteeing that each panel meets the highest industry standards.In line with {Company Name}'s commitment to sustainability, the Horizontal Profiled Panel Production Line incorporates energy-saving features, reducing power consumption and minimizing the overall environmental impact. Through efficient energy management systems and smart utilization of resources, the line not only fulfills stringent environmental regulations but also enables manufacturers to significantly reduce operational costs.Furthermore, the Horizontal Profiled Panel Production Line is designed with user-friendliness in mind. An intuitive interface and user-friendly controls allow operators to easily navigate the production process, minimizing downtime and maximizing productivity. To ensure seamless integration into existing manufacturing facilities, {Company Name} offers extensive technical support and customization options according to the specific requirements of each customer.As a global leader in industrial machinery, {Company Name} has an extensive presence and a strong track record of delivering high-quality equipment to industries worldwide. The introduction of the Horizontal Profiled Panel Production Line further solidifies the company's commitment to pushing the boundaries of manufacturing technology and providing innovative solutions to its customers.In conclusion, {Company Name}'s revolutionary Horizontal Profiled Panel Production Line represents a significant leap in manufacturing technology. Through its horizontal orientation, innovative components, automation features, sustainability initiatives, and user-friendly design, this production line offers numerous benefits to manufacturers, including improved efficiency, product quality, and customization options. With this cutting-edge equipment, {Company Name} continues to empower industries across the globe to enhance their production capabilities and achieve unparalleled success.

Durable Highway Guardrail Machine for Efficient Road Safety Installation

Highway Guardrail Machine Innovations Improving Road SafetyIn a bid to improve road safety and streamline the installation of guardrails on highways, {Company Name} has introduced a cutting-edge Highway Guardrail Machine. This innovative piece of equipment is set to revolutionize the way guardrails are installed, ultimately leading to safer roads for both drivers and pedestrians.The {Company Name} is a leader in the manufacturing and distribution of industrial equipment designed for infrastructure development and construction projects. With a strong focus on innovation and efficiency, the company has continuously provided solutions that address the challenges faced in the construction industry.The newly introduced Highway Guardrail Machine is the latest addition to {Company Name}’s lineup of construction equipment. This machine is specifically designed to streamline the process of installing guardrails along highways, ensuring that they are securely and accurately placed to enhance road safety.The Highway Guardrail Machine is equipped with advanced features that set it apart from traditional methods of guardrail installation. Its automated system enables precise measurement and cutting of guardrails, reducing the margin of error and ensuring that the guardrails are installed with utmost accuracy. This level of precision is vital in ensuring that the guardrails provide optimal protection in the event of a roadside accident.Additionally, the Highway Guardrail Machine is designed for efficiency, allowing for faster installation of guardrails without compromising on quality. This means that construction projects can be completed in a shorter timeframe, minimizing disruption to traffic and reducing overall project costs.Furthermore, the machine is equipped with safety features that prioritize the well-being of the workers involved in the installation process. By minimizing the need for manual labor and repetitive tasks, the Highway Guardrail Machine helps to reduce the risk of work-related injuries, creating a safer working environment for construction crews.The introduction of the Highway Guardrail Machine underscores {Company Name}’s commitment to innovation and its dedication to improving construction practices. By providing a solution that enhances road safety and construction efficiency, the company is contributing to the overall improvement of infrastructure development.In addition to the Highway Guardrail Machine, {Company Name} offers a range of construction equipment and machinery that cater to various aspects of infrastructure development. From road paving machines to concrete mixers, the company’s products are designed to meet the diverse needs of construction projects, regardless of scale or complexity.With a strong emphasis on customer satisfaction, {Company Name} also provides comprehensive support and maintenance services for its equipment. This ensures that clients can maximize the performance and longevity of their machinery, ultimately leading to greater efficiency and cost-effectiveness in their construction endeavors.The introduction of the Highway Guardrail Machine has been met with enthusiasm from construction companies and infrastructure development authorities. Its potential to significantly improve road safety and construction practices has positioned it as a game-changer in the industry.As road networks continue to expand and evolve, the importance of ensuring the safety and integrity of highways cannot be overstated. With the introduction of innovative equipment like the Highway Guardrail Machine, the construction industry is taking significant steps towards achieving this goal.In summary, the introduction of the Highway Guardrail Machine by {Company Name} represents a significant advancement in the construction industry. Its potential to enhance road safety, streamline construction practices, and improve overall efficiency underscores the company’s commitment to innovation and excellence. As construction projects continue to play a crucial role in shaping our infrastructure, the adoption of such innovative solutions is essential in ensuring the continued development of safe and reliable road networks.

High-Quality C Purlin Roll Forming Machine: A Complete Guide

The Manual C Purlin Roll Forming Machine is a game changer in the metalworking industry. This innovative machine is designed to produce high-quality C-shaped steel purlins with ease and efficiency. With its user-friendly manual operation, it is suitable for small to medium-sized enterprises and individuals looking to produce C purlins for construction projects.Company Introduction:Established in 2005, our company has been a pioneer in the field of metalworking machinery. Our dedication to continuous innovation and customer satisfaction has propelled us to become a leading manufacturer of roll forming machines. With a strong focus on research and development, we have consistently introduced cutting-edge technologies to the market, earning us a reputation for excellence and reliability.News Content:The Manual C Purlin Roll Forming Machine is a testament to our commitment to providing advanced solutions for our customers. This state-of-the-art machine is the ideal choice for businesses or individuals seeking to produce C purlins with precision and efficiency. With its manual operation, it offers an intuitive and user-friendly experience, making it accessible to operators of all skill levels.What sets this machine apart is its ability to produce high-quality C purlins with consistency. The precision engineering of the roll forming process ensures that each purlin meets the required specifications, whether it's for residential, commercial, or industrial construction projects. This level of accuracy is essential for ensuring the structural integrity and stability of buildings, making it a valuable asset for any metalworking operation.In addition to its performance, the Manual C Purlin Roll Forming Machine is designed with practicality in mind. Its compact size and efficient operation make it a space-saving and cost-effective solution for small to medium-sized enterprises. Furthermore, its manual operation eliminates the need for complex programming or extensive training, allowing operators to quickly familiarize themselves with the machine and start producing C purlins without unnecessary delays.The versatility of the Manual C Purlin Roll Forming Machine extends to its ability to accommodate a wide range of material thicknesses and widths, offering operators the flexibility to meet various project requirements. This adaptability is essential in the ever-changing construction industry, where diverse purlin specifications are often necessary to meet specific building designs and structural demands.As a testament to our ongoing commitment to customer satisfaction, the Manual C Purlin Roll Forming Machine is backed by our comprehensive technical support and training services. Our team of experts is readily available to provide guidance on machine operation, maintenance, and troubleshooting, ensuring that our customers can maximize the machine's capabilities and achieve optimal results.In conclusion, the Manual C Purlin Roll Forming Machine represents a significant advancement in the field of metalworking machinery. Its combination of high-performance capabilities, user-friendly operation, and versatility makes it a valuable addition to any metalworking operation. As we continue to uphold our tradition of innovation and excellence, we are confident that this machine will deliver exceptional value to our customers and contribute to the success of their construction projects.

High-Quality Cable Tray Roll Forming Machine from Leading Manufacturers & Suppliers in China

Title: Cable Tray Roll Forming Machines: Supporting Efficient Cable Management SolutionsIntroduction:In the field of cable management solutions, Cable Tray Roll Forming Machines have emerged as a vital component for industries across the globe. Catering to the growing demand for reliable cable tray systems, manufacturers in China are producing high-quality Cable Tray Roll Forming Machines. This blog will delve into the significance, benefits, and features of these machines while highlighting the wide range of choices available for businesses.Cable Tray Roll Forming Machines: Essential Equipment for Efficient Cable ManagementEfficient cable management plays a crucial role in ensuring uninterrupted power supply, reducing downtime, and enhancing safety in industrial settings. Cable trays have become an indispensable solution, providing ample support for organizing and protecting various cables within factories, commercial buildings, and other infrastructure projects. To meet the escalating demand for cable trays, Cable Tray Roll Forming Machines have become essential tools for manufacturers.Why Opt for Cable Tray Roll Forming Machines?1. High-Quality Production: Cable Tray Roll Forming Machines manufactured in China guarantee high-quality results due to their advanced technology and manufacturing processes. These machines are designed to produce cable trays of consistent dimensions, sturdiness, and durability, ensuring reliable cable management solutions.2. Wide Range of Choices: The Chinese Cable Tray Roll Forming Machine market offers a diverse range of options to suit different construction and cable management requirements. From small-scale units to large-scale production lines, manufacturers cater to the varying needs of different industries.3. Automation and Efficiency: Cable Tray Roll Forming Machines incorporate advanced features, such as automated operations, precise control systems, and high-speed production capabilities. The automation not only enhances efficiency but also reduces manual labor, leading to cost savings and improved productivity.4. Customization Possibilities: Businesses can avail themselves of customizable options while selecting a suitable Cable Tray Roll Forming Machine. Manufacturers in China offer flexibility in terms of tray size, material thickness, and design, enabling companies to meet specific project or industry requirements.5. Quality Assurance: Chinese manufacturers adhere to international quality standards and certifications to ensure the reliability and durability of Cable Tray Roll Forming Machines. This dedication to quality helps businesses instill confidence in their investments and delivers consistent, high-performing machines.Key Features of Cable Tray Roll Forming Machines:1. Material Flexibility: Cable Tray Roll Forming Machines can manufacture trays from a variety of materials, including mild steel, galvanized steel, and stainless steel. The ability to work with different materials provides businesses with versatility to cater to varied project specifications and budgets.2. Speed and Accuracy: With the use of advanced technology and precision engineering, Cable Tray Roll Forming Machines can produce trays at high speeds with exceptional accuracy. The consistent dimensions, hole punching, and edge profiling are achieved swiftly and efficiently, meeting production targets effectively.3. Ease of Operation: These machines are designed for ease of use, offering user-friendly interfaces and controls. Operators require minimal training to operate, program, and maintain the Cable Tray Roll Forming Machines, ensuring maximum uptime and productivity.Conclusion:China-based manufacturers have solidified their position as reliable and quality-conscious suppliers of Cable Tray Roll Forming Machines. These machines not only enable businesses to produce cable trays efficiently but also cater to diverse project needs through customization possibilities. The use of advanced technology, automation, and adherence to stringent quality standards ensures these machines will continue to play a crucial role in meeting global cable management requirements.Keywords: Cable Tray Forming Machine, Cable Tray Roll Forming Machine, Cable Tray Roll Forming Machine China, Cable Tray Roll Forming Machine Manufacturer, Cable Tray Roll Forming Machine Suppliers, Cable Tray Roll Forming Machine Factory, Cable Tray Roll Forming Machine Exporters, efficient cable management, high-quality production, wide range of choices, automation, customization possibilities, material flexibility, speed and accuracy, ease of operation.

How a Roofing Roll Former Can Benefit Your Next Project

Roofing Roll Former, a leading manufacturer in the roofing industry, has announced the launch of its newest product, the TRF-550 Roll Former. This state-of-the-art machine is designed to meet the increasing demand for high-quality roofing materials in the construction industry.With over 20 years of experience in the field, Roofing Roll Former has established itself as a trusted name in the industry. The company is known for its commitment to innovation, quality, and customer satisfaction. By continually investing in research and development, Roofing Roll Former has consistently delivered cutting-edge solutions to meet the evolving needs of the market.The TRF-550 Roll Former is the latest addition to the company's extensive product line. This machine is capable of producing a wide range of roofing materials, including standing seam panels, corrugated panels, and other custom profiles. Its high precision and efficiency make it an ideal choice for both small-scale and large-scale roofing projects.One of the key features of the TRF-550 Roll Former is its versatility. It is designed to accommodate various materials, including steel, aluminum, and copper, making it suitable for a diverse range of roofing applications. Additionally, the machine is equipped with advanced controls that allow for easy customization of panel profiles, ensuring that customers can achieve their desired aesthetic and functional requirements.The TRF-550 Roll Former is also designed with the operator in mind. Its user-friendly interface and automated processes streamline production, reducing the need for manual intervention and minimizing the risk of errors. This not only enhances productivity but also ensures consistent quality in every finished product.Furthermore, Roofing Roll Former's commitment to customer support sets it apart in the industry. The company provides comprehensive training and technical assistance to ensure that customers can maximize the potential of their investment in the TRF-550 Roll Former. This includes on-site support, remote troubleshooting, and access to a dedicated team of experts who are readily available to address any queries or concerns.In addition to its focus on innovation and customer support, Roofing Roll Former remains dedicated to sustainability and environmental responsibility. The TRF-550 Roll Former is designed to minimize material wastage and energy consumption, aligning with the company's commitment to promoting eco-friendly practices within the industry.As the construction industry continues to evolve, Roofing Roll Former stands at the forefront of innovation, delivering solutions that meet the demands of modern roofing projects. The introduction of the TRF-550 Roll Former further solidifies the company's position as a trusted partner for contractors, architects, and builders seeking reliable and efficient roofing solutions.With its proven track record of excellence, Roofing Roll Former is poised to make a significant impact with the launch of the TRF-550 Roll Former. The company's unwavering dedication to quality, innovation, and customer satisfaction ensures that it will continue to be a leading force in the roofing industry for years to come.

Get High-Quality Glazed Tile Roof Panel Roll Forming Machines in Kenya

Glazed Tile Roof Panel Roll Forming Machine is a revolutionary creation in the roofing industry. Its introduction is a significant milestone in fulfilling the roofing needs of millions of people across the globe. This machine is designed to cater to all the demands of both commercial and residential buildings. The Glazed Tile Roof Panel Roll forming Machine is an exclusive production of (need remove brand name), which is a reputed manufacturer of high-quality roll forming machines.The (need remove brand name) has been committed to providing state-of-the-art equipment for the metalworking industry for decades. They are a globally renowned roll forming machine manufacturer, with an extensive network of customers in over 50 countries worldwide. They have a team of experienced professionals who are dedicated to designing, developing, and manufacturing high-quality roll forming machines. Their products are manufactured with precision, meeting the most stringent quality standards, and hence, the company has an excellent reputation in the market.The traditional roofing materials have been replaced by modern ones to provide better energy efficiency, aesthetics, and durability. Glazed Tile roofing panels have become increasingly popular in recent times due to their superior performance characteristics. These panels are made up of galvanized steel sheets, which are coated with several layers of paint to give them a glossy finish. The glazed tile roofing panels are perfect for commercial and residential buildings due to their insulation properties, durability, and lightweight.The Glazed Tile Roof Panel Roll Forming Machine is designed to produce perfect glazed tile roofing panels. The machine uses advanced technology that ensures that the produced panels have high precision and good quality. The roofing panels produced by this machine have an impressive lifespan, with the ability to resist all harsh weather conditions, including extreme heat, wind, and heavy rainfall.The Glazed Tile Roof Panel Roll Forming Machine is a fully automated machine that has been enhanced by modern technology to ensure high efficiency and productivity. The machine is designed with user-friendly features that enable the operator to produce high-quality products with ease. The machine’s automated control system ensures that the rollers automatically adjust their position based on the specifications provided, thus avoiding any manual interventions in the process.Moreover, the Glazed Tile Roof Panel Roll Forming Machine is designed to be reliable, durable, and easy to maintain. The company provides a comprehensive after-sales support service, which includes training and ongoing technical support, to ensure that clients always get the best results from their machines. Also, the machine is built with the latest technology, which ensures that its energy consumption is minimal.In conclusion, the Glazed Tile Roof Panel Roll Forming Machine is an innovative solution for roofing needs. Its introduction is a significant milestone in fulfilling the roofing demands of millions of people worldwide. The machine is designed to cater to both commercial and residential buildings' roofing needs. It is an exclusive production of (need remove brand name), which is a highly reputable and experienced manufacturer of roll forming machines. The Glazed Tile Roof Panel Roll Forming Machine is reliable, durable, and easy to maintain, and customers can count on its excellent quality and performance. The machine is a must-have for any business or individual seeking high-quality roofing solutions.

Sheet Metal Roll Forming Machine for Horizontal Barrel Corrugated Sheets News Update

Title: Revolutionary Horizontal Barrel Corrugated Sheet Roll Forming Machine Set to Transform the Metal Manufacturing IndustryIntroduction:In a bid to revolutionize the metal manufacturing industry, an innovative company has introduced the groundbreaking Horizontal Barrel Corrugated Sheet Roll Forming Machine. This cutting-edge technology promises to offer unprecedented efficiency and accuracy, thus reducing production time and costs. With its seamless design and state-of-the-art features, this ingenious machine is poised to redefine the future of metal forming processes.Developed by a renowned company specializing in advanced machinery, the Horizontal Barrel Corrugated Sheet Roll Forming Machine aims to address the limitations of traditional roll forming methodologies. By incorporating advanced technological advancements, this revolutionary equipment exhibits remarkable capabilities, translating into enhanced productivity for metal manufacturers.Features and Technical Advancements:The Horizontal Barrel Corrugated Sheet Roll Forming Machine boasts a myriad of impressive features that make it stand out in the industry. A few of these notable features include:1. Innovative Design: The machine incorporates a horizontal barrel configuration, allowing for easier feeding and achieving a more precise corrugated sheet formation. This unique design ensures flawless output with minimal material wastage.2. High-Speed Production: Equipped with cutting-edge control systems, this machine offers faster production speeds compared to conventional roll forming equipment. This increased efficiency translates into higher output volumes and reduced production timelines.3. Customization: The machine offers flexible settings, enabling manufacturers to easily adjust the dimensions, thickness, and corrugation patterns of the sheets according to their specific requirements. This adaptability ensures the production of tailor-made metal sheets for various applications.4. Enhanced Accuracy: The precision engineering of the machine ensures consistently accurate dimensions, resulting in high-quality corrugated sheets that meet industry standards. This accuracy minimizes the need for additional processing or rectification, further streamlining the manufacturing process.Implications for the Metal Manufacturing Industry:The introduction of the Horizontal Barrel Corrugated Sheet Roll Forming Machine is set to have far-reaching implications for the metal manufacturing industry. Its numerous advantages and technical advancements hold significant potential to transform the way metal sheets are produced, offering benefits such as:1. Increased Efficiency and Cost Savings: The machine's faster production speeds and reduced material wastage significantly improve overall manufacturing efficiency. This, in turn, leads to substantial cost savings for metal manufacturers, making them more competitive in the market.2. Streamlined Supply Chain: The machine's customization capabilities enable manufacturers to swiftly adjust production parameters, resulting in shorter lead times and quicker response to customer demands. This streamlined supply chain ensures better customer satisfaction and increased market competitiveness.3. Improved Product Quality: With its heightened accuracy and precision, the Horizontal Barrel Corrugated Sheet Roll Forming Machine eliminates variations and defects often encountered in traditional manufacturing processes. The production of consistently high-quality metal sheets enhances product reliability and durability.4. Sustainability and Resource Optimization: The reduced material wastage, achieved through the machine's seamless design and precision engineering, significantly contributes to environmental sustainability. By optimizing resource utilization, metal manufacturing companies can significantly reduce their carbon footprint.Conclusion:The introduction of the Horizontal Barrel Corrugated Sheet Roll Forming Machine marks a significant milestone in the evolution of the metal manufacturing industry. With its innovative design, advanced features, and multiple benefits such as increased efficiency, reduced costs, and improved product quality, this revolutionary machine is set to redefine the future of metal forming processes. As more companies adopt this cutting-edge technology, the industry can expect to witness enhanced productivity, sustainability, and competitiveness.