The Basics of Slitting Process in Sheet Metal: Everything You Need to Know

By:Admin

One company at the forefront of the sheet metal slitting process is {}. With their state-of-the-art facilities and cutting-edge technology, they are able to offer precision slitting services that meet the diverse needs of their clients. Their emphasis on quality, efficiency, and innovation has made them a leader in the industry.

The slitting process begins with the uncoiling of the metal roll, which is then fed through a set of rollers that straighten the material and ensure a consistent thickness. The metal is then fed through a set of circular blades that cut it into narrower strips. These strips are then recoiled for further processing or shipped out as-is, depending on the specific requirements of the customer.

One of the key advantages of the slitting process is its ability to produce consistent, high-quality strips of metal with tight tolerances. This is essential for many applications where precision is paramount. Additionally, the ability to quickly and efficiently process large rolls of metal into smaller strips allows for greater flexibility and cost savings in the manufacturing process.

In addition to their cutting-edge technology, {} is known for their exceptional customer service and quick turnaround times. They work closely with their clients to understand their unique needs and specifications, and are able to tailor their slitting services to meet these requirements. This level of personalized attention has helped them forge long-lasting relationships with their customers and establish a reputation for reliability and excellence.

Furthermore, {} is committed to sustainability and environmental responsibility in their operations. They have implemented various measures to minimize waste and reduce the environmental impact of their manufacturing processes. This includes the responsible disposal of scrap metal and the use of energy-efficient machinery, as well as a focus on recycling and reusing materials whenever possible.

As a result of their dedication to quality, innovation, and sustainability, {} has become a trusted partner for companies across a wide range of industries. Their precision slitting services have been crucial in the production of components for automobiles, appliances, HVAC systems, and more. Their ability to deliver high-quality products in a timely manner has made them an invaluable resource for their clients, helping them stay competitive in today's ever-evolving marketplace.

Looking ahead, {} is poised to continue leading the way in the sheet metal slitting industry. With ongoing investments in technology and a steadfast commitment to meeting the needs of their customers, they are well-positioned for continued growth and success. As industries continue to demand high-quality, precision-cut sheet metal, {} will be there to deliver the solutions they need.

Company News & Blog

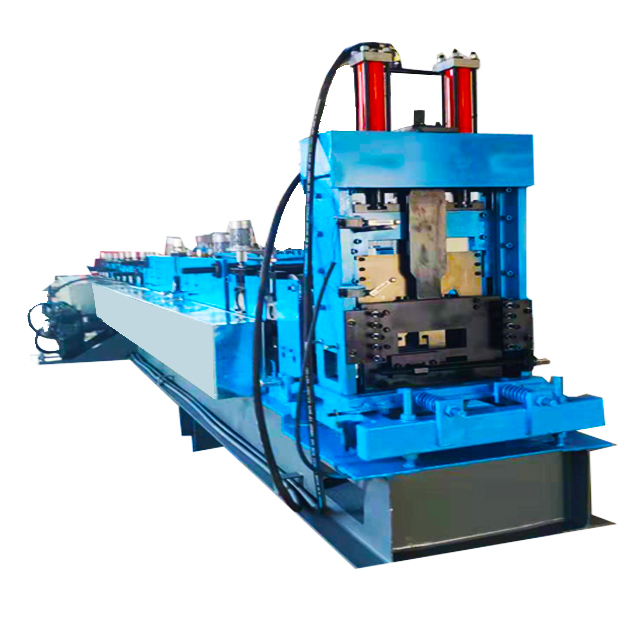

Learn About the Horizontal Profiled Panel Roll Forming Process

The roll forming process has long been recognized as a highly efficient and cost-effective method for producing continuous lengths of metal profiles with a consistent cross-section. This process involves feeding a metal strip through a series of roll stations, where each station performs a specific bending or forming operation to gradually shape the metal into the desired profile. One of the most commonly used roll forming processes is the Horizontal Profiled Panel Roll Forming Process, which is known for its versatility and ability to produce a wide range of complex profiles.{Company} is a leading manufacturer and supplier of roll forming equipment, known for its innovative and high-quality solutions for the metal forming industry. With over [X] years of experience, {Company} has built a solid reputation for delivering state-of-the-art roll forming machines and providing exceptional customer service to clients worldwide.The Horizontal Profiled Panel Roll Forming Process offered by {Company} is a highly efficient and automated solution for producing a variety of horizontal profiles with precision and consistency. This process involves feeding a metal strip into the roll forming machine, where a series of roll stations work together to gradually bend and form the metal into the desired profile. The flexibility and versatility of this process allow for the production of a wide range of panel profiles, including roofing panels, wall panels, and other structural components used in the construction and manufacturing industries.One of the key benefits of the Horizontal Profiled Panel Roll Forming Process is its ability to produce profiles with a high level of accuracy and repeatability. This ensures that each panel produced is uniform and meets the required specifications, leading to fewer rejects and higher overall production efficiency. Additionally, the automated nature of the process reduces the need for manual labor, leading to savings in labor costs and increased productivity.{Company} has further enhanced the Horizontal Profiled Panel Roll Forming Process with advanced technologies and features to improve its performance and reliability. The integration of computerized controls, precision tooling, and in-line inspection systems ensures that the production process is closely monitored and adjustments can be made in real time to maintain the quality of the profiles being produced. This results in a more streamlined and efficient production process, ultimately leading to higher customer satisfaction and a competitive edge in the market.In addition to its technical capabilities, {Company} also prides itself on its commitment to customer satisfaction and service. The company offers comprehensive support to its clients, including initial consultation and design, installation and training, as well as ongoing maintenance and technical assistance. This personalized approach has allowed {Company} to build long-lasting relationships with its clients and establish itself as a trusted partner in the roll forming industry.The Horizontal Profiled Panel Roll Forming Process offered by {Company} has been widely adopted by manufacturers in various industries, including construction, automotive, and aerospace, due to its versatility, efficiency, and high-quality output. As the demand for custom metal profiles continues to grow, {Company} remains at the forefront of innovation, continuously improving its roll forming solutions to meet the evolving needs of its clients.As the global market for roll formed products continues to expand, {Company} is well-positioned to capitalize on the growing demand for its Horizontal Profiled Panel Roll Forming Process. With its dedication to innovation, quality, and customer satisfaction, {Company} is poised to continue leading the way in the roll forming industry for years to come.

High-Quality Aluminum Profile Polishing Machine for Metal Finishing

Aluminum Profile Polishing Machine Helps Company Achieve High-Quality ProductsIn the fast-paced world of manufacturing, companies are constantly striving to enhance the quality of their products while also increasing efficiency. One crucial aspect of achieving this goal is the use of advanced machinery that can streamline production processes and improve the overall quality of final products. One company that has successfully incorporated cutting-edge technology into its operations is {Company Name}, a leading manufacturer of aluminum profiles.{Company Name} has recently implemented a state-of-the-art Aluminum Profile Polishing Machine, which has significantly improved the company's ability to produce high-quality aluminum profiles for a variety of applications. The machine, which has been carefully integrated into the company's production line, is capable of polishing aluminum profiles to a mirror-like finish, ensuring that the final products meet the highest standards of quality.The decision to invest in the Aluminum Profile Polishing Machine was driven by {Company Name}'s commitment to delivering exceptional products to its customers. By incorporating this advanced technology into its operations, the company has been able to elevate the quality of its aluminum profiles, setting it apart from its competitors in the industry.The Aluminum Profile Polishing Machine is equipped with advanced polishing techniques and precision controls, allowing {Company Name} to achieve a level of consistency and excellence that was previously unattainable. This has not only resulted in a significant improvement in the overall appearance of the aluminum profiles but has also enhanced their durability and resistance to corrosion, making them suitable for a wide range of applications in various industries.Furthermore, the integration of the Aluminum Profile Polishing Machine has had a notable impact on {Company Name}'s production efficiency. The machine's automated processes and efficient operation have helped to streamline the polishing process, reducing production lead times and increasing the company's overall output capacity. As a result, {Company Name} has been able to meet the growing demand for its high-quality aluminum profiles, without compromising on quality or consistency.The introduction of the Aluminum Profile Polishing Machine has also had a positive effect on the company's workforce. By automating certain aspects of the polishing process, {Company Name} has been able to redeploy its skilled workers to other areas of the production line, where their expertise and experience can create additional value. This has not only improved overall operational efficiency but has also enhanced employee satisfaction and morale within the organization.{Company Name} is proud to be at the forefront of technological innovation within the industry, and the successful incorporation of the Aluminum Profile Polishing Machine is a testament to the company's commitment to continuous improvement. By embracing advanced machinery and processes, {Company Name} is positioning itself as a leader in the manufacturing of high-quality aluminum profiles, meeting the ever-evolving needs of its customers and setting new standards for excellence in the industry.Moving forward, {Company Name} remains dedicated to investing in cutting-edge technology and equipment that will further enhance its production capabilities and product offerings. By staying ahead of the curve and embracing innovation, {Company Name} is poised to maintain its position as a trusted provider of premium aluminum profiles, delivering exceptional value to its customers and driving continued growth and success in the industry.

Metal Roofing Machines: A Guide for Contractors Looking to Purchase

article about the benefits of metal roofing machines for contractors.Metal roofing has been gaining popularity in recent years due to its durability, longevity, and eco-friendliness. As a contractor, the decision to invest in metal roofing machines is an important one, as it can greatly improve the efficiency and quality of your work. Metal roofing machines are specialized tools designed specifically for fabricating metal roofing panels and accessories, such as flashings and gutters. Here are some of the benefits of investing in metal roofing machines:EfficiencyOne of the biggest advantages of metal roofing machines is their ability to improve the efficiency of your work. With a metal roofing machine, you can quickly and easily fabricate custom panels and accessories on site, without having to rely on third-party suppliers or manufacturers. This saves time and greatly reduces the lead times associated with traditional metal roofing materials.VersatilityMetal roofing machines are incredibly versatile, and can be used to fabricate a wide range of roofing panels, including standing seam, corrugated, and tile profiles. This allows contractors to offer more options to their customers, and to tailor their solutions to the specific requirements of each project.QualityMetal roofing machines can greatly improve the quality of your work, as they are designed to produce consistent, high-quality panels and accessories. This means that you can ensure that every panel and accessory meets your exact specifications, and that you can achieve a level of precision and accuracy that is difficult to achieve with traditional roofing materials.Cost-effectivenessWhile the initial investment in metal roofing machines may seem steep, they can actually be a highly cost-effective solution for contractors. Since you can fabricate your own panels and accessories on site, you can greatly reduce your reliance on third-party suppliers, which can lower your material costs and increase your profit margins. Additionally, metal roofing machines are designed for durability and longevity, which means that they can provide a good return on investment over time.Eco-friendlinessMetal roofing machines are an eco-friendly solution for contractors, as they allow you to manufacture your own roofing panels and accessories on site, rather than relying on materials that have to be transported long distances. Additionally, metal roofing is a highly sustainable and recyclable material, which means that it is good for the environment.Company Introduction: Metal Roofing MachinesIf you are a contractor interested in investing in metal roofing machines, Metal Roofing Machines is a leading provider of high-quality, durable, and versatile machines for fabricating metal roofing panels and accessories. Our machines are designed and built to the highest standards, using the latest technology and materials. We offer a wide range of machines to suit the requirements of any project, from standing seam and corrugated panel machines to gutter machines and trim machines.At Metal Roofing Machines, we pride ourselves on our commitment to quality, reliability, and customer satisfaction. We understand the challenges that contractors face in the roofing industry, and we are dedicated to providing them with the tools and support they need to succeed. Whether you are a seasoned roofing contractor or just starting out in the industry, we have the expertise and experience to help you take your roofing business to the next level.ConclusionInvesting in metal roofing machines is a smart choice for contractors looking to improve the efficiency, quality, and sustainability of their work. With the right machines and the right support, you can take your roofing business to the next level and offer your customers the best possible solutions for their roofing needs. If you are interested in learning more about metal roofing machines and how they can benefit your business, contact Metal Roofing Machines today and speak to one of our experts.

High-Quality Metal Roof Sheet Making Machine for Sale

Metal Roof Sheet Making Machine Revolutionizes Roofing IndustryThe roofing industry has seen a significant advancement with the introduction of the Metal Roof Sheet Making Machine, a game-changing innovation that has revolutionized the way metal roofing sheets are manufactured. This cutting-edge machine, developed and manufactured by a leading machinery company, has set new standards for efficiency, productivity, and quality in the production of metal roof sheets.The Metal Roof Sheet Making Machine is a fully automated system that is capable of producing high-quality metal roof sheets with exceptional precision and speed. Equipped with state-of-the-art technology, this machine can handle various types of metal materials, including galvanized steel, aluminum, and stainless steel, making it extremely versatile and adaptable to different roofing requirements.One of the key features of the Metal Roof Sheet Making Machine is its ability to produce custom-designed roof sheets according to the specific needs and preferences of customers. This allows for a high level of flexibility and customization, enabling roofing companies to offer a wider range of products to their clients.In addition to its advanced technological capabilities, this machine is also designed with efficiency and cost-effectiveness in mind. By streamlining the manufacturing process and minimizing material waste, it helps companies reduce production costs and maximize their profitability. This is especially important in the current economic climate, where businesses are constantly looking for ways to improve their bottom line.Furthermore, the Metal Roof Sheet Making Machine is engineered for durability and reliability, ensuring long-term performance and minimal maintenance requirements. Its robust construction and high-quality components make it a sound investment for roofing companies looking to enhance their production capabilities.The company behind the Metal Roof Sheet Making Machine is a renowned manufacturer of industrial machinery with a strong track record of delivering innovative and reliable solutions to the market. With a commitment to excellence and customer satisfaction, the company has earned a solid reputation for its engineering expertise and dedication to quality.As a leader in the machinery industry, the company is continuously investing in research and development to stay at the forefront of technological advancements. The Metal Roof Sheet Making Machine is a testament to its commitment to innovation and its ability to meet the evolving needs of the market.In response to the growing demand for sustainable and energy-efficient building materials, the Metal Roof Sheet Making Machine is also designed to support green initiatives. By using metal roofing sheets produced by this machine, buildings can benefit from improved insulation, reduced energy consumption, and lower carbon emissions, contributing to a greener and more sustainable environment.The introduction of the Metal Roof Sheet Making Machine has already made a significant impact on the roofing industry, empowering companies to deliver superior products and services to their customers. With its advanced capabilities, efficiency, and flexibility, this machine is driving the industry towards a new era of excellence and innovation.In conclusion, the Metal Roof Sheet Making Machine represents a major leap forward for the roofing industry, offering a powerful solution for companies seeking to elevate their production capabilities and address the evolving needs of the market. With its cutting-edge technology, efficiency, and versatility, this machine is poised to shape the future of metal roofing and set new standards for quality and performance. As the industry continues to embrace innovation, the Metal Roof Sheet Making Machine stands out as a game-changing asset that is redefining the way metal roof sheets are manufactured.

Top Roller for Corrugated Roofing: Must-Have Tool for Easy Installation

Roller for Corrugated Roof: A Game-Changer in the Roofing IndustryCorrugated roofing has long been a popular choice for residential and commercial buildings due to its durability and cost-effectiveness. However, the process of installing and maintaining corrugated roofs has always been a time-consuming and labor-intensive task. That is, until now.Introducing the new Roller for Corrugated Roof, a revolutionary tool that has the potential to change the way corrugated roofs are installed and maintained. This innovative product, developed by a leading manufacturer in the roofing industry, is set to make waves in the construction and roofing sectors.The Roller for Corrugated Roof is designed to streamline the installation process, making it faster and more efficient than ever before. Its ergonomic and user-friendly design allows for easy handling, reducing the physical strain on workers during the installation process. This not only improves productivity but also enhances worker safety, a critical factor in any construction project.What sets the Roller for Corrugated Roof apart from other tools in the market is its ability to ensure a smooth and even finish on corrugated roofs. Its advanced technology allows for precise and consistent rolling, resulting in a professional-looking finish that adds to the aesthetic appeal of the building.In addition to its installation benefits, the Roller for Corrugated Roof also offers significant advantages in terms of maintenance. By using the roller to apply protective coatings and sealants, maintenance teams can extend the lifespan of corrugated roofs, preventing leaks and other damage that can result from exposure to harsh weather conditions.The company behind the Roller for Corrugated Roof, with a proven track record of delivering high-quality roofing products and tools, has invested considerable resources in research and development to bring this innovative tool to the market. With a commitment to excellence and a dedication to meeting the evolving needs of the construction industry, they have positioned themselves as a leader in the market.The company's mission is not only to provide innovative solutions but also to contribute to the sustainability of the industry. The Roller for Corrugated Roof is an environmentally friendly tool that minimizes waste and reduces the need for additional resources during the installation and maintenance processes. This eco-conscious approach aligns with the company's commitment to responsible and sustainable business practices.In line with its dedication to customer satisfaction, the company offers comprehensive support and training programs for the Roller for Corrugated Roof. This ensures that contractors and maintenance teams are equipped with the knowledge and skills to make the most of this game-changing tool, ultimately delivering superior results for their clients.The release of the Roller for Corrugated Roof has generated significant excitement within the roofing industry, with early adopters praising its performance and efficiency. Contractors and building owners alike are recognizing the potential of this tool to revolutionize the way corrugated roofs are installed and maintained, ultimately saving time and costs while delivering exceptional results.As the demand for innovative and sustainable construction solutions continues to grow, the Roller for Corrugated Roof stands out as a prime example of how cutting-edge technology can drive positive change in the industry. With its combination of efficiency, quality, and sustainability, this tool is set to become a staple in the toolkit of roofing professionals around the world.

Get High-Quality Replacement Roof Tiles in Cambridge PE7

In the world of roofing, one of the most important components is the roof tile. Roof tiles come in a range of materials including clay, slate, and concrete. They serve as both a protective barrier for the top of a building and as a decorative element. If you live in or around the Cambridge area and are in need of replacement roof tiles, you have several options to consider.One popular option for replacement roof tiles in Cambridge is to go with a clay tile. Clay tiles are popular in many areas because of their durability, longevity, and aesthetic appeal. They can come in many different styles and colors, which can make them perfect for a range of architectural styles.If you are looking for a more cost-effective option, concrete roof tiles may be the right choice for you. Concrete roof tiles can also come in a range of styles and colors, and are durable and long-lasting. They are also easy to install, which can save you time and money.In addition to the types of roofing materials you choose, you should also consider the quality of the roof tiles themselves. If you go with a cheap or low-quality tile, you may find yourself in need of replacement sooner than you would like. To ensure that you get the best possible quality, make sure to work with a reputable supplier who can provide you with durable and reliable roof tiles.One way to ensure that you get the best quality roof tiles is to work with a supplier that uses the latest roofing technology. One such technology is the Roof Tiles Machine. This machine can create high-quality roof tiles that are both durable and attractive. They are made using state-of-the-art manufacturing techniques that ensure consistency and quality every time.The Roof Tiles Machine uses innovative technology to create custom-made roof tiles that match your specific needs and requirements. This means that you can choose from a range of colors, styles, and finishes to ensure that your roof not only protects your building but looks great too.The process of making roof tiles using the Roof Tiles Machine involves several different stages. First, the raw material is mixed with water and formed into the desired shape. Then, the tiles are dried and fired in a kiln to create a strong and durable final product.If you are in need of replacement roof tiles in the Cambridge area, it is important to find a supplier that uses the latest technology and manufacturing techniques. The Roof Tiles Machine is one such technology that can provide you with the high-quality roof tiles you need to protect your building and enhance its appearance.In conclusion, whether you are looking for replacement roof tiles in Cambridge or elsewhere, there are several factors to consider. The type of material you choose, the quality of the roof tiles themselves, and the manufacturing technology used by your supplier are all important considerations. By working with a reputable supplier who uses the latest technology, such as the Roof Tiles Machine, you can ensure that you get the best possible quality roof tiles for your building.

Efficient Corrugated Roof Sheet Manufacturing Machines Now Available for Purchase

Title: Innovation Takes the Roofing Industry to New Heights: Corrugated Roof Sheet Manufacturing Machine Revolutionizes ProductionIntroduction:The global roofing industry has witnessed a remarkable transformation with the introduction of cutting-edge manufacturing technology. The latest breakthrough comes in the form of a highly advanced Corrugated Roof Sheet Manufacturing Machine (CRSMM), empowering companies to meet growing demand for durable and aesthetically pleasing roofing solutions. This revolutionary machine represents a significant leap forward in terms of efficiency, productivity, and overall quality in the production of corrugated roof sheets.Redefining Efficiency:The CRSMM is designed to streamline the entire manufacturing process, making it highly efficient and cost-effective for companies operating in the roofing industry. By automating key steps, such as material cutting, shaping, and forming, this advanced machinery significantly reduces production time and labor costs. It ensures precision in every stage, resulting in consistently high-quality roof sheets that meet market standards and customer expectations.Uncompromising Quality:The new generation of CRSMM is equipped with advanced technology that enables manufacturers to produce top-of-the-line corrugated roof sheets. The machine employs high-quality materials and robust engineering to fabricate sheets that offer exceptional durability, strength, and weather resistance. This cutting-edge technology also ensures dimensional accuracy, allowing for easy installation and long-lasting performance under diverse weather conditions.Versatile Range of Products:Despite its advanced technology, the CRSMM is highly versatile and can be customized to produce a wide range of corrugated roof sheets. From standard sizes to special dimensions, the machine accommodates different roofing specifications, catering to the unique needs of each construction project. With the ability to manufacture various profiles, colors, and coatings, this machine provides businesses with unparalleled flexibility to meet the ever-evolving demands of the roofing industry.Sustainable Manufacturing:As environmental concerns continue to grow, the CRSMM embraces sustainable manufacturing practices. This advanced machinery uses energy-efficient components and optimized processes to minimize the ecological footprint of the production line. By reducing material waste and optimizing resource usage, the CRSMM aligns with global sustainability goals, contributing to a greener future for the roofing industry.Market Impact and Future Prospects:The introduction of the CRSMM is set to revolutionize the roofing industry, presenting new opportunities for growth and innovation. Manufacturers can now produce high-quality roof sheets at a faster pace, efficiently meeting rising market demand. This advanced machinery also enhances product quality and consistency, fostering customer satisfaction and brand reputation.Moreover, the versatility of the CRSMM allows companies to expand their product offerings and tap into diverse market segments. In an era where architectural designs are becoming increasingly imaginative and varied, the machine enables manufacturers to deliver customized roofing solutions that cater to the unique needs of every project.Looking ahead, the CRSMM is expected to undergo continuous advancements, integrating artificial intelligence and machine learning technologies. This will further improve its efficiency, precision, and automation, revolutionizing the roofing industry as we know it. The continued development of the CRSMM will undoubtedly play a pivotal role in shaping the future of construction and infrastructure development worldwide.Conclusion:The Corrugated Roof Sheet Manufacturing Machine is transforming the roofing industry by revolutionizing the production of high-quality, durable, and aesthetically pleasing roof sheets. With its unmatched efficiency, versatility, and sustainability, this advanced machinery is set to redefine industry standards and provide manufacturers with a competitive edge. As technology evolves, the CRSMM will continue to pave the way for innovative solutions that meet the demands of a rapidly changing construction landscape, driving the growth and development of the roofing industry into the future.

Revolutionary Glazed Tile Corrugation Equipment Boosts Manufacturing Efficiency

[Company Name] Introduces Innovative Glazed Tile Corrugation Equipment Revolutionizing the Construction Industry[City, Date] - [Company Name], a leading provider of cutting-edge machinery and equipment, is pleased to announce the launch of its state-of-the-art Glazed Tile Corrugation Equipment. This groundbreaking machinery is set to revolutionize the construction industry by streamlining the production process and providing superior quality glazed tile products.Glazed tile has always been a popular choice for both residential and commercial buildings due to its aesthetic appeal and durability. However, the traditional manufacturing process is labor-intensive, time-consuming, and often leads to inconsistent quality. With the introduction of their innovative Glazed Tile Corrugation Equipment, [Company Name] aims to address these challenges and significantly enhance the production efficiency and quality of glazed tiles.The Glazed Tile Corrugation Equipment boasts a range of advanced features that set it apart from the competition. The precise and automated corrugation process ensures consistent and uniform patterns, eliminating human error and resulting in flawless glazed tiles. The integrated control system allows for easy configuration and operation, reducing the learning curve and maximizing productivity.Furthermore, the equipment's cutting-edge technology enables it to handle a variety of tile sizes, shapes, and colors, giving manufacturers the flexibility to cater to diverse customer demands. This adaptability is an essential quality in an industry that increasingly emphasizes customization and personalization.In addition to its exceptional performance, the Glazed Tile Corrugation Equipment also prioritizes safety and sustainability. Equipped with multiple safety features, such as emergency stop buttons and protective barriers, [Company Name] ensures the well-being of operators and minimizes the risk of accidents. Furthermore, the machinery is designed with energy-efficient mechanisms, reducing power consumption and minimizing its environmental impact.[Company Name] has a proven track record of delivering high-quality machinery and equipment to various industries, and the introduction of the Glazed Tile Corrugation Equipment is yet another testimony to their commitment to innovation. Their team of experienced engineers and technicians has tirelessly worked to develop this cutting-edge solution, combining their expertise with market research to meet the evolving needs of the construction industry."We are thrilled to unveil our Glazed Tile Corrugation Equipment," said [Spokesperson], the CEO of [Company Name]. "This machinery is a game-changer for manufacturers, enabling them to streamline their production processes and elevate the quality of their glazed tile products. We believe that this equipment will revolutionize the construction industry and open up new possibilities for our customers."The Glazed Tile Corrugation Equipment is compatible with both new and existing production lines, offering manufacturers a seamless transition. With its user-friendly interface and superior performance, this equipment is an investment in efficiency, quality, and profitability for businesses.In conclusion, the introduction of [Company Name]'s Glazed Tile Corrugation Equipment showcases their unwavering commitment to innovation and providing cutting-edge solutions to the construction industry. As the demand for glazed tiles continues to grow, this machinery will undoubtedly play a pivotal role in meeting customer expectations and driving industry growth.For more information about the Glazed Tile Corrugation Equipment and its features, visit [Company Name]'s website or reach out to their sales team.About [Company Name]:[Company Name] is a leading provider of innovative machinery and equipment across diverse industries. With a focus on research and development, they aim to deliver cutting-edge solutions that streamline processes and enhance productivity. Their commitment to excellence and customer satisfaction has made them a trusted partner for businesses worldwide.

Metal Sheet Roof Roll Forming Machine: A Guide to Efficient Roof Panel Production

Metal Sheet Roof Roll Forming Machine Revolutionizes Roofing IndustryInnovative and high-performance metal sheet roof roll forming machines have emerged as game-changers in the roofing industry. These state-of-the-art machines offer an efficient and cost-effective solution for producing metal roofs, catering to the rising demand for sustainable and durable roofing materials. With advanced technology, precision engineering, and seamless operations, this machinery is transforming the construction landscape.Metal roofs have gained immense popularity due to their superior strength, longevity, and aesthetic appeal. They provide excellent protection against extreme weather conditions, including hail, wind, and fire. Recognizing the growing demand for metal roofs, companies have dedicated their efforts to developing advanced manufacturing equipment. Among them, the metal sheet roof roll forming machine has emerged as a leader, revolutionizing the production process.The secret to the success of the metal sheet roof roll forming machine lies in its efficient and automated operation. This cutting-edge equipment can accurately shape metal sheets into various roofing profiles, such as standing seam, corrugated, and trapezoidal roofs. The machine itself is composed of a series of rollers and dies that progressively bend and shape the metal sheet into the desired profile. With precise measurements and consistent quality, these machines can produce roof panels with high dimensional accuracy.One of the key advantages of these machines is their versatility. They can process a wide range of metal sheets, including galvanized steel, aluminum, and copper, ensuring flexibility in design options for architects and homeowners. Furthermore, the metal sheet roof roll forming machines can seamlessly accommodate various widths and thicknesses, allowing for customization based on specific project requirements. This adaptability has positioned these machines at the forefront of the roofing industry.Enhanced operational efficiency is another notable feature of the metal sheet roof roll forming machines. Equipped with advanced computer numerical control (CNC) systems, these machines can effortlessly adjust to different production settings, saving time and reducing material waste. Operators can easily input the required dimensions and specifications, and the machine would automatically make the necessary adjustments. This level of automation significantly increases productivity and reduces human error.The durability and reliability of the metal sheet roof roll forming machines are unmatched. Built with heavy-duty materials and precision-engineered components, these machines offer long-lasting performance with minimal maintenance. They are designed to withstand harsh working environments and operate continuously, ensuring uninterrupted production capabilities for roofing manufacturers.Moreover, manufacturers of metal sheet roof roll forming machines prioritize the safety of operators and the environment. The machines are equipped with safety features such as emergency stop buttons, protective covers, and sensors, ensuring a secure working environment. Additionally, these machines are designed to minimize energy consumption, contributing to sustainable manufacturing practices.Leading the industry in the production of metal sheet roof roll forming machines, {}, has gained international recognition for its cutting-edge technology and commitment to exceptional quality. With an extensive product range, they offer a variety of customizable options to meet the diverse needs of their customers. Their machines have been widely adopted by roofing manufacturers worldwide, enabling them to produce high-quality metal roofs efficiently.In conclusion, metal sheet roof roll forming machines have revolutionized the roofing industry by providing efficient, cost-effective, and sustainable solutions for metal roof production. These machines offer versatility, accuracy, and enhanced operational efficiency, ensuring high-quality metal roofs with precise dimensions. With the continuous advancements in technology and the commitment of manufacturers, metal sheet roof roll forming machines are set to reshape the construction landscape, offering architects and homeowners an attractive, durable, and eco-friendly roofing solution.